THC plasma configs, with HOW TO.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21145

- Thank you received: 7221

31 Jul 2018 06:05 - 31 Jul 2018 06:18 #115206

by tommylight

If you use the toma config you can set everything in Linuxcnc. For what you need it, Proma 150 will do nicely, even for much more.

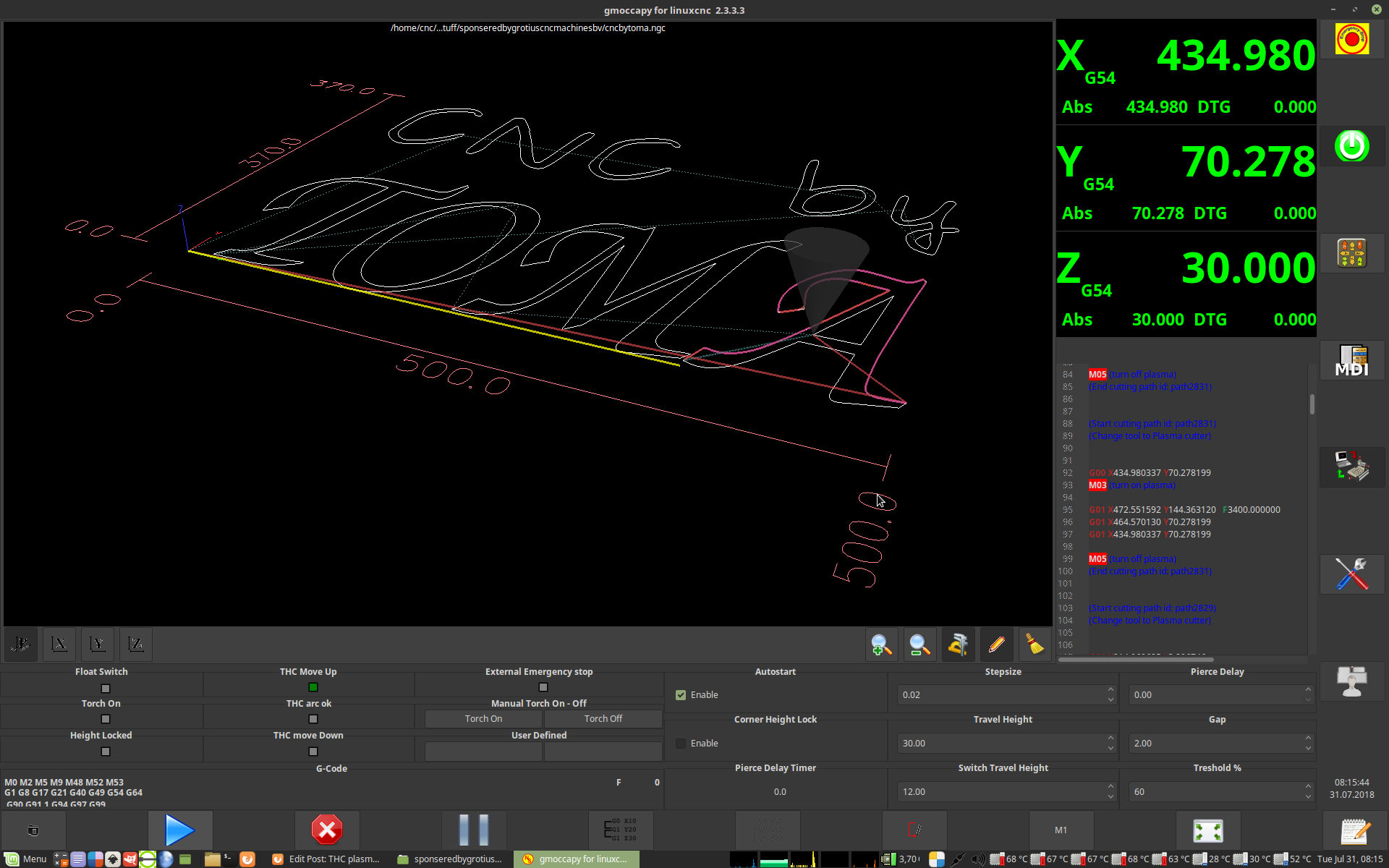

BTW here it is on one of the computers i use daily at 1920X1200,

Those LED's really need to be much bigger, and i see no velocity anywhere while the machine is moving, that is a must when plasma cutting.

