Spindle and encoder

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

13 Aug 2023 23:03 #277885

by rodw

Replied by rodw on topic Spindle and encoder

Am I missing something because the halscope looks to be a high of 1 volt and from above it should be 9.5 volt? If its 1 v that may explain why its not right according to PCW.Rod, he did.

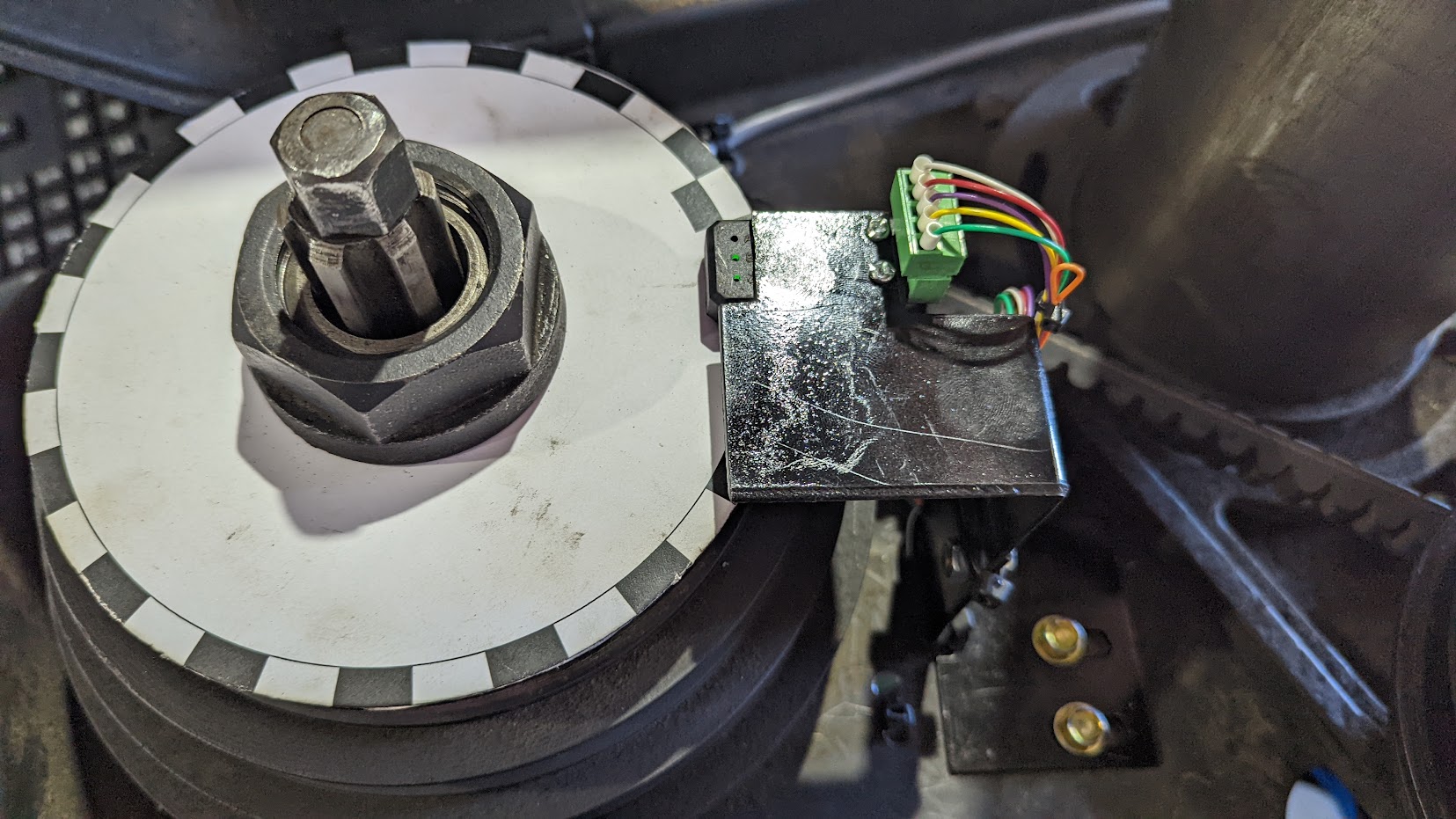

Spindle-off, manually rotate the pulley until the line intersects the channel and is lit.

