Retrofit of Precix 5x10 CNC

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 15

Thinking once I get the LinuxCNC machine up and running I would look at getting a Break Out Board.

Looking at mesa 7i76e board seems to work with linuxCNC, spindle control, ATC(i think) and has plenty of expansion. Little pricey, but I don't want to skimp on it.

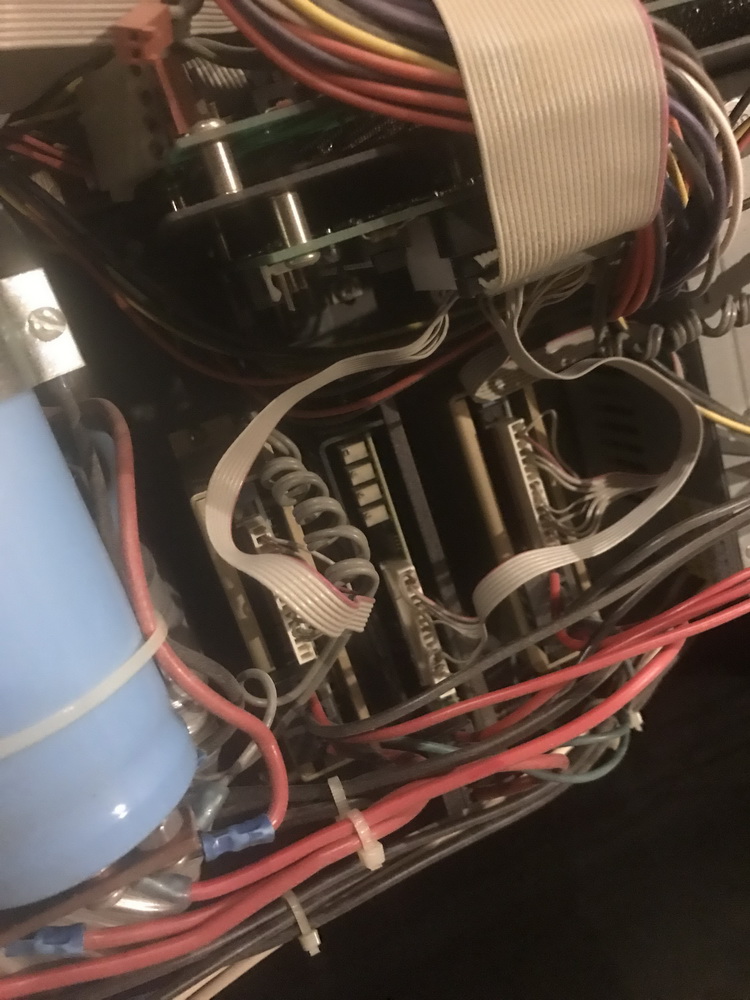

I am going to take apart the control box and find out more info about the drives. As it is, I can't really see much about them. Same with the motors for that matter. They appear to be servo motors trying to get some more info on them. They appear to be all different.

Want to ask you guys if the 7176e is good choice for this kind of retrofit, also if it's compatible with a wide range of drives. I was thinking about buying some new drives for the motors as well. Does anyone have any recommendations on those?

I retrofitted a mill with Gecko stuff and it seemed to work fine. I see this "G320X DIGITAL SERVO DRIVE" and thought that might be nice to change out the drives. Not sure if the G320X would be compatible "mesa 7i76e" and the motors I have. Will have to do more research. On my mill retrofit, I had to change the steppers out anyway, so I wasn't too concerned, but would like to keep these motors if possible.

Thanks for any input!

Here is what I know so far:

Pricix 11000 or 10500?

