15m Industrial Plasma Cutter

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

29 Aug 2019 18:14 #143589

by andypugh

Replied by andypugh on topic 15m Industrial Plasma Cutter

Anything useful here?

www.zappautomation.co.uk/machines/individual-parts.html

Or maybe this, you could have it tomorrow with Prime:

www.amazon.co.uk/KKmoon-Stainless-Actuat...ission/dp/B07HGS6PS1

And for the magnetic breakaway:

www.amazon.co.uk/Valeny-Magnetic-Buttons...andbag/dp/B07PY6LD31

www.zappautomation.co.uk/machines/individual-parts.html

Or maybe this, you could have it tomorrow with Prime:

www.amazon.co.uk/KKmoon-Stainless-Actuat...ission/dp/B07HGS6PS1

And for the magnetic breakaway:

www.amazon.co.uk/Valeny-Magnetic-Buttons...andbag/dp/B07PY6LD31

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

29 Aug 2019 18:37 #143591

by islander261

Replied by islander261 on topic 15m Industrial Plasma Cutter

$$ The Velox Z axis for plasma is nearly ready to go. Just add a NEMA 23 stepper some switches and a torch mount and you are ready to go.

www.veloxcncrouters.com/xz-za-series

John

www.veloxcncrouters.com/xz-za-series

John

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21279

- Thank you received: 7265

29 Aug 2019 19:04 #143592

by tommylight

There are plenty of options, and you can build your own floating head in half a day, using drawer slides with ball bearings. Built plenty of them and they do work perfectly ( well untill some of that fine dust gets to those balls, then some major leaning is needed ) granted you turn their slots to the back side to prevent the above. Find a hydraulic repair shop, there must be one near you ( there are 2 in my town with 110000 people ), they have shafts at any diameter in 6 meter lengths, so get 1 meter of 14 or 16 or 20mm shaft at around 30 to 40 euro, should be enough for a Z axis plus floating part ( floating part needs about 1 cm of movement, just enough to trigget the floating switch or sensor ), find a shop for bearings as they must have linear bearings for round rails/shafts, get 8 of them at 5 to 7 euro a piece, and a switch, 4 aluminium plates at 10 to 15 by 4 to 6 cm with 3 holes on them, allthread or a 20 to 30 cm long M6 or M8 or M10 screw, and in a day you have a fully functional Z axis with probe.

That makes 2 options, both cheap and very quick with hand tools and a bit of persistance.

And just in case you think that drawer slides are to thin or to flimsy, get two of them and mount them at 90 degrees to each other, you will be amazed at how stiff that becomes.

Replied by tommylight on topic 15m Industrial Plasma Cutter

That is a big no no, you will regret that during testing and tuning, before you make any usable cuts.I'm also wondering if I can throw together an extremely simplified version eg. no variable z axis height/magnetic breakaway or any of that. And just accept that the quality won't be fantastic, but at least it will get done.

There are plenty of options, and you can build your own floating head in half a day, using drawer slides with ball bearings. Built plenty of them and they do work perfectly ( well untill some of that fine dust gets to those balls, then some major leaning is needed ) granted you turn their slots to the back side to prevent the above. Find a hydraulic repair shop, there must be one near you ( there are 2 in my town with 110000 people ), they have shafts at any diameter in 6 meter lengths, so get 1 meter of 14 or 16 or 20mm shaft at around 30 to 40 euro, should be enough for a Z axis plus floating part ( floating part needs about 1 cm of movement, just enough to trigget the floating switch or sensor ), find a shop for bearings as they must have linear bearings for round rails/shafts, get 8 of them at 5 to 7 euro a piece, and a switch, 4 aluminium plates at 10 to 15 by 4 to 6 cm with 3 holes on them, allthread or a 20 to 30 cm long M6 or M8 or M10 screw, and in a day you have a fully functional Z axis with probe.

That makes 2 options, both cheap and very quick with hand tools and a bit of persistance.

