Another plasma component...

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

01 Aug 2019 03:19 #141066

by phillc54

Replied by phillc54 on topic Another plasma component...

Yeah, I have been playing around with a sim, I was using an X move of 0.0000001, pierce and cut height of 6.4 and pierce delay of 0

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

01 Aug 2019 08:56 #141081

by robertspark

Replied by robertspark on topic Another plasma component...

Why do you HAVE to have movement between M3 & M5?

a 2mm dimple is not that bad, remember that the normal kerf width will be somewhere between 1 and 1.5mm, so if you are blasting hot air (up to 20,000ºC) at a piece of steel it will first form a crater where the metal from the middle is displaced outward and upward.

I've not measured a dimple from a centre punch before, but its provably at best only half that, but would take much more time to mark out (with better accuracy) than doing a number of dimples on a cnc table and then bench / pedestal drilling them.

The ArcOK signal is normally a dry contact closure (i.e. a mechanical relay), and depending upon which relay the plasma cutter manufacturer used, they will all have some delay between the "actual" arcOK signal and the time it takes to close the relay.

I have in the past (with other THC's) changed the relays to be much faster acting.... to reed relays for example. Like the datasheet for this relay.

cotorelay.com/wp-content/uploads/2014/09..._relay_datasheet.pdf

operating time - 0.35mSec (350uSec), release time 0.1mSec (100uSec).... but only 5V or 12v

other variants are available at 24V......

cotorelay.com/product/8l-series-spartan-dip-reed-relays/

All just depends what you want / need.

Point being, maybe just check the front end specs within the plasma cutter if you are curious to see what they have left you with for the ARCOK relay within the machine. (be honest, I've not actually checked the PMX45, but will do tonight out of curiousity as I have the cover off).

a 2mm dimple is not that bad, remember that the normal kerf width will be somewhere between 1 and 1.5mm, so if you are blasting hot air (up to 20,000ºC) at a piece of steel it will first form a crater where the metal from the middle is displaced outward and upward.

I've not measured a dimple from a centre punch before, but its provably at best only half that, but would take much more time to mark out (with better accuracy) than doing a number of dimples on a cnc table and then bench / pedestal drilling them.

The ArcOK signal is normally a dry contact closure (i.e. a mechanical relay), and depending upon which relay the plasma cutter manufacturer used, they will all have some delay between the "actual" arcOK signal and the time it takes to close the relay.

I have in the past (with other THC's) changed the relays to be much faster acting.... to reed relays for example. Like the datasheet for this relay.

cotorelay.com/wp-content/uploads/2014/09..._relay_datasheet.pdf

operating time - 0.35mSec (350uSec), release time 0.1mSec (100uSec).... but only 5V or 12v

other variants are available at 24V......

cotorelay.com/product/8l-series-spartan-dip-reed-relays/

All just depends what you want / need.

Point being, maybe just check the front end specs within the plasma cutter if you are curious to see what they have left you with for the ARCOK relay within the machine. (be honest, I've not actually checked the PMX45, but will do tonight out of curiousity as I have the cover off).

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

01 Aug 2019 09:20 - 01 Aug 2019 09:22 #141083

by robertspark

Replied by robertspark on topic Another plasma component...

May have been the 9007's I used because they offer 5V, 12V and 24V.

cotorelay.com/wp-content/uploads/2014/09..._relay_datasheet.pdf

I tend to run everything I can at 24V

On switching time is 0.5mSec (500uSec), and release time 0.2mSec (200uSec).

cotorelay.com/wp-content/uploads/2014/09..._relay_datasheet.pdf

I tend to run everything I can at 24V

On switching time is 0.5mSec (500uSec), and release time 0.2mSec (200uSec).

Last edit: 01 Aug 2019 09:22 by robertspark.

Please Log in or Create an account to join the conversation.

- Franklin

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 19

01 Aug 2019 11:07 - 01 Aug 2019 12:09 #141085

by Franklin

Replied by Franklin on topic Another plasma component...

Hi, I'm using HF ignition plasma. And for marking holes I use M10 code

I added or2 and connected with motion.digital-out-00 and with plasmac: torch-on

Empirically I determined that at a height of 5 mm and a delay of 0.15s make good marks for drilling.

And before marking I remove the mass clamp.

I added or2 and connected with motion.digital-out-00 and with plasmac: torch-on

Empirically I determined that at a height of 5 mm and a delay of 0.15s make good marks for drilling.

