Retrofit of Precix 5x10 CNC

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

05 Mar 2020 14:19 #159258

by andypugh

I am not sure that they are mentioned in the docs, but they exist in the code:

github.com/LinuxCNC/linuxcnc/blob/2.7/sr...tmot2/encoder.c#L509

So you need to set the "error-enable" bit in the HAL, and then you can monitor the outputs.

Replied by andypugh on topic Retrofit of Precix 5x10 CNC

Give me a minute while I look up what "quadrature-error outputs" are.

I am not sure that they are mentioned in the docs, but they exist in the code:

github.com/LinuxCNC/linuxcnc/blob/2.7/sr...tmot2/encoder.c#L509

So you need to set the "error-enable" bit in the HAL, and then you can monitor the outputs.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

19 Oct 2020 15:54 #186589

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

In case someone has similar problem wanted to report back.

After changing out the cables, CNC has not had any issues. So must have been encoder cables that I replaced. Used CNC a lot since then and been acting perfect [knock on wood].

Thanks for everyone's help as always.

After changing out the cables, CNC has not had any issues. So must have been encoder cables that I replaced. Used CNC a lot since then and been acting perfect [knock on wood].

Thanks for everyone's help as always.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

03 Dec 2020 21:07 #190981

by bevins

I have a Precix to retrofit for a customer. Did you end up swapping out motors and/or drives? Or did everything work ok with the 7i77?

Replied by bevins on topic Retrofit of Precix 5x10 CNC

In case someone has similar problem wanted to report back.

After changing out the cables, CNC has not had any issues. So must have been encoder cables that I replaced. Used CNC a lot since then and been acting perfect [knock on wood].

Thanks for everyone's help as always.

I have a Precix to retrofit for a customer. Did you end up swapping out motors and/or drives? Or did everything work ok with the 7i77?

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

03 Dec 2020 21:30 #190984

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Bevins,

No, I kept using the same motors. Same motors/drivers/power supply.

I'd be glad to help however I can, if you have any specific questions ask away! Otherwise I will record a quick video of how my machine is set up, maybe can help or anyone else with a retrofit.

Used it today worked fine.

If you do use same motors, maybe we can compare notes on servo tuning Which model are you retrofitting?

Which model are you retrofitting?

No, I kept using the same motors. Same motors/drivers/power supply.

I'd be glad to help however I can, if you have any specific questions ask away! Otherwise I will record a quick video of how my machine is set up, maybe can help or anyone else with a retrofit.

Used it today worked fine.

If you do use same motors, maybe we can compare notes on servo tuning

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

03 Dec 2020 22:04 #190986

by bevins

It is a 2100 Series CNC Router DC3BR. 3 phase motor drives and 3 phase spindle inverter. thats all I know for now. The customer hasn't got back to me with more details. Its a Oct 2000 manufacture date. Delta VFD, Perske servo's.

thats all I got now. It kinda looks like your control box.

Replied by bevins on topic Retrofit of Precix 5x10 CNC

Bevins,

No, I kept using the same motors. Same motors/drivers/power supply.

I'd be glad to help however I can, if you have any specific questions ask away! Otherwise I will record a quick video of how my machine is set up, maybe can help or anyone else with a retrofit.

Used it today worked fine.

If you do use same motors, maybe we can compare notes on servo tuningWhich model are you retrofitting?

It is a 2100 Series CNC Router DC3BR. 3 phase motor drives and 3 phase spindle inverter. thats all I know for now. The customer hasn't got back to me with more details. Its a Oct 2000 manufacture date. Delta VFD, Perske servo's.

thats all I got now. It kinda looks like your control box.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

28 Feb 2021 23:20 #200484

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

First off I want to say, thanks so much for all the help this forum has provided! I really appreciate it...

Trying to expand the machine a bit to make it function better for me.

It came with a touch plate, however I never thought it would work properly. It's an air cooled spindle and it was added afterwards. The tool bit is not making any connection with any of the wiring. It is sometimes grounded to the unit, but if I rotate the bit the connection goes on/off, is that normal?

Since I am having issues with my V-engraving being sometimes too deep, sometimes too shallow, I really want a reliable and accurate way to tell the surface of my material. Thanks to the forum, using my XHC-WHB04B is working great! but hard to get the Z exactly right.

I took the plate they provided and I added a clip to it, there were 2 wires going to the plate, now 1 goes to the clip and 1 goes to the plate.