Replied by tommylight on topic THC plasma configs, with HOW TO.

I have all of them set to the fastest reaction time, so Hysteresis is at 2V i think and delay is at 0.1.Can you share with me what are your recommended settings on the Proma 150 THC controller (Hysteresis, Delay, etc.) as well as your recommended Z parameters (velocity and acceleration) while under THC control.

If you use the toma config you can set everything in Linuxcnc. For what you need it, Proma 150 will do nicely, even for much more.

BTW here it is on one of the computers i use daily at 1920X1200,

Those LED's really need to be much bigger, and i see no velocity anywhere while the machine is moving, that is a must when plasma cutting.

Last edit: 31 Jul 2018 06:18 by tommylight.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

31 Jul 2018 12:22 #115218

by bevins

Replied by bevins on topic THC plasma configs, with HOW TO.

Hi Tommylight,

Would this be easily setup for 5i25-7i76 stepper system with no FB? I noticed some FB in the thc hal.

Thanks, nice work.

Would this be easily setup for 5i25-7i76 stepper system with no FB? I noticed some FB in the thc hal.

Thanks, nice work.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21145

- Thank you received: 7221

31 Jul 2018 12:40 #115221

by tommylight

Replied by tommylight on topic THC plasma configs, with HOW TO.

It should be fairly easy, but i sold my 7i76E so i can not test it.

I did set up a 6i25 with stepgens so it should be similar, but i had not time to test it yes.

I did set up a 6i25 with stepgens so it should be similar, but i had not time to test it yes.

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- jawneelogik

-

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

31 Jul 2018 12:59 #115224

by jawneelogik

Replied by jawneelogik on topic THC plasma configs, with HOW TO.

tommylight, thx for your reply.

Cool screens. Almost makes me regret my decision to choose UCCNC instead of LinuxCNC. However, I needed something that I could comfortably implement out-of-the-box without too steep a learning curve and UCCNC met that criteria (It seems like a "cleaned-up" clone of Mach3.). I do intend to explore LCNC going forward, but I have contract obligations to maintain a level of production in my shop.

Regarding your screen, I don't see anywhere a setting for Z response velocity under THC control? Is there no need for this parameter within LinuxCNC?

Cool screens. Almost makes me regret my decision to choose UCCNC instead of LinuxCNC. However, I needed something that I could comfortably implement out-of-the-box without too steep a learning curve and UCCNC met that criteria (It seems like a "cleaned-up" clone of Mach3.). I do intend to explore LCNC going forward, but I have contract obligations to maintain a level of production in my shop.

Regarding your screen, I don't see anywhere a setting for Z response velocity under THC control? Is there no need for this parameter within LinuxCNC?

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

31 Jul 2018 13:12 #115225

by bevins

Thanks for your work on this project. Will help a tons when I get to the THC.

Just have to figure out which THCad, 10v or 300v.....

Bob

Replied by bevins on topic THC plasma configs, with HOW TO.

It should be fairly easy, but i sold my 7i76E so i can not test it.

I did set up a 6i25 with stepgens so it should be similar, but i had not time to test it yes.

Thanks for your work on this project. Will help a tons when I get to the THC.

Just have to figure out which THCad, 10v or 300v.....

Bob

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11601

- Thank you received: 3900

31 Jul 2018 13:22 #115228

by rodw

Bob, I'd recommend the 300v version if you don't have a voltage divider and 10v if you do. (unless you have a > 130 amp plasma cutter that produces > 300 volts!

Also mount the THCAD on or in your plasma cutter as the frequency signal will be much more immune to noise on its trip to the control box....

Replied by rodw on topic THC plasma configs, with HOW TO.

Just have to figure out which THCad, 10v or 300v.....

Bob

Bob, I'd recommend the 300v version if you don't have a voltage divider and 10v if you do. (unless you have a > 130 amp plasma cutter that produces > 300 volts!

Also mount the THCAD on or in your plasma cutter as the frequency signal will be much more immune to noise on its trip to the control box....

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

31 Jul 2018 13:39 #115230

by bevins

Thanks rodw.

You use a pyvcp panel for your plasma? Also, you use any external buttons?

Replied by bevins on topic THC plasma configs, with HOW TO.

Just have to figure out which THCad, 10v or 300v.....

Bob

Bob, I'd recommend the 300v version if you don't have a voltage divider and 10v if you do. (unless you have a > 130 amp plasma cutter that produces > 300 volts!