And just in case you think that drawer slides are to thin or to flimsy, get two of them and mount them at 90 degrees to each other, you will be amazed at how stiff that becomes.

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- Jarman

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 8

05 Sep 2019 09:50 #144226

by Jarman

Replied by Jarman on topic 15m Industrial Plasma Cutter

Hello everyone, just an update.

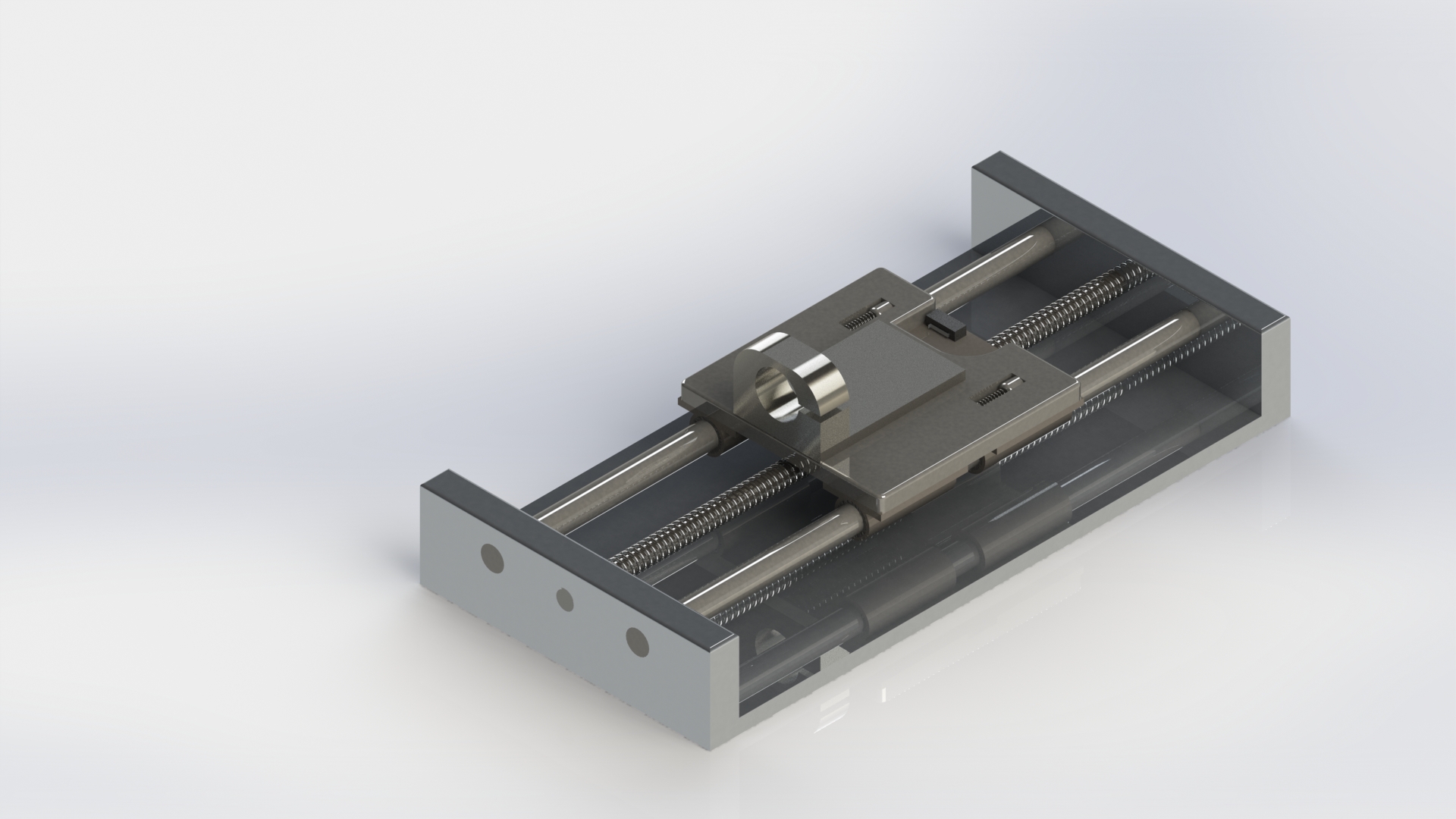

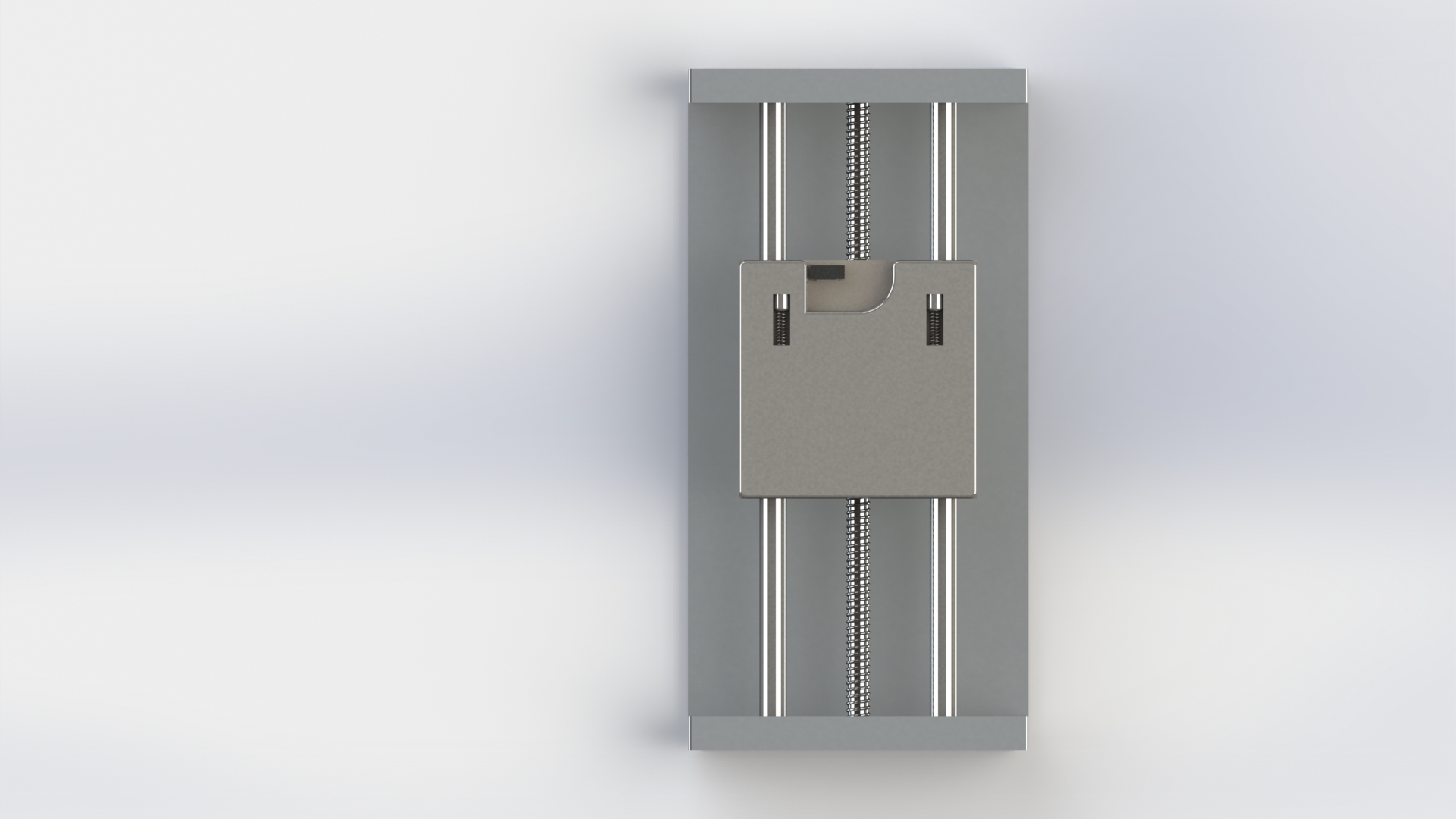

