Spindle and encoder

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

12 Aug 2023 22:58 - 13 Aug 2023 01:09 #277764

by PCW

Replied by PCW on topic Spindle and encoder

hm2_7i96s.0.encoder.00.velocity-rpm should be the current RPM

Note that with a 10 PPR encoder wheel, RPM will be quite noisy unless the encoder

signal quality is very good.

A perfect quadrature signal would have 50% duty cycle on A and B and exactly

90 degree phase difference between A and B. Any deviation from these values

will cause apparent noise in the velocity (RPM) readout

For RPM display use, you can low-pass filter the RPM from the encoder to smooth

the displayed values.

As far as noise goes, on spindle synchronized moves, a 10 PPR (40 counts per turn)

will have large (9 degree) steps in the spindle position which will make the spindle

synchronized axis moves very noisy as they try to follow this stepped signal.

If you have a relatively current LinuxCNC master installation, you can substitute

hm2_7i96s.0.encoder.00.position

with

hm2_7i96s.0.encoder.00.position-interpolated

Which will eliminate the large steps in spindle position

Note that with a 10 PPR encoder wheel, RPM will be quite noisy unless the encoder

signal quality is very good.

A perfect quadrature signal would have 50% duty cycle on A and B and exactly

90 degree phase difference between A and B. Any deviation from these values

will cause apparent noise in the velocity (RPM) readout

For RPM display use, you can low-pass filter the RPM from the encoder to smooth

the displayed values.

As far as noise goes, on spindle synchronized moves, a 10 PPR (40 counts per turn)

will have large (9 degree) steps in the spindle position which will make the spindle

synchronized axis moves very noisy as they try to follow this stepped signal.

If you have a relatively current LinuxCNC master installation, you can substitute

hm2_7i96s.0.encoder.00.position

with

hm2_7i96s.0.encoder.00.position-interpolated

Which will eliminate the large steps in spindle position

Last edit: 13 Aug 2023 01:09 by PCW. Reason: clarify

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

13 Aug 2023 01:13 #277784

by smplc

Replied by smplc on topic Spindle and encoder

Thanks. The hm2_7i96s.0.encoder.00.velocity-rpm isn't the current RPM yet, however, I'd like it corrected, and please advise if know. The last RPM is 1000 commanded in the enclosed video. How to make a low-pass filter from the encoder to smooth the RPM? The -interpolated was added to the end of hm2_7i96s.0.encoder.00.position at the .hal file but the attempt to launch LinuxCNC errored and 2.9.0 might not be the latest version unless something missing.

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

13 Aug 2023 01:26 #277786

by smplc

Replied by smplc on topic Spindle and encoder

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

13 Aug 2023 02:57 #277792

by PCW

Replied by PCW on topic Spindle and encoder

What RPM does hm2_7i96s.0.encoder.00.velocity-rpm report vs the real RPM

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

13 Aug 2023 03:26 - 13 Aug 2023 03:29 #277794

by smplc

Replied by smplc on topic Spindle and encoder

The hm2_7i96s.0.encoder.00.velocity-rpm showed shuffled numbers. Please go to the above link and select 'Per the video foregoing' if not already. The MDI, g97 s1000 m3 during the Hal Meter shows pin hm2_7i96s.0.encoder.00.velocity-rpm but a portable tachometer read 400 RPM.

Last edit: 13 Aug 2023 03:29 by smplc. Reason: Shuffle.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