Also mount the THCAD on or in your plasma cutter as the frequency signal will be much more immune to noise on its trip to the control box....

Thanks rodw.

You use a pyvcp panel for your plasma? Also, you use any external buttons?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11601

- Thank you received: 3900

31 Jul 2018 13:54 #115231

by rodw

Replied by rodw on topic THC plasma configs, with HOW TO.

I use a modified version of the Gmoccappy plasma screen which has similar features to whats shown on this thread. I have GUI buttons for THC enable and torch enable. The screen handler is customised to parse gcode M68 commands so we can set values from the GUI and from gcode.

A lot of my test cuts have been with an external offsets Axis screen with just cornerlock and auto sampling components I've written with the THC programmed to come on with a simple delay component on arcOK that triggers the torch sample and that in turn enables the THC.

I've documented a lot of my components and research into a single document and my plan is to rewrite them all into a complete set already configured with a easy to include hal file.

A lot of my test cuts have been with an external offsets Axis screen with just cornerlock and auto sampling components I've written with the THC programmed to come on with a simple delay component on arcOK that triggers the torch sample and that in turn enables the THC.

I've documented a lot of my components and research into a single document and my plan is to rewrite them all into a complete set already configured with a easy to include hal file.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21145

- Thank you received: 7221

31 Jul 2018 13:56 #115232

by tommylight

Replied by tommylight on topic THC plasma configs, with HOW TO.

Velocity is set in the ini file at the maximum Z axis can handle, and on screen you have "step size" to adjust how much it will move when commanded from THC.Regarding your screen, I don't see anywhere a setting for Z response velocity under THC control? Is there no need for this parameter within LinuxCNC?

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

31 Jul 2018 18:22 - 31 Jul 2018 20:53 #115248

by Grotius

Replied by Grotius on topic THC plasma configs, with HOW TO.

