Light Machine Corp. Benchman XTr (retrofit)

- steve_a

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 2

17 Oct 2015 05:30 #63854

by steve_a

Replied by steve_a on topic Light Machine Corp. Benchman XTr (retrofit)

MacGalempsy, Thanks for the good information about the Tormach tool holders. I am not there yet but I hope to eventually populate the tool carriage.

I have done some close inspections of the unit and a few voltage checks. As I suspected, the computer cannot initialize the motion controller card. I suspect it is bad. When I got power and air I attempted to raise and lower the tool carousel with the front panel buttons. It did not work. I could manually push the pneumatic solenoid buttons and that operated the lift to the down position. I received an email from intelitek and the support agent indicated that there needed to be communication with the motion control card before the front buttons would work. Can anyone verify that?

Other than that I believe the unit has a 4th axis control built in. Also flood and that is a BIG plus. I did spot one small capacitor that looks like it was going bad and replaced it. So far, it is a big glorified paperweight.

I have done some close inspections of the unit and a few voltage checks. As I suspected, the computer cannot initialize the motion controller card. I suspect it is bad. When I got power and air I attempted to raise and lower the tool carousel with the front panel buttons. It did not work. I could manually push the pneumatic solenoid buttons and that operated the lift to the down position. I received an email from intelitek and the support agent indicated that there needed to be communication with the motion control card before the front buttons would work. Can anyone verify that?

Other than that I believe the unit has a 4th axis control built in. Also flood and that is a BIG plus. I did spot one small capacitor that looks like it was going bad and replaced it. So far, it is a big glorified paperweight.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

17 Oct 2015 05:51 #63855

by andypugh

The big bits are OK, (the castings and moving parts). Everything else is replaceable at moderate (or zero) cost.

Replied by andypugh on topic Light Machine Corp. Benchman XTr (retrofit)

So far, it is a big glorified paperweight.

The big bits are OK, (the castings and moving parts). Everything else is replaceable at moderate (or zero) cost.

Please Log in or Create an account to join the conversation.

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

17 Oct 2015 08:33 #63858

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

Steve, After 2+ years of having this "paper weight" in my garages, I just want to encourage you to stay faithful. Since it appears we have the same unit, my efforts of backing out all the wiring will benefit you greatly because that part alone took a few months. All said and done, if all that is bad is the PC interface card, then for the price of a few Mesa cards you will be up and running. The only things I ended up replacing were things I fried, PID tuned incorrectly, broke, or was already broken.

Please Log in or Create an account to join the conversation.

- dynamyte24

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 1

17 Oct 2015 11:54 #63861

by dynamyte24

Mac, if you have a copy of the user's manual (34-7713-0001 dated 11/98) you have the same info I've got.

There does not seem to be any drive tuning info within the software that I have noticed.

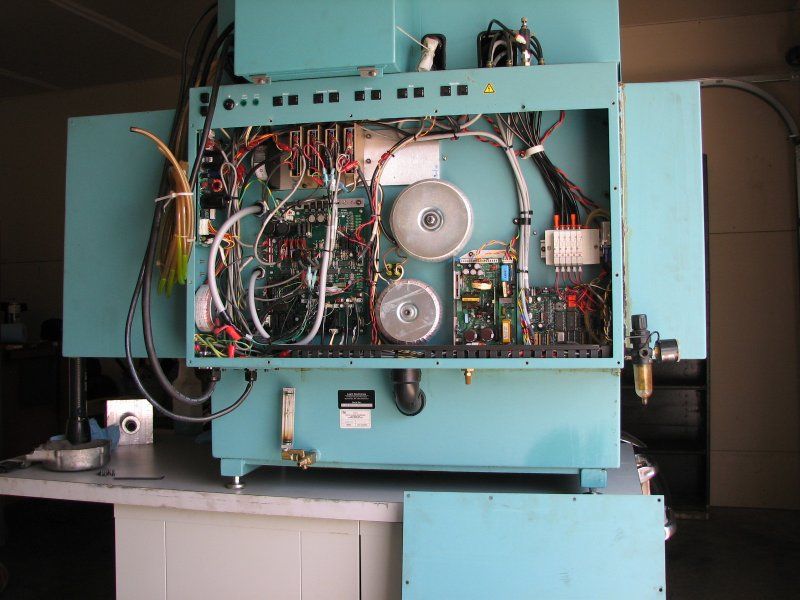

I would really like to get my hands on the schematic for my machine (Ser# 021-55AE-0184) . It's pretty busy in the back of the machine!