I verified that I have a good connection going from that to some wires in my controller that can go to my 7i77 card, just hoping to get some help on how/where to connect them. Also, seems like I will need a new probe screen?

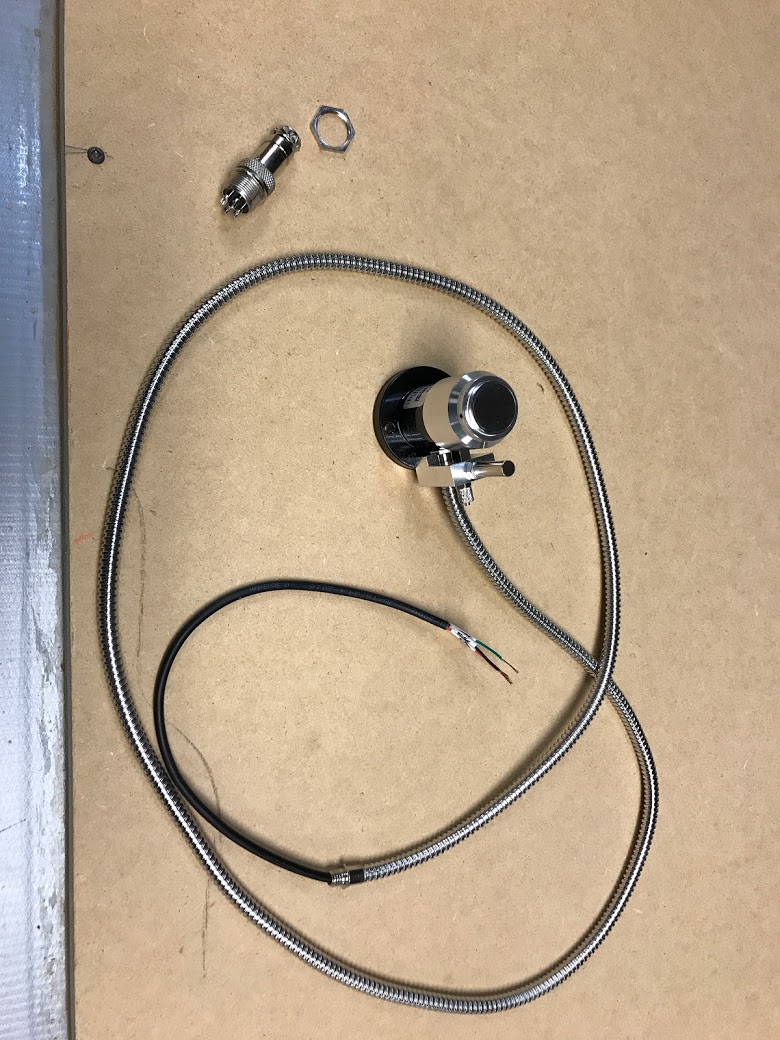

I also purchased a tool setter probe in hopes that during tool changes I can be more accurate.

Bought of Amazon:

www.amazon.com/gp/product/B07PRPMZKS/ref...05_s00?ie=UTF8&psc=1

Not worried about that right now, want to focus on workplace z height accuracy and whatever software I will need to do it.

Thanks for any help!

random things made on the CNC

cell holder for co-workers

apple for daughters teacher

Trying to expand the machine a bit to make it function better for me.

It came with a touch plate, however I never thought it would work properly. It's an air cooled spindle and it was added afterwards. The tool bit is not making any connection with any of the wiring. It is sometimes grounded to the unit, but if I rotate the bit the connection goes on/off, is that normal?

Since I am having issues with my V-engraving being sometimes too deep, sometimes too shallow, I really want a reliable and accurate way to tell the surface of my material. Thanks to the forum, using my XHC-WHB04B is working great! but hard to get the Z exactly right.

I took the plate they provided and I added a clip to it, there were 2 wires going to the plate, now 1 goes to the clip and 1 goes to the plate.

I verified that I have a good connection going from that to some wires in my controller that can go to my 7i77 card, just hoping to get some help on how/where to connect them. Also, seems like I will need a new probe screen?

I also purchased a tool setter probe in hopes that during tool changes I can be more accurate.

Bought of Amazon:

www.amazon.com/gp/product/B07PRPMZKS/ref...05_s00?ie=UTF8&psc=1

Not worried about that right now, want to focus on workplace z height accuracy and whatever software I will need to do it.

