- Other Stuff

- Show Your Stuff

- Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

05 Jun 2020 03:42 #170196

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

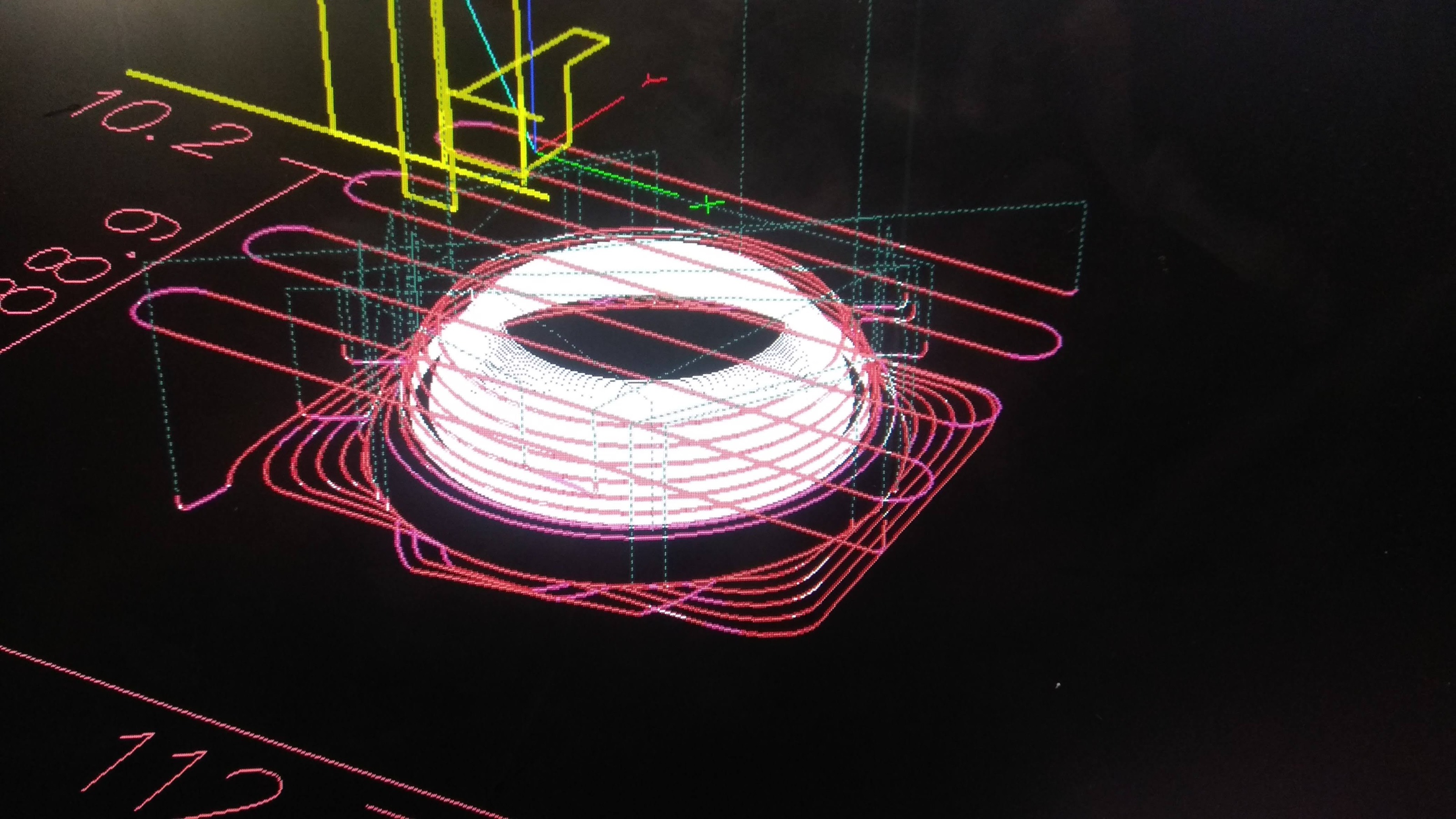

more photos

I know how much everyone loves them. if you don't have photos it didn't happen lol

I did a accuracy test today to see how my servo tuning was. I have since found out that I actually need to change some parameters but the accuracy was still pretty good.

at 300 mm/min finishing speed with a 0.05mm cut 20 mm deep and a nice ultra sharp carbide endmill for alloy I milled a 110 mm circle and measured it afterwards.

It came out definitely within 0.01mm but possibly within 0.005mm of round when measuring all over with a mitutoyo mic

basicely it was close enough that it was hard to decide which side was the largest so pretty happy with that.

at 2000mm min the accuracy was still about 0.015 tops

I know how much everyone loves them. if you don't have photos it didn't happen lol

I did a accuracy test today to see how my servo tuning was. I have since found out that I actually need to change some parameters but the accuracy was still pretty good.

at 300 mm/min finishing speed with a 0.05mm cut 20 mm deep and a nice ultra sharp carbide endmill for alloy I milled a 110 mm circle and measured it afterwards.

