Retrofit of Precix 5x10 CNC

- Valdis

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

06 Feb 2023 10:29 #263810

by Valdis

Replied by Valdis on topic Retrofit of Precix 5x10 CNC

Thank you, Randy!

Please Log in or Create an account to join the conversation.

- ahess

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

20 Apr 2023 15:56 #269489

by ahess

Replied by ahess on topic Retrofit of Precix 5x10 CNC

Hello all!

First i want to give big THANKS! to Randy for giving all the infos of his precix retrofit!

We also have an Precix mill (almost the same config as Randy's running since 2000 at our university department (Art academy in Austria).

Mechanically we ran through many repairs/fixes during the last years on our own as we got no support from precix. Mostly we suffered from UNC part supplies in europe, so the mechanics turn more and more into metric

Thanks to Randy's posts we were encouraged to give our old lady another chance to stay in our workshop, as our controller went down 2 years ago.

So far we go the same track with mesa 7i77 and 7i92 (just shipped)... and i am super eager to get it running again.

So far we have no major issues, thanks also to linux cnc and the forum! ... but i would be very grateful if you guys could help me when stuck with the project.

Best wishes from Austria,

Armin

First i want to give big THANKS! to Randy for giving all the infos of his precix retrofit!

We also have an Precix mill (almost the same config as Randy's running since 2000 at our university department (Art academy in Austria).

Mechanically we ran through many repairs/fixes during the last years on our own as we got no support from precix. Mostly we suffered from UNC part supplies in europe, so the mechanics turn more and more into metric

Thanks to Randy's posts we were encouraged to give our old lady another chance to stay in our workshop, as our controller went down 2 years ago.

So far we go the same track with mesa 7i77 and 7i92 (just shipped)... and i am super eager to get it running again.

So far we have no major issues, thanks also to linux cnc and the forum! ... but i would be very grateful if you guys could help me when stuck with the project.

Best wishes from Austria,

Armin

The following user(s) said Thank You: randypetersen

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

20 Apr 2023 20:24 #269511

by tommylight

Replied by tommylight on topic Retrofit of Precix 5x10 CNC

Feel free to shot questions as much as you like/can/want.

Wilcomen bei uns.

Wilcomen bei uns.

The following user(s) said Thank You: ahess

Please Log in or Create an account to join the conversation.

- ahess

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

22 Apr 2023 15:33 #269611

by ahess

Replied by ahess on topic Retrofit of Precix 5x10 CNC

@tom thanks for your warm welcome!