Thanks for any help!

random things made on the CNC

cell holder for co-workers

apple for daughters teacher

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- GJTuck

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

13 Mar 2021 02:22 #202052

by GJTuck

Replied by GJTuck on topic Retrofit of Precix 5x10 CNC

Thanks for all the great information really appreciate the info. I’m hoping someone can help me out with a precix issue I’m having.

When I go to home the machine the z homes then the x but when it comes to the y it jumps about a inch then says y axis error. Any help would be greatly appreciated. I swapped the y and x encoder cables and nothing changed. I swapped the power cables nothing changed. I changed the amplifier nothing changed. I swapped the y moter with the z axis and immediately the z axis did the slight jump then a error. I ordered a new motor/encoder and just tried it out being certain that was the issue and it’s still doing the same thing. Any ideas? I thinking about changing out the limit switch wires, the lights on the board say they are working but I don’t have anything left to try. They have been repaired a few times.

When I go to home the machine the z homes then the x but when it comes to the y it jumps about a inch then says y axis error. Any help would be greatly appreciated. I swapped the y and x encoder cables and nothing changed. I swapped the power cables nothing changed. I changed the amplifier nothing changed. I swapped the y moter with the z axis and immediately the z axis did the slight jump then a error. I ordered a new motor/encoder and just tried it out being certain that was the issue and it’s still doing the same thing. Any ideas? I thinking about changing out the limit switch wires, the lights on the board say they are working but I don’t have anything left to try. They have been repaired a few times.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

13 Mar 2021 15:39 #202102

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Hoping a more knowledgeable person will chime in with a quick answer for you. Sounds like you did a lot of troubleshooting...

Could it just be your tuning parameters? Something in your software?

Could it be in your gears/belts? I had my Y bearing clog up with dust (before I had dust removal) and behave oddly. It was very hard to move my spindle across my Y axis. On your machine, is everything smooth physically?

I will ponder on this as well, but hoping the experts (who have helped me so much) will speak up and provide a quick answer for you.

Tell me more about your machine, post some pics...

Could it just be your tuning parameters? Something in your software?

Could it be in your gears/belts? I had my Y bearing clog up with dust (before I had dust removal) and behave oddly. It was very hard to move my spindle across my Y axis. On your machine, is everything smooth physically?

I will ponder on this as well, but hoping the experts (who have helped me so much) will speak up and provide a quick answer for you.

Tell me more about your machine, post some pics...

The following user(s) said Thank You: GJTuck

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

13 Mar 2021 15:45 #202103

by jmelson

Replied by jmelson on topic Retrofit of Precix 5x10 CNC

What type of motors and drives are you using? Do you have position feedback to the PC? If so, move the machine manually and watch the DRO to see if the position changes smoothly and the correct amount. If not, then the encoder or anything in the chain back to the PC is suspect.

If you don't have position feedback to the PC, it is a little harder to diagnose. If the drives have a programming port you might be able to run diagnostics on the drive and see if it shows an issue or error.

Jon

If you don't have position feedback to the PC, it is a little harder to diagnose. If the drives have a programming port you might be able to run diagnostics on the drive and see if it shows an issue or error.

Jon

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

13 Mar 2021 16:07 #202107

by jmelson

Replied by jmelson on topic Retrofit of Precix 5x10 CNC

OK, I gather you are using the original Copley and AMC analog servo amps. Are you using tachometers in the motors for velocity servo mode, or are you using them in torque mode (no tachs)? If you are using the tachs, it is possible the tach or tach cable has gone bad. That will definitely cause a jump if the amp doesn't see the tach showing velocity when it starts to command movement.

If you are running the amps in torque mode (no tachs) then it probably is an encoder feedback issue, or possibly a failure in the servo amp. Since you have the Mesa interface, you do have position feedback to the PC, so check the DRO as described in the previous message. You can also use Halscope to display encoder velocity and the PID command out to see which is causing the jump.

Jon

If you are running the amps in torque mode (no tachs) then it probably is an encoder feedback issue, or possibly a failure in the servo amp. Since you have the Mesa interface, you do have position feedback to the PC, so check the DRO as described in the previous message. You can also use Halscope to display encoder velocity and the PID command out to see which is causing the jump.

Jon

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.258 seconds