Troubles to get started with SD240 Retrofit

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

15 Jan 2024 17:45 #290776

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Thanks for the reply and the correct command!

Well this I realized when I read the returned message.

Thanks

Sigi

Well this I realized when I read the returned message.

Thanks

Sigi

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

16 Jan 2024 20:49 #290905

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

success... just a little one, but...

with your command mesaflash --device 7i80hd-25 --addr 10.10.10.10 --readhmid

I could the first time get something out of this box

...the attached file, nothing special but at least something!! I am happy at the moment.

Now I will need to carry on somehow....tomorrow... baby steps, but steps!

Thanks for the help PCW

Sigi

with your command mesaflash --device 7i80hd-25 --addr 10.10.10.10 --readhmid

I could the first time get something out of this box

...the attached file, nothing special but at least something!! I am happy at the moment.

Now I will need to carry on somehow....tomorrow... baby steps, but steps!

Thanks for the help PCW

Sigi

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

01 Feb 2024 20:44 #292161

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Made some efforts watching Tall83 and reading quite a bit. And I even managed to load the sv12 bitfile to the 7i80

Mesaflash returned serveral times "file xxx.bit could not be found" because I could not find out where to store it. Finally found out if you simply put it on the desktop then itt works- things can be so easy...

I made a config with the pcconf wizzard, could only detect the 7i80 by using "Discovery option" ...as it was not recognized by pcconf, finished and ran the machine. Worked fine except throwing positioning errors when jogging the axes, but seems ok as there is no hardware connected.