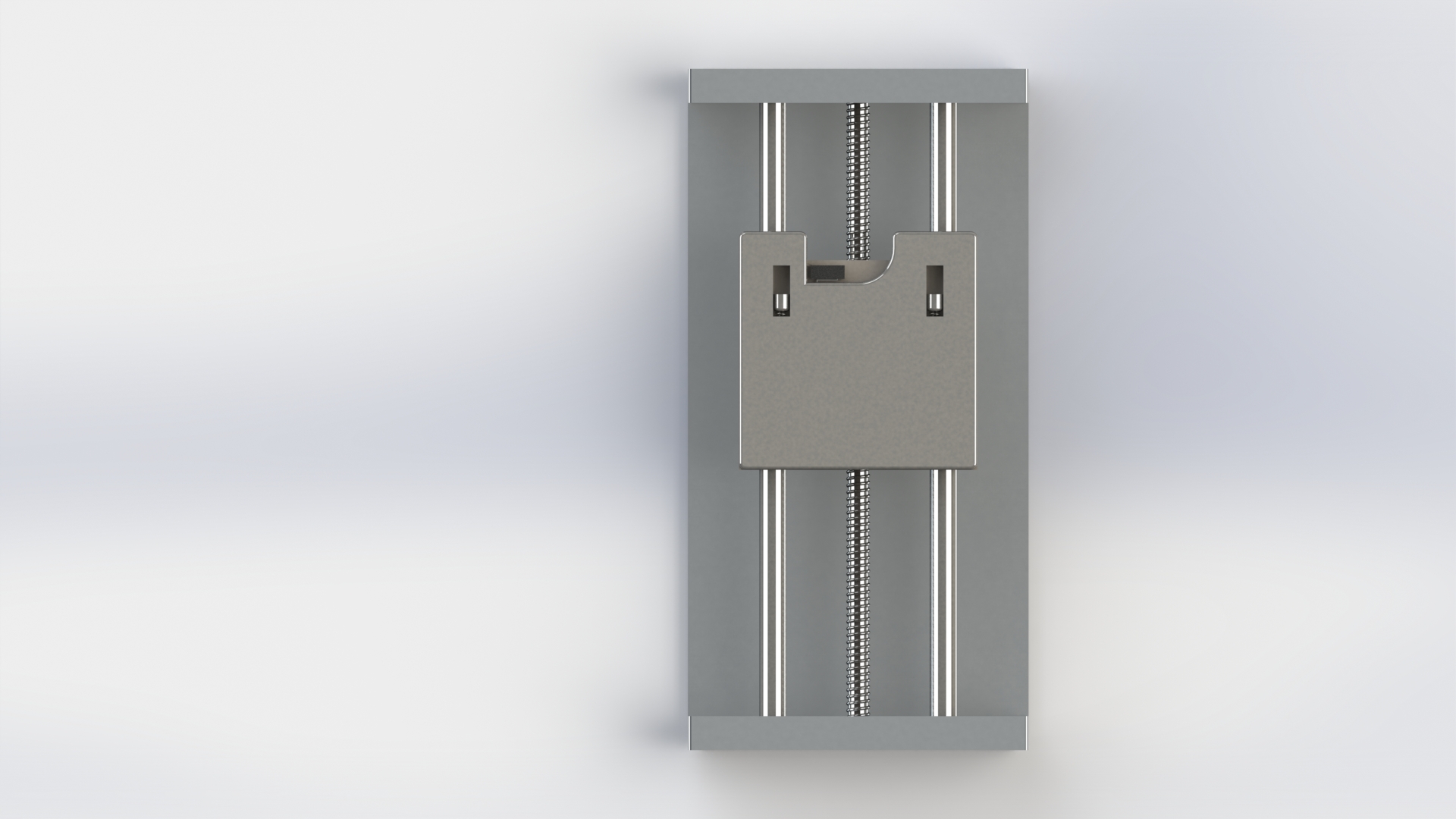

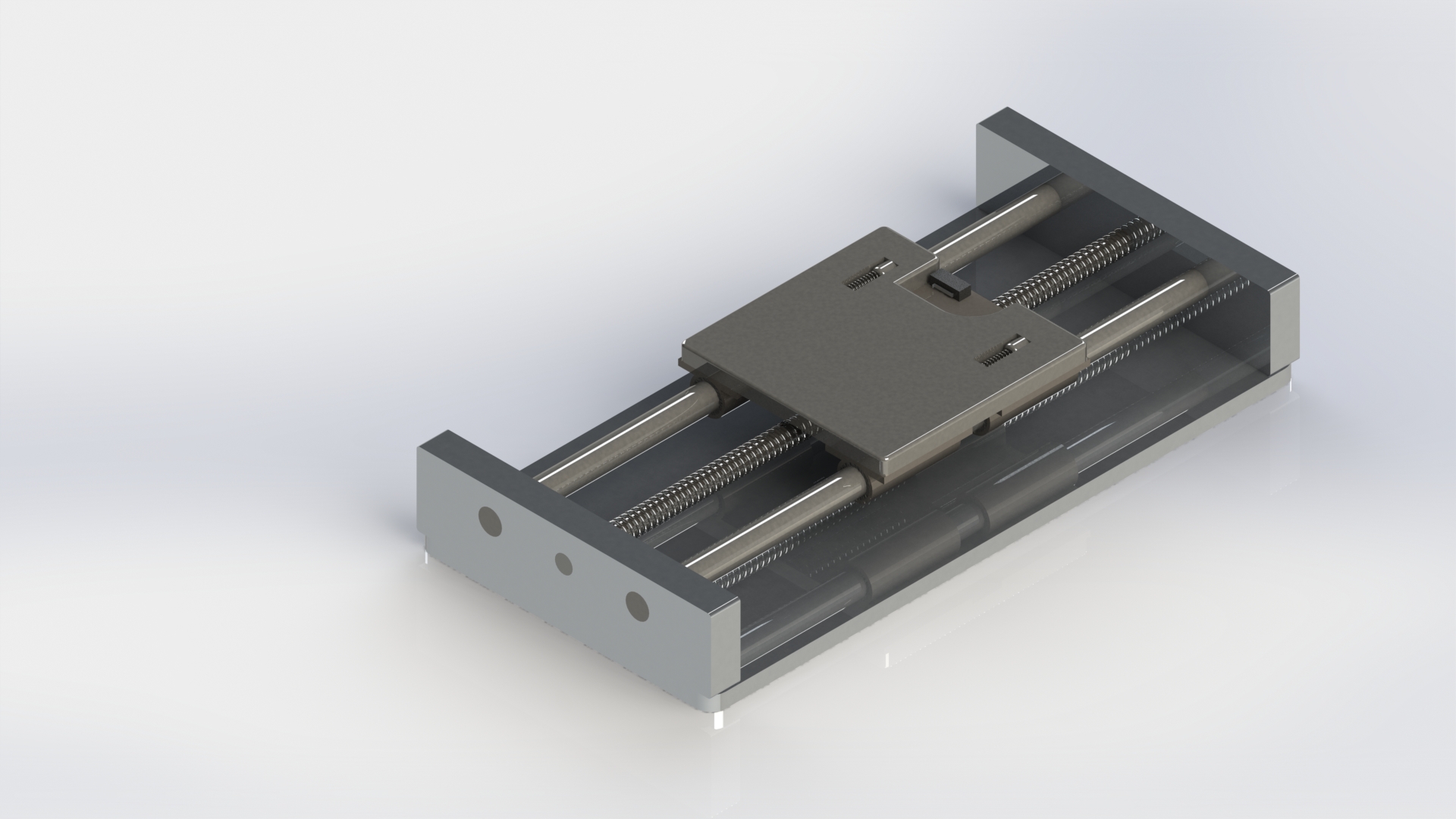

I'm in the process of building my z axis following a similar design to this:

