1 or 2 dedicated 120VAC circuits for my CNC?

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

05 Jan 2023 18:44 #261018

by spumco

Replied by spumco on topic 1 or 2 dedicated 120VAC circuits for my CNC?

For your purposes, strand count and voltage don't affect ampacity.

I'm sure they do, in fact, affect ampacity somehow - an EE can chime in here - but for what you're doing it's a non-issue.

What you (we) care about is insulation rating, gauge (cross-section), length, fill factor, and conductor count (for multi-conductor cables).

And yea, it sucks when a component's terminals are just a bit too small for the gauge you've installed. Cramming the wire in is tempting but not the right move.

I'm sure they do, in fact, affect ampacity somehow - an EE can chime in here - but for what you're doing it's a non-issue.

What you (we) care about is insulation rating, gauge (cross-section), length, fill factor, and conductor count (for multi-conductor cables).

And yea, it sucks when a component's terminals are just a bit too small for the gauge you've installed. Cramming the wire in is tempting but not the right move.

The following user(s) said Thank You: Sray69

Please Log in or Create an account to join the conversation.

- Sray69

- Offline

- Elite Member

-

Less

More

- Posts: 255

- Thank you received: 13

05 Jan 2023 19:13 #261020

by Sray69

Replied by Sray69 on topic 1 or 2 dedicated 120VAC circuits for my CNC?

Great! Thanks!

Please Log in or Create an account to join the conversation.

- Sray69

- Offline

- Elite Member

-

Less

More

- Posts: 255

- Thank you received: 13

05 Jan 2023 21:15 #261034

by Sray69

Replied by Sray69 on topic 1 or 2 dedicated 120VAC circuits for my CNC?

