Gildemeister NEF 480 Retrofit

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

27 Feb 2021 21:44 #200353

by chris@cnc

Replied by chris@cnc on topic Gildemeister NEF 480 Retrofit

Hi Patrick,

there is a chamber in the valve. when the pump is running it makes the chamber full of oil and builds up pressure. if the pressure is reached = chamber full. no pressure = chamber leaking. When the pump stops, the chamber slowly opens and oil drips into the line. Takes a little longer. If the chamber does not open it is clogged. You can open the chamber but carefully. There are very small parts in.

Chris

there is a chamber in the valve. when the pump is running it makes the chamber full of oil and builds up pressure. if the pressure is reached = chamber full. no pressure = chamber leaking. When the pump stops, the chamber slowly opens and oil drips into the line. Takes a little longer. If the chamber does not open it is clogged. You can open the chamber but carefully. There are very small parts in.

Chris

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

27 Feb 2021 21:53 - 27 Feb 2021 21:56 #200354

by db1981

Replied by db1981 on topic Gildemeister NEF 480 Retrofit

Hi,

zum übersetzen ist jetzt zu spät für mich....

Such mal nach SKF Monoflex, da gibts ein dickes pdf und schaue dir mal den Teil mit den Nachschmierverteilern an. Ich weiß nicht 100% ob das bei der Kiste so ist, könnte aber sein. Kenne ein paar alte Bohrmaschinen mit dem Zeugs.

d.h. Pumpe muss laufen bis Druck aufgebaut ist (Druckschalter links) -> Pumpe aus -> Schmierzyklus erfolgt...

zum übersetzen ist jetzt zu spät für mich....

Such mal nach SKF Monoflex, da gibts ein dickes pdf und schaue dir mal den Teil mit den Nachschmierverteilern an. Ich weiß nicht 100% ob das bei der Kiste so ist, könnte aber sein. Kenne ein paar alte Bohrmaschinen mit dem Zeugs.

d.h. Pumpe muss laufen bis Druck aufgebaut ist (Druckschalter links) -> Pumpe aus -> Schmierzyklus erfolgt...

Last edit: 27 Feb 2021 21:56 by db1981. Reason: deutsch hängt auch, können wir in C schreiben

Please Log in or Create an account to join the conversation.

- sivaraj

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 23

28 Feb 2021 04:23 - 28 Feb 2021 05:48 #200369

by sivaraj

Replied by sivaraj on topic Gildemeister NEF 480 Retrofit

Usually lub system will have metering valve or piston valve on each line.

Your lube system includes pressure switch and Based on photo I assume your lube system uses piston oil distributor.

Lub Pump has to run till pressure build up , once pressure switch operates (usually around 10-15 bar), then hold 2or3 sec more then switch off the Lube pump .

After lub pump goes off piston distributor will work and push output few drops of oil .

Usually there will be a punched value on each piston distributor (brass material) which shows rate of oil output like 2cc

You need to disconnect all nylon outlet tubes and simulate the sequence to check piston distributor .

Since you do not have automatic control now you need do it manually .

While pump running if any distributor has continuous oil flow means it is a defective

You should see drops of oil coming out from the piston distributor each time while pump goes of after the pressure build up .

There will not be oil flow while pump running .

piston valve ejects oil only if pressure builds up and then input pressure goes down due to pump goes off .

Hope this helps

Your lube system includes pressure switch and Based on photo I assume your lube system uses piston oil distributor.

Lub Pump has to run till pressure build up , once pressure switch operates (usually around 10-15 bar), then hold 2or3 sec more then switch off the Lube pump .

After lub pump goes off piston distributor will work and push output few drops of oil .

Usually there will be a punched value on each piston distributor (brass material) which shows rate of oil output like 2cc

You need to disconnect all nylon outlet tubes and simulate the sequence to check piston distributor .

Since you do not have automatic control now you need do it manually .

While pump running if any distributor has continuous oil flow means it is a defective

You should see drops of oil coming out from the piston distributor each time while pump goes of after the pressure build up .

There will not be oil flow while pump running .

piston valve ejects oil only if pressure builds up and then input pressure goes down due to pump goes off .