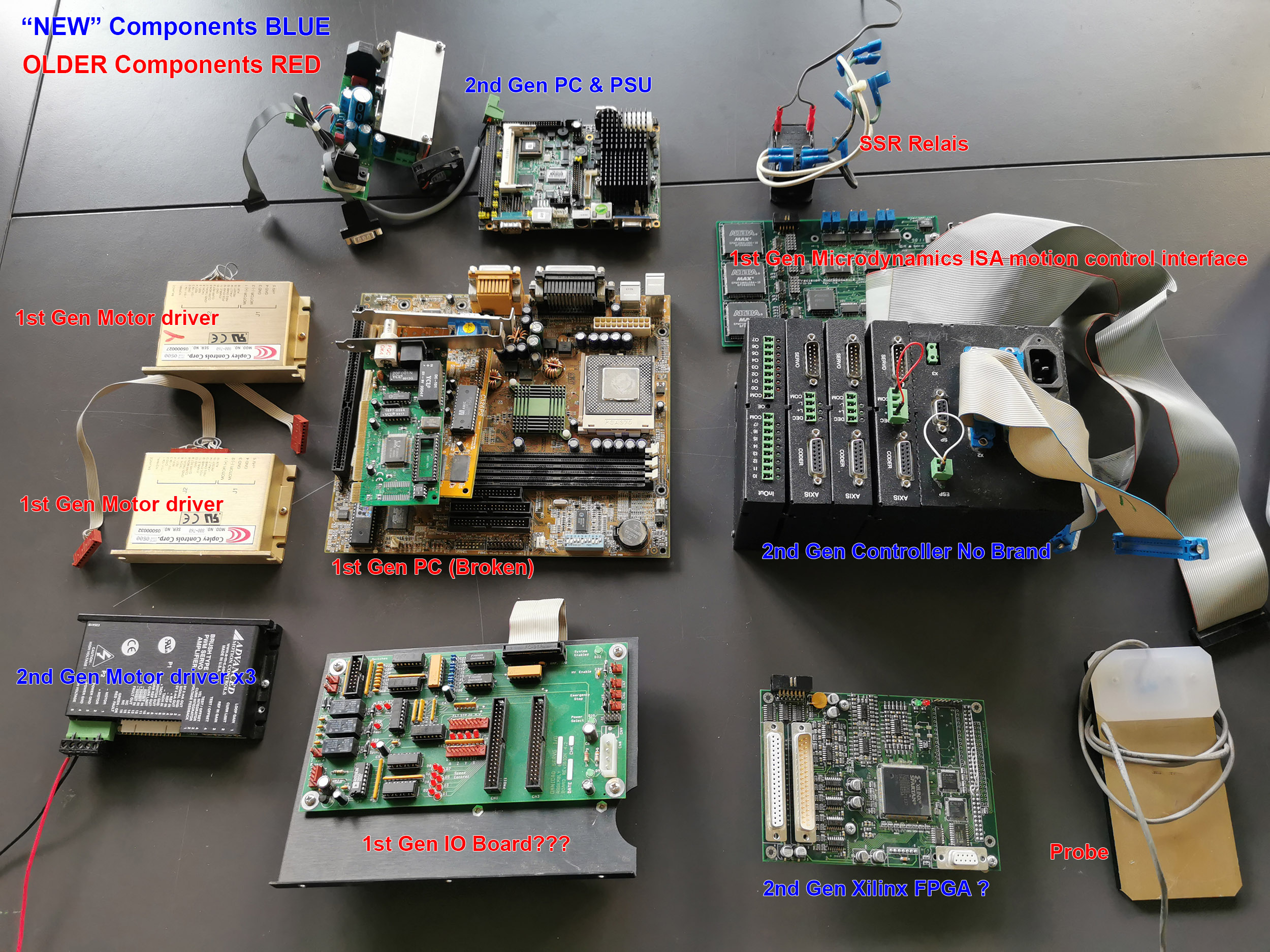

@my project:i cleaned up my controller cases- so we had two controllers:

-one very old and original from precix dating back to 2000, and

-a newer one (~2010?) which was changed already to linux cnc. sadly i could not figure out the controller type/brand from the newer one.

so all hardware (mostly) twice

-i will try to keep most hardware motor/encoder/servo drivers. and the toroidal psu(s).

made a photo of the old stuff:

- i tried both motordrivers (1.Gen and 2.Gen from the image) pinout is fairly the same, but i would go with the older drivers first (for testing) ?

- i am trying now to set up a servo loop on the bench for learning. i could also go with an mpg controller - would this make more sense?

