What do you really get for a $350 desk top engraver ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Mar 2024 00:17 #296271

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

built a box added some lights and chips still find a way out  just a short video cutting my makeshift vise down. i tried to cut some steps in the jaws but it did not hold the part well so plan B is to cut them down so i can make some better low-profile work holding. nothing to exciting. just trying to see what it can do and can't do.

just a short video cutting my makeshift vise down. i tried to cut some steps in the jaws but it did not hold the part well so plan B is to cut them down so i can make some better low-profile work holding. nothing to exciting. just trying to see what it can do and can't do.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

19 Mar 2024 00:34 #296274

by tommylight

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

That is definitely NOT a 350$ desktop engraver!

Damn, i have to start building mine, the rails are rusting badly waiting... after i finish another Voron...

Damn, i have to start building mine, the rails are rusting badly waiting... after i finish another Voron...

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Mar 2024 02:32 #296285

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

facing i can probably do twice that cut. radial cuts with the side are a little bit more demanding. 1/2 inch depth of cut with a .020 step over seems to be about the limit right now.

i ran out of feed override to test that little bit of cutting. the first few passe are cutting at 400 IPM and the last pass is a finish pass at 200 IPM.

a bit more bang for quite a few more bucks than the $350 toy. something that can at least make some stuff.

i ran out of feed override to test that little bit of cutting. the first few passe are cutting at 400 IPM and the last pass is a finish pass at 200 IPM.

a bit more bang for quite a few more bucks than the $350 toy. something that can at least make some stuff.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Mar 2024 23:06 #296348

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

better removal rates with a deeper cut of .060 at 200 IPM. sometime soon i will try to see if i can get a .040 DOC @400ipm that would be faster yet

