- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

14 Sep 2021 14:26 #220601

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Question, how much would you pay for one of those Z axis, fully assembled and how much for a kit without motor ?

Or how much would you sell one if you build it ?

Or how much would you sell one if you build it ?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

14 Sep 2021 15:30 #220614

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Attachments:

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

14 Sep 2021 20:40 #220648

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

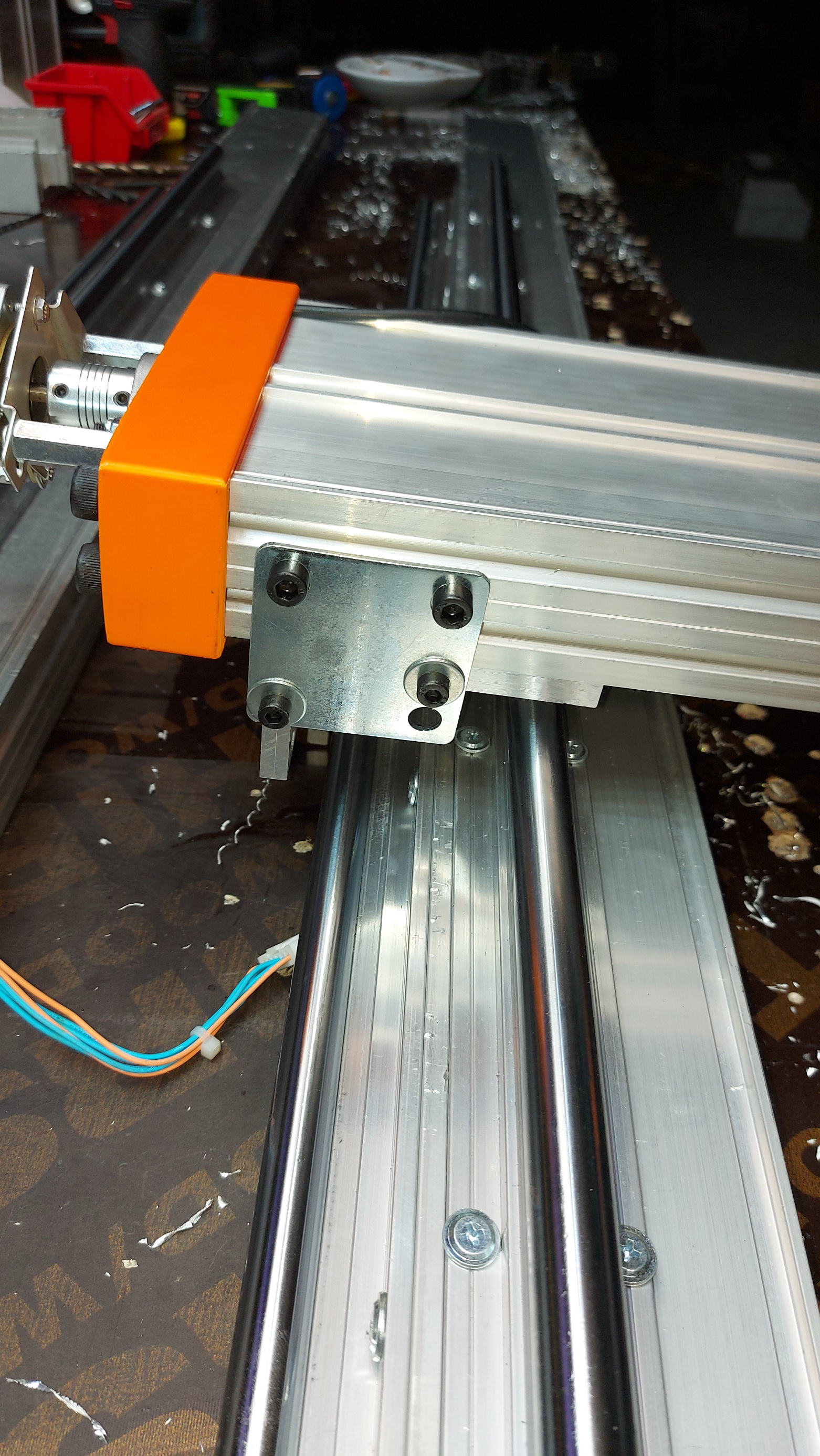

Doing some test fittings and "research" !

