What do you really get for a $350 desk top engraver ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

17 Jan 2024 15:41 #290962

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

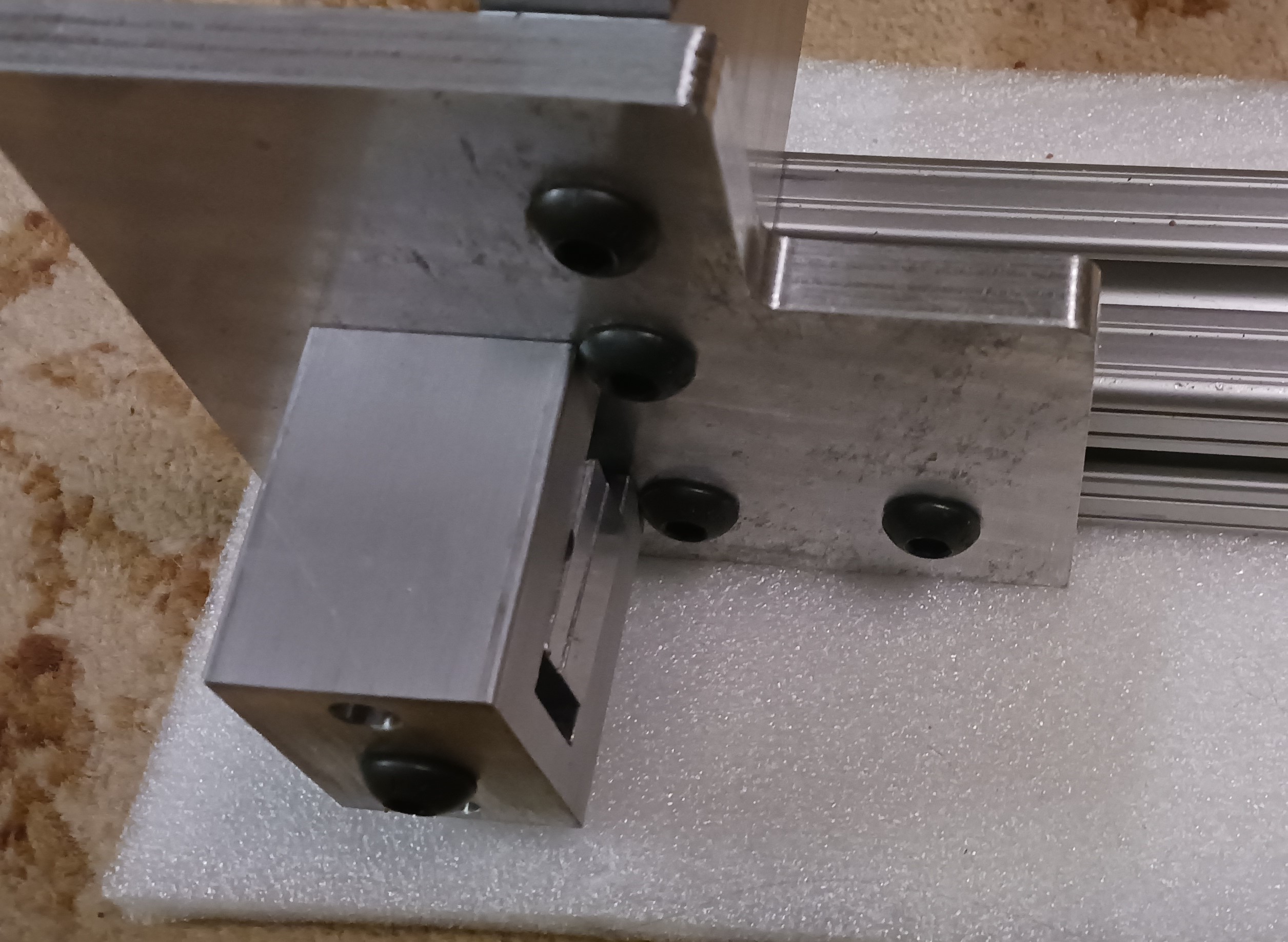

it turns out bearing fits and keeping things concentric are too much to ask of a $350 machine. so i went to plan B and just stacked two bearings together with some washers as spacers where needed and things work really well now. i added some extra wiggle room for adjustment if needed and i am glad i did so  i have one side working on the Y axis but have enough to share some more pictures.

i have one side working on the Y axis but have enough to share some more pictures.