It came out definitely within 0.01mm but possibly within 0.005mm of round when measuring all over with a mitutoyo mic

basicely it was close enough that it was hard to decide which side was the largest so pretty happy with that.

at 2000mm min the accuracy was still about 0.015 tops

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

05 Jun 2020 09:49 #170225

by tommylight

Replied by tommylight on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Very nice, indeed.

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

05 Jun 2020 11:03 #170236

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

thanks tommy

funny thing is I have found that the servos are set up with the wrong motor codes lol. I was sure I got it right but obviously not.

so I can probably get it better than this. But my encoder counter in the 7i76 is not working now very good so I will just leave it as is for now i think and wait for my 7i89 encoder counter card to come.

that is the good thing about linear bearing machines they are often in better condition and have much less backlash than box way machines

actually me spindle encoder card arrived yesterday so i need to connect it up with me vfd encoder card and set up closed loop vector control for the spindle and then get the spindle orientation working.

I have my whole toolchanger working good now I think apart from the spindle orientation so once that is done that will be amazing

then just need to tidy up the wiring once the extra cards arrive.

and the machine is pretty much finished

yeah right

next I need to set up the probe basic screens properly

set up a auto touch off probe for toolsetting

and maybe put a 4 and 5 axis on the table.

and then fix the cnc lathe lol.

it just doesn't end does it.

I am becoming like the rest of you guys this retrofitting this is fun!

regards

Andrew

funny thing is I have found that the servos are set up with the wrong motor codes lol. I was sure I got it right but obviously not.

so I can probably get it better than this. But my encoder counter in the 7i76 is not working now very good so I will just leave it as is for now i think and wait for my 7i89 encoder counter card to come.

that is the good thing about linear bearing machines they are often in better condition and have much less backlash than box way machines

actually me spindle encoder card arrived yesterday so i need to connect it up with me vfd encoder card and set up closed loop vector control for the spindle and then get the spindle orientation working.

I have my whole toolchanger working good now I think apart from the spindle orientation so once that is done that will be amazing

then just need to tidy up the wiring once the extra cards arrive.

and the machine is pretty much finished

yeah right

next I need to set up the probe basic screens properly

set up a auto touch off probe for toolsetting

and maybe put a 4 and 5 axis on the table.

and then fix the cnc lathe lol.

it just doesn't end does it.

I am becoming like the rest of you guys this retrofitting this is fun!

regards

Andrew

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

05 Jun 2020 11:06 #170237

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

actually on a side matter the first few jobs on this cnc mill have almost paid off half the total cost of the machine and the retrofit cost. and that was just a weeks work.

so there is definitely money in this when we don't have to spend 100k on a machine

I can buy them for 4-5 k for a nice machine with dead control about 17 years old.. and fix them for about 3k. that includes new motors and drives. if I could reuse the original stuff the cost would go down of course

regards

Andrew

so there is definitely money in this when we don't have to spend 100k on a machine

I can buy them for 4-5 k for a nice machine with dead control about 17 years old.. and fix them for about 3k. that includes new motors and drives. if I could reuse the original stuff the cost would go down of course