www.veloxcncrouters.com/xz-za-series

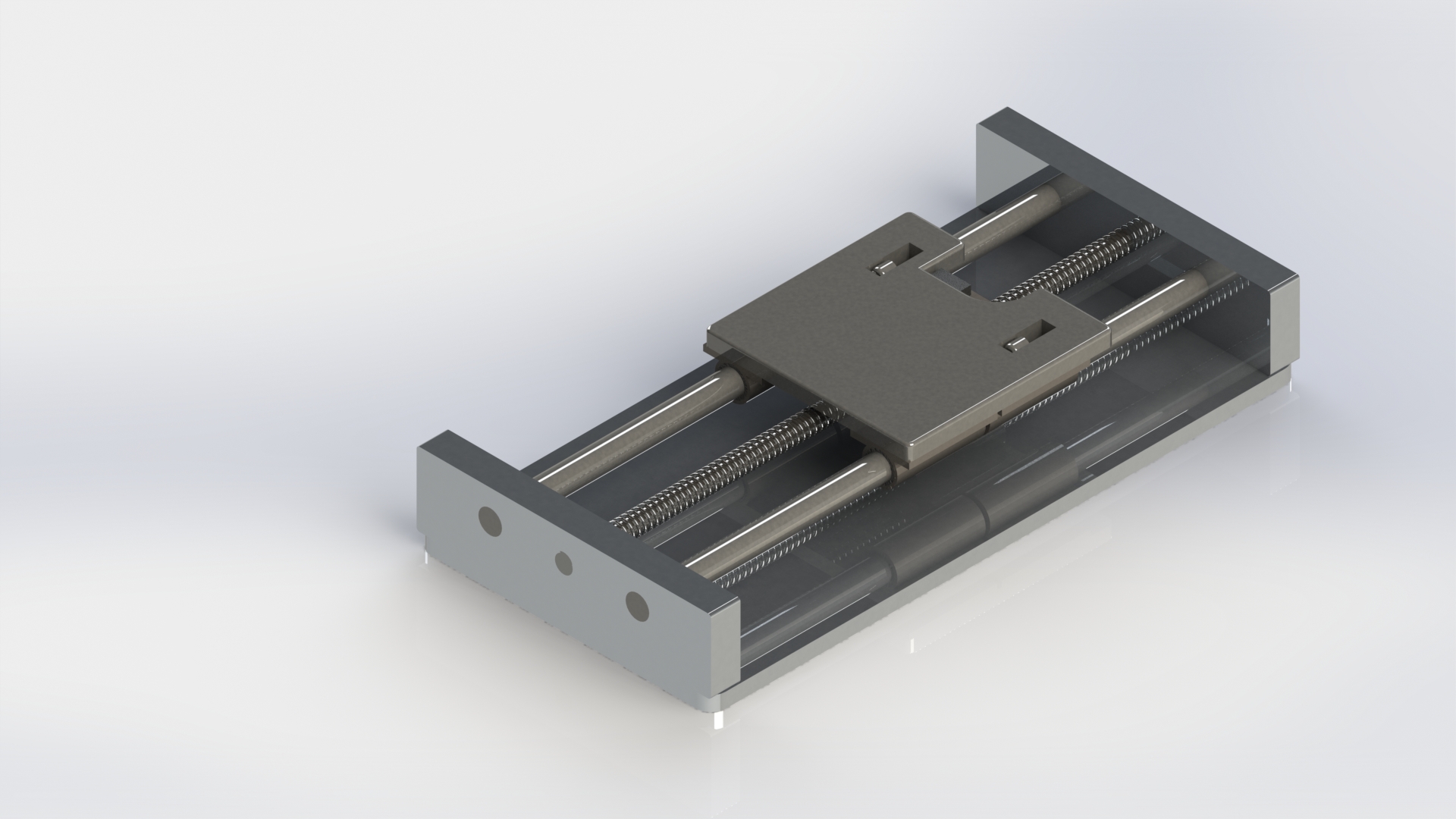

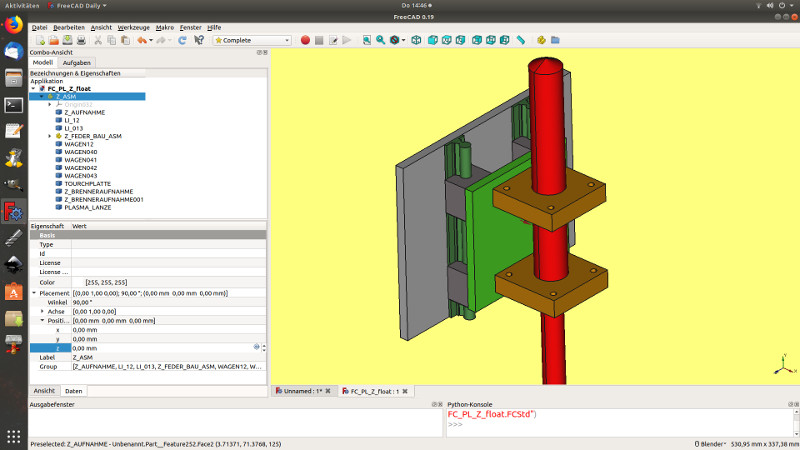

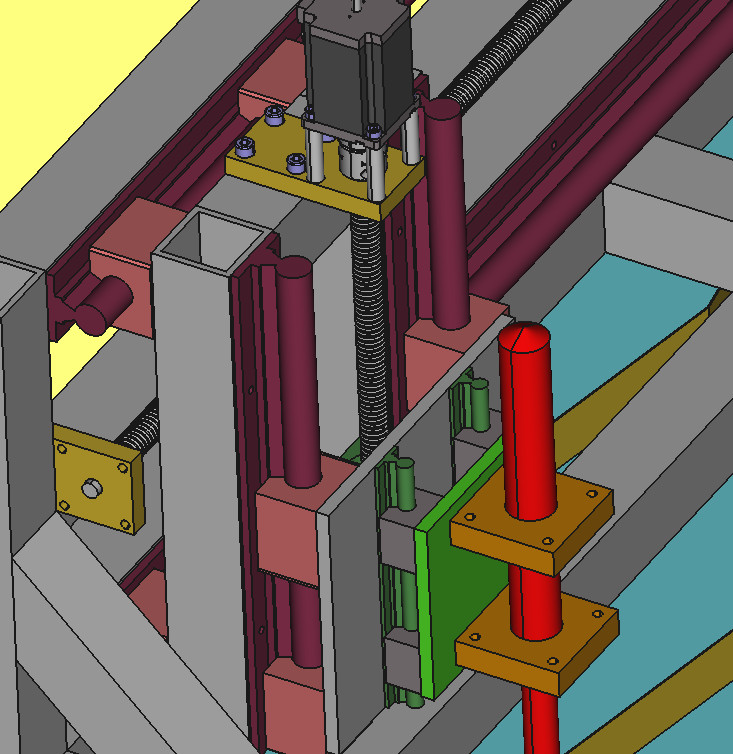

My design will look a bit like this:

The idea is that the floating head is on the same set of rails as z travel, using a spring loaded system (the plate with floating head attached is only connected to the bottom 2 linear rails and can therefore slide over the top 2 rails and trigger a pnp switch).