Hope this helps

Last edit: 28 Feb 2021 05:48 by sivaraj.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

28 Feb 2021 09:11 - 28 Feb 2021 11:05 #200381

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Thanks all of you. This helps a lot. I think I trashed one of the valves then. I thin when I shot it out I lost a seal or something. I will have a look today but I am not very confident to find it. So its hinting for spare parts then. With the hint from db1981 I found the part number I need (995-994-110) now I just need to find a source that sells to privateers. And patiently bleed the system.

Thanks everyone!

Thanks everyone!

Last edit: 28 Feb 2021 11:05 by anfänger.

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

28 Feb 2021 13:08 #200403

by scotth

Replied by scotth on topic Gildemeister NEF 480 Retrofit

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

28 Feb 2021 13:29 #200410

by db1981

Replied by db1981 on topic Gildemeister NEF 480 Retrofit

try here :

www.schmieranlagen.com

maybe the parts numbers have changed over the years, but i'm shure they can help you.

maybe the parts numbers have changed over the years, but i'm shure they can help you.

The following user(s) said Thank You: anfänger, J Green

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

28 Feb 2021 13:51 #200417

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

they are still the same. Many thanks! I ordered 13 just in case

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

28 Feb 2021 15:48 #200426

by J Green

Replied by J Green on topic Gildemeister NEF 480 Retrofit

anfanger

Thank's for describing your shop , sounds like it is really spacious an useful .I am envious

scotth & db1981 ---- Have been looking for that information about the Oil an distribution parts for some time . Thanks for sharing the information ,it is a big help to me and others having DMG machines .

Bob

Thank's for describing your shop , sounds like it is really spacious an useful .I am envious

scotth & db1981 ---- Have been looking for that information about the Oil an distribution parts for some time . Thanks for sharing the information ,it is a big help to me and others having DMG machines .

Bob

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

01 Mar 2021 07:17 #200509

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

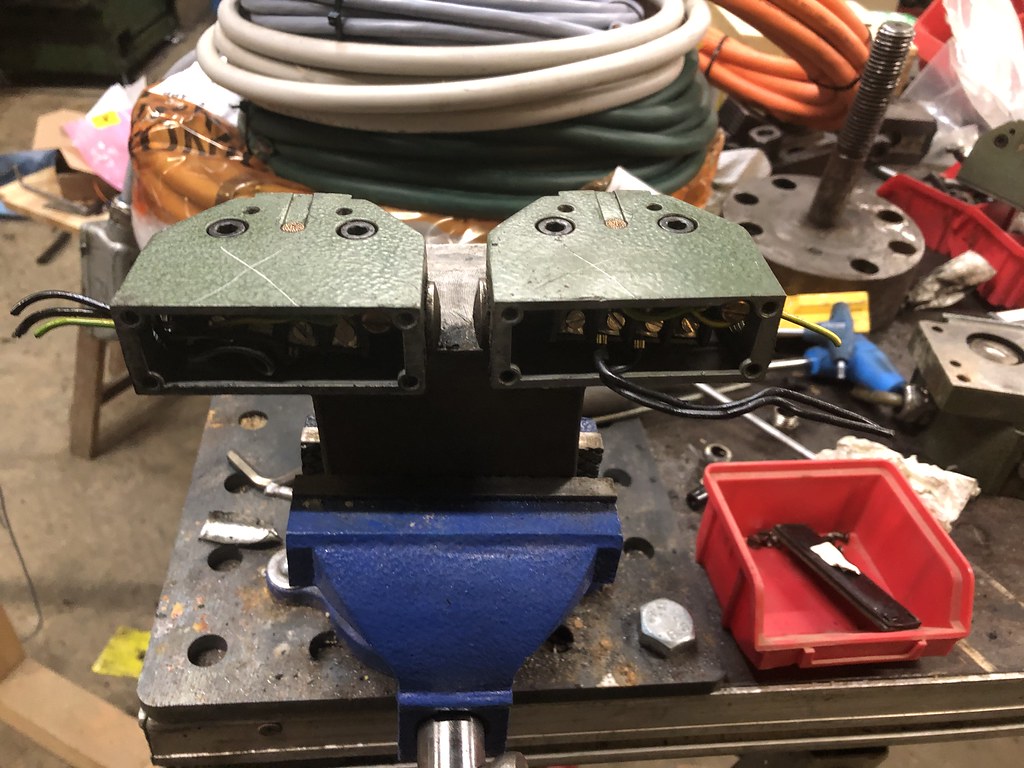

While waiting for the spare parts for the oiling system I continued to assemble the lathe. If I need to change some lines on the oil system this will backfire, but I wanted to make some progress.