I had been fighting an alarm which turned out to be the Renco encoder on the SMW 4th. After much Googling and phone calls and emails,

the folks at www.encoder.com got me set up with a replacement.

Rex

Replied by dynamyte24 on topic Light Machine Corp. Benchman XTr (retrofit)

I am curious if you guys running the factory software have been able to come across PID values for the X/Y/Z axes?

Mac, if you have a copy of the user's manual (34-7713-0001 dated 11/98) you have the same info I've got.

There does not seem to be any drive tuning info within the software that I have noticed.

I would really like to get my hands on the schematic for my machine (Ser# 021-55AE-0184) . It's pretty busy in the back of the machine!

I had been fighting an alarm which turned out to be the Renco encoder on the SMW 4th. After much Googling and phone calls and emails,

the folks at www.encoder.com got me set up with a replacement.

Rex

Please Log in or Create an account to join the conversation.

- steve_a

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 2

18 Oct 2015 03:52 #63887

by steve_a

Replied by steve_a on topic Light Machine Corp. Benchman XTr (retrofit)

Hey Mac. I have the computer with the original software. I think there is a config program for the Benchman. I didn't mess with it but I THINK there was some motor information. I'll have a look at it on Monday. I'm not sure it had any PID info but I wasn't actually looking for it so I might not have noticed.

You sound like you are well advanced in the process and I believe you are right with the Mesa combo being the way to move forward. Did you replace the servo drivers? My initial thoughts are to try to keep the power supplies, servos and motors. I will also keep the tool changer pneumatics but will probably need to develop a controller to handle some of the operations. My first goal is to get movement and spindle. Do you have those working?

You sound like you are well advanced in the process and I believe you are right with the Mesa combo being the way to move forward. Did you replace the servo drivers? My initial thoughts are to try to keep the power supplies, servos and motors. I will also keep the tool changer pneumatics but will probably need to develop a controller to handle some of the operations. My first goal is to get movement and spindle. Do you have those working?

Please Log in or Create an account to join the conversation.

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

18 Oct 2015 06:19 - 18 Oct 2015 06:21 #63888

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

Steve,

The servo drives have been a challenge to tune properly. If you can come across the original PID values, that would help out tremendously. A brief chat with Copely Controls a while back left me with the impression that the drives were specially tuned. Others who have used Copelys in the past said they shouldn't tune any differently. I have contemplated getting new drives, but wanted to try and get some PID FF0/FF1/FF2 values from someone before buying new drives. Ultimately, new amps may be the best way to go, but I was trying to keep costs down.

My machine also came with a SWM 4th axis, so when you are in the parameters, try to get the numbers for everything!

If you want, let's find some public place to post files. I have a ton of technical specs and other stuff from the last few years of digging.

The servo drives have been a challenge to tune properly. If you can come across the original PID values, that would help out tremendously. A brief chat with Copely Controls a while back left me with the impression that the drives were specially tuned. Others who have used Copelys in the past said they shouldn't tune any differently. I have contemplated getting new drives, but wanted to try and get some PID FF0/FF1/FF2 values from someone before buying new drives. Ultimately, new amps may be the best way to go, but I was trying to keep costs down.

My machine also came with a SWM 4th axis, so when you are in the parameters, try to get the numbers for everything!

If you want, let's find some public place to post files. I have a ton of technical specs and other stuff from the last few years of digging.

Last edit: 18 Oct 2015 06:21 by MacGalempsy. Reason: Saw the pic was not Steve's

Please Log in or Create an account to join the conversation.

- dynamyte24

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 1

19 Oct 2015 02:55 #63905

by dynamyte24

Replied by dynamyte24 on topic Light Machine Corp. Benchman XTr (retrofit)

Digging through the documentation package that came with the XT, I found a 20 page "Addendum: Control Program Version 2.0".

The addendum detailed how to access the servo parameters.

The X-Y-Z servo parameters are the same:

Kp 40

Ki 2

Kd 70

Kv 80

Kvff 80

Follow Error .1

SPU 50,000

Int Range 40

Accel 20

Decel 20

"A" (rotary) axis servo parameters (SWM RT 5C):

Kp 40

Ki 2

Kd 80

Kv 80

Kvff 80

Follow Error .1

SPU 40,000

Int Range 40

Accel 20

Decel 20

Spindle parameters (45,000 rpm spindle):

Kp 10

Ki 10

Kd 40

Kv 0

Kvff 0

Follow Error .1

SPU 8000

Int Range .1

Accel 50

Decel 50

I also found CDs for the control programs V2.0.4, V2.0.9 which are compatible with the ISA NextMove card, and V3.0.10 which is for the

PCI card. There is no 3.5 floppy for the machine specific configuration files.