Hi

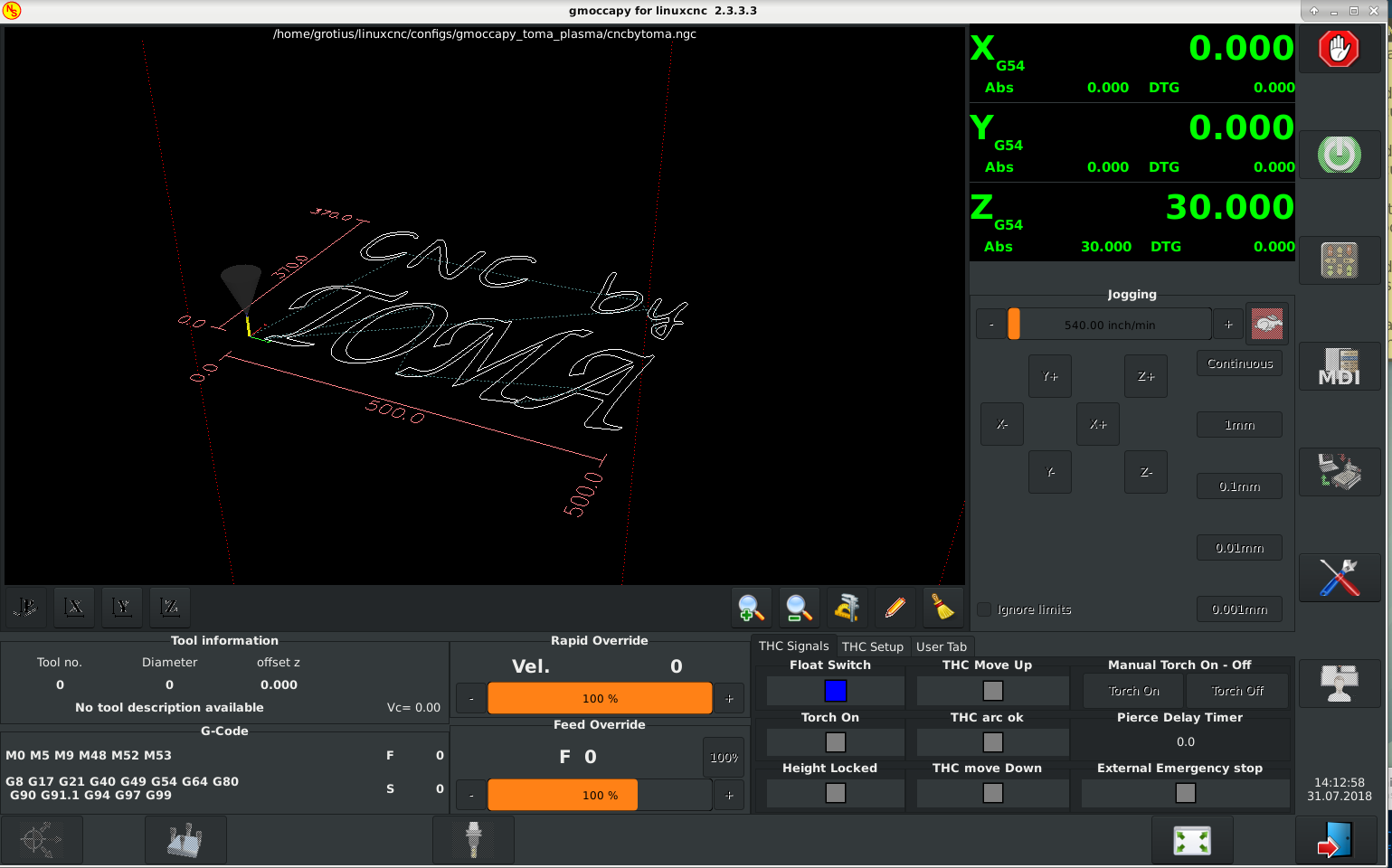

The THC screen now follows the user defined theme. I had to add the plasma.py and plasma.pyc file.

The leds are 2x bigger.

It has the orginal gmoccapy speed panel.

I had to merge the 2 panels to one panel with tabs, to give it something functional.

There is a user defined tap. I advice for users to select Halui i/o and connect them in the plasmaled.hal file, not in postgui.hal

because it is a embedded panel with separate hal file. It will not work with postgui.hal.

Have fun. Attached the zip file list.

To Bevins,

This forum section is only intended for work with Proma THC.

Proma works fine with Mach3 plasma, the same config's work also fine on Linuxcnc with this forum section THC Toma Hal configuration, available in :

Orginal Axis screen with pyvcp side screen (download from Proma)

Axis screen with glade side screen (the .ui file can be opened in glade and modified by user in graphical way, pyvcp screen is only coded)

Gmoccapy screen with embedded plasma screen (above picture with black theme)

My work is now to go with the exernal offset's branche, testing new thc real time components and scripts to make the perfect

Mesa Plasma Machine. My friend Rodw is very good in this c scripting, making doc's, he is a very awesome men. I am proud to

have someone like him on the linuxcnc forum.

For the future of plasma, laser, thc etc, i will order my first Mesa setup soon, and i will leave the Ltp1 section behind me.

If Mesa will not marry me, it will be a stand alone FPGA project for me during the winter periode. But i will be back after that.

The THC screen now follows the user defined theme. I had to add the plasma.py and plasma.pyc file.

The leds are 2x bigger.

It has the orginal gmoccapy speed panel.

I had to merge the 2 panels to one panel with tabs, to give it something functional.

There is a user defined tap. I advice for users to select Halui i/o and connect them in the plasmaled.hal file, not in postgui.hal

because it is a embedded panel with separate hal file. It will not work with postgui.hal.

Have fun. Attached the zip file list.

To Bevins,

Just have to figure out which THCad, 10v or 300v.....

This forum section is only intended for work with Proma THC.

Proma works fine with Mach3 plasma, the same config's work also fine on Linuxcnc with this forum section THC Toma Hal configuration, available in :

Orginal Axis screen with pyvcp side screen (download from Proma)

Axis screen with glade side screen (the .ui file can be opened in glade and modified by user in graphical way, pyvcp screen is only coded)

Gmoccapy screen with embedded plasma screen (above picture with black theme)

My work is now to go with the exernal offset's branche, testing new thc real time components and scripts to make the perfect

Mesa Plasma Machine. My friend Rodw is very good in this c scripting, making doc's, he is a very awesome men. I am proud to

have someone like him on the linuxcnc forum.

For the future of plasma, laser, thc etc, i will order my first Mesa setup soon, and i will leave the Ltp1 section behind me.

If Mesa will not marry me, it will be a stand alone FPGA project for me during the winter periode. But i will be back after that.

Last edit: 31 Jul 2018 20:53 by Grotius.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.139 seconds