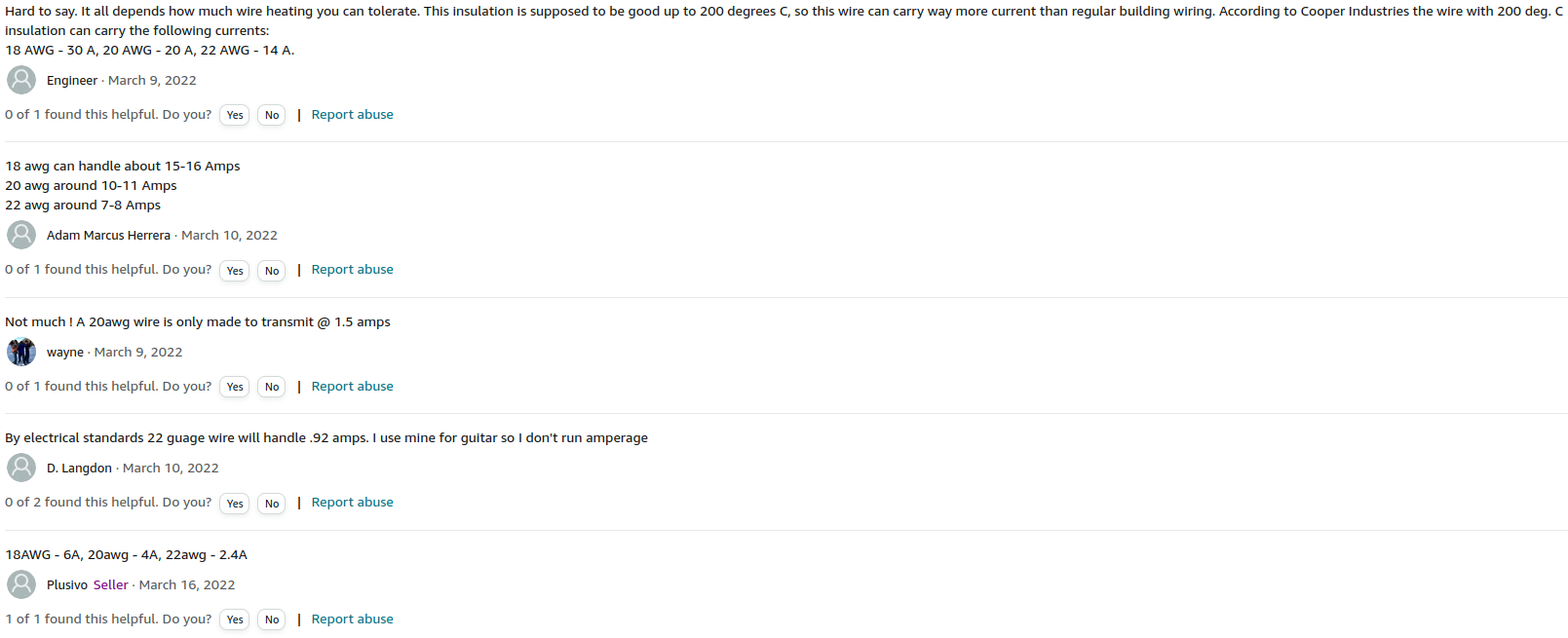

In researching some of the 18AWG wire I bought I came across these answers (by people) to the question about amp ratings for the 18-22AWG wire. It is crazy how drastically different they all are. They obviously all got the ratings from different charts/calculators.

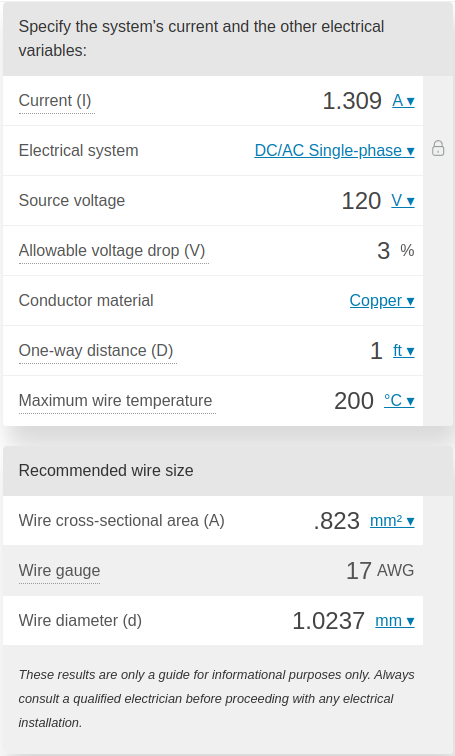

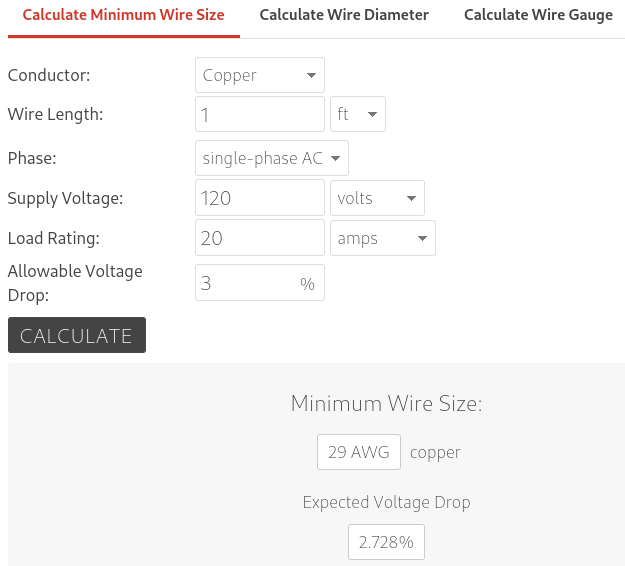

I have also tried a bunch of calculators and they all seem different as well. Most of them spit out a super low amp rating. And then a few spit out super high ratings. Here are two different calculators. The first shows really low amp rating and the second shows really high rating. Note that they are not comparing similar size wire. But look at the gauge wire compared to the amp ratings.

It seems almost impossible to find accurate data.

I have also tried a bunch of calculators and they all seem different as well. Most of them spit out a super low amp rating. And then a few spit out super high ratings. Here are two different calculators. The first shows really low amp rating and the second shows really high rating. Note that they are not comparing similar size wire. But look at the gauge wire compared to the amp ratings.

It seems almost impossible to find accurate data.

Attachments:

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

05 Jan 2023 23:46 #261051

by spumco

Replied by spumco on topic 1 or 2 dedicated 120VAC circuits for my CNC?

Yep.

That's why I go by NEC and then treat everything smaller than 18awg as signal wires.