-ve, Ground

+ve, 12.95VDC power supply

Output Signal Z 9.5VDC

Output Signal B 9.49VDC

Output Signal A 9.52VDC

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

13 Aug 2023 23:38 #277889

by smplc

Replied by smplc on topic Spindle and encoder

I reset the spacing of the encoder but it might not be any different than last time. All three LED's require to rest equally against the spacer and code wheel. It appears my images of this string cover most of the PncConfig setup on my behalf. Please inform me if any of the images could require adjusting the configuration and any editing with the .hal and .ini files. I could probably adjust the speed controller acceleration dial to match the commanded RPM to the tachometer reading. However, still, the shuffling numbers at the Hal Meter pin hm2_7i96s.0.encoder.00.velocity-rpm and the GUI and Hal Show pins hm2_7i96s.0.encoder.00.input-a and hm2_7i96s.0.encoder.00.input-b not quite 90 degrees out of phase. Would a prescale stop the shuffle numbers? Do the .hal or .ini files use a prescaler with an encoder? For instance, set the prescale 4 and encoder 10. 4 * 10 = 40 CPR.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

14 Aug 2023 00:28 #277894

by PCW

Replied by PCW on topic Spindle and encoder

Can you get decent looking quadrature signals in halscope?

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

14 Aug 2023 00:34 #277895

by smplc

Replied by smplc on topic Spindle and encoder

Motor 6100 RPM max. The pulleys to the spindle have a speed reduction of approximately 46%. Adjusting the speed controller dial probably should be near the maximum acceleration which is 2800 RPM, however, matches the pulley ratio. I'm considering LinuxCNC_Documentation.pdf 12.2, using and editing some code if not already and if applicable.

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

14 Aug 2023 00:40 #277896

by smplc

Replied by smplc on topic Spindle and encoder

Yes, somewhat. About as decent as it is, is from the last image in this string. I tried other times after and the analog signal still looks about the same yet. I think the signal could use improvement.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

14 Aug 2023 01:01 #277897

by PCW

Replied by PCW on topic Spindle and encoder

Can you post a current haslcope screenshot of the quadrature signals?

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

14 Aug 2023 01:27 #277898

by smplc

Replied by smplc on topic Spindle and encoder

Yes. The MDI g97 s1000 m3 entered but the portable tachometer read 645 RPM. The Hal Meter pin hm2_7i96s.0.encoder.00.velocity-rpm and GUI RPM still shuffle.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

14 Aug 2023 02:39 #277904

by PCW

Replied by PCW on topic Spindle and encoder

Unfortunately, those signals are nowhere near actual quadrature.

Maybe a disk issue, don't know. Nothing that can be fixed in software

or settings.

Can you:

1. run the spindle at ~200 RPM

2. try adjusting the encoder while watching for

50 % duty cycle and 90 degree shift between A and B

(90 degree shift means A,B Signals change in the middle of the

B,A high or low period)

Maybe a disk issue, don't know. Nothing that can be fixed in software

or settings.

Can you:

1. run the spindle at ~200 RPM

2. try adjusting the encoder while watching for

50 % duty cycle and 90 degree shift between A and B

(90 degree shift means A,B Signals change in the middle of the

B,A high or low period)

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

14 Aug 2023 04:00 - 14 Aug 2023 04:30 #277909

by smplc

Replied by smplc on topic Spindle and encoder

I tried to adjust the distance of the encoder LED's from the face of the code wheel variably during 257 RPM but the Hal Scope did not show channels A and B 90-degree shift. I wonder if a reflective code wheel would have any improvement which might be worth a try. Any idea why the RPM is still shuffling?

Alternatively, I could obtain transmissive encoders which could mount on a customized bracket that mounts on the existing bracket. Another code wheel with perforations or slits might need to be manufactured. The Sherline Chucker Lathe spindle bore protrudes outside the headstock containing the pulley and a fastened retaining (face) ring which reinforces the 3C collet draw tube. A spacer and the other code wheel could go between the pulley and retainer.

Another option. Sherline did use a rotary encoder that was mounted on their early Chucker Lathes headstock. The Chucker Lathe pulley has two sheaves. The other sheave could be used to drive the rotary encoder.

Is 7i96s firmware known to have good quadrature, A and B channels about a 90-degree shift? Did the RPM GUI look stable?

Alternatively, I could obtain transmissive encoders which could mount on a customized bracket that mounts on the existing bracket. Another code wheel with perforations or slits might need to be manufactured. The Sherline Chucker Lathe spindle bore protrudes outside the headstock containing the pulley and a fastened retaining (face) ring which reinforces the 3C collet draw tube. A spacer and the other code wheel could go between the pulley and retainer.

Another option. Sherline did use a rotary encoder that was mounted on their early Chucker Lathes headstock. The Chucker Lathe pulley has two sheaves. The other sheave could be used to drive the rotary encoder.

Is 7i96s firmware known to have good quadrature, A and B channels about a 90-degree shift? Did the RPM GUI look stable?

Last edit: 14 Aug 2023 04:30 by smplc. Reason: Spelling.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

14 Aug 2023 06:32 #277916

by rodw

Replied by rodw on topic Spindle and encoder

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.127 seconds