Another plasma component...

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

30 Jul 2019 17:11 - 30 Jul 2019 17:15 #140962

by robertspark

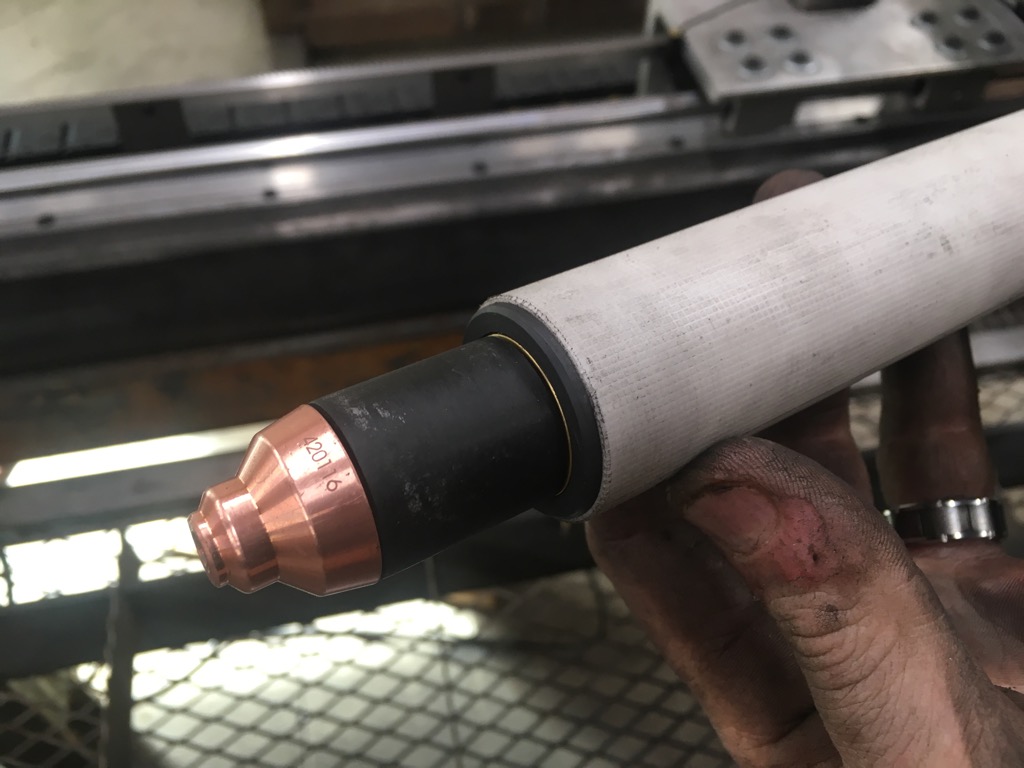

is that a genuine machine torch or fabricated?

Replied by robertspark on topic Another plasma component...

is that a genuine machine torch or fabricated?

Last edit: 30 Jul 2019 17:15 by robertspark.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

30 Jul 2019 23:25 #140979

by phillc54

Replied by phillc54 on topic Another plasma component...

It's a neat conversion he did on

this thread

The following user(s) said Thank You: robertspark

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

31 Jul 2019 06:01 #140985

by robertspark

Replied by robertspark on topic Another plasma component...

thanks very nice

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

31 Jul 2019 10:45 #140994

by phillc54

Replied by phillc54 on topic Another plasma component...

I have pushed an update:

Add small hole feature to the GCode parser

This is only for folk who don't use a post processor or their post processor cannot do small hole stuffs...

home.iprimus.com.au/phillcarter/plasma/p...#_hole_cutting_intro

Add small hole feature to the GCode parser

This is only for folk who don't use a post processor or their post processor cannot do small hole stuffs...

home.iprimus.com.au/phillcarter/plasma/p...#_hole_cutting_intro

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3928

31 Jul 2019 10:53 #140995

by rodw

Replied by rodw on topic Another plasma component...

Pretty wild enhancement Phill. It will be good to see feedback about hole cutting as users get into testing it.