13 Aug 2023 03:55 #277795

by PCW

Replied by PCW on topic Spindle and encoder

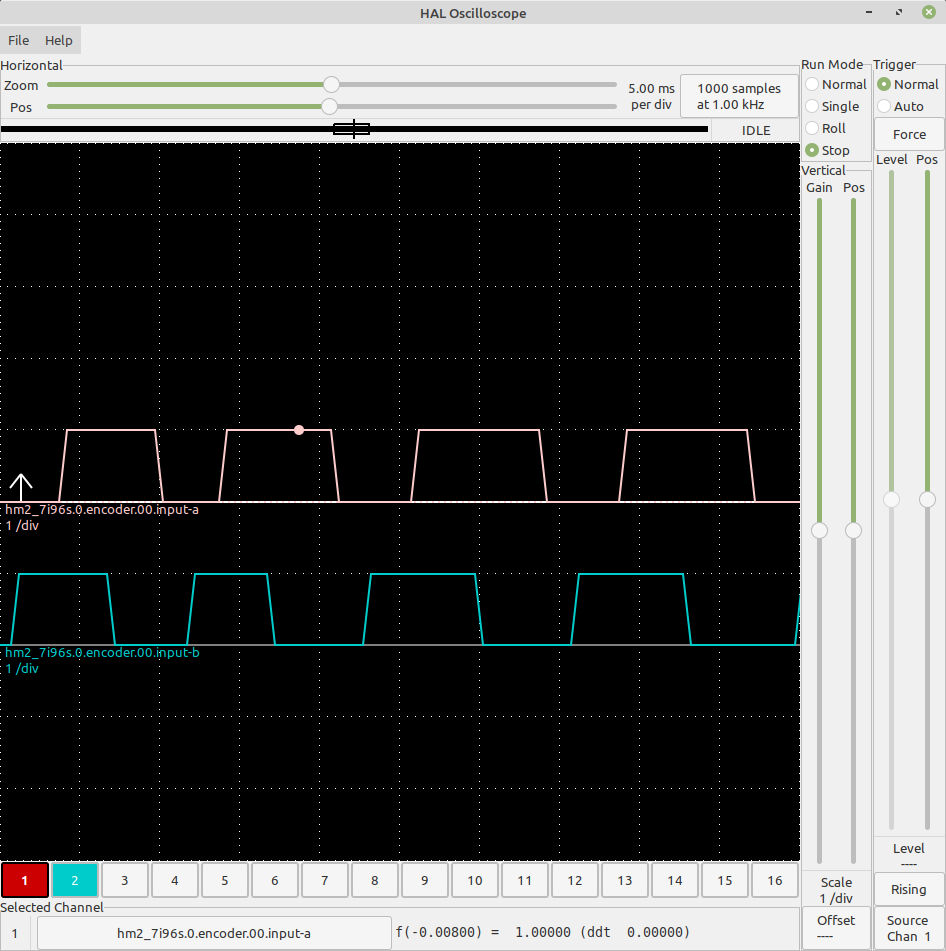

Attachments:

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

13 Aug 2023 04:34 #277799

by smplc

Replied by smplc on topic Spindle and encoder

The Masso encoder came with a spacer and it was used to set the distance of the encoder from the face of the code wheel (pulley). docs.masso.com.au/wiring-and-setup/setup...asso-optical-encoder . I can try to set the offset distance of the encoder a little closer. The encoder comes with a top cover (shield) to reduce some of the surrounding light. I might want to try an alternative encoder but I'd expect the Masso encoder pretty good for the price. I wonder if I could have missed something complex or not obvious setting up the profile in the PncConfig Wizard but what? Is a suggestion for a detailed site that provides clear instructions for configuring the 7i96s? I'd like to review my configuration.

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

13 Aug 2023 05:02 #277801

by smplc

Replied by smplc on topic Spindle and encoder

An optical encoder with code wheel slits and a photo sensor (transmissive) might be more accurate but they could be difficult to maintain if they're unshielded.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

13 Aug 2023 06:34 #277803

by rodw

Replied by rodw on topic Spindle and encoder

Your halscope seems to me that something is not right. It appears your vertical scale is 1 volt per division and high appears to be 1 volt but I would have expected it would be 10 volt when high. Check your wiring and test with a multimeter. You did not tell us what the Hugh voltage was.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7290

13 Aug 2023 11:04 #277814

by tommylight

Replied by tommylight on topic Spindle and encoder

Rod, he did.

Spindle-off, manually rotate the pulley until the line intersects the channel and is lit.

-ve, Ground

+ve, 12.95VDC power supply

Output Signal Z 9.5VDC

Output Signal B 9.49VDC

Output Signal A 9.52VDC

Please Log in or Create an account to join the conversation.

Time to create page: 0.354 seconds