And before marking I remove the mass clamp.

Last edit: 01 Aug 2019 12:09 by Franklin.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

01 Aug 2019 11:24 #141087

by robertspark

what is the "mass clamp"? Do you mean the "work clamp"?

Bascially its all trial and error, and if you try a few setups then whatever works best for you works!

point being try different heights, and different times, I've not removed the work clamp, but no harm in trying it (just you won't get an ARCOK signal as the arc won't transfer...... but I can see the reasoning behind it as the torch fire duration is so short its just another start sequence.

Replied by robertspark on topic Another plasma component...

And before marking I remove the mass clamp.

what is the "mass clamp"? Do you mean the "work clamp"?

Bascially its all trial and error, and if you try a few setups then whatever works best for you works!

point being try different heights, and different times, I've not removed the work clamp, but no harm in trying it (just you won't get an ARCOK signal as the arc won't transfer...... but I can see the reasoning behind it as the torch fire duration is so short its just another start sequence.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11544

- Thank you received: 3871

01 Aug 2019 11:50 #141093

by rodw

Replied by rodw on topic Another plasma component...

Re relays, I've been using these for 24V which are 250 usec on and 2 usec off

RS Components Part # 888-6843

LinuxCNC only looks every 1000 usecs on the 1 ms servo thread so we can't get better than that. Some of the opto22's are much slower.

What I found today when I commented out the small move between M3 and M5, the torch skipped firing totally. I guess that makes sense as there was nothing to cut. So I made it smaller..

Unless Phill comes up with an alternative, I'll just keep spotting the way I am

RS Components Part # 888-6843

LinuxCNC only looks every 1000 usecs on the 1 ms servo thread so we can't get better than that. Some of the opto22's are much slower.

What I found today when I commented out the small move between M3 and M5, the torch skipped firing totally. I guess that makes sense as there was nothing to cut. So I made it smaller..

Unless Phill comes up with an alternative, I'll just keep spotting the way I am

Please Log in or Create an account to join the conversation.

- Franklin

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 19

01 Aug 2019 12:10 #141096

by Franklin

Replied by Franklin on topic Another plasma component...

yes i mean the work clamp. Sorry for my English.

I do not wait for the ArkOk I make marks with the pilot arc

when the work clamp connected, the marks are deeper but not round enough.

I do not wait for the ArkOk I make marks with the pilot arc

when the work clamp connected, the marks are deeper but not round enough.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

01 Aug 2019 15:07 #141113

by robertspark

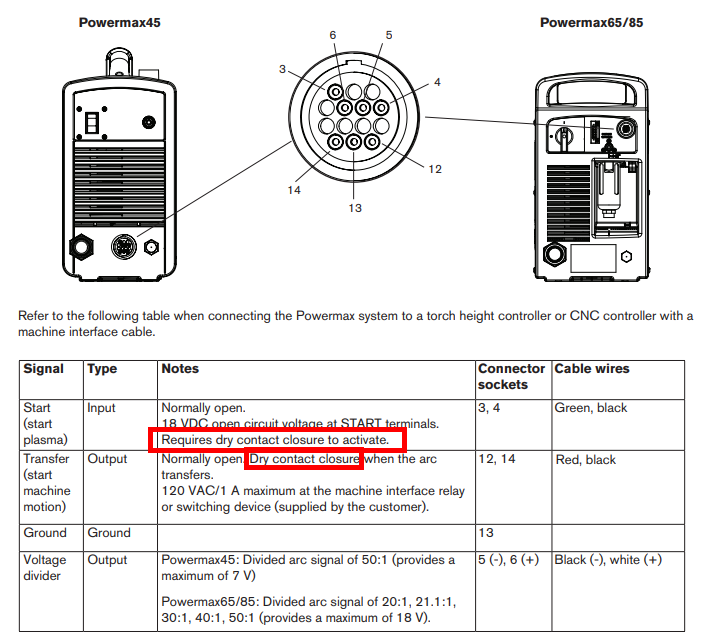

Rod, those relays are solid state using a Mosfet, normally you'll see that with plasma that the datasheet asks for "dry contact" (i.e. non-solid state).

I think it is to do with the leakage current and also maybe the minimum switching current.

To be fair those solid state relays seem fine, but some optoisolators probably are not a good idea. Hence why I switched to reed relays.