So now you need to add a feature to spot hole centres if less than a user specified diameter (eg < 6mm). This will be dependent a bit on the user's build quality re backlash, rigidity etc. Probably needs to be able to set from gcode to allow for variations in thickness.

So now you need to add a feature to spot hole centres if less than a user specified diameter (eg < 6mm). This will be dependent a bit on the user's build quality re backlash, rigidity etc. Probably needs to be able to set from gcode to allow for variations in thickness.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

31 Jul 2019 11:37 #140998

by phillc54

Replied by phillc54 on topic Another plasma component...

Would you need to be able to adjust current to do this or would a timed torch pulse be adequate?

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3928

31 Jul 2019 11:52 - 31 Jul 2019 11:52 #141000

by rodw

I just turn it off when I get an ArcOK. Thats nice and simple. Possibly timing would be useful as ArcOK can put a fair divot in thicker material. Not many people can control current but perhaps its an option too. Robertspark or Stefan would have a better idea. I know Beefy in Melbourne has played around with monitoring the current with a current sensor and killing the arc at a certain threshold but that requires adding electronics inside a plasma cutter.

Replied by rodw on topic Another plasma component...

Would you need to be able to adjust current to do this or would a timed torch pulse be adequate?

I just turn it off when I get an ArcOK. Thats nice and simple. Possibly timing would be useful as ArcOK can put a fair divot in thicker material. Not many people can control current but perhaps its an option too. Robertspark or Stefan would have a better idea. I know Beefy in Melbourne has played around with monitoring the current with a current sensor and killing the arc at a certain threshold but that requires adding electronics inside a plasma cutter.

Last edit: 31 Jul 2019 11:52 by rodw.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

31 Jul 2019 12:47 - 31 Jul 2019 12:49 #141004

by robertspark

Replied by robertspark on topic Another plasma component...

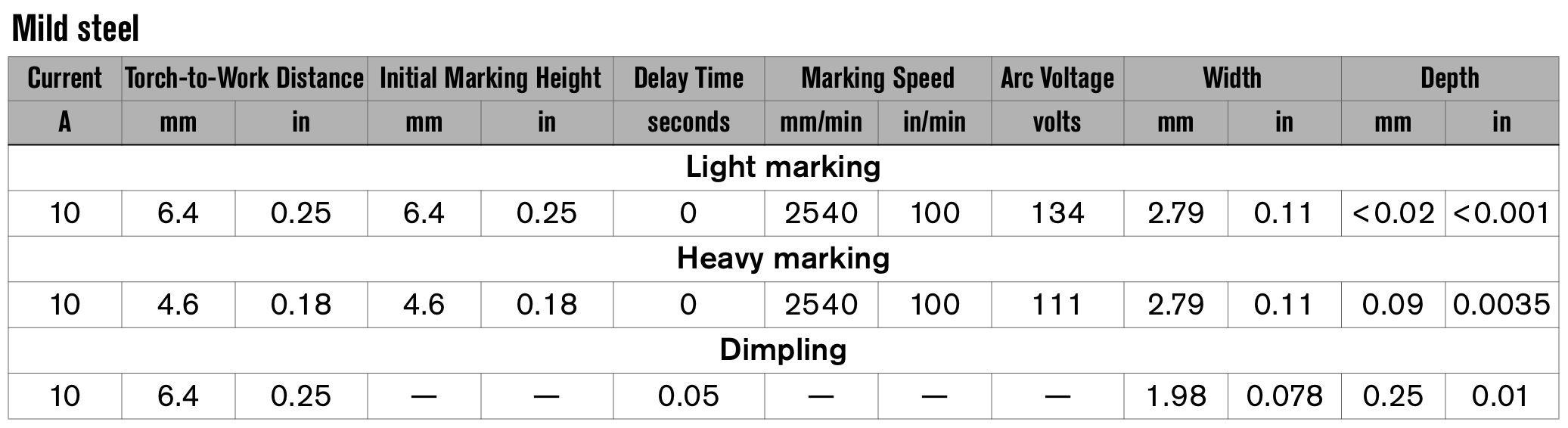

With regards to plasma center punch, I'd suggest having a read of the Hypertherm 45XP Operator manual as the 45XP does plasma marking and dimpling.