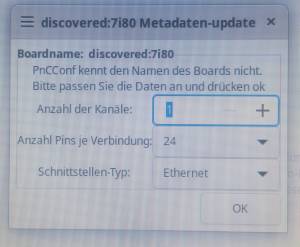

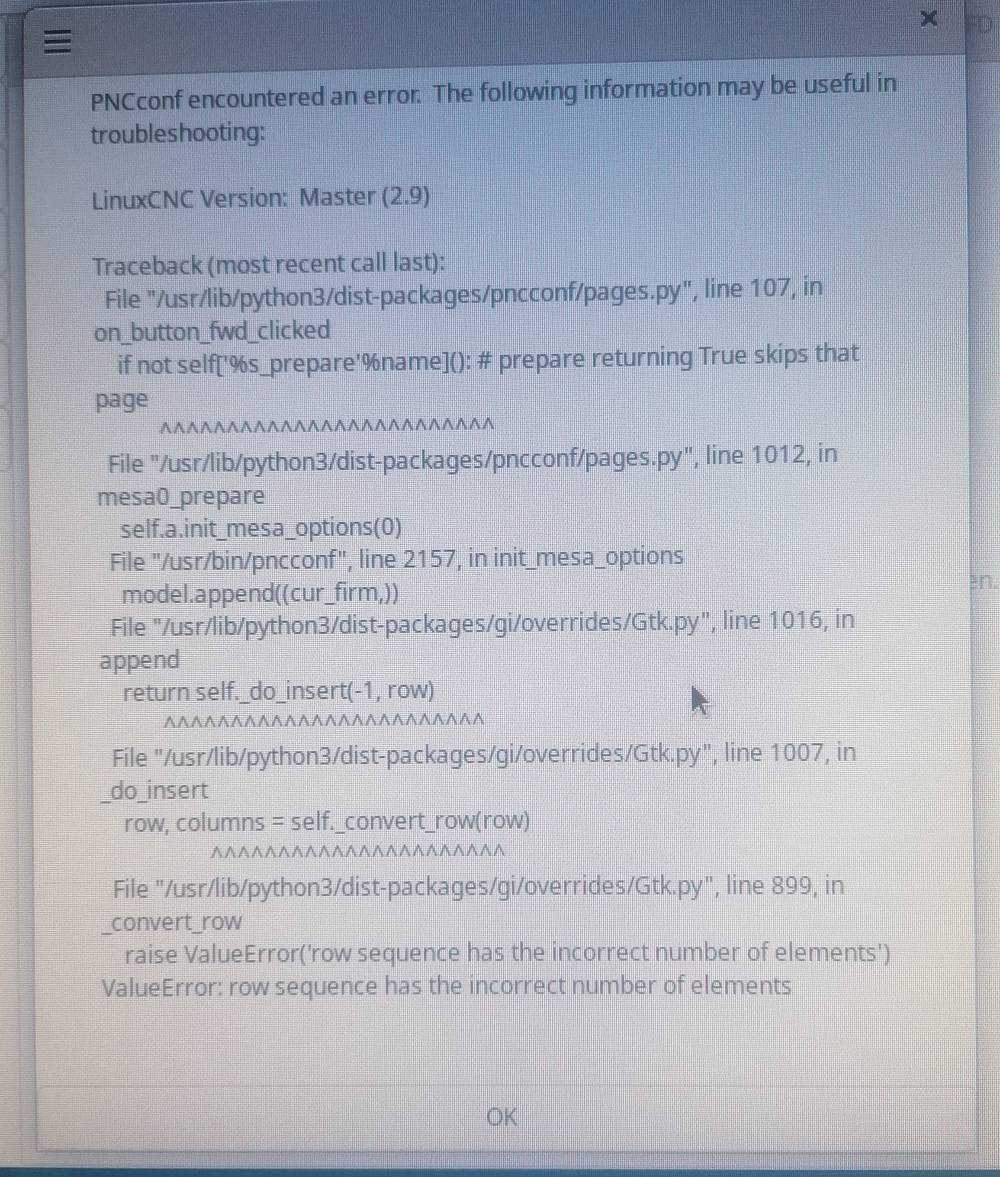

But when wanting to edit the existing config file with pcconf- wizzard I getto a point where I am asked to enter the number of ports

And no matter what I enter there I get this error message:

Is this normal, or did I do something wrong?

Thanks

Sigi

Mesaflash returned serveral times "file xxx.bit could not be found" because I could not find out where to store it. Finally found out if you simply put it on the desktop then itt works- things can be so easy...

I made a config with the pcconf wizzard, could only detect the 7i80 by using "Discovery option" ...as it was not recognized by pcconf, finished and ran the machine. Worked fine except throwing positioning errors when jogging the axes, but seems ok as there is no hardware connected.

But when wanting to edit the existing config file with pcconf- wizzard I getto a point where I am asked to enter the number of ports

And no matter what I enter there I get this error message:

Is this normal, or did I do something wrong?

Thanks

Sigi

Attachments:

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

04 Jan 2025 22:52 #318127

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Hi everyone- no, havent yet given up

But after having shot 3 Mesas, I got them repaired luckily- this took a bit longer but now I seem to be back in the race ...

At the moment I could really use some help please. I am trying to get my motors tuned but this seems to be tricky.

the motors are Fanuc A06B_522_B042_7000 with a AB06_650_B200 drive (the Mesas a 7i80HD-25 and a 7i33 connected if this is of importance)

Has anyone some experience withe these Fanuc components and probably got them tuned sucessfully?

I played around quite a bit but do not get it under control.

I just can get the motor either going forth and back about 1/4 turn or if it stands still it is vibrating pretty much.

I have no experience in motor-tuning. the smaller the P value gets the smaller the forth and back movement is.

Changing the I value does not do anything, but a small D value of 0.3 almost keeps it in the position but then the vibrations come.

Any suggestions appreciated

Thanks

Sigi

But after having shot 3 Mesas, I got them repaired luckily- this took a bit longer but now I seem to be back in the race ...

At the moment I could really use some help please. I am trying to get my motors tuned but this seems to be tricky.

the motors are Fanuc A06B_522_B042_7000 with a AB06_650_B200 drive (the Mesas a 7i80HD-25 and a 7i33 connected if this is of importance)

Has anyone some experience withe these Fanuc components and probably got them tuned sucessfully?

I played around quite a bit but do not get it under control.

I just can get the motor either going forth and back about 1/4 turn or if it stands still it is vibrating pretty much.

I have no experience in motor-tuning. the smaller the P value gets the smaller the forth and back movement is.

Changing the I value does not do anything, but a small D value of 0.3 almost keeps it in the position but then the vibrations come.

Any suggestions appreciated

Thanks

Sigi

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

04 Jan 2025 22:56 - 12 Jan 2025 11:32 #318129

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Sorry, for some reason I can not edit the post-

the drive is a AB06_6050_H200

the drive is a AB06_6050_H200

Last edit: 12 Jan 2025 11:32 by ziggi.

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

30 Jun 2025 10:47 #331030

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Hi, though it seems to be rather a monologue I have still not given up

. Ok mean while the error was found- the repaired 7i33 unfortunately still was not working correctly.

Now I have the two axis working properly and smoothly and would want to be able to implement a shared handwheel for the X and Z axis.

Therefore it was recommended to do a second config file with PC-Config and copy the necessary lines to the original HAL and INI files, sonot to overwrite the original config.

And so I did. But obviously I made some mistake and get an error message when starting LinuxCNC now telling me one infrmation is missing.

Can someone help me to get this corrected please? I am not able to find the mistake....

Thank you

Sigi

Now I have the two axis working properly and smoothly and would want to be able to implement a shared handwheel for the X and Z axis.

Therefore it was recommended to do a second config file with PC-Config and copy the necessary lines to the original HAL and INI files, sonot to overwrite the original config.

And so I did. But obviously I made some mistake and get an error message when starting LinuxCNC now telling me one infrmation is missing.

Can someone help me to get this corrected please? I am not able to find the mistake....

