Probe_basic Toolchanger

- spumco

- Offline

- Platinum Member

-

- Posts: 1965

- Thank you received: 799

Very good point. And maybe if the wheel is printed strong enough it'd work as-is on a lightweight platter. I'd certainly use a roller bearing for the drive pin, but having a little bit of compliance in the rotational position is a benefit.With 3d printers, trial and error is pretty painless and cheap.

We'll see where CNC_ANDI wants to go with the mechanical side and keep nudging him to glory...

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1965

- Thank you received: 799

Here's a CAD model of a geneva wheel:

grabcad.com/library/geneva-mechanism-mkii-1

It could use some improvements for use on an ATC, but it's parametric and should get you going.

Things to consider:

- slots wide enough to use a roller or needle bearing on the drive pin

- Mount the drive wheel above with the pin pointing down

- Print the driven gear wheel with a continuous diameter for a few layers (i.e. make a solid circle for it to 'sit' on) to help support the gear teeth/tabs

- Add a bunch of screw holes to the driven gear so it can be screwed tight to the main carousel platter

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

- Posts: 233

- Thank you received: 31

i ordered a mesa 7i78 for more step/dir Ports...

for the future i need more axis anyway.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1965

- Thank you received: 799

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21098

- Thank you received: 7205

Not the rack one, that is easy in hardware and software.

Something more complicated, say, something with a Geneva mechanism?

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

- Posts: 233

- Thank you received: 31

Anyone know of a usable 3D printed ATC?

Not the rack one, that is easy in hardware and software.

Something more complicated, say, something with a Geneva mechanism?

don´t find anything, hoping my Printred ATC runs good....

Do you think you want to try a geneva mechanism? It'll make the software side much, much easier. The stepper can be driven in velocity mode through th Mesa you just bought.

i don´t know... i thnik im to stupid to create a geneva mechanism....

found one for a 10 tool changer... but 10x don´t work on my machine. or i have to do the plate much bigger.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21098

- Thank you received: 7205

en.wikipedia.org/wiki/File:Geneva_mechan...6spoke_animation.gif

Now lets see if gifs can be attached here:

Attachments:

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1965

- Thank you received: 799

The one I linked to earlier on GrabCAD is parametric. You can easily edit the number of slots.

Anyone know of a usable 3D printed ATC?

Not the rack one, that is easy in hardware and software.

Something more complicated, say, something with a Geneva mechanism?

don´t find anything, hoping my Printred ATC runs good....Do you think you want to try a geneva mechanism? It'll make the software side much, much easier. The stepper can be driven in velocity mode through th Mesa you just bought.

i don´t know... i thnik im to stupid to create a geneva mechanism....

found one for a 10 tool changer... but 10x don´t work on my machine. or i have to do the plate much bigger.

There are also plenty of YT vids on creating a geneva mechanism in F360 and other CAD software.

Finally, if you post your existing design as a .step file or .f3d file I'll have a go at making one for you. I think that an internal geneva mechanism would be better for a 3d printed application.

Where are you located and what materials/suppliers are available to you? You mentioned Germany, right? So you can easily get bearings, pins, stuff like that?

Please Log in or Create an account to join the conversation.

- CNC_ANDI

- Offline

- Elite Member

-

- Posts: 233

- Thank you received: 31

yes for sure...

added the actually status from my atc project... i have tested to place in my 63mm Facemill and it works with that motor position...

Attachments:

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1965

- Thank you received: 799

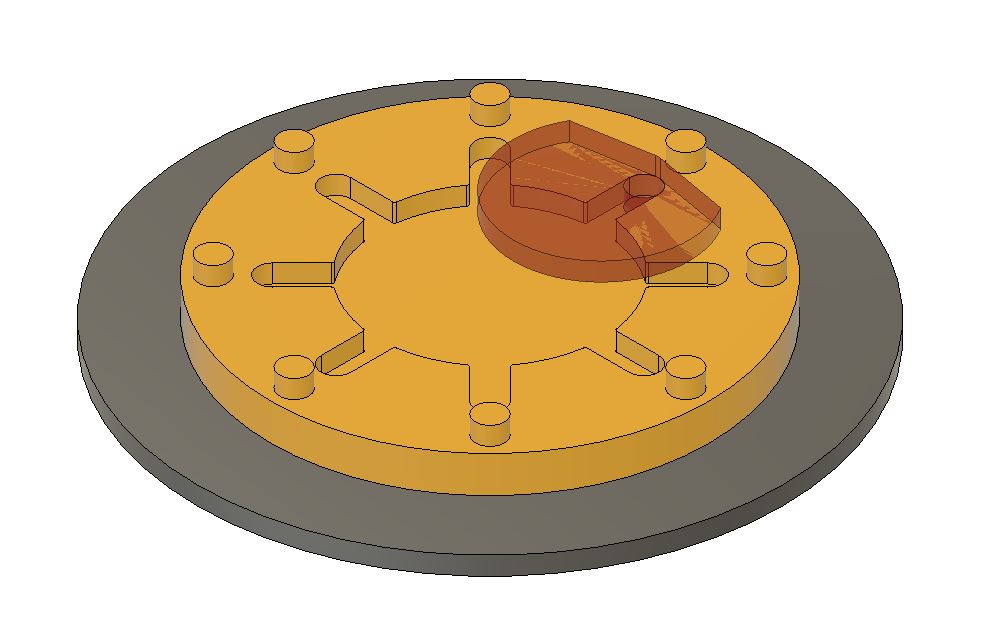

Internal geneva drive, obviously not detailed out... but works in F360.

- All contact is through rolling elements (bearings), so no plastic wearing out or requiring lubricant. The drive wheel pin is a 10mm needle bearing on a 6mm shoulder screw, and the outer anti-rotation pins are the same.

- Driven wheel should be easy to print

- Drive wheel should be easy to print, but should really use a metal flange to attach to the Nema 23 (?) motor.

- Yellow driven wheel will get mounted to the tool carousel from below using slotted holes to permit slight alignment adjustment to the spindle.

- Outer pins can also double as pocket sensor flags, and one can be longer for a home flag.

- Everything in the model is in 'Murican units, but I've got the constraints and relationships sorted out. For reference, the driven wheel is about 150mm.

In addtion, I plan to (or suggest you) add a spring-loaded hinge on the carousel mount. BT/ISO30 spindles will push the tool down as the drawbar grabs it and you need some compliance in the system. You also want a little compliance in the rotational position and the clearance between the driving wheel and lock pins will set that.

Attachments:

Please Log in or Create an account to join the conversation.