My Newb Plasma Table Attempted Build

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

27 Apr 2020 03:40 #165749

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

I'm in a terminal and can't even pull up the linuxcnc tree (command not found)...so apparently my install isn't right to begin with. Gonna work on fixing that and I'll be back, this stuff has me pretty overwhelmed.

Pat

Pat

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

27 Apr 2020 13:59 #165821

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

I started from scratch on the computer and resinstalled linuxcnc, updated to the master branch. The first go I had followed someone else's instructions. As I said before, the movement would get choppy or sputter as it would wait to change directions. After the reinstall following the plasmac guide, the movement is now smooth as silk...and no sputtering (I don't know the technical jargon).

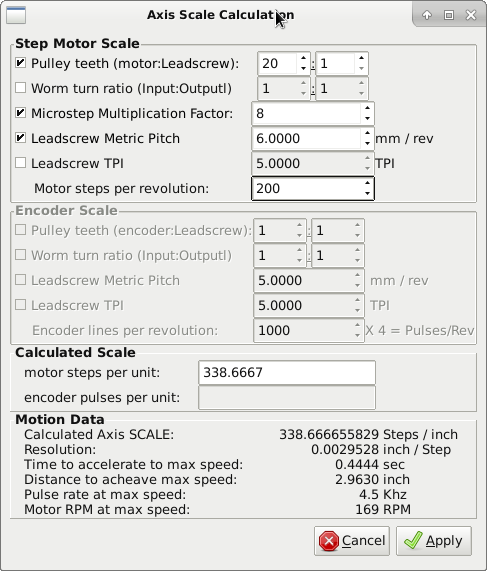

Now I'm just trying to get the X-axis to move the correct distance. I'm confused, as although I selected 'inches', in the pncconf it asks for thread pitch in mm/rev (I have a 20 tooth pulley, 3mm pitch). I'm assuming that in the block titled "Leadscrew Metric Pitch ... " this is where you tell it how far it should move with my pulley and belt?

Pat

Now I'm just trying to get the X-axis to move the correct distance. I'm confused, as although I selected 'inches', in the pncconf it asks for thread pitch in mm/rev (I have a 20 tooth pulley, 3mm pitch). I'm assuming that in the block titled "Leadscrew Metric Pitch ... " this is where you tell it how far it should move with my pulley and belt?

Pat

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20972

- Thank you received: 7146

27 Apr 2020 14:14 #165824

by tommylight

Replied by tommylight on topic My Newb Plasma Table Attempted Build

Start Linuxcnc, home the machine, measure the distance, press F5 to get the MDI tab, enter a known value and measure again, back to 0 on the MDI. While you are doing this, use the "calibration" from the machine menu, there you can enter the scale values and test in real time, without the need to restart Linuxcnc. When you are done, click on OK and save to file.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

27 Apr 2020 14:20 #165828

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Ok, I'll try that. I'm fumbling around (completely iliterate on this). I have to finish pncconf first then open the machine, correct? Not even sure how to home the machine yet lol. I only have one proximity sensor per axis (with a trigger at each end), as well as the Z float microswitch.

Pat

Pat

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20972

- Thank you received: 7146

27 Apr 2020 14:25 #165829

by tommylight

What microstepping are you using, what type of motion, what size pulley's, etc ?

Replied by tommylight on topic My Newb Plasma Table Attempted Build

First try to configure the limits, then scaling.Ok, I'll try that. I'm fumbling around (completely iliterate on this). I have to finish pncconf first then open the machine, correct? Not even sure how to home the machine yet lol. I only have one proximity sensor per axis (with a trigger at each end), as well as the Z float microswitch.

Pat

What microstepping are you using, what type of motion, what size pulley's, etc ?

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

27 Apr 2020 14:31 #165830

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

I think my trouble (due to being unfamiliar with this at all) is that no reference material actually shows how to do this on a Mesa card in master branch, for example most things I see are stepconf instructionals running on 2.7.14, which is very different than what I'm seeing.

Anyway, here is the info:

1/8 microstepping

Motion...do you mean belt drive and using belt as rack? If so, yes that's it. 20T pulley, GT3 belt 3mm pitch on X and Y1/Y2, and leadscrew on Z (8mm leadscrew, 2mm pitch Tr8*8-2p)

Pat

Anyway, here is the info:

1/8 microstepping

Motion...do you mean belt drive and using belt as rack? If so, yes that's it. 20T pulley, GT3 belt 3mm pitch on X and Y1/Y2, and leadscrew on Z (8mm leadscrew, 2mm pitch Tr8*8-2p)

Pat

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20972

- Thank you received: 7146

27 Apr 2020 14:53 #165833

by tommylight

Replied by tommylight on topic My Newb Plasma Table Attempted Build

Directly driving a 20 tooth pulley from the motor ?

That will make 60mm for every rotation of the motor and that is to much.

So that will be 200 steps of the motor per revolution times 8 for microstepping equals to 1600 step pulse per revolution.

Since you get 60mm of movement per revolution, the scale should be 1600/60, or how many steps are needed for 1 unit of movement, in this case 1mm.

26.666 is the scale.

Here are the docs, choose the version you are using.

linuxcnc.org/documents/

That will make 60mm for every rotation of the motor and that is to much.

So that will be 200 steps of the motor per revolution times 8 for microstepping equals to 1600 step pulse per revolution.

Since you get 60mm of movement per revolution, the scale should be 1600/60, or how many steps are needed for 1 unit of movement, in this case 1mm.

26.666 is the scale.

Here are the docs, choose the version you are using.

linuxcnc.org/documents/

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

27 Apr 2020 15:17 #165835

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Between the time I last responded and you posted again, I was tinkering around with it in pncconf. Looks like it needs the pully teeth count entered in a field at the top (in the calculator). I entered some raw math numbers I came up with earlier, and it was actually moving within about .25in of where it should have been. So close!

I went back and entered the scaling you came up with and tested it. It was way out for some reason. I went back and tweaked the pitch numbers and now it's right on the money (2in test movements in pncconf). I absolutely don't understand how it got there, but it falls in with what you told me before...make it work!

Pat

I went back and entered the scaling you came up with and tested it. It was way out for some reason. I went back and tweaked the pitch numbers and now it's right on the money (2in test movements in pncconf). I absolutely don't understand how it got there, but it falls in with what you told me before...make it work!

Pat

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

27 Apr 2020 15:24 #165837

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20972

- Thank you received: 7146

27 Apr 2020 15:36 #165838

by tommylight

Replied by tommylight on topic My Newb Plasma Table Attempted Build

Nice, glad you got it working properly.

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.139 seconds