- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Hypersensing with THCAD - better way to do ohmic sensing

Hypersensing with THCAD - better way to do ohmic sensing

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

15 Apr 2020 00:21 - 15 Apr 2020 00:21 #163994

by rodw

With no water in the tray

Mains disconnected with Ohmic clip connected to the nozzle so THCAD is connected 1.15 M Ohm

With Ohmic clip disconnected from the Nozzle no connection to THCAD - Open circuit no resistance measured.

From LinuxCNC:

probe not touching: 0 volts

probe touching table 24.07 volts

Wet on/off thresholds in use the other day. 23.8V/23.6V

Replied by rodw on topic Hypersensing with THCAD - better way to do ohmic sensing

I would disconnect power and the THCAD and the measure the resistance from the probe to the table

With no water in the tray

Mains disconnected with Ohmic clip connected to the nozzle so THCAD is connected 1.15 M Ohm

With Ohmic clip disconnected from the Nozzle no connection to THCAD - Open circuit no resistance measured.

From LinuxCNC:

probe not touching: 0 volts

probe touching table 24.07 volts

Wet on/off thresholds in use the other day. 23.8V/23.6V

Last edit: 15 Apr 2020 00:21 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

15 Apr 2020 00:37 #163995

by rodw

Well we both have the same power supply.

I will check my wiring is as I documented later today.

I'm pretty sure the issue is water entering the torch tip and creating a circuit when we don't expect one with a water table. I know I have sometimes cleared a stuck probe (with a low off threshold) by either a Plasmac torch pulse to get air flowing or flicking the airflow switch on my plasma cutter.

The behaviour on a dry table now is exactly how it was when we first put this together.

Replied by rodw on topic Hypersensing with THCAD - better way to do ohmic sensing

Attached shows how I have my ohmic sensing power supply connected.

Well we both have the same power supply.

I will check my wiring is as I documented later today.

I'm pretty sure the issue is water entering the torch tip and creating a circuit when we don't expect one with a water table. I know I have sometimes cleared a stuck probe (with a low off threshold) by either a Plasmac torch pulse to get air flowing or flicking the airflow switch on my plasma cutter.

The behaviour on a dry table now is exactly how it was when we first put this together.

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

Less

More

- Posts: 145

- Thank you received: 46

15 Apr 2020 00:48 #163998

by Uthayne

That sounds likely. I think I'm having ground issues as well. I'll have to take a look at my wiring again and clean it up. Depending upon where I placed my "table (V-)" wire, I would sometimes get 24v on contact, and then only 14v on contact when it was attached somewhere else. This was the first time ever seeing that.

Replied by Uthayne on topic Hypersensing with THCAD - better way to do ohmic sensing

I will check my wiring is as I documented later today.

I'm pretty sure the issue is water entering the torch tip and creating a circuit when we don't expect one with a water table. I know I have sometimes cleared a stuck probe (with a low off threshold) by either a Plasmac torch pulse to get air flowing or flicking the airflow switch on my plasma cutter.

The behaviour on a dry table now is exactly how it was when we first put this together.

That sounds likely. I think I'm having ground issues as well. I'll have to take a look at my wiring again and clean it up. Depending upon where I placed my "table (V-)" wire, I would sometimes get 24v on contact, and then only 14v on contact when it was attached somewhere else. This was the first time ever seeing that.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

15 Apr 2020 06:15 #164022

by rodw

Replied by rodw on topic Hypersensing with THCAD - better way to do ohmic sensing

So I filled the water tray and tested probing before cutting anything and its exactly the same as I reported before:

probe not touching: 0 volts

probe touching table 24.07 volts

I realised now that I did not have the plasma turned on So I'll try and remember to check tomorrow again.

I thinks we've proved its a wet torch (for me anyway). I would suggest pulsing the torch before starting your job so that there is air flowing through the torch to stop water egress.That was the intended function.

probe not touching: 0 volts

probe touching table 24.07 volts

I realised now that I did not have the plasma turned on So I'll try and remember to check tomorrow again.

I thinks we've proved its a wet torch (for me anyway). I would suggest pulsing the torch before starting your job so that there is air flowing through the torch to stop water egress.That was the intended function.

