Retrofit of Precix 5x10 CNC

- +Jan+

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 16

24 Nov 2021 10:08 #227493

by +Jan+

Replied by +Jan+ on topic Retrofit of Precix 5x10 CNC

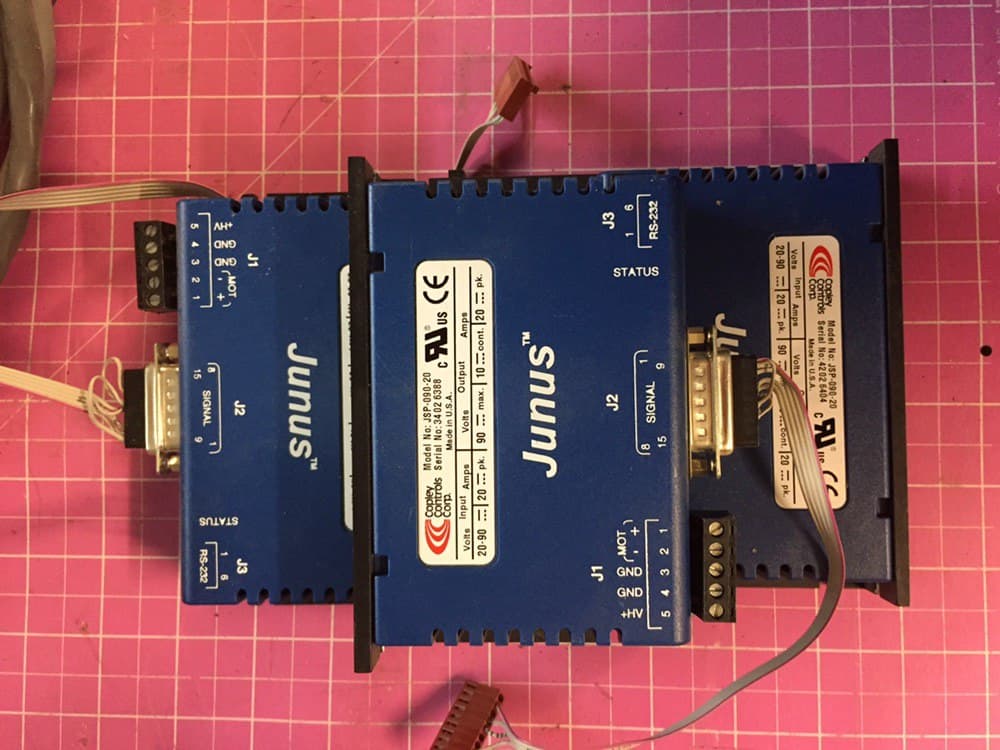

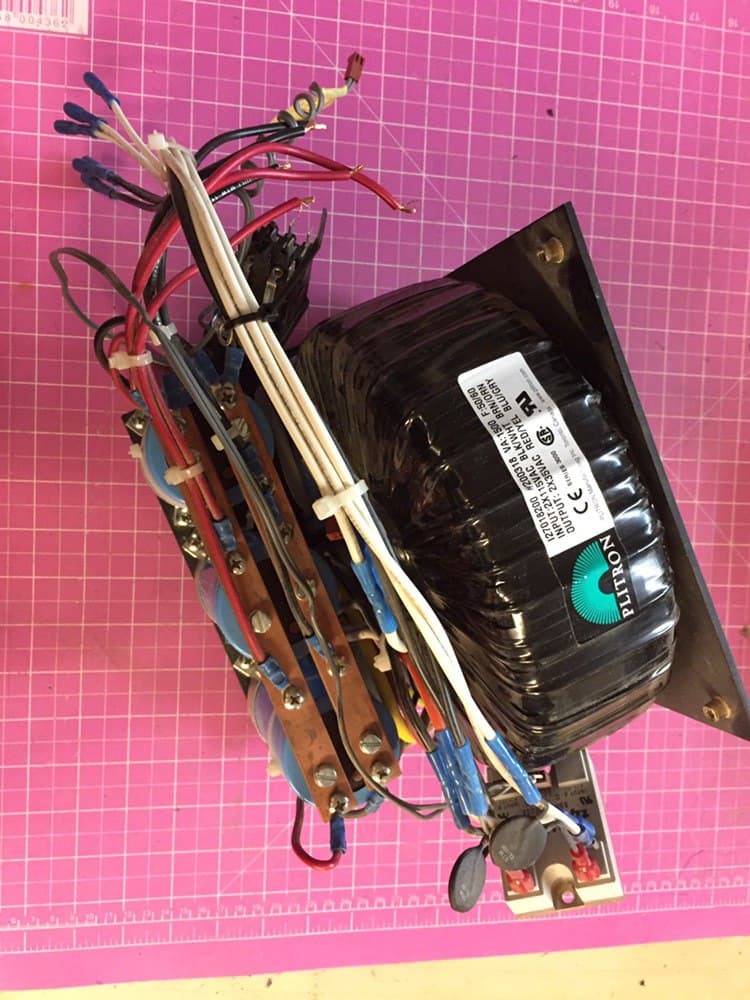

Hello, I also retrofitted such a machine last year. Since I had modern AC servos and power amplifiers with Step/Dir input on the shelf, I converted to a 7i76e. If I find time I will make some pictures in the future and open a separate topic. Since I still have the servo amplifier, servos and Power Supply left over from the conversion I wanted to ask if anyone here is interested before I sell elsewhere. I think we could agree on a fair price. Location is Germany.

Best wishes

Jan

Best wishes

Jan

Attachments:

Please Log in or Create an account to join the conversation.

- Valdis

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

26 Jan 2023 09:55 #262926

by Valdis

Replied by Valdis on topic Retrofit of Precix 5x10 CNC

Hello everybody!

I have an old Precix CNC router 5x10 without ATC.

It works properly with the Precix controls (as I know there is SENSORAY I/O system but manufacturer of controls is is Ridge Control Systems .

Since I want to get real 3D milling, as well as a more modern control shell, I decided to retrofit it.

The original equipment includes:

3 pcs. T31-23 (I think Astromech) motors with encoders connected to AMC brush type PWM servo amplifier C25A1B.

Perske v50.02 3 hp spindle, connected to a VLT VFD.

I have carefully studied this entire section, but I still have a few questions:

If I'l going to use 7i92 + 7i77 - which one do I need 7i77 (Sourcing output version) or 7i77D (Sinking output version)?

If the Precix control can control the VLT frequency converter, then Messa can?

I'd like to replace 7i92 + 7i77 with 7I97 Ethernet interfaced Analog servo plus I/O (sourcing or sinking input applications in one). Will it work without any additional Daughter Cards?

Looking for old Astromech (Renco) encoder wiring diagramm.

I thank all those who responded in advance.

I have an old Precix CNC router 5x10 without ATC.