Thank you

Sigi

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

30 Jun 2025 10:52 - 30 Jun 2025 11:03 #331031

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Probably important: the connected enconder is a 1000 increments TTL encoder connected to Enc3 on the 7i33 and in Halshow I could see the counts in/decreasing when turning it left/right- so it seems to work in principle and is recognized by LCNC

And I would for the moment want to be able to move the axes by handwheel without having to home the axes before.

The whole setup is a 7i80hdt-->7i33-->7i37

And I would for the moment want to be able to move the axes by handwheel without having to home the axes before.

The whole setup is a 7i80hdt-->7i33-->7i37

Last edit: 30 Jun 2025 11:03 by ziggi.

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

30 Jun 2025 18:41 - 30 Jun 2025 18:42 #331043

by PCW

Replied by PCW on topic Troubles to get started with SD240 Retrofit

You are missing the "servo-thread" for the "jogincr" component

that is:

addf hm2_7i80.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf jogincr

addf hm2_7i80.0.write servo-thread

should be:

addf hm2_7i80.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf jogincr servo-thread

addf hm2_7i80.0.write servo-thread

that is:

addf hm2_7i80.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf jogincr

addf hm2_7i80.0.write servo-thread

should be:

addf hm2_7i80.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf jogincr servo-thread

addf hm2_7i80.0.write servo-thread

Last edit: 30 Jun 2025 18:42 by PCW.

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

30 Jun 2025 21:49 - 30 Jun 2025 21:53 #331050

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Thank you PCW- appreciated! I will add this asap and test it.

Thanks a lot

Ziggi

Thanks a lot

Ziggi

Last edit: 30 Jun 2025 21:53 by ziggi.

Please Log in or Create an account to join the conversation.

- ziggi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 2

04 Jul 2025 18:46 - 04 Jul 2025 20:42 #331259

by ziggi

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Great, now the error is gone and LinuxCNC starts normally.

Unfortunately the Encoder handwheel does not move the selected axes. I can see it counting in Halshow, but the axis selected stays where it is.

I read in the documentation that the use of a MPG would reqire homing of the axis- my machine is not homed at the moment- but I thought the line

NO_FORCE_HOMING = 1

would let me use the MPG without homing- probably not, or is there any simple possibility to move the axes via MPG without homing them first?

The other thing I would like to get running is the spindle. I seached quite a bit, but did not really find out how to use the parameters. In diffeerent threads these are described differently.

The spindle is a Fanuc Servo which is capable to make 8000 rpm. Its connected to the correct Fanuc servo drive. The spindle itself only is allowed for 5000rpm. With the old control connected, I found that the max voltage the servo drive gets from the control is 7,6V+ at 5000rpm. So if I scale this to 10V it would give me 6570rpm.

As far as I know only pos voltage is used in the analog signal (0 to 7,6V) and the spindle is reversed by an additional signal to the drive unit. The 2500incr. encoder that I want to connect to the 7I33 is an additional encoder (TTL) driven by the spindle via toothed belt and is originally used with the old control for threadcutting (synch) only- the servo drive gets its info from an encoder inside the motor which I can not access.

So thats what I think currently the spindle params should be I wrote below. Is it correct- I guess not,but how is the calculation in this case done?

And how can I determine the output of min 0V to max 7V and no neg. voltage is used, if not this way.

MAX_OUTPUT = 5000

ENCODER_SCALE = 2500

OUTPUT_SCALE = 6570

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 7

Thanks

Sigi

Unfortunately the Encoder handwheel does not move the selected axes. I can see it counting in Halshow, but the axis selected stays where it is.

I read in the documentation that the use of a MPG would reqire homing of the axis- my machine is not homed at the moment- but I thought the line

NO_FORCE_HOMING = 1

would let me use the MPG without homing- probably not, or is there any simple possibility to move the axes via MPG without homing them first?

The other thing I would like to get running is the spindle. I seached quite a bit, but did not really find out how to use the parameters. In diffeerent threads these are described differently.

The spindle is a Fanuc Servo which is capable to make 8000 rpm. Its connected to the correct Fanuc servo drive. The spindle itself only is allowed for 5000rpm. With the old control connected, I found that the max voltage the servo drive gets from the control is 7,6V+ at 5000rpm. So if I scale this to 10V it would give me 6570rpm.

As far as I know only pos voltage is used in the analog signal (0 to 7,6V) and the spindle is reversed by an additional signal to the drive unit. The 2500incr. encoder that I want to connect to the 7I33 is an additional encoder (TTL) driven by the spindle via toothed belt and is originally used with the old control for threadcutting (synch) only- the servo drive gets its info from an encoder inside the motor which I can not access.

So thats what I think currently the spindle params should be I wrote below. Is it correct- I guess not,but how is the calculation in this case done?

And how can I determine the output of min 0V to max 7V and no neg. voltage is used, if not this way.

MAX_OUTPUT = 5000

ENCODER_SCALE = 2500

OUTPUT_SCALE = 6570

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 7

Thanks

Sigi

Last edit: 04 Jul 2025 20:42 by ziggi.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.236 seconds