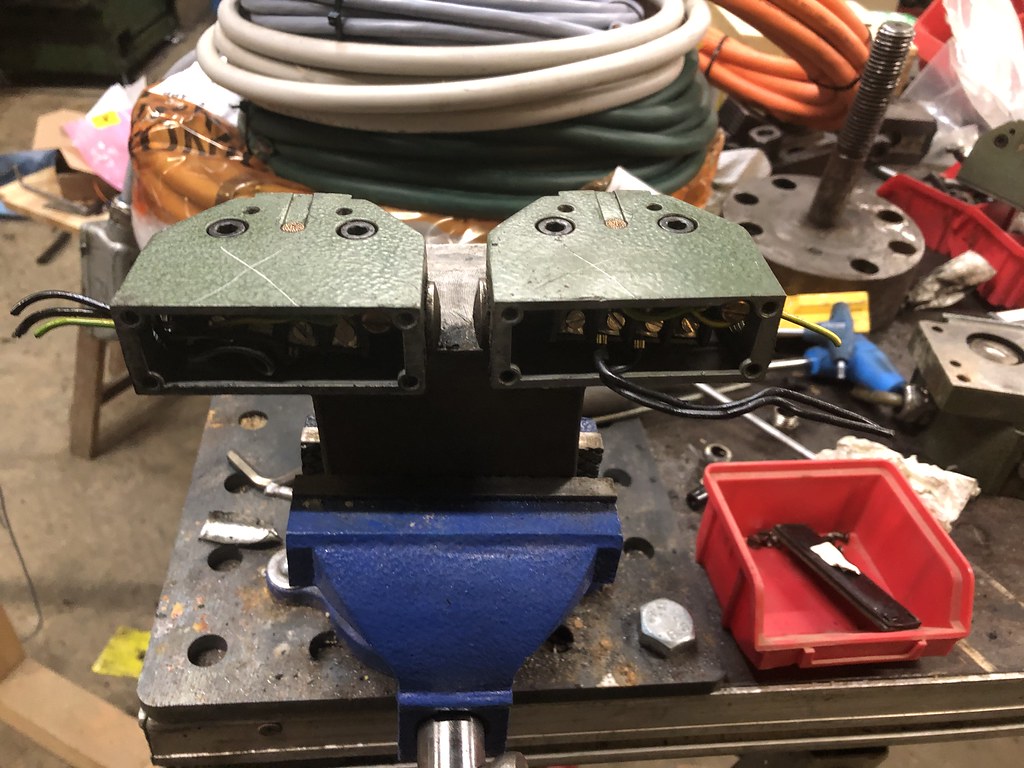

So I cleaned the switches and prepared them for wireing:

I also cleaned off some welded parts on the panel

Still need to think of a neat way to cover the holes. Then I gave the cover for the old control interface a test:

With a bit of straightening this should fit nicely. And I prepared the wire terminals in the console:

Now it‘s waiting for some more spare parts and continue to wire everything up.

So I cleaned the switches and prepared them for wireing:

I also cleaned off some welded parts on the panel

Still need to think of a neat way to cover the holes. Then I gave the cover for the old control interface a test:

With a bit of straightening this should fit nicely. And I prepared the wire terminals in the console:

Now it‘s waiting for some more spare parts and continue to wire everything up.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

01 Mar 2021 07:38 #200511

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Talking about backfire. After I posted this I realised I need to reinstall the retainers the prevent the carriage from lifting. And I am pretty sure with the console in place I won‘t be able to tighten the screws...

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.118 seconds