This is supposed to be the axis the moves perpendicular to square tube, so have to think how to also make/attach the swivel and tilting parts to it as i am aiming for full 5 axis. Gona be interesting how this ends up.

This is 3.15M long aluminium gantry with a single HiWin HGR25 since i had one rusting away and seing as i do not have any more of SBR16, only enough for 2 machines. Planing to mount this on the 1.4M long 150x150x4 used for Y axis ending up in 1.2X2.4M cut area, and the best thing is next time i get 6M SBR25 = make 2 of Y axis at full 6M and bolt this gantry to it making it 5.8X2.4M. Strange dimensions, i know, but when life gives you lemons ....

This is supposed to be the axis the moves perpendicular to square tube, so have to think how to also make/attach the swivel and tilting parts to it as i am aiming for full 5 axis. Gona be interesting how this ends up.

This is 3.15M long aluminium gantry with a single HiWin HGR25 since i had one rusting away and seing as i do not have any more of SBR16, only enough for 2 machines. Planing to mount this on the 1.4M long 150x150x4 used for Y axis ending up in 1.2X2.4M cut area, and the best thing is next time i get 6M SBR25 = make 2 of Y axis at full 6M and bolt this gantry to it making it 5.8X2.4M. Strange dimensions, i know, but when life gives you lemons ....

Attachments:

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

15 Sep 2021 18:09 #220725

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Question, how much would you pay for one of those Z axis, fully assembled and how much for a kit without motor ?

Or how much would you sell one if you build it ?

Tom i would add up a total cost per unit for materials first then figure out exactly how much time you have in labor and decide what labor costs are per unit then add some extra in for the business as profit so the business can grow.

so if it cost $100 in material and takes 4 hours to produce and you pay yourself or someone else $25 per hour for a total labor cost of $100 the business should make $100 at least on top of this in a perfect world but China Pricing does not allow this if the market is saturated with like products.

you need the business to get a cut so you can grow and you have to be able to pay yourself or someone else to process the units. so this is a basic guide line i use to evaluate things. it's tough since China can sell a lot of stuff cheaper than i can even buy material for? but it does seem like the prices are going up on their goods lately. it makes you wonder how they can buy material and process it and ship it so far and make anything on it? the government probably has something to do with it all but who knows?

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

15 Sep 2021 18:17 #220727

by snowgoer540

Make 5 Axis!

Do you plan to use air plasma for that?

It'll be interesting to see how you handle the amperage changes (or feed rate changes?) required as the cut thickness increases due to changes in the angle. Or I guess you could figure that out up front with some simple trig... hmm.

At my old job, we had a ...many... axis high def plasma pipe cutter, and the bevels for weld prep to the "stab ins" became quite challenging. I am not sure how Alltra handled that exactly, but it was done in conjunction with pronest. Here is the exact machine, for those curious: www.alltracorp.com/alltra-pipe-cutting

At any rate, if anyone can pull it off, I'm sure it's you! I'm tuned in waiting to see some sparks!!

Replied by snowgoer540 on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

but when life gives you lemons ....

Make 5 Axis!

Do you plan to use air plasma for that?

It'll be interesting to see how you handle the amperage changes (or feed rate changes?) required as the cut thickness increases due to changes in the angle. Or I guess you could figure that out up front with some simple trig... hmm.

At my old job, we had a ...many... axis high def plasma pipe cutter, and the bevels for weld prep to the "stab ins" became quite challenging. I am not sure how Alltra handled that exactly, but it was done in conjunction with pronest. Here is the exact machine, for those curious: www.alltracorp.com/alltra-pipe-cutting

At any rate, if anyone can pull it off, I'm sure it's you! I'm tuned in waiting to see some sparks!!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

15 Sep 2021 22:33 #220745

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

@MachineDude,

Dang you were close, it came out to exactly 110 Euro for parts only, and that high since i have to pay 5 E/piece for the KFL08 bearing, 5.5 E/P for LM12UU (4 of them), 29 E/P for china Nema 17 motor, 19 E/P for the lead screw with nut and coupling, etc ....