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

Less

More

- Posts: 145

- Thank you received: 46

15 Apr 2020 18:35 #164070

by Uthayne

Replied by Uthayne on topic Hypersensing with THCAD - better way to do ohmic sensing

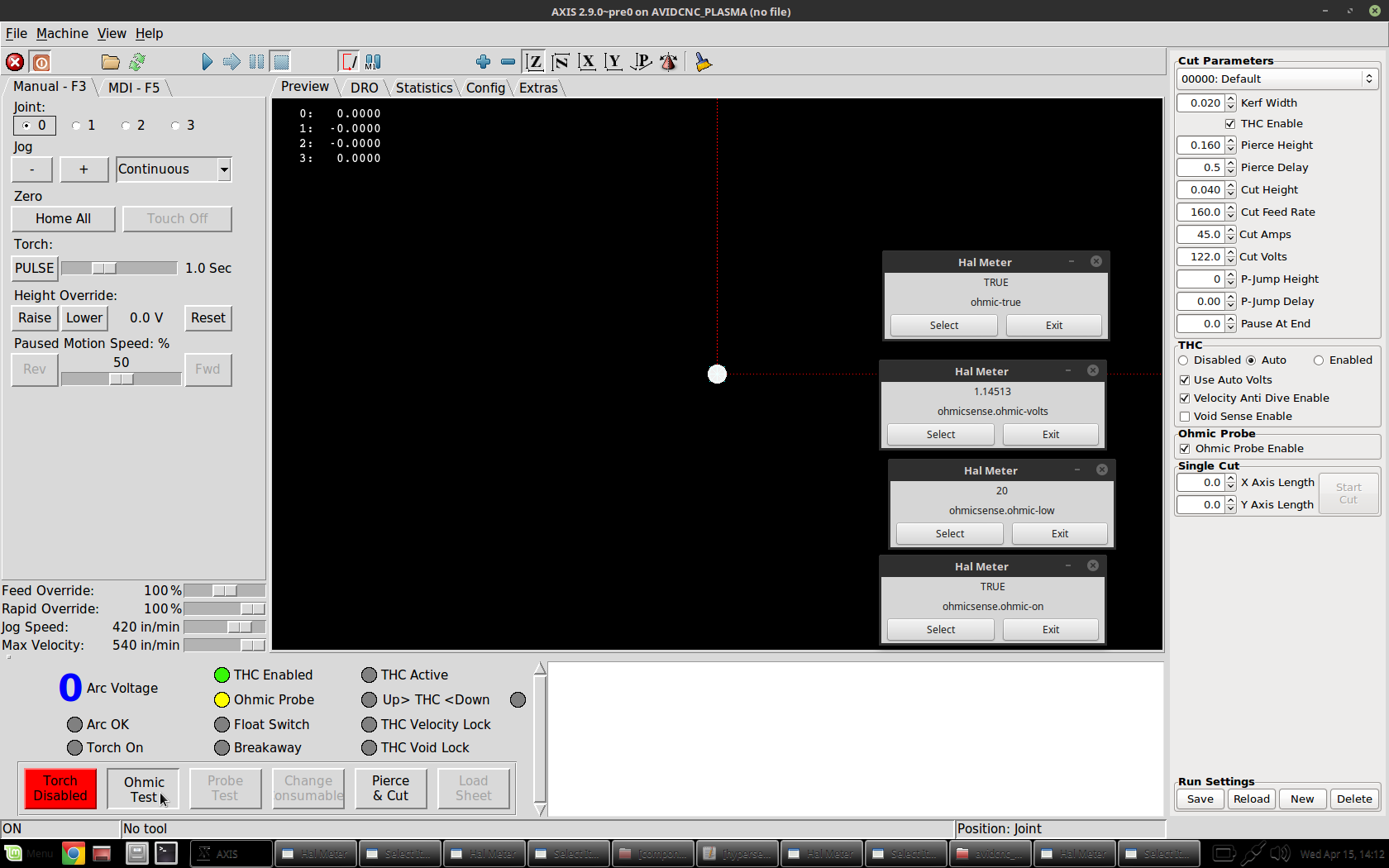

I think I may be getting somewhere. I see the light!

