what to do with a free scrap dumpster find ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 Apr 2022 17:11 #241084

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

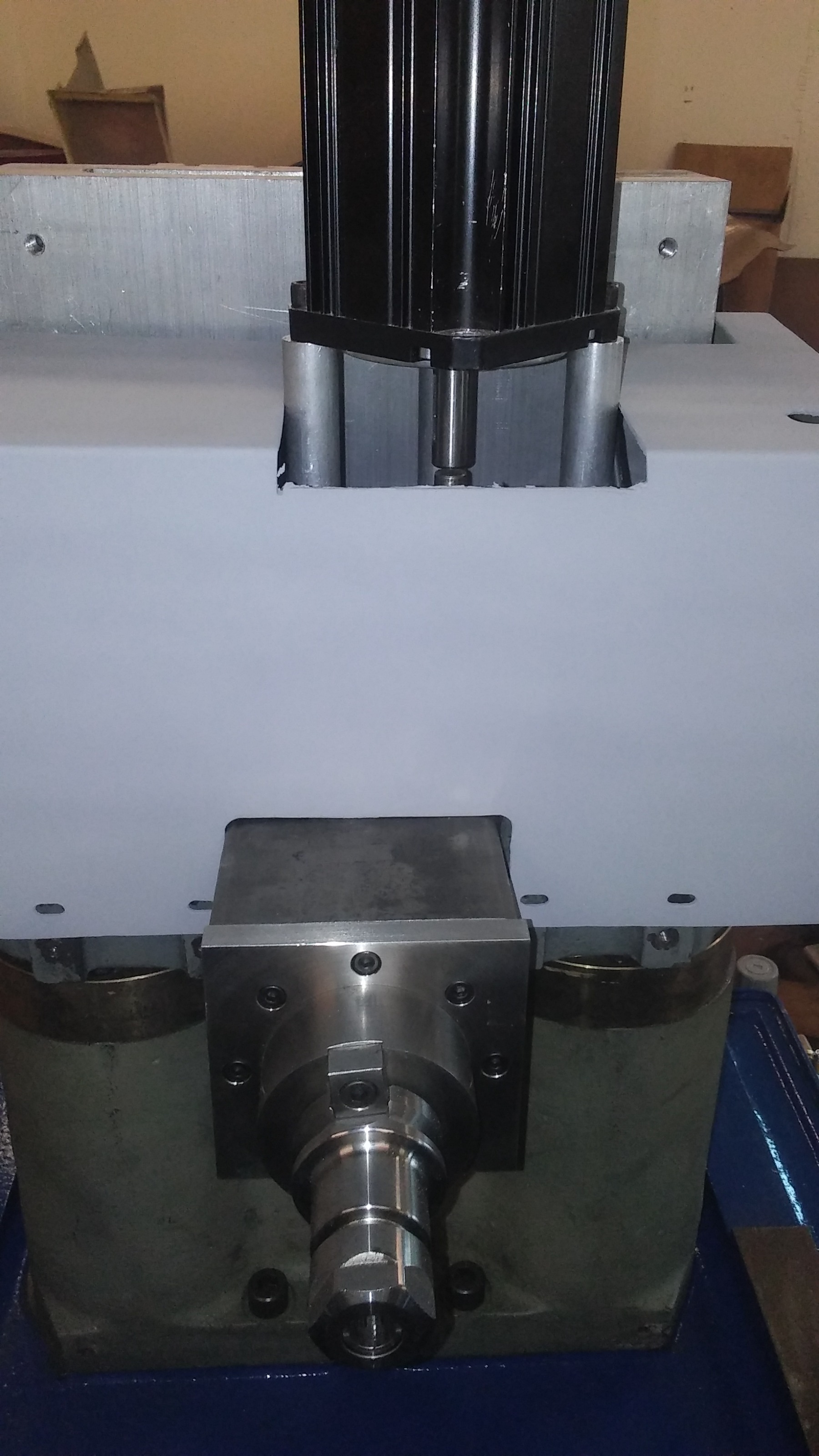

i have had the longer bolts needed to mount the servo for a while but needed to make those stand offs for the motor. i finally got around to making them yesterday. i was not to excited about only having 3 points to mount to but if it works and i can't see it then it won't bug me as much so i came up with a cover to hide it all. out of sight out of mind

i should be able to use the original way covers for the head so that part is figured out i think i just need to strip the rest of the piece down to bare metal so i can give them a fresh coat of paint. what i cleaned up just has some rattle can primer now. i was a little cut happy with the clearance for the motor but the new cover hides all that.

i should be able to use the original way covers for the head so that part is figured out i think i just need to strip the rest of the piece down to bare metal so i can give them a fresh coat of paint. what i cleaned up just has some rattle can primer now. i was a little cut happy with the clearance for the motor but the new cover hides all that.