Just something to consider or be aware of .... if it works, it works.... but may not work for everyone... if it ain't broke don't fix it etc.

I agree 100% about the 1kHz (1mSec) loop, anything being faster than this is fine. It was actually Keith (aka Beefy . mancavedweller) who pointed it out a couple of years ago now to me, about looking for relays which are consistent. i.e. a 10% variance on a 1mSec relay is not much.... but 10% variance on a 500mSec relay is a lot more of a consideration... hence again I try to find a branded product with a good believable datasheet if my aim is consistency in something.

Replied by robertspark on topic Another plasma component...

Re relays, I've been using these for 24V which are 250 usec on and 2 usec off

RS Components Part # 888-6843

LinuxCNC only looks every 1000 usecs on the 1 ms servo thread so we can't get better than that. Some of the opto22's are much slower.

Rod, those relays are solid state using a Mosfet, normally you'll see that with plasma that the datasheet asks for "dry contact" (i.e. non-solid state).

I think it is to do with the leakage current and also maybe the minimum switching current.

To be fair those solid state relays seem fine, but some optoisolators probably are not a good idea. Hence why I switched to reed relays.

Just something to consider or be aware of .... if it works, it works.... but may not work for everyone... if it ain't broke don't fix it etc.

I agree 100% about the 1kHz (1mSec) loop, anything being faster than this is fine. It was actually Keith (aka Beefy . mancavedweller) who pointed it out a couple of years ago now to me, about looking for relays which are consistent. i.e. a 10% variance on a 1mSec relay is not much.... but 10% variance on a 500mSec relay is a lot more of a consideration... hence again I try to find a branded product with a good believable datasheet if my aim is consistency in something.

Attachments:

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

01 Aug 2019 15:22 #141116

by robertspark

Replied by robertspark on topic Another plasma component...

Rod,

Also the thing to probably watch is the switching frequency at 50Hz, i.e. you can't (or shouldn't) switch it faster than 20mSec, even though it makes in 250uSec, and breaks in 2uSec

also the RS datasheet does not really tell you the switch on and off voltage (it says mnimum switching voltage 10, maximum 30V)

docs-apac.rs-online.com/webdocs/1696/0900766b816969f5.pdf

compared to the ones I posted say for a 24V one, it says the switch on voltage is 18 v and the switch off voltage is 2V

cotorelay.com/wp-content/uploads/2014/09..._relay_datasheet.pdf

(i.e. a clearly defined wide window of high and low so noise is less likely to be an issue)..... but magnetism / magnetic field effect may be a consideration with a reed switch relay I admit.....

again If it works ... it works.... (maybe someone else reading this may want to be aware of trying to understand all considerations)

Also the thing to probably watch is the switching frequency at 50Hz, i.e. you can't (or shouldn't) switch it faster than 20mSec, even though it makes in 250uSec, and breaks in 2uSec

also the RS datasheet does not really tell you the switch on and off voltage (it says mnimum switching voltage 10, maximum 30V)

docs-apac.rs-online.com/webdocs/1696/0900766b816969f5.pdf

compared to the ones I posted say for a 24V one, it says the switch on voltage is 18 v and the switch off voltage is 2V

cotorelay.com/wp-content/uploads/2014/09..._relay_datasheet.pdf

(i.e. a clearly defined wide window of high and low so noise is less likely to be an issue)..... but magnetism / magnetic field effect may be a consideration with a reed switch relay I admit.....

again If it works ... it works.... (maybe someone else reading this may want to be aware of trying to understand all considerations)

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11544

- Thank you received: 3871

01 Aug 2019 21:05 #141150

by rodw

Replied by rodw on topic Another plasma component...

It often comes back down to what you can find in your market. Initially, I was using ordinary electro magnetic panel relays but purchased these as I wanted opto isolated relays for the Ohmic circuit and because I had to buy a pack of 5, I upgraded the mechanical ones to these as well. I don't think using opto relays is an issue. People are using the built in relay outputs on the 7i96 and even the spindle relay on the 7i76e to trigger their torches.

One thing to be aware of if you use a magnetic relay with a Mesa card, be sure to install a flyback diode between the relay input terminals (with the band on the diode pointing towards the Mesa output).

One thing to be aware of if you use a magnetic relay with a Mesa card, be sure to install a flyback diode between the relay input terminals (with the band on the diode pointing towards the Mesa output).

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.180 seconds