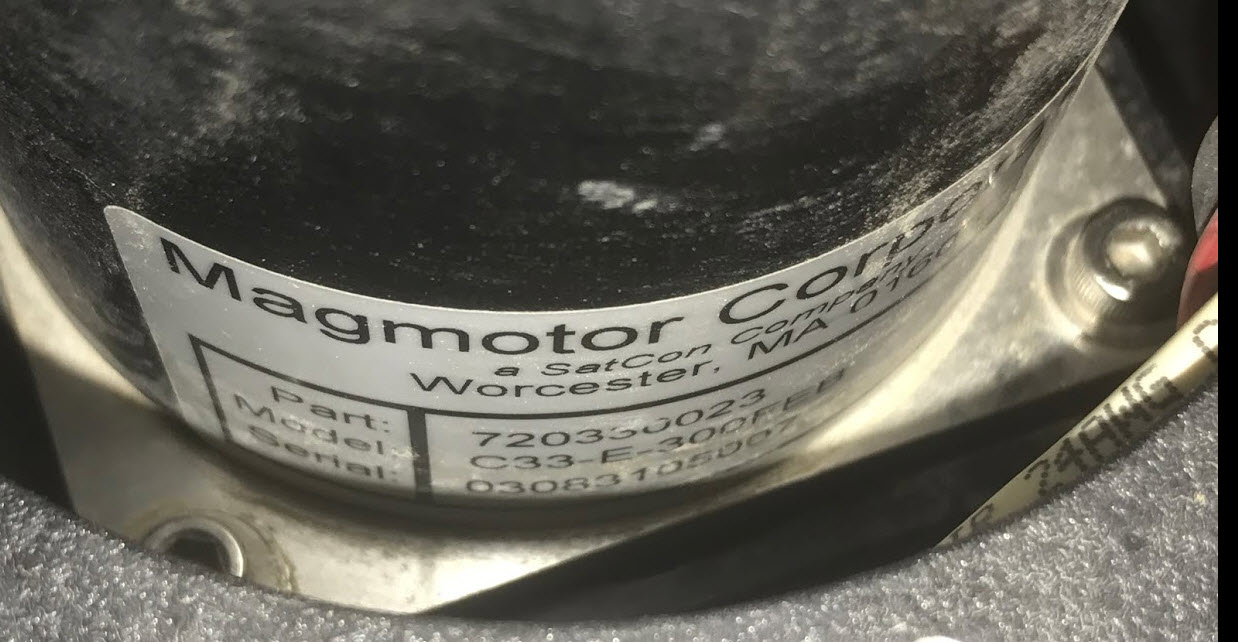

X - Axis Motor Magmotor

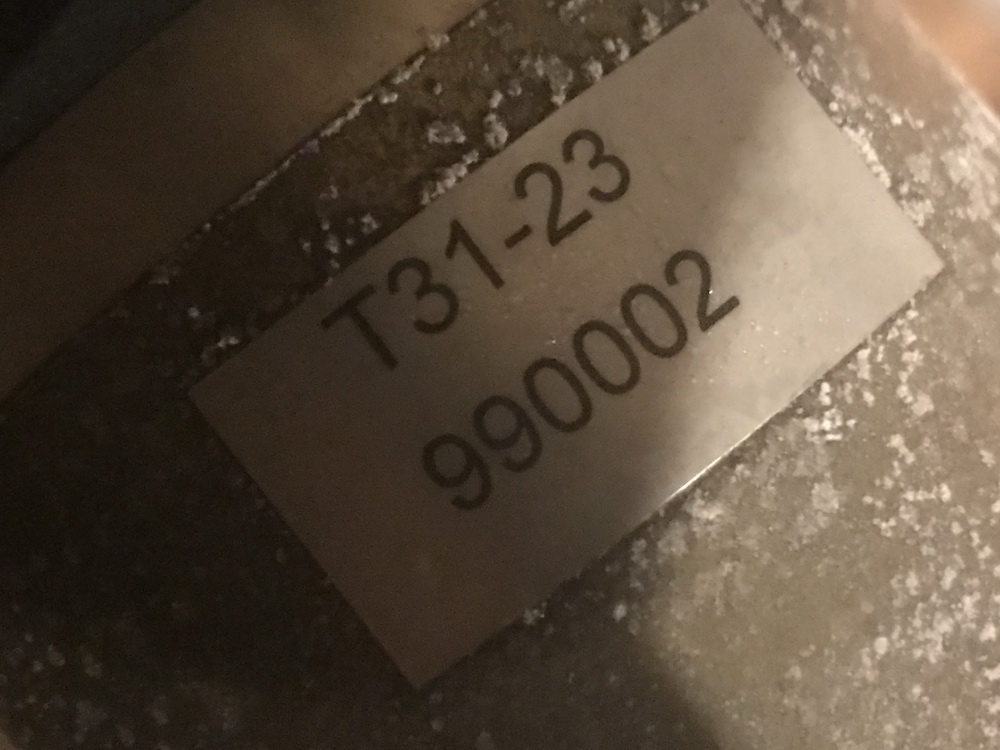

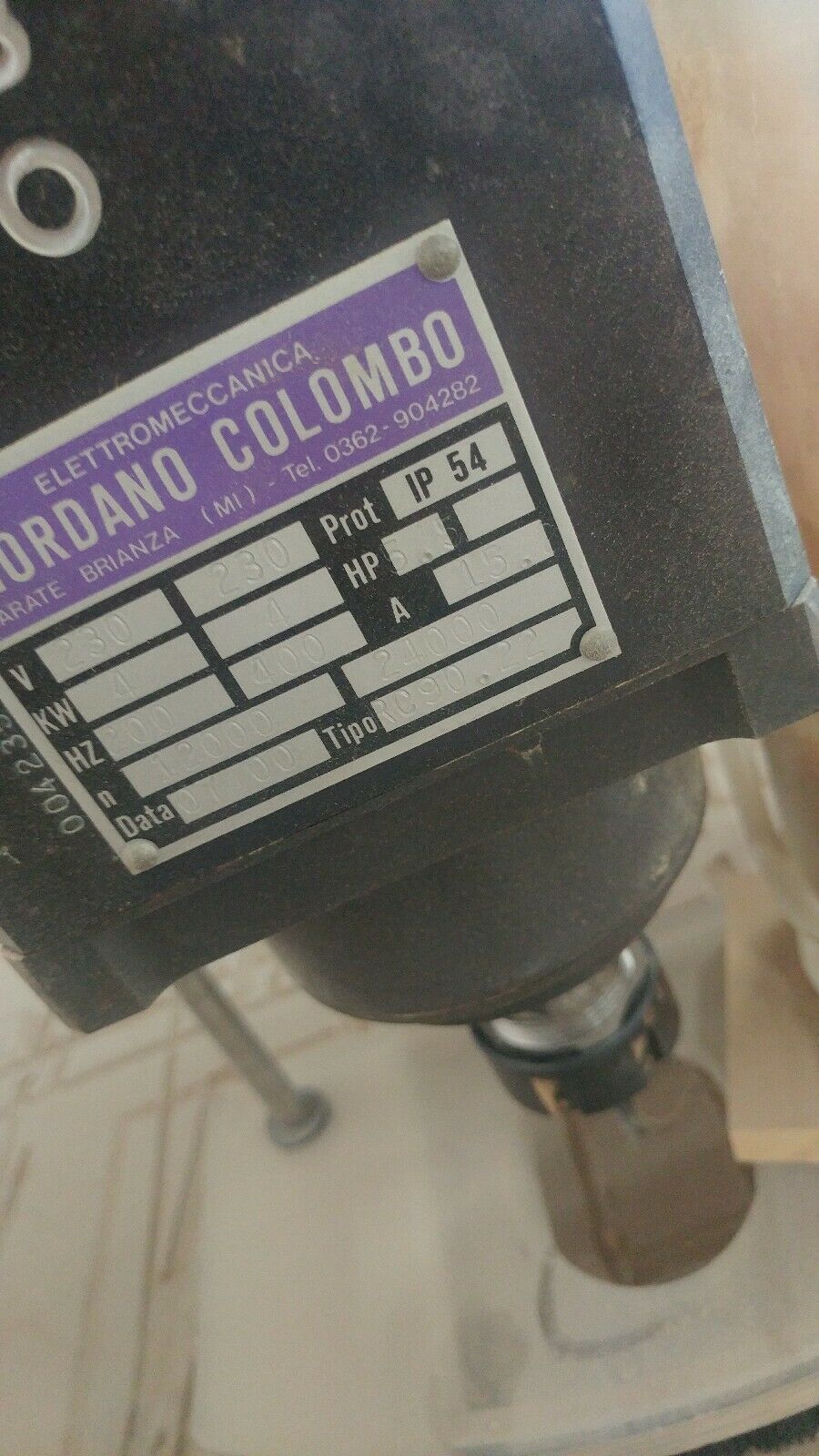

Y - Axis Motor T31-22

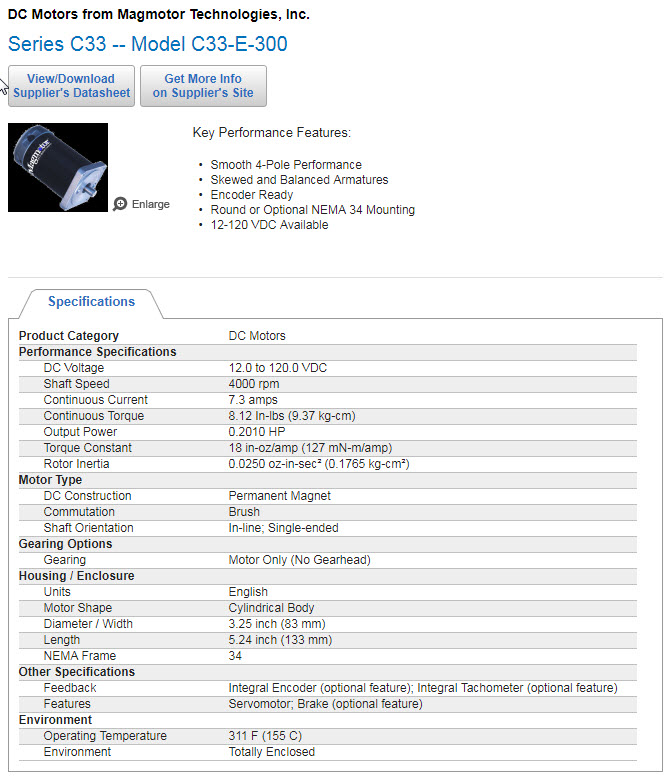