Attachments:

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19767

- Thank you received: 4589

25 Apr 2022 01:31 #241132

by andypugh

Replied by andypugh on topic what to do with a free scrap dumpster find ?

Can you get thick-walled aluminium tube to make one part containing 3 standoffs?

I have done no analysis, but visually that looks too compliant.

I have done no analysis, but visually that looks too compliant.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

25 Apr 2022 02:24 - 25 Apr 2022 02:36 #241137

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

those standoffs are 1" diameter with a .330 thru hole so the walls are about as thick as i can get them keeping them basic.

i will have to look tomorrow but i might have a flat motor mount section made or needing some slight modification to make use of the boss on the motor? i will have to look tomorrow. nothing is ever final or complete with this project

i will have to look tomorrow but i might have a flat motor mount section made or needing some slight modification to make use of the boss on the motor? i will have to look tomorrow. nothing is ever final or complete with this project

Last edit: 25 Apr 2022 02:36 by machinedude.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19767

- Thank you received: 4589

25 Apr 2022 13:06 #241204

by andypugh

Replied by andypugh on topic what to do with a free scrap dumpster find ?

It's probably best to try it and see. I don't imagine it will flex enough to cause any actual inaccuracy. My concern is that it might have a torsional resonance at some speeds.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

25 Apr 2022 14:45 #241209

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

i actually checked this morning to see if i had some extra parts and i have some NEMA 34 flat mounts made from 1/2 Aluminum. The servo's have an 86mm frame size but the boss on the motor for the 86mm fame is actually bigger than a NEMA 34 frame. so i can bore the boss hole to fit the 86mm motor boss and relocate the the mounting hole since the are close to the 86mm mounting hole. the flat mounts have a small taped hole and i only need a trough hole in that part so i have some correction room. i can bore half way into the flat mount and press fit the standoffs into the flat mount. this way it's almost a 1 piece mount. i like this much better since i only have 3 points on the connection.

i probably got ahead of myself on the motor mount and was more tied up making the cover. i know i had a lot of my free day over the weekend used up making the cover and hardly an time making standoffs

i probably got ahead of myself on the motor mount and was more tied up making the cover. i know i had a lot of my free day over the weekend used up making the cover and hardly an time making standoffs