I am now wondering about the x axis that the z axis sits on. If I want 1.25m of x axis travel how much extra space should I allow for sensors/switches etc. on either side? Do I need home/limit on both sides? And how much should the X axis overlap the Y axis on each side? Just the width of the linear rails it runs on or more?

Thanks.

I'm in the process of building my z axis following a similar design to this:

www.veloxcncrouters.com/xz-za-series

My design will look a bit like this:

The idea is that the floating head is on the same set of rails as z travel, using a spring loaded system (the plate with floating head attached is only connected to the bottom 2 linear rails and can therefore slide over the top 2 rails and trigger a pnp switch).

I am now wondering about the x axis that the z axis sits on. If I want 1.25m of x axis travel how much extra space should I allow for sensors/switches etc. on either side? Do I need home/limit on both sides? And how much should the X axis overlap the Y axis on each side? Just the width of the linear rails it runs on or more?

Thanks.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11709

- Thank you received: 3961

05 Sep 2019 10:31 #144228

by rodw

Replied by rodw on topic 15m Industrial Plasma Cutter

Every machine will be different depending on how you lay it out. My limit switches are within 2-3mm of the hard endstops.

A good length might be 1600mm rail with a 1400mm rack. On my Y axis, this gave me 1264mm of travel but my carriages are further apart there than on my X.

A good length might be 1600mm rail with a 1400mm rack. On my Y axis, this gave me 1264mm of travel but my carriages are further apart there than on my X.

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

05 Sep 2019 12:18 #144233

by andypugh

Replied by andypugh on topic 15m Industrial Plasma Cutter

I have never even seen a plasma cutter, so take this idea as purely theoretical.

But I think this could make a good floating mount:

uk.rs-online.com/web/p/slide-unit-actuators/1244615/

The idea being that after the probe the air pressure can be increased to lock the head down to avoid false-tripping by vibration.

But I think this could make a good floating mount:

uk.rs-online.com/web/p/slide-unit-actuators/1244615/

The idea being that after the probe the air pressure can be increased to lock the head down to avoid false-tripping by vibration.

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

05 Sep 2019 12:52 #144234

by pl7i92

Replied by pl7i92 on topic 15m Industrial Plasma Cutter

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

05 Sep 2019 13:07 #144236

by andypugh

Replied by andypugh on topic 15m Industrial Plasma Cutter

There are definitely cheaper ways than the pneumatic cylinder. I only really proposed that as an off-the-shelf unit to save time.

The cylinders also have provision for mounting solid state switches in a range of styles and types: uk.rs-online.com/web/c/?sra=oss&r=t&searchTerm=D-M9

The cylinders also have provision for mounting solid state switches in a range of styles and types: uk.rs-online.com/web/c/?sra=oss&r=t&searchTerm=D-M9

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

- Jarman

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 8

06 Sep 2019 07:38 #144335

by Jarman

Replied by Jarman on topic 15m Industrial Plasma Cutter

Ok, I am thinking of using a Nema 23 for my z axis, as used in this design.

www.veloxcncrouters.com/xz-za-series

Does LinuxCNC and 7i67E interface well with hybrid steppers? Do you guys using steppers have rotary encoders?

www.veloxcncrouters.com/xz-za-series

Does LinuxCNC and 7i67E interface well with hybrid steppers? Do you guys using steppers have rotary encoders?

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11709

- Thank you received: 3961

06 Sep 2019 07:43 #144337

by rodw

Replied by rodw on topic 15m Industrial Plasma Cutter

Yes. I think normally, the closed loop steppers are closed on the stepper driver so Mesa and Linuxcnc don't care. Wait for others to respond because I think feedback can be closed in Linuxcnc but it may not be worth the complexity.

Nema 23 is fine. I use 269 Oz/in Nema23 on mine

Nema 23 is fine. I use 269 Oz/in Nema23 on mine

The following user(s) said Thank You: Jarman

Please Log in or Create an account to join the conversation.

Time to create page: 0.503 seconds