Yes I know this may not apply to you, but my point is that you at least consider how they do it. i.e. set the amperage on the lowest setting, increase the pierce height and for dimpling, giving the pulse a VERY fast pulse.

www.hypertherm.com/Download?fileId=HYP172110&zip=False

PDF page 117

ALSO the cut table is on 137 (for air)

For dimpling, the recommended current is 10A, at a pierce (dimple) height of 6.4mm (0.25"), with a delay time listed as 0.05 Seconds.

Also if you look the air pressure may need to be lowered, given for something like "standard shielded 45A consumables" the airflow is 390scfh (standard cubic feet / hour [cold]), and for the marking / dimpling it is 300scfh. the "may need to be is based upon the airflow being lower, but the 45XP has marking consumables and cutting consumables...... they "may" have different orifice sizes.... which will lower the flow too. The point being have a play and see what works for you, but if you machine can fire the torch on and off fast you are most of the way there.

Yes I know this may not apply to you, but my point is that you at least consider how they do it. i.e. set the amperage on the lowest setting, increase the pierce height and for dimpling, giving the pulse a VERY fast pulse.

www.hypertherm.com/Download?fileId=HYP172110&zip=False

PDF page 117

ALSO the cut table is on 137 (for air)

For dimpling, the recommended current is 10A, at a pierce (dimple) height of 6.4mm (0.25"), with a delay time listed as 0.05 Seconds.

Also if you look the air pressure may need to be lowered, given for something like "standard shielded 45A consumables" the airflow is 390scfh (standard cubic feet / hour [cold]), and for the marking / dimpling it is 300scfh. the "may need to be is based upon the airflow being lower, but the 45XP has marking consumables and cutting consumables...... they "may" have different orifice sizes.... which will lower the flow too. The point being have a play and see what works for you, but if you machine can fire the torch on and off fast you are most of the way there.

Last edit: 31 Jul 2019 12:49 by robertspark. Reason: {was looking at the argon table....

The following user(s) said Thank You: phillc54, rodw

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

01 Aug 2019 01:54 #141062

by phillc54

Replied by phillc54 on topic Another plasma component...

Just looking at the chart for the PM45XP with marking consumables, the resultant dimple size is 2mm.

Is that really accurate enough for a centre spot?

I guess that figure would also be worse with non marking consumables and higher amperage.

From the manual:

PierceDelayTime – Length of time the triggered torch remains stationary at the pierce height before the torch starts the cutting motion. In marking charts, this is referred to as Delay Time.

I take from that the Delay Time is the time from Arc OK until torch is turned off.

Is that really accurate enough for a centre spot?

I guess that figure would also be worse with non marking consumables and higher amperage.

From the manual:

PierceDelayTime – Length of time the triggered torch remains stationary at the pierce height before the torch starts the cutting motion. In marking charts, this is referred to as Delay Time.

I take from that the Delay Time is the time from Arc OK until torch is turned off.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3928

01 Aug 2019 02:49 #141065

by rodw

Replied by rodw on topic Another plasma component...

Hmm, Phill, you helped me find a bug in my post processor.

This is three spots at 40 amps on 2mm mild steel, no pierce delay.

To actually cut something, you need a movement between M3 and M5 so the post processor moved 0.001mm which is insignificant. The post processor I based mine on used 0.0254 mm for the move.

Remembering that a plasma is more like a blunt axe than a precision milling machine, these have proved accurate enough for drilling if you use the normal 1.0mm larger drill than the bolt. But clearly you are not going to spot to drill 1mm diameter holes but 4mm has proven OK.

This is three spots at 40 amps on 2mm mild steel, no pierce delay.

To actually cut something, you need a movement between M3 and M5 so the post processor moved 0.001mm which is insignificant. The post processor I based mine on used 0.0254 mm for the move.

Remembering that a plasma is more like a blunt axe than a precision milling machine, these have proved accurate enough for drilling if you use the normal 1.0mm larger drill than the bolt. But clearly you are not going to spot to drill 1mm diameter holes but 4mm has proven OK.

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.326 seconds