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 May 2022 04:14 #242202

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

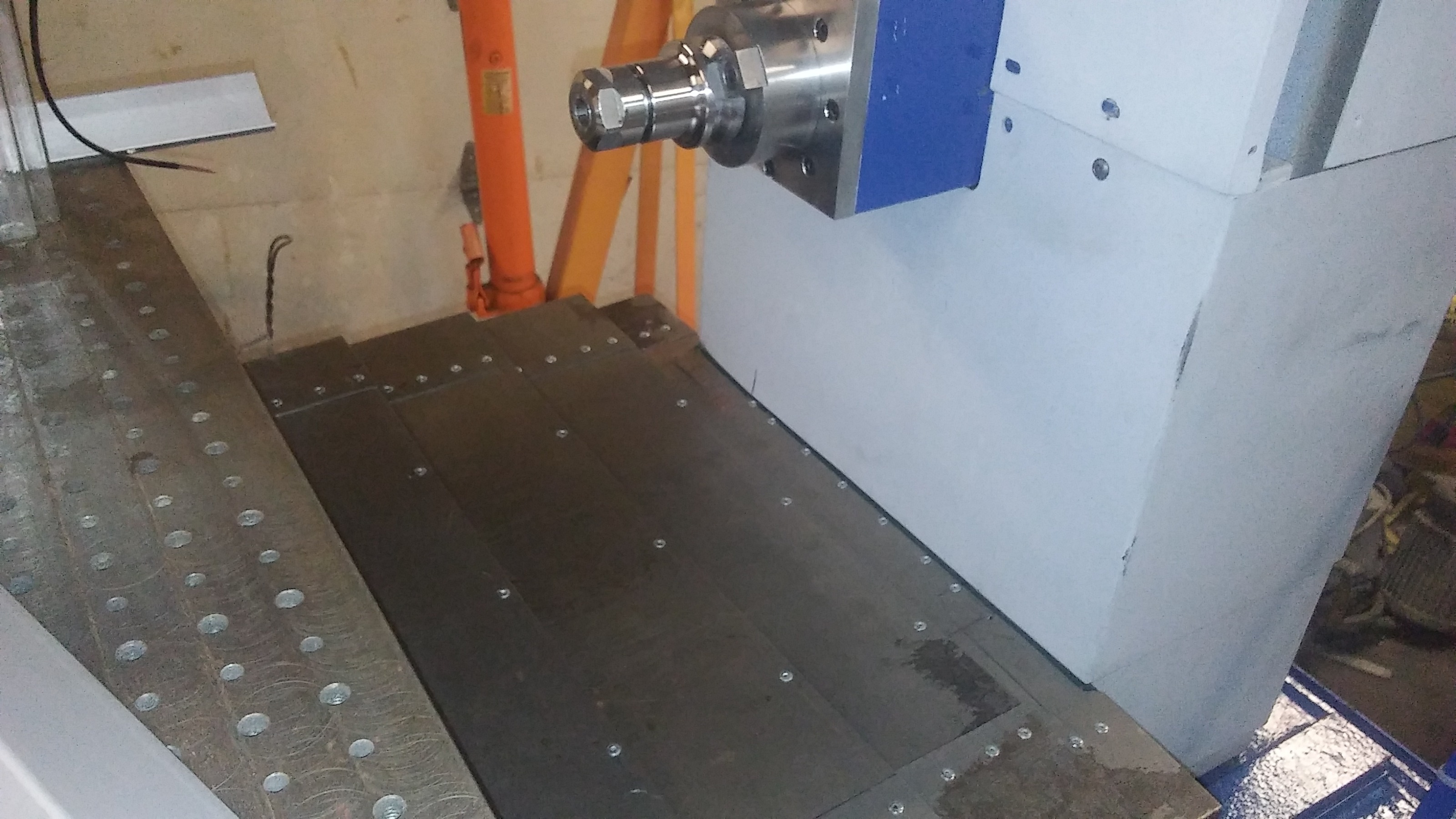

i thought i could use the old covers on the upright but things are just not going as planned on the moving parts of the covers the way it was set up before. so later today i will see if i can figure something out here. it's probably better to upgrade since the covers were not intended to be under power and moving very fast.

while i am at it i am going to try to get a cover across the back side where every thing is going to be landing so i have some sort of plan for chip control. it would be nice to get the lubrication pump mounted and the line run to supply the split bearings and ball screw since other than wires is all that is left to do there.

once all this is sorted out i can start mounting the linear scale on the upright. i have one 400mm scale here and just ordered the other two i need today so i should have those next week.

9 months later and i finally feel like i am starting the on the downhill side of the mechanical part of this adventure

while i am at it i am going to try to get a cover across the back side where every thing is going to be landing so i have some sort of plan for chip control. it would be nice to get the lubrication pump mounted and the line run to supply the split bearings and ball screw since other than wires is all that is left to do there.

once all this is sorted out i can start mounting the linear scale on the upright. i have one 400mm scale here and just ordered the other two i need today so i should have those next week.

