PlasmaC Fiber laser 1Kw head height control + auto focuas

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

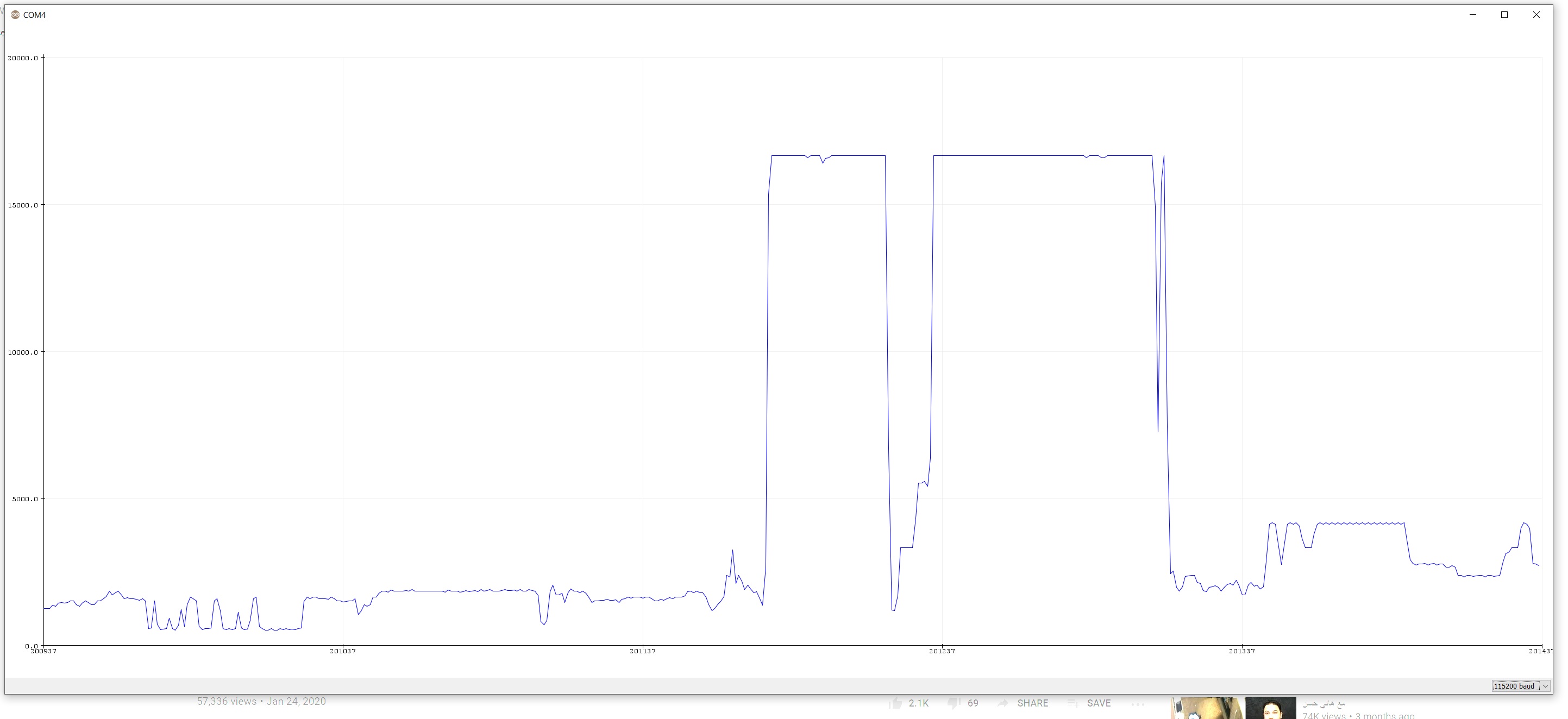

btw the encoder signal is very stable,,, i just rewire it again., and start over,, i have very stable readings nowI guess that depends on height measurement scaling

(what distance range scales to 0 --> 10V) and what precision

you need

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21077

- Thank you received: 7192

Good.

The slowest thing in your setup is the RS485 interface, everything else is much faster.

i change the head no more rs485

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

wetransfer.com/downloads/f1ca513c6e1a26b...0200413172114/ffb78e

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

this is my pwm generator,, using stm32 board good for testing

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

The core clock speed on 3.3v promini style boards is 8 MHz, providing:

8 MHz / 64 = 125 kHz /13 ticks = 9600 /sec (256 reads =27.6ms, 1024 =106ms, 4096 =426ms) (default)

8 MHz / 32 = 250 kHz /13 = 19230 /sec (256 reads = 13ms, 1024=53ms, 4096=200ms)

8 MHz / 16 = 500 kHz /13 = 38000 /sec (256 reads = 6.7ms, 1024=27ms, 4096=108ms)

8 MHz / 8 = 1 MHz /13 = 76900 /sec (256 reads = 3.3ms, 1024=13ms, 4096=53ms)

based on THCAD it makes how many read/second? 1MHZ

1024=1ms?

this result for promini@8mhz.. i will use stm32@72mhz

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

Attachments:

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

there is no much noise from the system,, 10 bit is good for me

but how can the low pass filtering effect the resolution

Because the THCAD is a V-F converter. It has an output frequency range of

about 100 KHz to about 1 MHz. LinuxCNC reads this frequency by measuring

counts per servo thread period, so if the servo thread period is 1 ms , full scale

volts will read about 1000 counts per servo period (roughly 10 bits of resolution)

If you chose a longer servo period you would have more counts and higher resolution

A low pass filter has a similar effect, that is, the more the frequency output is averaged,

the higher the resolution.

I would try the 9V battery, you should not see 1% of full scale noise, only about 0.12%

(at 1 ms servo thread)

i dont think its calculated this way

because the servo thread check 1000 times a seconds and if i run @ 50khz then 5 pulse will be count in each cycle, this count measure the pulse frequency with 5 pulse per cycle servo threat then count this 5 pulses and measure the frequency

i think adding IIR filter will smooth out those pulses

iir filter will produce more stable and less fluctuated

easyupload.io/540elt

u can see the effect of low freq on the video

also after test i found esp32 a way more better for this application,,, i use the web-server in the esp to set the higher and lower frequency,, and i will add the scale factor there,,

it accept capacitance and analog voltage 0-3.3 for plasma THC becouse probing using capacitance will be faster the float or ohmic, specially for type of sheet we cut

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17492

- Thank you received: 5112

i dont think its calculated this way

because the servo thread check 1000 times a seconds and if i run @ 50khz then 5 pulse will be count in each cycle, this count measure the pulse frequency with 5 pulse per cycle servo threat then count this 5 pulses and measure the frequency

Actually it _is_ calculated this way when using the Encoder velocity.

Even if the maximum frequency is 1 KHz you still get ~ 10 bit

resolution full scale, this is because of the way velocity is calculated

(its not just counts/servo period)

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

for example i have 1k servo and 50khz pwm,,

each count 5 pulse,, but is the 1st pulse is 45khz and second pulse is 46khz pulse and 3rd is 47khz and so on till 50k

( this simulate sheet is moving away from the head)

then Linuxcnc will count the average or those pulses?

more pulse = more accurate signal,.

if the signal is not filtered,, then u have to have more freq,, to build more stable signal

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17492

- Thank you received: 5112

edge and last edge per period so say you have 4500 hz = 4.5 pulses per servo thread

The encoder component will count 4 pulses and divide 4 by the time between

count 1 and count 4 to get the frequency (4.5 KHz) so the resolution is not

dependent on the number of pulses per servo thread.

Please Log in or Create an account to join the conversation.