regards

Andrew

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

06 Jun 2020 08:48 - 06 Jun 2020 08:52 #170324

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

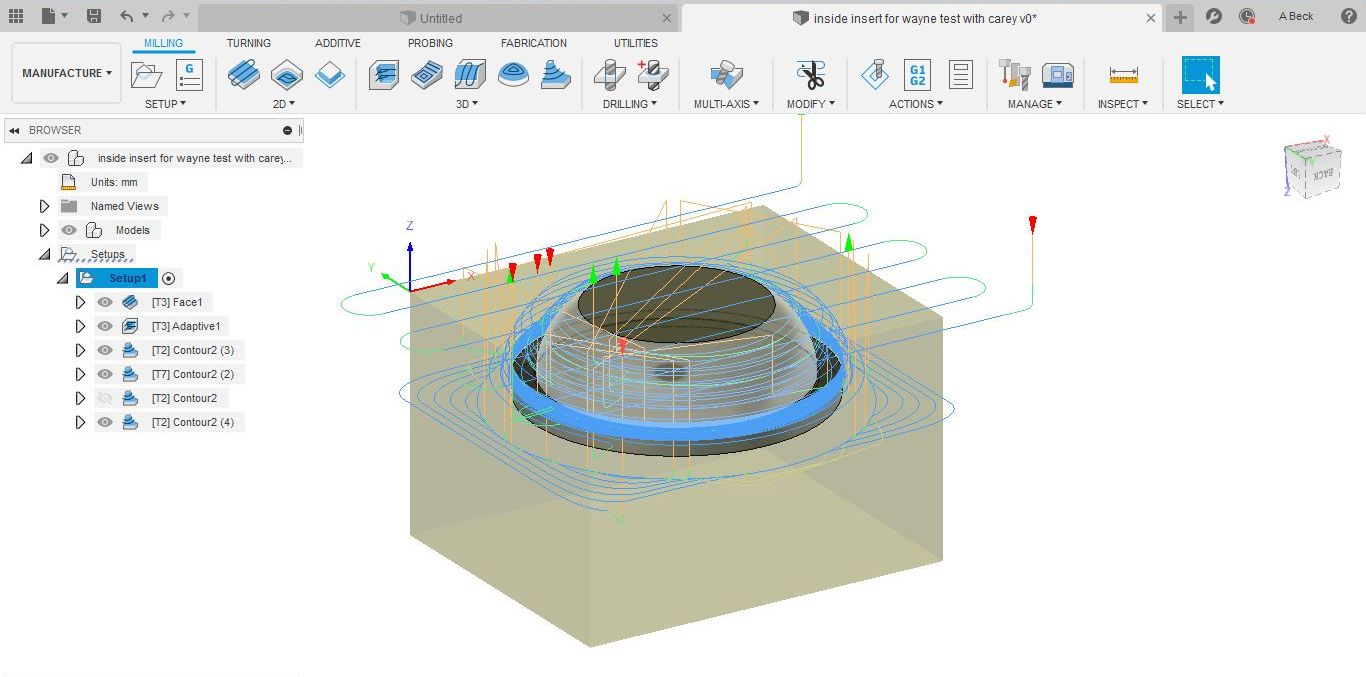

hey guys just some more photos here I am making a injection mold on my machine. and thought I would share some photos here of the processLinuxcnc doesn't get enough people taking photos of stuff they have made on big machines in commercial shops. this leads to many people thinking it is not capable enough for big stuff. But it totally is and I think I will keep posting photos here for the next person that comes along looking for a solution to fix there machine.

Attachments:

Last edit: 06 Jun 2020 08:52 by Becksvill. Reason: fixing photo

The following user(s) said Thank You: tommylight, johnmc1

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

11 Jun 2020 10:13 #171106

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

this deserves a update lol

I bought another cnc mill! yeha. the same machine with a dead control also.

it is almost the exact same model as what I already have

my retrofitted cnc mill has done quite a lot of hrs. and is getting tired.

this new one is almost unused and comes with a 4th axis

does anyone have any interest in some photos of how I move it down to my shed? it is coming 400 km away

I am planning on keeping both cnc mills as one is never enough!

just need to get it going and also get my cnc lathe going and we are away. then I need to make them pay for themselves

regards

Andrew

I bought another cnc mill! yeha. the same machine with a dead control also.

it is almost the exact same model as what I already have

my retrofitted cnc mill has done quite a lot of hrs. and is getting tired.

this new one is almost unused and comes with a 4th axis

does anyone have any interest in some photos of how I move it down to my shed? it is coming 400 km away

I am planning on keeping both cnc mills as one is never enough!

just need to get it going and also get my cnc lathe going and we are away. then I need to make them pay for themselves

regards

Andrew

Attachments:

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

11 Jun 2020 10:15 #171107

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

forgot to say it comes with about 40 holders

and I am buying it for just over scrap price

so heaps more questions coming guys!

and I am buying it for just over scrap price

so heaps more questions coming guys!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

29 Jun 2020 21:34 - 29 Jun 2020 21:40 #173140

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

hey guys here are some photos of the new machine I bought. same heidenhain controller as last time. another project on the back burner for a few months lol

one thing about the new machine that i didn't realise at the time is the new machine has box ways.

my other machine has linear bearings on X and Y and box ways on Z

old box ways are a pain as you can't really fix them when they are worn out. But new box ways are much more rigid than linear ball bearings. so I will have a fast machine now and a rigid machine which is pretty nice

one thing about the new machine that i didn't realise at the time is the new machine has box ways.

my other machine has linear bearings on X and Y and box ways on Z

old box ways are a pain as you can't really fix them when they are worn out. But new box ways are much more rigid than linear ball bearings. so I will have a fast machine now and a rigid machine which is pretty nice

Attachments:

Last edit: 29 Jun 2020 21:40 by Becksvill. Reason: adding text to photo

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 94

29 Jun 2020 21:37 #173141

by Becksvill

Replied by Becksvill on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

I have a auto tool setter I bought from aliexpress that I need to set up and I think the easiest way is to use probe basic and I am also wanting it for the tool probing and just all the awesome futures it has..

anyway if anyone has any expertise there I would love to ask you guys. I will make some posts on the forum also but if anyone sees this and can help let me know

regards

Andrew

anyway if anyone has any expertise there I would love to ask you guys. I will make some posts on the forum also but if anyone sees this and can help let me know

regards

Andrew

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

29 Jun 2020 21:43 #173142

by tommylight

Replied by tommylight on topic Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Nice!

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- Vertical Machining Centre Retrofit with Chinese Servo Drives Build Thread (NZ)

Time to create page: 0.701 seconds