All this might change soon as yesterday found out some internal information's about the customs here, when ordering stuff from abroad as a private person they have total power to do whatever they see fit to get as much money as possible, but when ordering as a company they must stick to the legal 19% tax + 10% customs + some bureaucracy cr@p that can not go over 10%. I will have to test this promptly ! Will pay 40% gladly. Oh yes, they can not also pull the "we are busy" stuff at the cargo part.

Will pay 40% gladly. Oh yes, they can not also pull the "we are busy" stuff at the cargo part.

@Snowwy,

I have searched and looked and analyzed plenty of pipe/tube cutting machines online and missed the one you posted, somehow ! Looks interesting and much easier to do for big diameters than what i use.

Still not sure how to go about for the square tube one. ...

Dang you were close, it came out to exactly 110 Euro for parts only, and that high since i have to pay 5 E/piece for the KFL08 bearing, 5.5 E/P for LM12UU (4 of them), 29 E/P for china Nema 17 motor, 19 E/P for the lead screw with nut and coupling, etc ....

All this might change soon as yesterday found out some internal information's about the customs here, when ordering stuff from abroad as a private person they have total power to do whatever they see fit to get as much money as possible, but when ordering as a company they must stick to the legal 19% tax + 10% customs + some bureaucracy cr@p that can not go over 10%. I will have to test this promptly !

@Snowwy,

I have searched and looked and analyzed plenty of pipe/tube cutting machines online and missed the one you posted, somehow ! Looks interesting and much easier to do for big diameters than what i use.

Still not sure how to go about for the square tube one. ...

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

17 Sep 2021 09:54 #220872

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

not sure what kind of volume you plan to sell at but 3D printing is pretty slow if you need a bunch of parts. i don't think injection molding is something in need at this point but one other possible solution for the 3D printed parts might be casting plastic parts from a mold. that might open up a bottle neck in your production methods if you get something going in volume. probably faster than 3D printing but not as set up intensive as injection molding.

i know you can tint the casting material to what ever color you want and i'm pretty sure you could even make them glow in the dark they even have casting rubbers. i have some i got a while back for something but i might try casting wipers for the grinder project since the old ones are dry rotted and brittle on the 3" columns .

they even have casting rubbers. i have some i got a while back for something but i might try casting wipers for the grinder project since the old ones are dry rotted and brittle on the 3" columns .

i know you can tint the casting material to what ever color you want and i'm pretty sure you could even make them glow in the dark

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

17 Sep 2021 14:17 #220897

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Not planing yet, just a thought.

But i do have 8 of 3D printers and building 2 small ones and a huge one.

Can not sell them as the post office here does not function at all, so only DHL is viable and that adds over 100$ to the price.

But i do have 8 of 3D printers and building 2 small ones and a huge one.

Can not sell them as the post office here does not function at all, so only DHL is viable and that adds over 100$ to the price.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

18 Sep 2021 14:18 - 18 Sep 2021 14:21 #221000

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Gantries for 2 of the machines are nearly done, reductions, belts and Z axis monuts next.

Got news that legs for all 3 plate cutting ones are bent and painted black, waiting for the blue powder coat for the 150X150X4 Y axis. Not looking forward to all the holes and tapping that has to be done, but it has to be done.

Oh joy !

Need to start work on another two machines, mills, one for me for Alu and one for engraving text on Granite and marble.

More holes ....

Got news that legs for all 3 plate cutting ones are bent and painted black, waiting for the blue powder coat for the 150X150X4 Y axis. Not looking forward to all the holes and tapping that has to be done, but it has to be done.

Oh joy !

Need to start work on another two machines, mills, one for me for Alu and one for engraving text on Granite and marble.

More holes ....

Attachments:

Last edit: 18 Sep 2021 14:21 by tommylight.

The following user(s) said Thank You: billykid, shpatb, snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

18 Sep 2021 16:23 #221020

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Attachments:

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 1.127 seconds