It works properly with the Precix controls (as I know there is SENSORAY I/O system but manufacturer of controls is is Ridge Control Systems .

Since I want to get real 3D milling, as well as a more modern control shell, I decided to retrofit it.

The original equipment includes:

3 pcs. T31-23 (I think Astromech) motors with encoders connected to AMC brush type PWM servo amplifier C25A1B.

Perske v50.02 3 hp spindle, connected to a VLT VFD.

I have carefully studied this entire section, but I still have a few questions:

If I'l going to use 7i92 + 7i77 - which one do I need 7i77 (Sourcing output version) or 7i77D (Sinking output version)?

If the Precix control can control the VLT frequency converter, then Messa can?

I'd like to replace 7i92 + 7i77 with 7I97 Ethernet interfaced Analog servo plus I/O (sourcing or sinking input applications in one). Will it work without any additional Daughter Cards?

Looking for old Astromech (Renco) encoder wiring diagramm.

I thank all those who responded in advance.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4594

26 Jan 2023 17:06 #262943

by andypugh

Replied by andypugh on topic Retrofit of Precix 5x10 CNC

Whether you want sourcing or sinking outputs depends on what you are controlling. What do the outputs need to drive?

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

26 Jan 2023 17:16 #262944

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

I think posted the way I connected my unit on this thread.

Here are some of my notes, which you are welcome to look at.

drive.google.com/drive/folders/138NwzKSV...wru9Mgxn?usp=sharing

I am sure an expert on MESA cards can help you like they did me.

I switched my last Astromech motor to MAGMOTOR which I recommend. They were very helpful. The motors aren't cheap, but I think they are good quality and good support. However I did have a ASTROMECH motor for about a year. Every once in a while I would get a runaway condition on the X axis (the last astromech) so replaced with Magmotor and no problems since.

If you have any questions on my machine, let me know and I will show you what I did - I can take pic/video of my machine... It's not pretty, but it does work!