I stripped out all unecessary connections to my cabinet (sensors, steppers, etc) just to have a barebones setup. 7i76 connected to 5i25 in PC, 24v logic PSU on, THCAD-5 connected. Spindle connector disconnected.

I started everything up and THCAD-5 was working fine. Reading ~0v at idle. Touched the material and 24V. So far so good. Pulsed the torch (not over water) and re-checked everything. All is well, ohmic sensor still triggers and still at 0v when not touching. Then I pulsed over water and sure enough, ~16-18v was back after pulsing. It would remain somewhat constant when the air was not running, but if I pulsed the torch (again, not over the water), it would go down quite quickly, about 1v every 7 seconds or so. This confirms what you were suspecting about water shorting out the torch internally. It is quite easy to work around so that is fine.

However, I realized that by pressing the ohmic test button in axis, it would still light up the ohmic light even though the current voltage was below my ohmicsense.ohmic-low value (20v). I found out that 1v was the trigger point. If the ohmic-volts was above 1v, it would throw ohmic true. Now to investigate where this is coming from, because in my hal file I definitely have ohmic-low at 20v, but it just doesn't seem to be using it.

I would appreciate a second set of eyes looking over my hal files.

hypersensing.hal is where I configure the ohmicsense comp connections. Note I commented out ohmic_dev component which was my modified version, as well as some collision detection connections I was working on.

Rod, could you post your hal files pertaining to your setup?

I stripped out all unecessary connections to my cabinet (sensors, steppers, etc) just to have a barebones setup. 7i76 connected to 5i25 in PC, 24v logic PSU on, THCAD-5 connected. Spindle connector disconnected.

I started everything up and THCAD-5 was working fine. Reading ~0v at idle. Touched the material and 24V. So far so good. Pulsed the torch (not over water) and re-checked everything. All is well, ohmic sensor still triggers and still at 0v when not touching. Then I pulsed over water and sure enough, ~16-18v was back after pulsing. It would remain somewhat constant when the air was not running, but if I pulsed the torch (again, not over the water), it would go down quite quickly, about 1v every 7 seconds or so. This confirms what you were suspecting about water shorting out the torch internally. It is quite easy to work around so that is fine.

However, I realized that by pressing the ohmic test button in axis, it would still light up the ohmic light even though the current voltage was below my ohmicsense.ohmic-low value (20v). I found out that 1v was the trigger point. If the ohmic-volts was above 1v, it would throw ohmic true. Now to investigate where this is coming from, because in my hal file I definitely have ohmic-low at 20v, but it just doesn't seem to be using it.

I would appreciate a second set of eyes looking over my hal files.

hypersensing.hal is where I configure the ohmicsense comp connections. Note I commented out ohmic_dev component which was my modified version, as well as some collision detection connections I was working on.

Rod, could you post your hal files pertaining to your setup?

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

15 Apr 2020 19:14 #164074

by rodw

Replied by rodw on topic Hypersensing with THCAD - better way to do ohmic sensing

I've attached my ohmic hal file. Note that the encoder is set up elsewhere so I added that to the example in the plasma primer. It does not have the threshold values I set the other day.

If the probe comes on when it shouldn't then the bug has to be the code in the component.

Do the pins show up correctly in Halshow when this happens?

Can you post your revised component again?

I'll revisit the logic. I know I made a quick change at my end too so I need to revisit that when I am next with my machine.

Anyway, at least we have both confirmed the issue is due to water splash.

In your testing, there is a rather cool component called sim_pin you can add to your ini file so you can change the thresholds on the fly. See: linuxcnc.org/docs/devel/html/man/man1/sim_pin.1.html

If the probe comes on when it shouldn't then the bug has to be the code in the component.

Do the pins show up correctly in Halshow when this happens?

Can you post your revised component again?

I'll revisit the logic. I know I made a quick change at my end too so I need to revisit that when I am next with my machine.

Anyway, at least we have both confirmed the issue is due to water splash.