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

21 Jan 2024 11:59 #291254

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

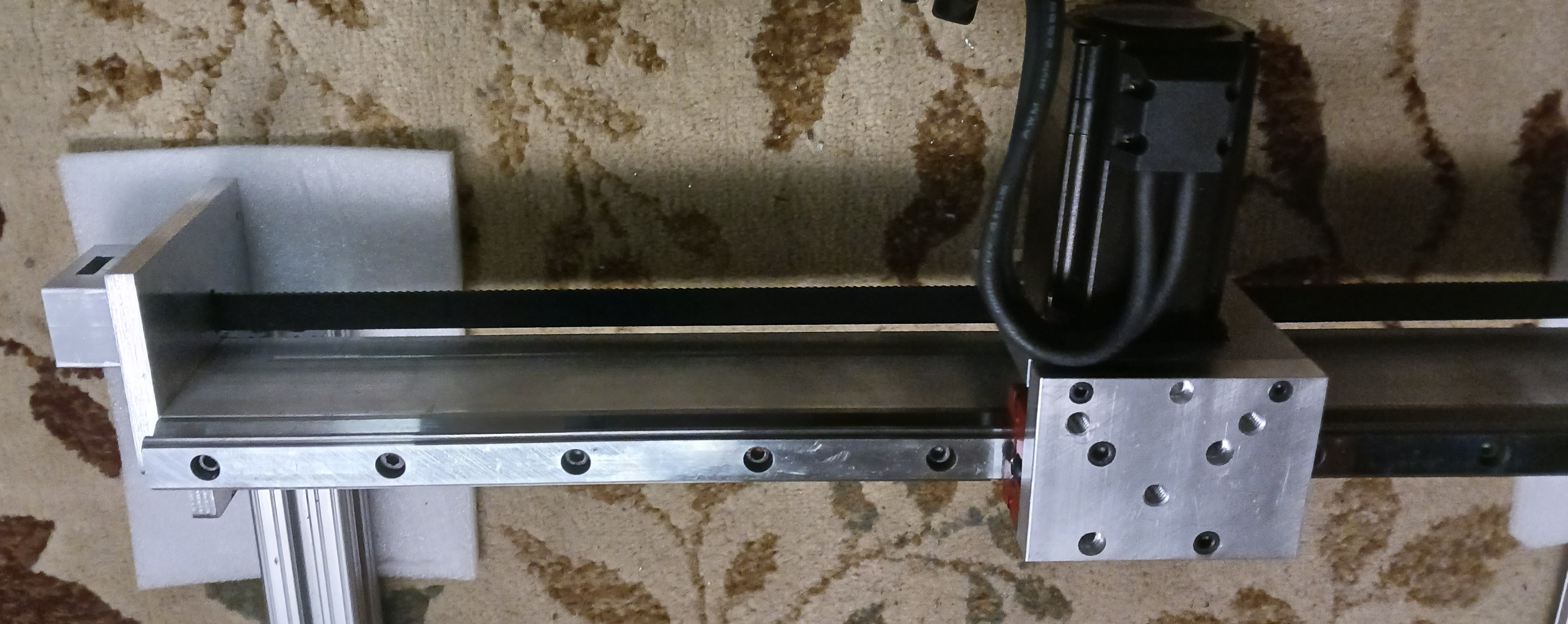

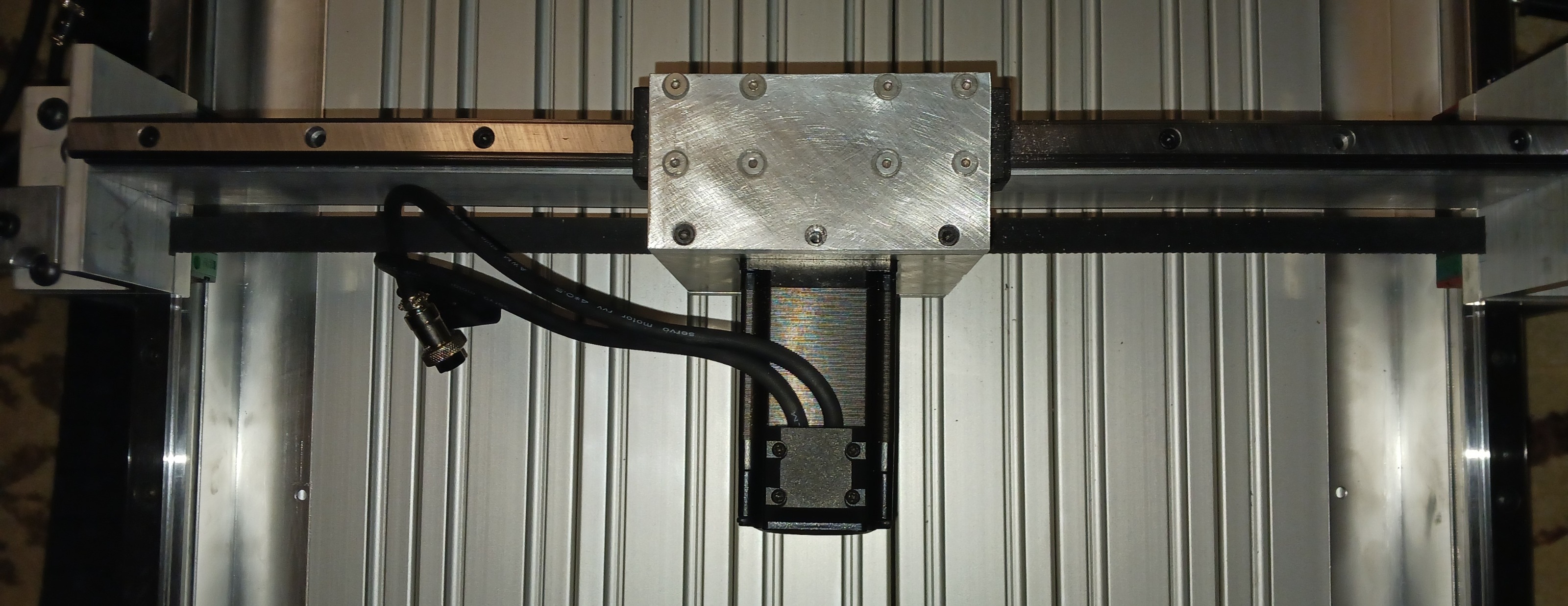

Ok managed to keep all the belt tensioning to the outside of the travel area and will have 16 inches on the X axis and around 20.5 inches on the Y axis before limits are added so around 15.5 inches x 20 inches after the fact give or take. Everything seems to work really well and feels pretty good too so i decided to go all in and upgrade to a better spindle with some proper bearings and ER20 collets with some better numbers for light cuts and fast travel rates. after looking it seems to fit easy on what i have but i will be adding a second set of bearing trucks to the Z just to be safe.

more pictures to share so enjoy

more pictures to share so enjoy

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

25 Jan 2024 16:18 - 25 Jan 2024 16:21 #291606

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

Attachments:

Last edit: 25 Jan 2024 16:21 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Feb 2024 19:38 #293780

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

OK fought with the install of Linuxcnc but got that installed with tommy's help  fought with my network connection for a large part of today got that fixed with a sticky that tommy made thanks again

fought with my network connection for a large part of today got that fixed with a sticky that tommy made thanks again  had errors when opening Linuxcnc got that fixed. all i wanted to do was to see something move or at least twitch but still no luck just yet

had errors when opening Linuxcnc got that fixed. all i wanted to do was to see something move or at least twitch but still no luck just yet