Here are some of my notes, which you are welcome to look at.

drive.google.com/drive/folders/138NwzKSV...wru9Mgxn?usp=sharing

I am sure an expert on MESA cards can help you like they did me.

I switched my last Astromech motor to MAGMOTOR which I recommend. They were very helpful. The motors aren't cheap, but I think they are good quality and good support. However I did have a ASTROMECH motor for about a year. Every once in a while I would get a runaway condition on the X axis (the last astromech) so replaced with Magmotor and no problems since.

If you have any questions on my machine, let me know and I will show you what I did - I can take pic/video of my machine... It's not pretty, but it does work!

The following user(s) said Thank You: Valdis, ahess

Please Log in or Create an account to join the conversation.

- Valdis

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

27 Jan 2023 07:25 #262983

by Valdis

Incoming and outgoing signals from T31-23 Astromech Motor encoders (propably old type Renco) + signals to AMC brush type PWM servo amplifier C25A1B + signals to VLT VFD (frequency converter).

I saw your diagrams (thank you very much again), but your picture with the encoder wiring diagramm shows the Magmotor on the photo. I don't know if the wires match the Astromech (Renco) encoder.

Off Topic:

My table has 8 holes for 8 vacuum pumps (some of them are connected in pairs) on the bottom, but only 6 zones (switches). Can someone give me a diagram of the vacuum zones and connection points?

Thanks again.

With best regards, Valdis.

Replied by Valdis on topic Retrofit of Precix 5x10 CNC

Incoming and outgoing signals from T31-23 Astromech Motor encoders (propably old type Renco) + signals to AMC brush type PWM servo amplifier C25A1B + signals to VLT VFD (frequency converter).

I saw your diagrams (thank you very much again), but your picture with the encoder wiring diagramm shows the Magmotor on the photo. I don't know if the wires match the Astromech (Renco) encoder.

Off Topic:

My table has 8 holes for 8 vacuum pumps (some of them are connected in pairs) on the bottom, but only 6 zones (switches). Can someone give me a diagram of the vacuum zones and connection points?

Thanks again.

With best regards, Valdis.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

27 Jan 2023 15:01 #263010

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Here are some photos from around that time if any can help:

photos.app.goo.gl/wBgjA9fuxgXsEZX96

Also some of the vacuum system I took today if they can help:

photos.app.goo.gl/UWqd7nxTHYDhtidh8

Honestly, I usually am trying to hold down 4x8 sheets so they are all open.

Even more honest, I rarely use the vacuum now. I use a composite nailer and hold down my materials that way. It's loud and doesn't do a real good holding down full sheets. I probably got some air leaks and it's only 15hp? or 10hp? I can't recall now. Probably work great for smaller pieces if I had it switched properly.

On mine I think the magmotor and astromec were wired similarly. Who knows how they did them, since mine had 2 magmotors and 1 astromec when I converted. I think when I switched to magmotor I kept the same wiring it's been a while.

If I was you, I'd start documenting the info you have. Taking photos of your connections and start laying out a game plan - kind of how I did it. It helped me... and there is NO way I could have done it without this forum's help. So I am very grateful for these helpful folks. You got to give them what you are working with of course. So maybe start your own thread with photos of what you got and what your plan of attack is, and ask for advise.

I remember looking at this: ridgecontrolsystems.com/ and wondering if it could be a quick solution for me. Looking at his manuals was helpful in diagnosing some of my wiring. I am not sure if he could make a LinuxCNC / Mesa version of his replacement controller.

A set of 3 stepper motors is inexpensive as well. I almost went that route, but I was under the impression servos were better so wanted to stick with them. My accuracy isn't the best so I am thinking steppers would have been fine. I am not focused on production speeds. I use it a few times a month is all.

Let me know what else I can do to help!

photos.app.goo.gl/wBgjA9fuxgXsEZX96

Also some of the vacuum system I took today if they can help:

photos.app.goo.gl/UWqd7nxTHYDhtidh8

Honestly, I usually am trying to hold down 4x8 sheets so they are all open.

Even more honest, I rarely use the vacuum now. I use a composite nailer and hold down my materials that way. It's loud and doesn't do a real good holding down full sheets. I probably got some air leaks and it's only 15hp? or 10hp? I can't recall now. Probably work great for smaller pieces if I had it switched properly.

On mine I think the magmotor and astromec were wired similarly. Who knows how they did them, since mine had 2 magmotors and 1 astromec when I converted. I think when I switched to magmotor I kept the same wiring it's been a while.