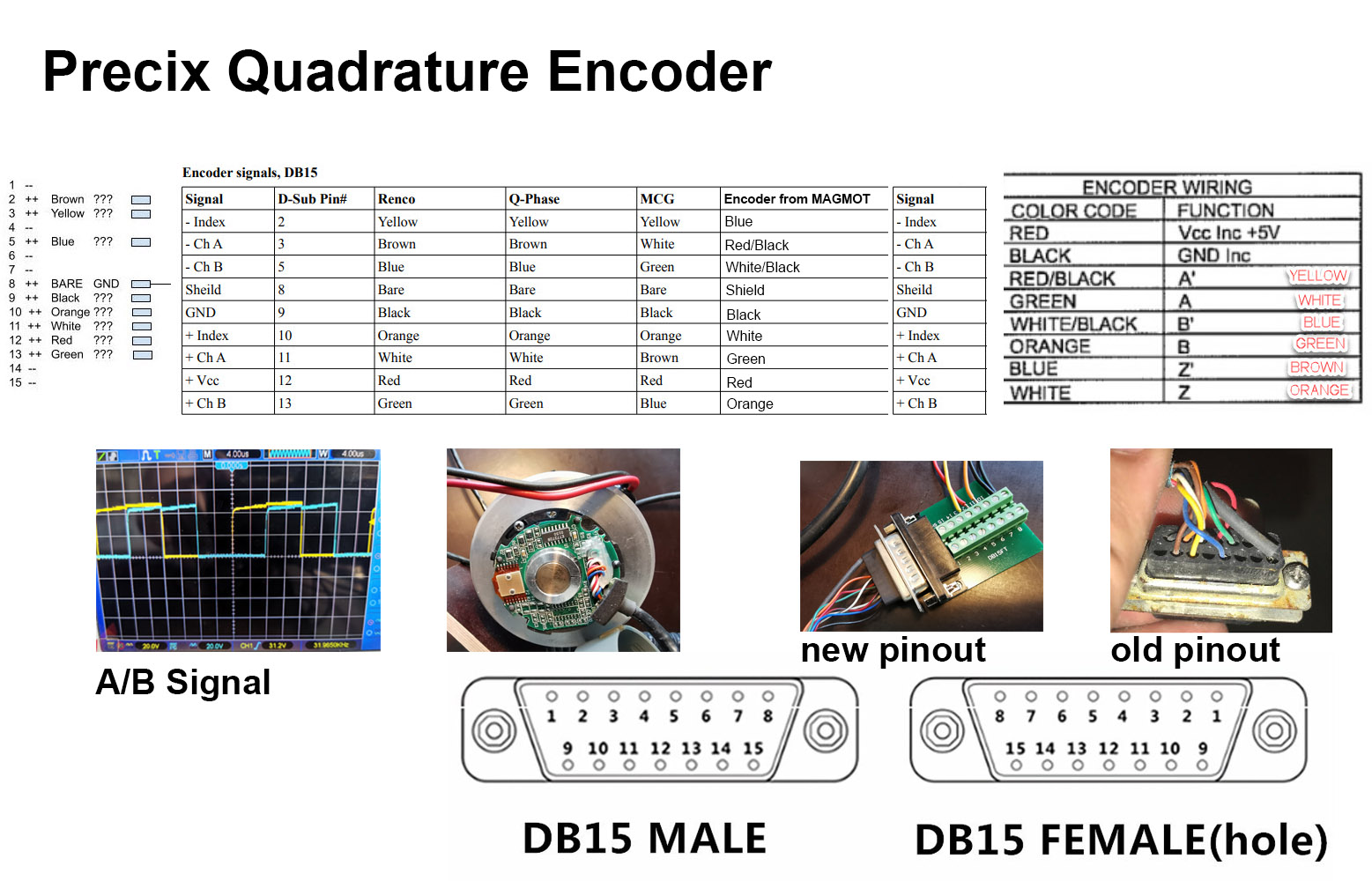

- tested the encoder signals, not sure if the signal looks ok ?

- last but not least i would like to test the toroidal transformers, the capacitors are rather old, would this make sense ?

- i also would like to add up to randy's documentation as we have fairly the same machine, but i am not sure if this is the right policy here?

thx in advance,

Armin

@my project:i cleaned up my controller cases- so we had two controllers:

-one very old and original from precix dating back to 2000, and

-a newer one (~2010?) which was changed already to linux cnc. sadly i could not figure out the controller type/brand from the newer one.

so all hardware (mostly) twice

-i will try to keep most hardware motor/encoder/servo drivers. and the toroidal psu(s).

made a photo of the old stuff:

- i tried both motordrivers (1.Gen and 2.Gen from the image) pinout is fairly the same, but i would go with the older drivers first (for testing) ?

- i am trying now to set up a servo loop on the bench for learning. i could also go with an mpg controller - would this make more sense?

- tested the encoder signals, not sure if the signal looks ok ?

- last but not least i would like to test the toroidal transformers, the capacitors are rather old, would this make sense ?

- i also would like to add up to randy's documentation as we have fairly the same machine, but i am not sure if this is the right policy here?

thx in advance,

Armin

Attachments:

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

25 Apr 2023 13:22 #269859

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Excited to see your progress, please let me know if I can help in anyway.

I really need to spend some more time on my machine. Getting the wireless MPG controller to work was very helpful. I'd like to get the automatic tool change functioning. That would be a huge improvement to workflow. I also bought a tool touch sensor I'd like to hook up.

I am glad you chose to breath some new life into your Precix machine, mine has done just fine since the retrofit. It doesn't get used as much as I'd like, but it's really nice machine to have in the shop.

It looks like you have a better understanding of this stuff, I relied on the kindness and knowledge of the experts on this forum. I couldn't have done it without them and I really appreciate their help.

I am still using the original drivers and power supply. I wondered if a new power supply would help with things. I read where someone said the capacitors should be replaced, since they are original.

I spent a lot of time on tuning trying to get it to accurately and quickly go to where it needed to, and still have some issues. It's better than 1/8" but not as exact as I'd like it to be, and I am not sure if it's machine or settings.

Again, reach out if I can help with anything!!!

I really need to spend some more time on my machine. Getting the wireless MPG controller to work was very helpful. I'd like to get the automatic tool change functioning. That would be a huge improvement to workflow. I also bought a tool touch sensor I'd like to hook up.

I am glad you chose to breath some new life into your Precix machine, mine has done just fine since the retrofit. It doesn't get used as much as I'd like, but it's really nice machine to have in the shop.

It looks like you have a better understanding of this stuff, I relied on the kindness and knowledge of the experts on this forum. I couldn't have done it without them and I really appreciate their help.

I am still using the original drivers and power supply. I wondered if a new power supply would help with things. I read where someone said the capacitors should be replaced, since they are original.

I spent a lot of time on tuning trying to get it to accurately and quickly go to where it needed to, and still have some issues. It's better than 1/8" but not as exact as I'd like it to be, and I am not sure if it's machine or settings.

Again, reach out if I can help with anything!!!

Please Log in or Create an account to join the conversation.

- ahess

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

26 Apr 2023 11:28 #269968

by ahess

Replied by ahess on topic Retrofit of Precix 5x10 CNC

I am still messing with hal etc. so my progress is not really great.