In your testing, there is a rather cool component called sim_pin you can add to your ini file so you can change the thresholds on the fly. See: linuxcnc.org/docs/devel/html/man/man1/sim_pin.1.html

Attachments:

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

Less

More

- Posts: 145

- Thank you received: 46

15 Apr 2020 19:19 - 15 Apr 2020 19:20 #164077

by Uthayne

Replied by Uthayne on topic Hypersensing with THCAD - better way to do ohmic sensing

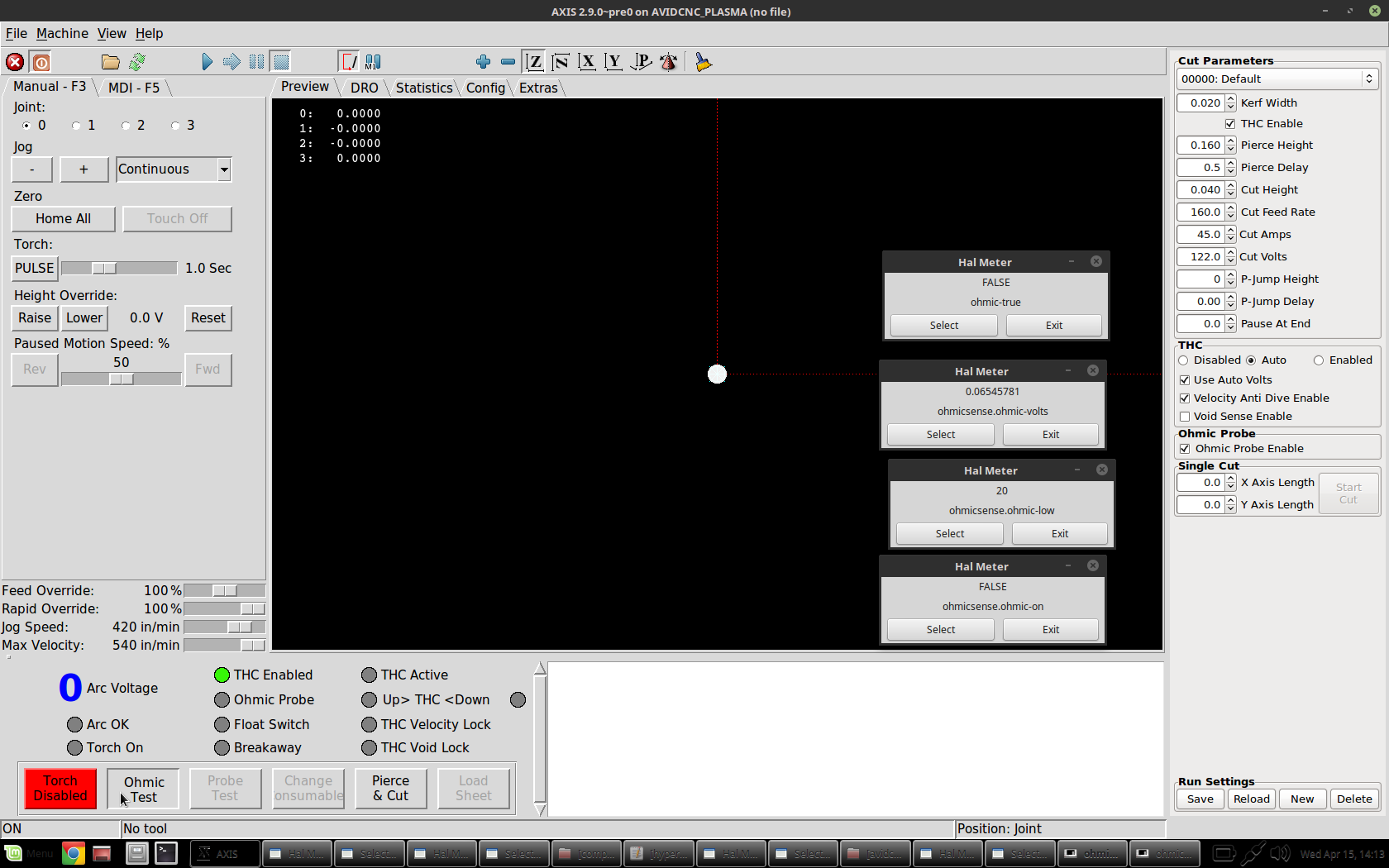

Rod, as of right now I'm back to using the stock component. (Attached)

I was able to brute force the component into working properly by changing the ohmic_low to a set value, i.e. 20

Then I didand it turned off at 20.0v

This will work until I investigate why it's not being pulled from the hal file to begin with.