Rex

The addendum detailed how to access the servo parameters.

The X-Y-Z servo parameters are the same:

Kp 40

Ki 2

Kd 70

Kv 80

Kvff 80

Follow Error .1

SPU 50,000

Int Range 40

Accel 20

Decel 20

"A" (rotary) axis servo parameters (SWM RT 5C):

Kp 40

Ki 2

Kd 80

Kv 80

Kvff 80

Follow Error .1

SPU 40,000

Int Range 40

Accel 20

Decel 20

Spindle parameters (45,000 rpm spindle):

Kp 10

Ki 10

Kd 40

Kv 0

Kvff 0

Follow Error .1

SPU 8000

Int Range .1

Accel 50

Decel 50

I also found CDs for the control programs V2.0.4, V2.0.9 which are compatible with the ISA NextMove card, and V3.0.10 which is for the

PCI card. There is no 3.5 floppy for the machine specific configuration files.

Rex

The following user(s) said Thank You: MacGalempsy

Please Log in or Create an account to join the conversation.

- MacGalempsy

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 2

19 Oct 2015 04:32 #63907

by MacGalempsy

Replied by MacGalempsy on topic Light Machine Corp. Benchman XTr (retrofit)

That is fantastic! Nice to know my numbers were not too far off. I am curious about some of the other numbers other than the PID, but that will help tremendously.l

Please Log in or Create an account to join the conversation.

- steve_a

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 2

19 Oct 2015 10:10 #63913

by steve_a

Replied by steve_a on topic Light Machine Corp. Benchman XTr (retrofit)

WOW! Thank you dynamyte24! Good information to have! I will check mine tomorrow, if it is there, and see how they match!

Mac.... you brought up something I had not really considered before... PID tuning... I am rethinking the Mesa controller and think I might go with a Kflop/Kanalog system as they seem to have more support when it comes to PID testing. Might make it more attractive in a re-sale situation. Not really thinking of resale but hey, 20 year old Bridgeport mills still sell because there are no barriers to use them. This thread rocks!

Mac.... you brought up something I had not really considered before... PID tuning... I am rethinking the Mesa controller and think I might go with a Kflop/Kanalog system as they seem to have more support when it comes to PID testing. Might make it more attractive in a re-sale situation. Not really thinking of resale but hey, 20 year old Bridgeport mills still sell because there are no barriers to use them. This thread rocks!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

19 Oct 2015 16:42 #63928

by andypugh

Are you sure about that? You might be looking in the wrong place.

The Mesa cards don't do the PID loop, that happens in LinuxCNC. This has the advantage that you can "watch" the controller and see exactly what it is doing. It has the potential disadvantage that it isn't a super-fast PID loop, running typically at 1 or 2 kHz.

(There will often be a hardware loop in the drives controlling motor current, I am only talking here about the position loop)

If your drives take velocity input from the motors then there is also a hardware velocity loop. In this situation a 1kHz LinuxCNC position loop is more than adequate.

Are you aware that Kflop is an alternative to LinuxCNC, ie, not something that you can use _with_ LinuxCNC?

Replied by andypugh on topic Light Machine Corp. Benchman XTr (retrofit)

I am rethinking the Mesa controller and think I might go with a Kflop/Kanalog system as they seem to have more support when it comes to PID testing

Are you sure about that? You might be looking in the wrong place.

The Mesa cards don't do the PID loop, that happens in LinuxCNC. This has the advantage that you can "watch" the controller and see exactly what it is doing. It has the potential disadvantage that it isn't a super-fast PID loop, running typically at 1 or 2 kHz.

(There will often be a hardware loop in the drives controlling motor current, I am only talking here about the position loop)

If your drives take velocity input from the motors then there is also a hardware velocity loop. In this situation a 1kHz LinuxCNC position loop is more than adequate.

Are you aware that Kflop is an alternative to LinuxCNC, ie, not something that you can use _with_ LinuxCNC?

Please Log in or Create an account to join the conversation.

Time to create page: 0.112 seconds