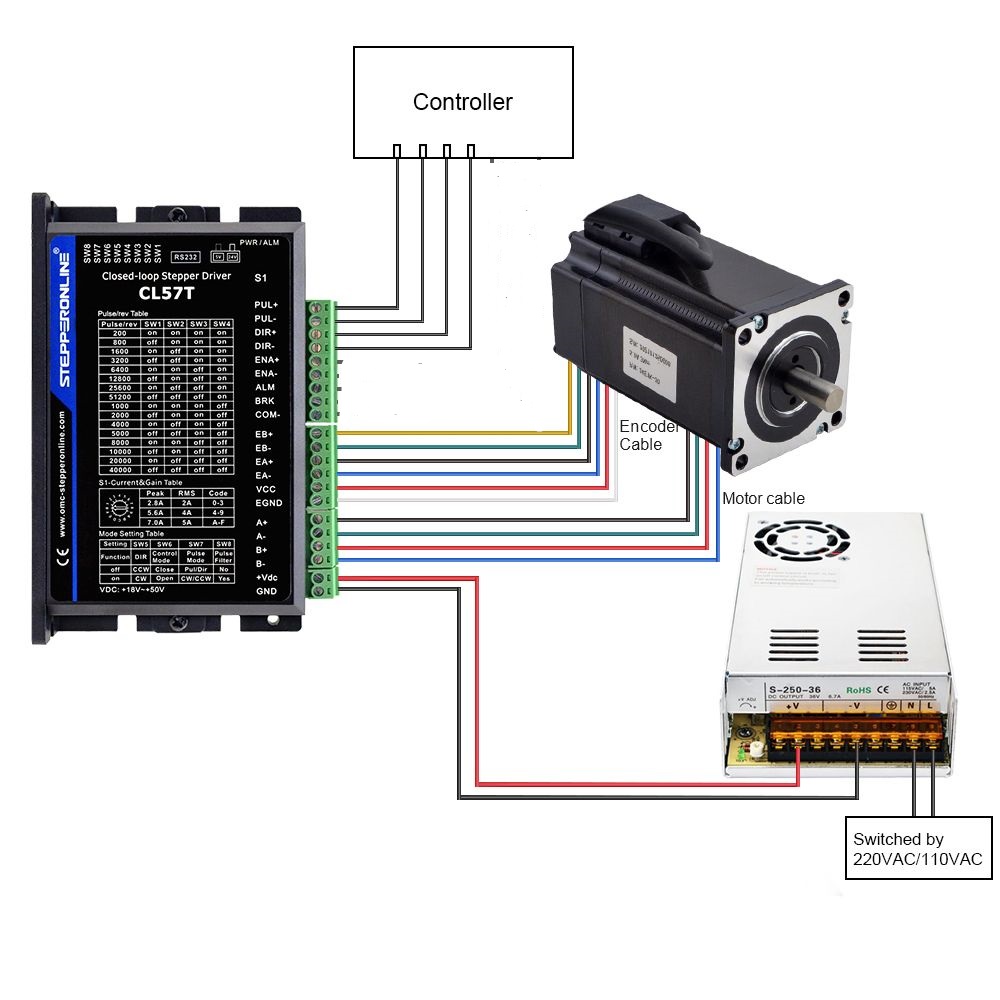

Has anyone used the closed loop steppers from stepperonline here ? i am using the CL57T drivers and i have them working for the most part but think the ena+ and ena- need hooked up in order to work? the way i seen it from the manual was they were not needed but i am thinking they do need hooked up. right now the motors hold and the drives are working with the encoders to correct any stray movement but i can't jog anything? the ena can run from 3.5V to 24V but i have to flip a dip switch to use 5V since the factory setting is 24V. what is the proper way to hook that part up? i seen the 7i96s has a 5v pin and ground right there but am not sure if it is ok to use that or what it is for ? any help is welcome at this point Linuxcnc has kicked my A$$ today