If I was you, I'd start documenting the info you have. Taking photos of your connections and start laying out a game plan - kind of how I did it. It helped me... and there is NO way I could have done it without this forum's help. So I am very grateful for these helpful folks. You got to give them what you are working with of course. So maybe start your own thread with photos of what you got and what your plan of attack is, and ask for advise.

I remember looking at this: ridgecontrolsystems.com/ and wondering if it could be a quick solution for me. Looking at his manuals was helpful in diagnosing some of my wiring. I am not sure if he could make a LinuxCNC / Mesa version of his replacement controller.

A set of 3 stepper motors is inexpensive as well. I almost went that route, but I was under the impression servos were better so wanted to stick with them. My accuracy isn't the best so I am thinking steppers would have been fine. I am not focused on production speeds. I use it a few times a month is all.

Let me know what else I can do to help!

Please Log in or Create an account to join the conversation.

- Valdis

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

30 Jan 2023 09:59 #263222

by Valdis

Replied by Valdis on topic Retrofit of Precix 5x10 CNC

Randy!

I think your vacuum system was modified before you became the owner of Precix.

I attach a photo of the original control of vacuum pumps.

There are twelve (AMETEK lamb electric 116312-00 ) vacuum pumps (mine are now removed for maintenance). Four of them are connected to the holes one to one. The other eight are two to one hole. (See the appendix.)

This is controlled by six switches. One switch to two pumps, how they were connected in the original I do not know.

I have holes on top of the table in the sacrificial material not drilled and I can't check which hole is responsible for which part of the table (yet).

For good holding down, it is not the power of the vacuum pump motor is important, but its air performance. Original pumps have an Air flow 50 l/Sec that means: 50*60*60 - 180 m3/hr. Total 180*12 - 2016 m3 per hour (Vac 133 mm H2O). I suppose you need a more productive vacuum pump.

You wrote: "Let me know what else I can do to help!".

OMG! I saw a picture of the Precix Servo Controller USER MANUAL v.99f ! Do you have a scanned copy? It would be very helpful to me.

Thanks again for your respponse.

I think your vacuum system was modified before you became the owner of Precix.

I attach a photo of the original control of vacuum pumps.

There are twelve (AMETEK lamb electric 116312-00 ) vacuum pumps (mine are now removed for maintenance). Four of them are connected to the holes one to one. The other eight are two to one hole. (See the appendix.)

This is controlled by six switches. One switch to two pumps, how they were connected in the original I do not know.

I have holes on top of the table in the sacrificial material not drilled and I can't check which hole is responsible for which part of the table (yet).

For good holding down, it is not the power of the vacuum pump motor is important, but its air performance. Original pumps have an Air flow 50 l/Sec that means: 50*60*60 - 180 m3/hr. Total 180*12 - 2016 m3 per hour (Vac 133 mm H2O). I suppose you need a more productive vacuum pump.

You wrote: "Let me know what else I can do to help!".

OMG! I saw a picture of the Precix Servo Controller USER MANUAL v.99f ! Do you have a scanned copy? It would be very helpful to me.

Thanks again for your respponse.

Please Log in or Create an account to join the conversation.

- Valdis

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

30 Jan 2023 17:13 #263251

by Valdis

Replied by Valdis on topic Retrofit of Precix 5x10 CNC

Unfortunately for me user manual (www.precix.com/bill/manual .zip) containing the vacuum system data is no longer available. There is an incomplete Html copy of the user manual on my Precix disk. Only three sections. Maybe someone has a complete copy of the user manual on a disk or a precix (QNX) disk image?

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

30 Jan 2023 17:15 #263253

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

I'll scan everything I got here - just give me some time. I think it's out of order, but I'll scan it all and get it to you today or tomorrow.

The following user(s) said Thank You: Valdis

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

03 Feb 2023 14:06 #263599

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Sorry for the delay - I got my shoebox of papers scanned...

Sorry for the upside down papers and out of order documents. I meant to get the sorted, but I didn't want to wait any longer!

drive.google.com/drive/folders/138NwzKSV...pRtmt4HYuMTJwru9Mgxn

Let me know how else I can help!

Sorry for the upside down papers and out of order documents. I meant to get the sorted, but I didn't want to wait any longer!

drive.google.com/drive/folders/138NwzKSV...pRtmt4HYuMTJwru9Mgxn

Let me know how else I can help!

The following user(s) said Thank You: Valdis

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.172 seconds