Z - Axis Motor Magmotor C33-E-300 / C33-E-300FEB

Coolant/Lubricant Trico MD-1200

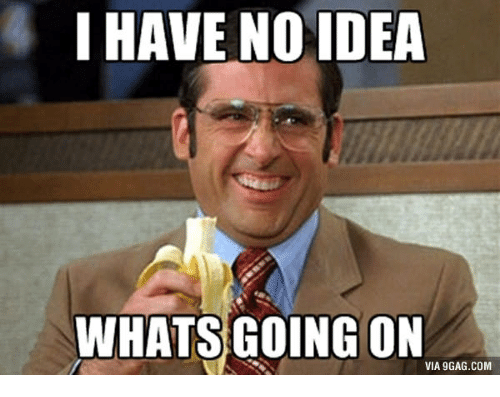

Spindle RC 90.22 Colombo Spindle with Automatic Tool Changer

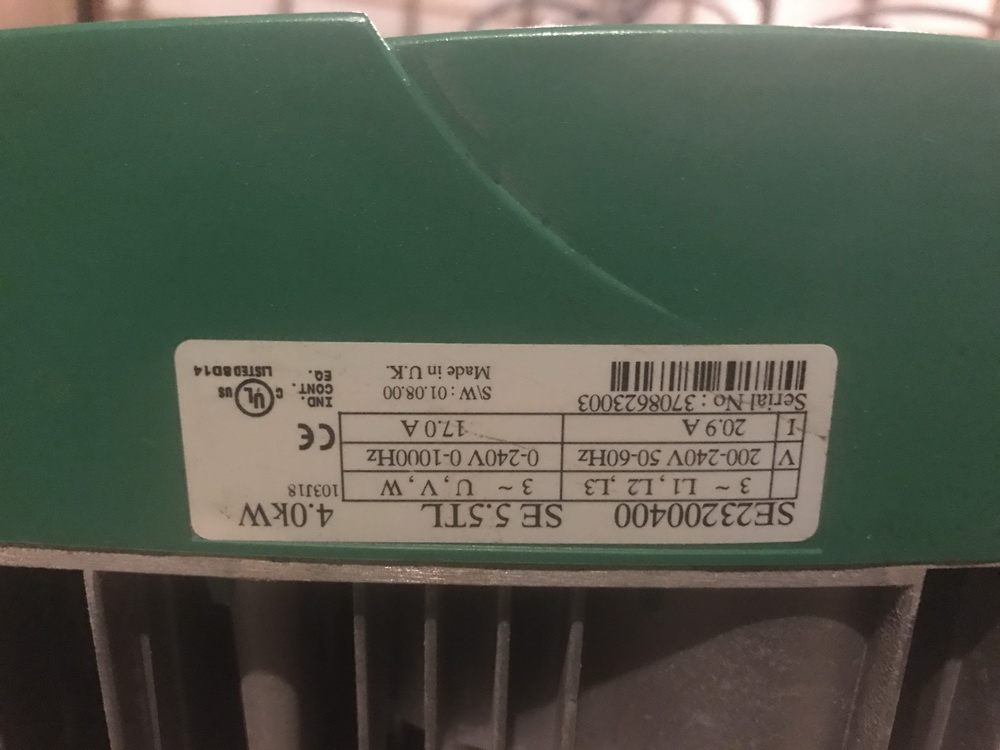

Spindle VFD Control Techniques SE23200400 AC Drive 5HP

Vacuum MAT: B70514 2003 TIPO: SCL 90 DH

Vacuum Motor EMG 3 Phase Type 132 / 15HP

Servo Drivers ???