9 months later and i finally feel like i am starting the on the downhill side of the mechanical part of this adventure

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

21 May 2022 23:48 #243510

by machinedude

making chip covers is not something i like doing but am getting close to having it all sorted out. i now have all my linear scales and 2 out of three of them should be simple to mount i have to think about the Y axis mounting a bit more. i think i figured out why the old covers were giving me a hard time. i should have taken pictures of things before i tore the machine down. i had one of the cover section on wrong and i need to shorten up the guide rods that i replaced they were hitting the base when the travel was almost all the way down.

but am getting close to having it all sorted out. i now have all my linear scales and 2 out of three of them should be simple to mount i have to think about the Y axis mounting a bit more. i think i figured out why the old covers were giving me a hard time. i should have taken pictures of things before i tore the machine down. i had one of the cover section on wrong and i need to shorten up the guide rods that i replaced they were hitting the base when the travel was almost all the way down.

as for the chip cover on the back i had just enough sheet metal here to make a crude telescoping cover to keep the chips away from getting under everything. i had to resort to attaching some bent end caps since i had next to nothing here to work with. i still have some things to adjust and maybe add some clearance for but they will do what i need them to do for now. i still need to do some kind of skirt on the table to close it up better but it's getting there slowly .

.

i have an open section on the original covers that was for grinder stuff. i think i will make a cover and attach a lighted switch there to control the air cylinder for the draw bar. it will be easy to fish some wires around to the back to keep all that stuff organized.

Replied by machinedude on topic what to do with a free scrap dumpster find ?

making chip covers is not something i like doing

as for the chip cover on the back i had just enough sheet metal here to make a crude telescoping cover to keep the chips away from getting under everything. i had to resort to attaching some bent end caps since i had next to nothing here to work with. i still have some things to adjust and maybe add some clearance for but they will do what i need them to do for now. i still need to do some kind of skirt on the table to close it up better but it's getting there slowly

i have an open section on the original covers that was for grinder stuff. i think i will make a cover and attach a lighted switch there to control the air cylinder for the draw bar. it will be easy to fish some wires around to the back to keep all that stuff organized.

Attachments:

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

28 Jun 2022 15:55 #246088

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

took a little break from working on this and got back to it this past weekend. i was sorting out oil line needs and picked a few odds and ends up and somehow managed to spend almost $200 for next to nothing  check valves for oil lines and 10ft of VFD cable was over a $100 ouch

check valves for oil lines and 10ft of VFD cable was over a $100 ouch

sad part is i had some stuff laying around and was able to reuse some of the original stuff and this was the cheapest way out i guess the days of being nickeled and dimed to death are a thing of the past

i guess the days of being nickeled and dimed to death are a thing of the past

sad part is i had some stuff laying around and was able to reuse some of the original stuff and this was the cheapest way out