Has anyone used the closed loop steppers from stepperonline here ? i am using the CL57T drivers and i have them working for the most part but think the ena+ and ena- need hooked up in order to work? the way i seen it from the manual was they were not needed but i am thinking they do need hooked up. right now the motors hold and the drives are working with the encoders to correct any stray movement but i can't jog anything? the ena can run from 3.5V to 24V but i have to flip a dip switch to use 5V since the factory setting is 24V. what is the proper way to hook that part up? i seen the 7i96s has a 5v pin and ground right there but am not sure if it is ok to use that or what it is for ? any help is welcome at this point Linuxcnc has kicked my A$$ today

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

19 Feb 2024 21:19 #293792

by tommylight

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

Pictures of wiring and config files?

-

For some strange reason you keep wandering on the dark corners of the internet and always seem to find the worst "howto", or should we call them "hownotto"?

From now on, before you do anything, ask here. Deal?

-

For some strange reason you keep wandering on the dark corners of the internet and always seem to find the worst "howto", or should we call them "hownotto"?

From now on, before you do anything, ask here. Deal?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17754

- Thank you received: 5191

19 Feb 2024 22:12 #293796

by PCW

Replied by PCW on topic What do you really get for a $350 desk top engraver ?

If the drives are holding position, it means they are enabled.

(most step drives have DISABLE inputs which disable the drives if powered)

(most step drives have DISABLE inputs which disable the drives if powered)

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

20 Feb 2024 03:31 - 20 Feb 2024 03:32 #293816

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

worked all night came home and fought with issues for 8 hours  my computer is a bit old Dell Optiplex780 with dual core so half of my struggles were latency issues i think. which still need some attention but is working.

my computer is a bit old Dell Optiplex780 with dual core so half of my struggles were latency issues i think. which still need some attention but is working.

nothing is wired up weird and is working correctly as far as i can tell .it's just the bare bones to test with. the drive manual said enable was optional so i just skipped that for now.

i'm on my way out the door to work so i will have to come back to this in the morning.

nothing is wired up weird and is working correctly as far as i can tell .it's just the bare bones to test with. the drive manual said enable was optional so i just skipped that for now.

i'm on my way out the door to work so i will have to come back to this in the morning.

Last edit: 20 Feb 2024 03:32 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

20 Feb 2024 05:32 #293819

by machinedude

here is what i have as of now to test with. like i said bare bones and just enough to get things moving.

i might have just seen something i missed with the configuration going off memory but need to get some eyes on to be sure. i was thinking the configuration wizard has the step and direction drop down selection on TB2 for all but only one is actually located there on the board. so i need to run trough the wizard again and look at the TB1 section closer because that is where they are all wired too since i am only using 4 of the 5.

would explain why everything else is working and not the step and direction so maybe i got l lucky and solved my own problems i knew i needed 0 ,1, 2, and 3 and thought i was in the right place but TB1 is where i need to do this. over sight on my part in the process of trying to learn this platform.

i knew i needed 0 ,1, 2, and 3 and thought i was in the right place but TB1 is where i need to do this. over sight on my part in the process of trying to learn this platform.

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

here is what i have as of now to test with. like i said bare bones and just enough to get things moving.

i might have just seen something i missed with the configuration going off memory but need to get some eyes on to be sure. i was thinking the configuration wizard has the step and direction drop down selection on TB2 for all but only one is actually located there on the board. so i need to run trough the wizard again and look at the TB1 section closer because that is where they are all wired too since i am only using 4 of the 5.

would explain why everything else is working and not the step and direction so maybe i got l lucky and solved my own problems

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

20 Feb 2024 15:44 #293848

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

well i was wrong and it turned out to be a control signal setting on the driver with a dip switch. things move under power now.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

20 Feb 2024 21:39 #293862

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

i would love to see what this could do with a better computer? the computer seems to be the weak link. i think i still have room for finer tuning, cutting back on the micro stepping helped a lot with acceleration. but the X and Z axis seem to work well. the tandem Y i have not figured out how to test with no home switches yet?

today was a good day

today was a good day

Please Log in or Create an account to join the conversation.

Time to create page: 0.347 seconds