The responses below with crazy high amps are for 200c... and I don't want anything in my cabinet at that temp even if the wire can handle it.

And 1.5a for 20awg? Maybe for aluminum conductor insulated with dog turds.

That's why I go by NEC and then treat everything smaller than 18awg as signal wires.

The responses below with crazy high amps are for 200c... and I don't want anything in my cabinet at that temp even if the wire can handle it.

And 1.5a for 20awg? Maybe for aluminum conductor insulated with dog turds.

Please Log in or Create an account to join the conversation.

- Sray69

- Offline

- Elite Member

-

Less

More

- Posts: 255

- Thank you received: 13

06 Jan 2023 00:13 #261053

by Sray69

Replied by Sray69 on topic 1 or 2 dedicated 120VAC circuits for my CNC?

If I have a 200C wire that is rated at lets say 20A, would that be adequate for a 20A circuit if my temps are going to be nowhere near the 200C? Is the amp rating of the wire the same up to the 200C? Or does the amp rating go up as the temp goes up and maxes out at 200C? That sounds like a completely stupid question now that I read it, but I just want to be sure I understand it.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

06 Jan 2023 02:39 #261057

by spumco

Replied by spumco on topic 1 or 2 dedicated 120VAC circuits for my CNC?

Please Log in or Create an account to join the conversation.

- Sray69

- Offline

- Elite Member

-

Less

More

- Posts: 255

- Thank you received: 13

09 Feb 2023 16:22 #264146

by Sray69

Replied by Sray69 on topic 1 or 2 dedicated 120VAC circuits for my CNC?