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

10 Jul 2022 17:24 - 10 Jul 2022 17:28 #247026

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

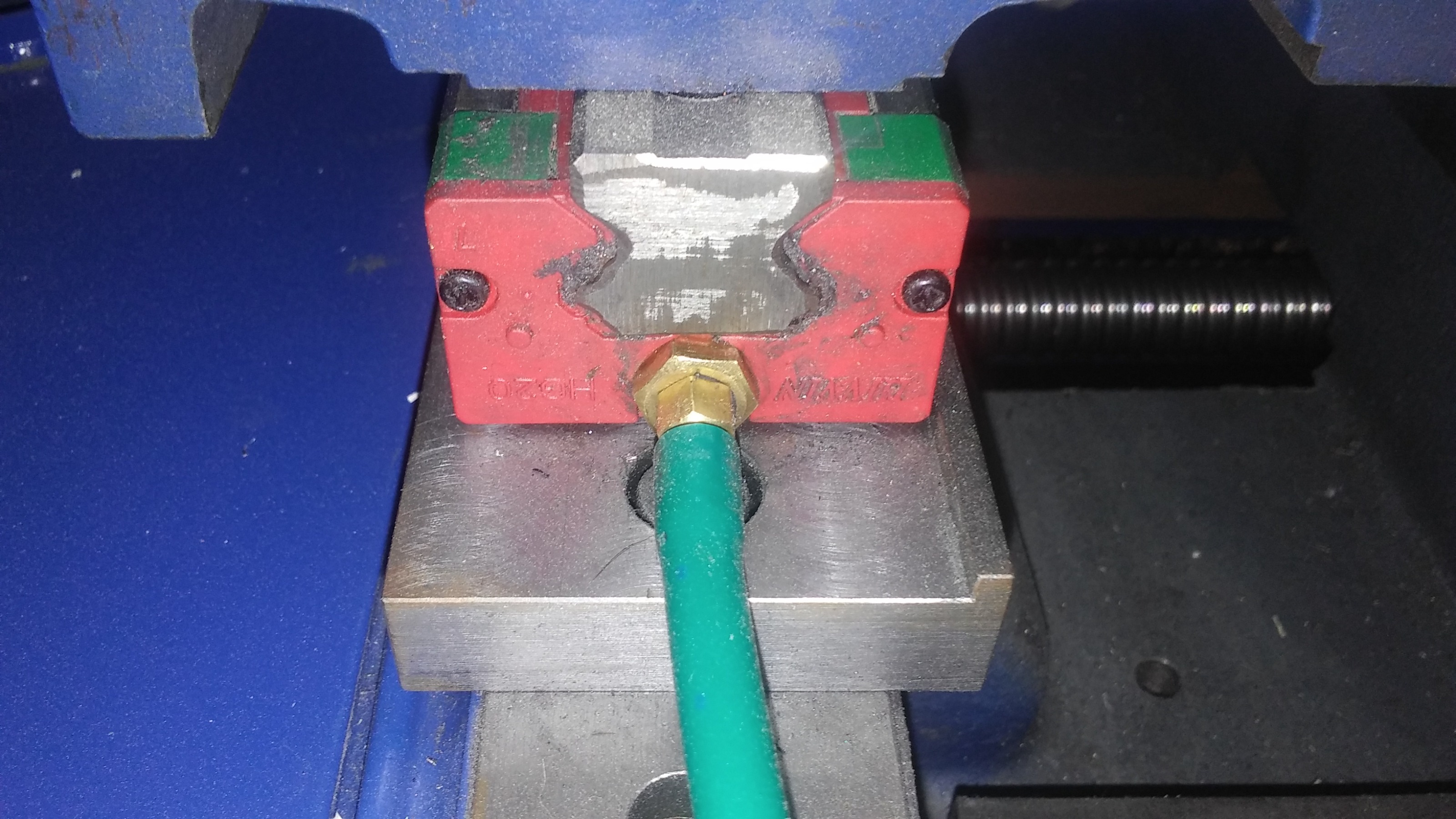

Part of the trouble with the oil point connections was the need for some of it to be able to move with the saddle and table on a few of the connections. all the bearing blocks and ball nuts have a M6 x 1.0 hole for the grease fittings they come with. i had a bunch of 10-32 barbed fittings ( will probably need another pack of 10 ) so what i did was get some brass M6 x 1.0 bolts and tap the head so i could attach the barbed fittings and put around a 3mm through hole in the bolt so the oil can flow through it.

i also gutted the old control box and stripped it down bare and put a fresh coat of paint on it to freshen it up some. I got that back on the machine in the original location and ran my VFD cable into this box. the plan is to use this box for the VFD and probably some DC power supplies to keep it away from the sensitive stuff. the braking resistor i will probably mount out side somewhere since they generate some heat. i'm not sure if it would be wise to mount it in the box?

i have check vales for all my oil points too. i just have to sort that end out still. i was try to use the old manifolds for the oil lines needs but i might have to make something custom since i have more points than what was original.

not much progress but the way oil pump in mounted and the lines for the head axis was already done so i reused that part and it's hooked up. the rest i will most likely end up making taking a guess. but here is a few pictures. everyone like pictures

i also gutted the old control box and stripped it down bare and put a fresh coat of paint on it to freshen it up some. I got that back on the machine in the original location and ran my VFD cable into this box. the plan is to use this box for the VFD and probably some DC power supplies to keep it away from the sensitive stuff. the braking resistor i will probably mount out side somewhere since they generate some heat. i'm not sure if it would be wise to mount it in the box?

i have check vales for all my oil points too. i just have to sort that end out still. i was try to use the old manifolds for the oil lines needs but i might have to make something custom since i have more points than what was original.

not much progress but the way oil pump in mounted and the lines for the head axis was already done so i reused that part and it's hooked up. the rest i will most likely end up making taking a guess. but here is a few pictures. everyone like pictures

Attachments:

Last edit: 10 Jul 2022 17:28 by machinedude.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

10 Jul 2022 17:28 #247027

by tommylight

Replied by tommylight on topic what to do with a free scrap dumpster find ?

Those are original HiWin HGH20 carriages !

Nice.

Nice.

Please Log in or Create an account to join the conversation.

Time to create page: 0.578 seconds