Not 100% sure but i guess i measured the repeatability once- was less than 1mm. At least good enough for wood and foam we work with.

Hopefully i get it running soon so we could compare specs and precision.

Not 100% sure but i guess i measured the repeatability once- was less than 1mm. At least good enough for wood and foam we work with.

Hopefully i get it running soon so we could compare specs and precision.

Please Log in or Create an account to join the conversation.

- ahess

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

24 Oct 2023 11:47 #283693

by ahess

Replied by ahess on topic Retrofit of Precix 5x10 CNC

Dear Randy,

Sry, it took a while to get my precix project further. Not sure if you are still on this forum.

Meanwhile i build the electronics from scratch (also the electricity supply), i did a (almost) complete blueprint with Kicad which turned out super helpful. Also ran some gcode (just with the test setup, not the whole machine).

But:

After some testing it turned out i have a issue with my transformer: when switching off all breakers on the AC side go down. Also my SSR Relay which switches the toroid trafo went up in smoke. So i guess an ssr was not a good idea to switch the trafo.

Maybe you could help me with my issue(s):

Did you have similar issues? - Primary Fuses Blown?

What components do you have in front of your servo trafo? Maye a varistor or some other circuitry?

Did you change the big capacitors as they were end of life? - But i guess this is not the issue.

I added a screenshot of my blueprint with my actual configuration. The trafo/PSU is marked in grey.

Also if someone else could help me with inductive overcurrent/overvoltage issues i was super happy, even if it has nothing to do with LinuxCnc.

Thks,

Armin

Sry, it took a while to get my precix project further. Not sure if you are still on this forum.

Meanwhile i build the electronics from scratch (also the electricity supply), i did a (almost) complete blueprint with Kicad which turned out super helpful. Also ran some gcode (just with the test setup, not the whole machine).

But:

After some testing it turned out i have a issue with my transformer: when switching off all breakers on the AC side go down. Also my SSR Relay which switches the toroid trafo went up in smoke. So i guess an ssr was not a good idea to switch the trafo.

Maybe you could help me with my issue(s):

Did you have similar issues? - Primary Fuses Blown?

What components do you have in front of your servo trafo? Maye a varistor or some other circuitry?

Did you change the big capacitors as they were end of life? - But i guess this is not the issue.

I added a screenshot of my blueprint with my actual configuration. The trafo/PSU is marked in grey.

Also if someone else could help me with inductive overcurrent/overvoltage issues i was super happy, even if it has nothing to do with LinuxCnc.

Thks,

Armin

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

24 Oct 2023 13:08 #283700

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Wow, that's awesome! What a cool build out.

I am sorry, but I am not that knowledgeable on that. I had to get help to hook up my vacuum and spindle VFD. The other components powered up as normal. No issues with tripped breakers or blown fuses. I didn't change the capacitors, but I think I should as I am having some issues on fine motor control.

I am sorry I can't help much, I'll take a video of my controller, maybe you can see something mine has that yours doesn't.

This forum is filled with super intelligent people, I am guessing someone will chime in. If not, you might want to make a new forum post and I'll bet someone will help.

I am sorry, but I am not that knowledgeable on that. I had to get help to hook up my vacuum and spindle VFD. The other components powered up as normal. No issues with tripped breakers or blown fuses. I didn't change the capacitors, but I think I should as I am having some issues on fine motor control.

I am sorry I can't help much, I'll take a video of my controller, maybe you can see something mine has that yours doesn't.

This forum is filled with super intelligent people, I am guessing someone will chime in. If not, you might want to make a new forum post and I'll bet someone will help.

The following user(s) said Thank You: ahess

Please Log in or Create an account to join the conversation.

- ahess

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

24 Oct 2023 13:52 #283704

by ahess

Replied by ahess on topic Retrofit of Precix 5x10 CNC

Thx for your fast reply,

Strange thing i did it the same way the old controller was

Yep this old toroid is nice (Hifi Enthusiasts love them), but maybe i have to switch to modern PSU`s one for each motor.

Just in case a photo of cabling and components before the powersupply would help

Next week my board will move hopefully to the machine- fingers crossed.

Best,

Armin

Strange thing i did it the same way the old controller was

Yep this old toroid is nice (Hifi Enthusiasts love them), but maybe i have to switch to modern PSU`s one for each motor.

Just in case a photo of cabling and components before the powersupply would help

Next week my board will move hopefully to the machine- fingers crossed.

Best,

Armin

Please Log in or Create an account to join the conversation.

- ahess

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

25 Oct 2023 17:53 #283816

by ahess

Replied by ahess on topic Retrofit of Precix 5x10 CNC

yep just did open a new topic in cnc machines. got some great input!

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.788 seconds