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 Mar 2024 18:47 #296637

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

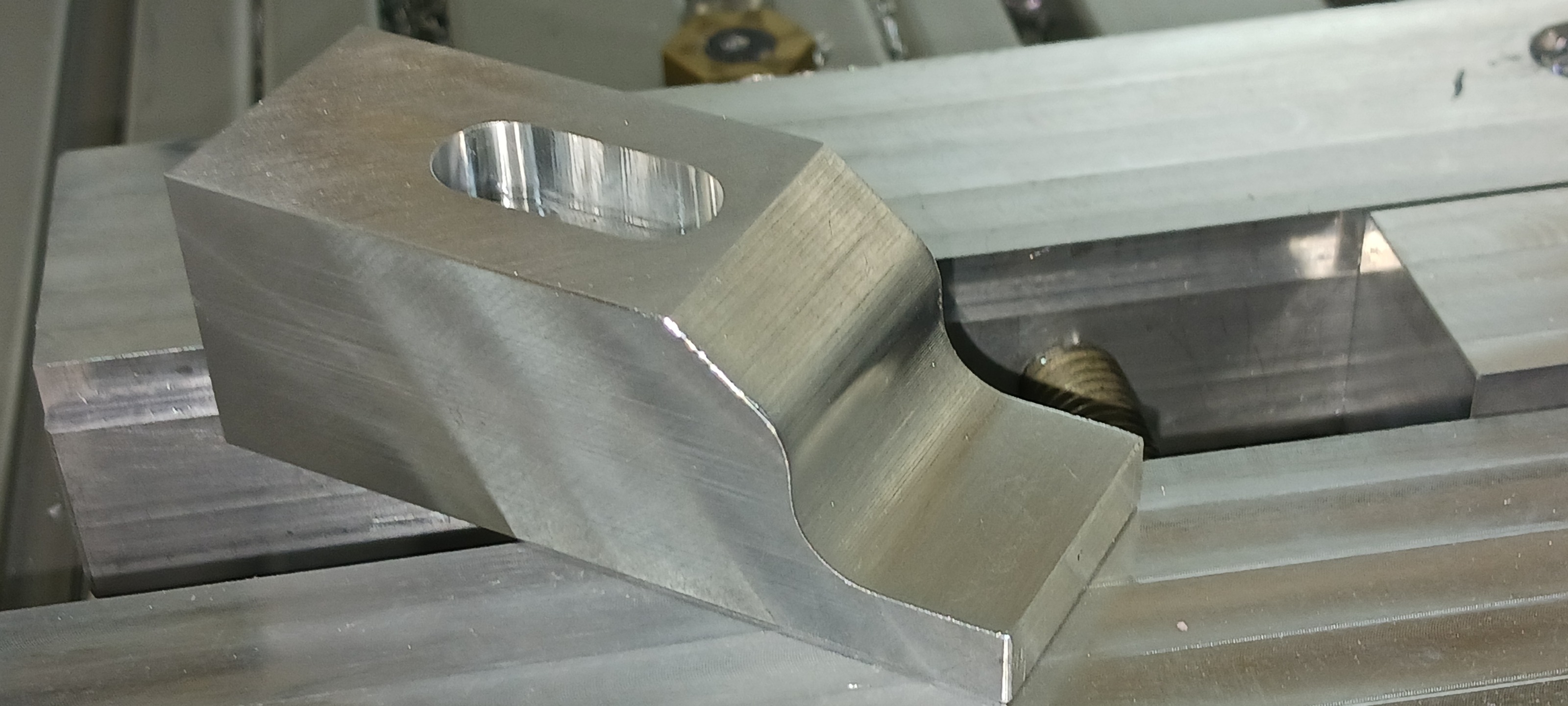

starting my first real project with this machine to give it a real test actually making something. i would probably go about doing these different if i had more to work with but it was a good test on what i think will be a strong point with this machine. A picture of the end result and a video link if you want to see how the machine did.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

05 Apr 2024 20:39 #297667

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

i came into about 200 lbs of random off cuts and have to square a lot of material so it's not so random in size. did another test with a 1/2 3 flute to see how the bigger cutter would do. The machine did fine but my homemade work holding is the weak link  the parts are starting to lift up so not very practical but fun to watch

the parts are starting to lift up so not very practical but fun to watch  .03 DOC @ 625IPM with almost full width of the tool for a stepover.

.03 DOC @ 625IPM with almost full width of the tool for a stepover.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

30 Apr 2024 04:35 #299371

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

I had some time to try out some new work holding, and it does open up ways to go about secondary operations. But what i noticed is working holding factors into these little machines quite a bit. when you start getting into thicker pieces. radial cutting becomes a pain when you want a good finish. one other thing i don't care for with the new clamps is the fact that you have to count on aluminum threads. over time they will fail due to wear and since it is part of the clamp that will become a problem at some point. So i think i will try a new approach with a 3 part clamp that uses the steel T nuts for the clamping force. once I thought of it i was like stupid simple is a Plus sometimes

one other thing i was working with was the uses of work offsets. and came into the issue of table variation on the Z axis. i wanted to try not skimming the table top but i think if i do it will make things much more simple in the long run.

i actually am waiting for some solid carbide High-feed mills to try too. I think they might work well with this machine they are not cheap but if they work well it is what it is and you just suck it up

one other thing i was working with was the uses of work offsets. and came into the issue of table variation on the Z axis. i wanted to try not skimming the table top but i think if i do it will make things much more simple in the long run.

i actually am waiting for some solid carbide High-feed mills to try too. I think they might work well with this machine they are not cheap but if they work well it is what it is and you just suck it up

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 May 2024 21:21 #300400

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

With great speed comes great weldability

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

11 May 2024 21:36 #300403

by tommylight

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

Dang it my parts are rusting... I really need to start building the mill or i will be left with a pile of rust!

I had no idea mist can help that much, i was aware it helps a bit with cooling, but this is far better than what i imagined.

Thank you, great job and the last pass sounds nice at 4X speed with youtube playing at 2X speed

I had no idea mist can help that much, i was aware it helps a bit with cooling, but this is far better than what i imagined.

Thank you, great job and the last pass sounds nice at 4X speed with youtube playing at 2X speed

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 May 2024 21:43 #300404

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

yeah when you are running at high speeds heat is a real pain in the butt. i use Kool mist which is pretty safe all around. it's not the cheapest but a little goes a long way. it only takes 4 oz per gallon to mix up and a gallon costs around $50 in my neck of the woods.

Please Log in or Create an account to join the conversation.

Time to create page: 0.171 seconds