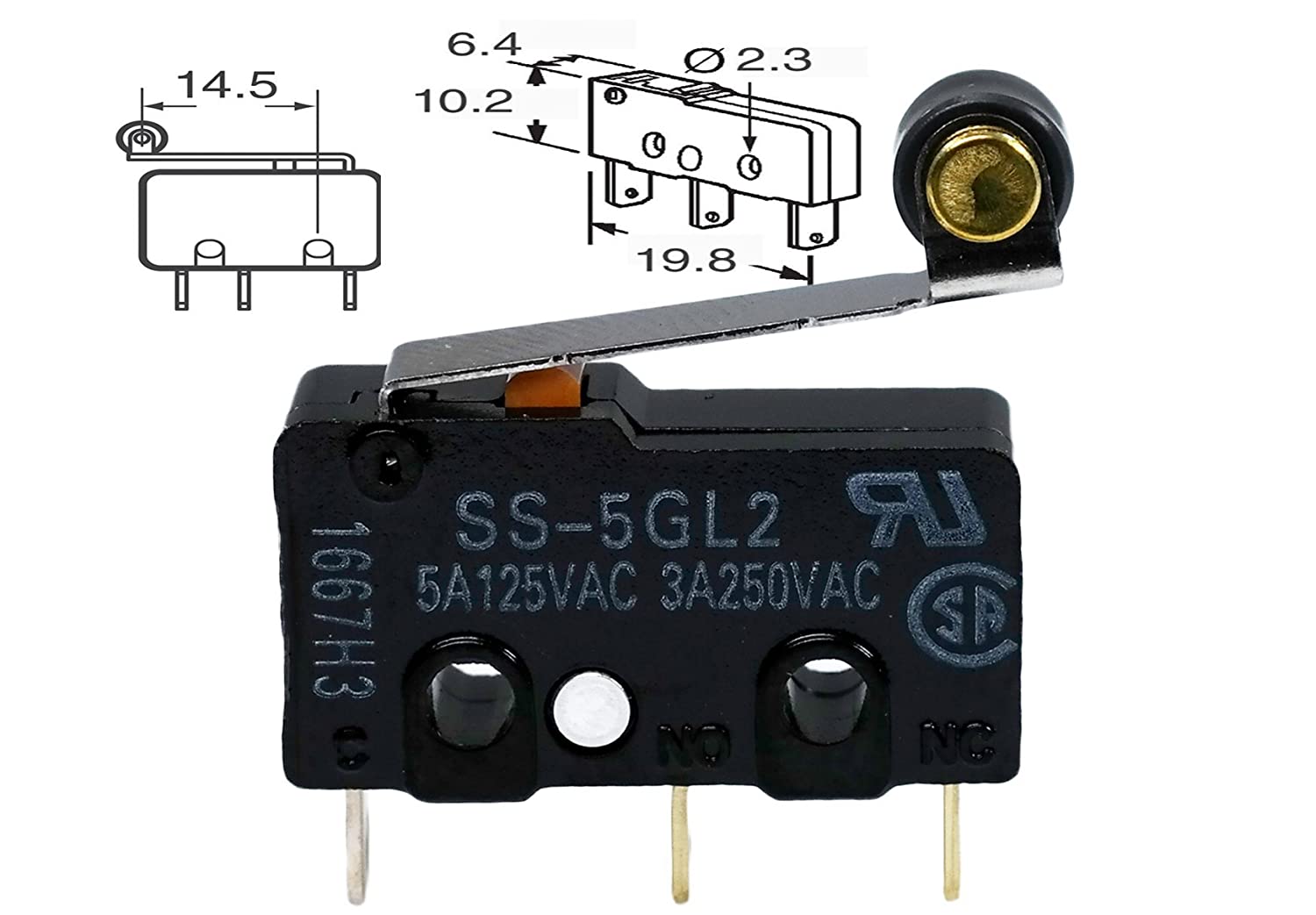

So I have the CNC completely wired except end stops. I forgot to order them. Will just any old limit switch work? Any recommendations?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21154

- Thank you received: 7223

09 Feb 2023 16:52 #264149

by tommylight

Replied by tommylight on topic 1 or 2 dedicated 120VAC circuits for my CNC?

Ones made by Balluff are good, but be seated before checking the price!

Mechanical fully enclosed ones should do for metal mills and plasma, inductive ones also good but might need a bit of protection from debris.

Anything from Omron should do, since you are aiming for good quality.

Mechanical fully enclosed ones should do for metal mills and plasma, inductive ones also good but might need a bit of protection from debris.

Anything from Omron should do, since you are aiming for good quality.

The following user(s) said Thank You: Sray69

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

09 Feb 2023 17:04 #264152

by spumco

Replied by spumco on topic 1 or 2 dedicated 120VAC circuits for my CNC?

I'm partial to NC 3-wire inductive proximity switches. I believe the trick with these is to mount them in a way that the trigger/flag crosses the sensing volume rather than approaches. Put another way, if you think of the proxy like a flashlight, you want something (flag) to cut the beam from the side rather than moving the flashlight towards the device you're trying to sense.

I've read they're more repeatable this way. And you aren't going to smash the proxy if something goes wrong and tries to hit the hard stop. And the NC circuit means if a wire breaks or something, the controller will see it as triggering the limit (fail-safe).

On the other hand, I've also used $0.25 cheapo microswitches as limits on a couple of low-budget builds. They weren't repeatable to a 'thou, but that didn't matter much for a stepper plasma and I could run them at 24vdc for some noise immunity (at the cost of the contacts burning out sooner).

As with everything, it's a cost-performance decision. If you have a table-mounted ATC, tool length probe, or specific fixturing you may wish to have very repeatable limits. Otherwise, anything that gets you in the ballpark and doesn't fail frequently should be sufficient.

I've read they're more repeatable this way. And you aren't going to smash the proxy if something goes wrong and tries to hit the hard stop. And the NC circuit means if a wire breaks or something, the controller will see it as triggering the limit (fail-safe).

On the other hand, I've also used $0.25 cheapo microswitches as limits on a couple of low-budget builds. They weren't repeatable to a 'thou, but that didn't matter much for a stepper plasma and I could run them at 24vdc for some noise immunity (at the cost of the contacts burning out sooner).

As with everything, it's a cost-performance decision. If you have a table-mounted ATC, tool length probe, or specific fixturing you may wish to have very repeatable limits. Otherwise, anything that gets you in the ballpark and doesn't fail frequently should be sufficient.

The following user(s) said Thank You: Sray69

Please Log in or Create an account to join the conversation.

- Sray69

- Offline

- Elite Member

-

Less

More

- Posts: 255

- Thank you received: 13

09 Feb 2023 17:29 #264155

by Sray69

Replied by Sray69 on topic 1 or 2 dedicated 120VAC circuits for my CNC?

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.206 seconds