Out of curiousity, why does there need to be a ohmic_low pin? Is it for hysterisis? Can the ohmic_threshold be enough

I was able to brute force the component into working properly by changing the ohmic_low to a set value, i.e. 20

if( ohmic_volts < ohmic_low)

ohmic_on = 0;if( ohmic_volts < 20.0)

ohmic_on = 0;Then I did

halcompile --install ohmic.compThis will work until I investigate why it's not being pulled from the hal file to begin with.

Out of curiousity, why does there need to be a ohmic_low pin? Is it for hysterisis? Can the ohmic_threshold be enough

Last edit: 15 Apr 2020 19:20 by Uthayne.

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

Less

More

- Posts: 145

- Thank you received: 46

15 Apr 2020 19:37 #164078

by Uthayne

Replied by Uthayne on topic Hypersensing with THCAD - better way to do ohmic sensing

halshow confirms that ohmic-low is being set at what was in my hal file

Shows current ohmic-volts @ 12.6888V

ohmic-low @ 22

ohmic-threshold @ 23

ohmic-on true

Shows current ohmic-volts @ 12.6888V

ohmic-low @ 22

ohmic-threshold @ 23

ohmic-on true

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

15 Apr 2020 19:49 #164079

by rodw

Replied by rodw on topic Hypersensing with THCAD - better way to do ohmic sensing

Initially, I had a single threshold but then I did some testing of the opto isolated relays I was using originally to see the hysteresis. They turned on way below their specified minimum voltage (at about 8 volts) and went off at about 5 volts. I thought the low on threshold and narrow hysterisis might cause reliability issues. We figured that by adding more hysteresis would be desirable and maybe prevent false triggering. But the intent was always to provide the ability to adjust the sensitivity by changing the voltage threshold to suit different environments.

The original experiment was based on a premise by PCW that the THCAD might be able to measure the resistance in the circuit. Which it does becasue we can see the voltage change as contact is made.

For the record, using the high values to deal with the water table proved very reliable. There is well over 1500 pierces here I did last week.

The biggest issue I had was warpage forcing a probe fault as the plate was above probe height but Phill has shared a revised plasmac.comp with a changed algorithm to deal with this.

So now we have had some success, I will revise the component and the docs when I get a chance.

The original experiment was based on a premise by PCW that the THCAD might be able to measure the resistance in the circuit. Which it does becasue we can see the voltage change as contact is made.

For the record, using the high values to deal with the water table proved very reliable. There is well over 1500 pierces here I did last week.

The biggest issue I had was warpage forcing a probe fault as the plate was above probe height but Phill has shared a revised plasmac.comp with a changed algorithm to deal with this.

So now we have had some success, I will revise the component and the docs when I get a chance.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Apr 2020 04:37 #164397

by rodw

Replied by rodw on topic Hypersensing with THCAD - better way to do ohmic sensing

I wonder with the feedback from water table users that the algorithm is not changed to be more like:

1. Set a voltage threshold (say 23.8 volts) that must be exceeded to trigger

2. Set a number of servo cycles the voltage signal must remain a constant state before the ohmic-on signal (say 3 servo cycles)

So then when probing the voltage must exceed 23.8 volts and be trending upwards for 3 servo cycles before turning on.

And then when it fell below that threshold and was trending down for 3 consecutive servo cycles we turn it off.

By looking at the trend, it would be more responsive than just waiting for a number of servo cycles after the threshold was crossed.

Let me know your thoughts guys.

1. Set a voltage threshold (say 23.8 volts) that must be exceeded to trigger

2. Set a number of servo cycles the voltage signal must remain a constant state before the ohmic-on signal (say 3 servo cycles)

So then when probing the voltage must exceed 23.8 volts and be trending upwards for 3 servo cycles before turning on.

And then when it fell below that threshold and was trending down for 3 consecutive servo cycles we turn it off.

By looking at the trend, it would be more responsive than just waiting for a number of servo cycles after the threshold was crossed.

Let me know your thoughts guys.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Hypersensing with THCAD - better way to do ohmic sensing

Time to create page: 0.226 seconds