Power Supply ???

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17728

- Thank you received: 5186

(and brushed DC motors)

so an analog servo interface rather than step/direction interface

would be needed if you are going to keep the drives.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 15

Going to have to do some more reading about that.

Can I ask, what equipment would you recommend?

Would the Mesa 6i25 + 7i77 work with my setup? (I always used parallel, but it kinda sounded like Ethernet was the direction the industry was going)

Would you recommend Mesa? Someone said they were good so I was looking that direction, but I would love to hear your input.

How would I find out if my analog servo drives (and brushed DC motors) would work with the Mesa 6i25 + 7i77?

or would you suggest I look at getting replacement Drives as well? if so which ones?

and I guess I might as well ask if I should keep the motors?

Sorry for all the questions...

Thanks again PCW, this stuff is fascinating and I am in awe with this world as I have been an admirer of CNC machines, I wish I had more time to be really be a PRO at this stuff like you and the folks on this forum are.

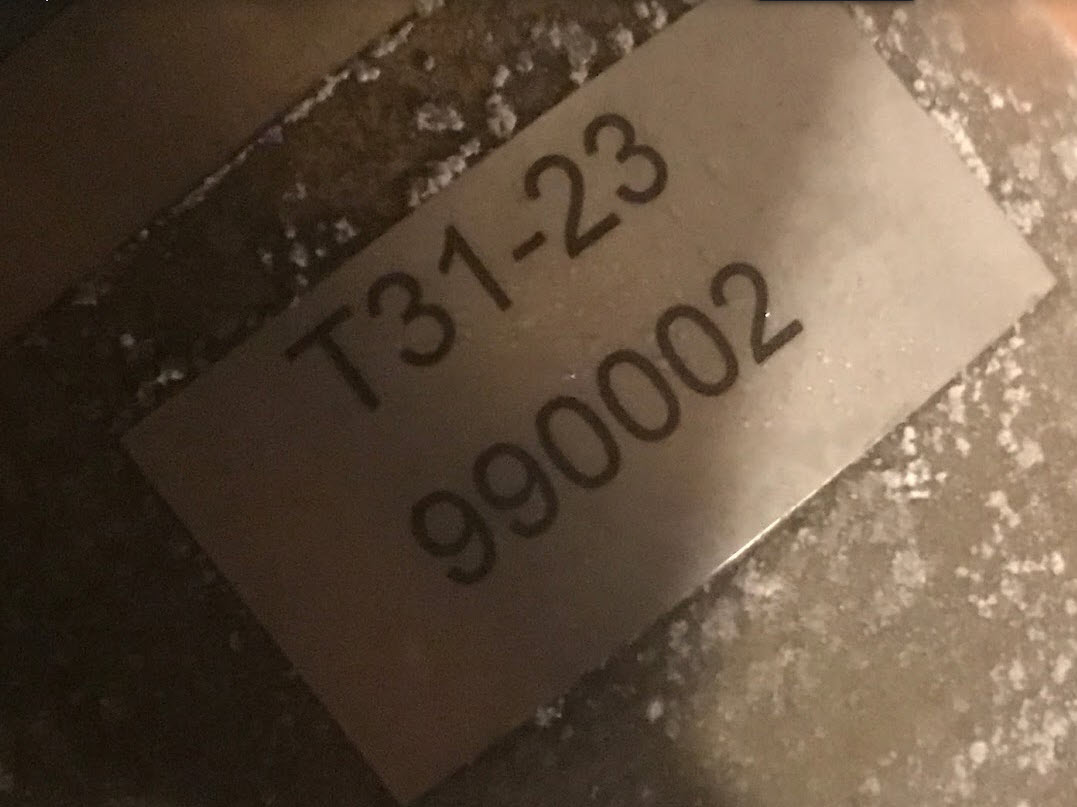

Still couldn't find details about the motors, manual only says:

Randy

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17728

- Thank you received: 5186

Would you recommend Mesa? Someone said they were good so I was looking that direction, but I would love to hear your input.

Umm that's a bit awkward and I definitely am biased since my wife and I basically are Mesa...

If you want Ethernet, a 7I92M +7I77 (or 7I77D) is one option

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

- Posts: 1872

- Thank you received: 358

is this on the Front a Rack tool changer

also the Blue Valves is the table a full Vacuum Table with 4 sections

the Spindle is a 4KW Duo so no problem with a standard VFD

are all 3 Axis motors the same

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 15

Attachments:

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 15

Yes, it's a tool changer.

Yep, Vacuum table with 4 sections.

Could use some new composite sections, but otherwise appears to be decent.

I wonder if the 7I92M +7I77 solution would work with the spindle ok?

All the motors are different: X / Z are same brand, Y appears to be different. I am not sure how compatible they are. When I retrofitted a Mill I found out they were 5 wire motors and very hard to work with other drives. Be nice to know if these drives would work or if I should look at getting some new drives.

Thanks for the reply pl7i92

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17728

- Thank you received: 5186

Thanks for the 7192M+7i77 recommendation. Do you think that would be compatible with my drives/motors?

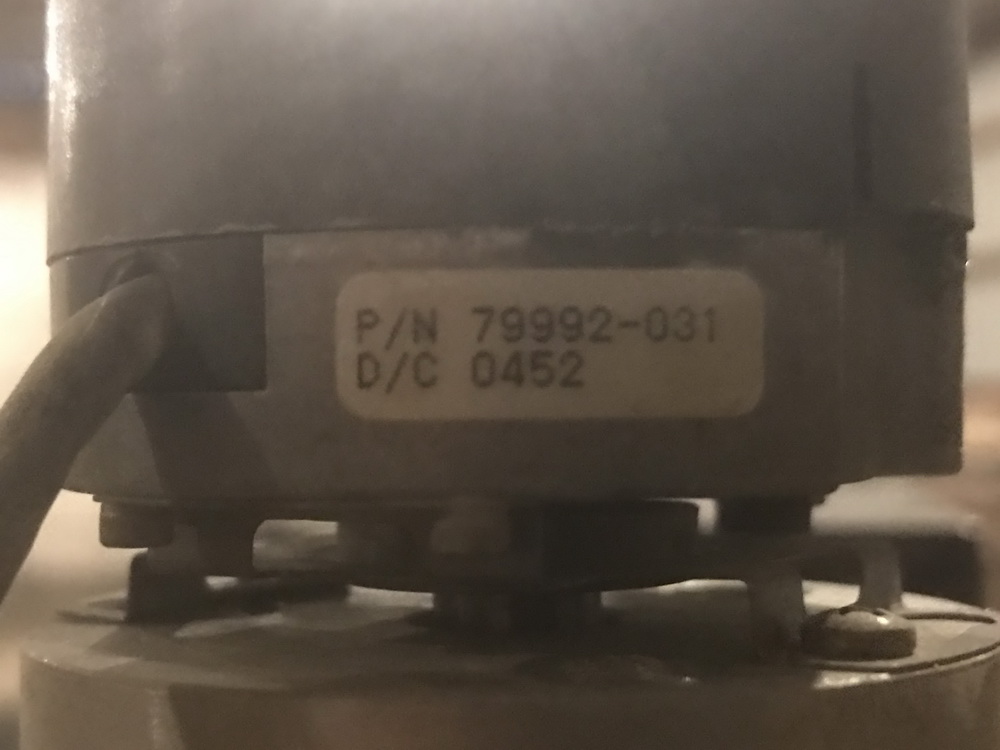

I am just guessing by looking at the motors/drives. To accurately determine the needed interface hardware

(and how to connect it), you will need to get the drive part numbers ( there appear to be two drive types )

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

- Posts: 1872

- Thank you received: 358

the Axis drivers may be first to be adviced at working

the 7i92 can do the stuff you need

can you unplug one of the Cards that are connected in the axis area and give us the numbers

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 15

I can kinda see the Z axis:

Magmotor C33-E-300 / C33-E-300FEB

The Y axis info isn't too helpful:

T31-22

I'll pull them and get a better look.

Would this info be helpful:

Encoder is a separate item, correct?

Please Log in or Create an account to join the conversation.