- Other Stuff

- Show Your Stuff

- Developments on my Home built 5C CNC Lathe - new spindle and progress on the ATC

Developments on my Home built 5C CNC Lathe - new spindle and progress on the ATC

- NoJo

- Offline

- Elite Member

-

- Posts: 180

- Thank you received: 43

I am still rather lost, but there have been a few knowledgeable moments, so I am going to keep at it till I have something around which I can ask useful questions..

Maybe in a week or so..

Thanks!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21345

- Thank you received: 7284

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

- Posts: 180

- Thank you received: 43

Thanks

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

If you can't get it working then I am sure there will be help here. Not from me for another week, though. I am just back from 2 weeks working in Spain and now have a week away from home on "holiday" (pointing a barn)

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

- Posts: 180

- Thank you received: 43

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

- Posts: 180

- Thank you received: 43

The Live spindle is now the issue..

Before I started on it's component I wanted to understand better how the G_code file would command the spindle and the coordinated C_axis motion.

This spindle is axial to the main spindle, so would only cut on the face of the workpiece normally.

Let's take a simple job - a 20mm diameter shaft in the chuck, and machining a hexagon head on the end of the shaft, say 5mm long.The Z motion is easy to comprehend - move till milling cutter is at stock start, and move in 5mm towards the headstock to cut the 5mm long hex.To cut the flats requires that the C axis and X axis move in a coordinated manner cutting the flat.

So I am trying to understand what G/M codes would perform this motion in Linuxcnc, and am not having much luck.

Trying a different approach I searched ( many many hours..) for CAM packages that were 'affordable' and able to do such a hex head machining process. I found 2 packages, e-CamV4 from a fellow in italy and KipwareT from Kentech in the USA.

e-Cam about 300 Euro and KipwareT around $500.00 - both do C axis and Live spindle.

e_Cam allows basic cross section sketching of side and face of the job and does turn and end-face milling, such as the HEX end on a shaft. e_Cam is free to use on weekends.

KipwareT is much more Pro, and is more a conversational CAM SW, and seems very powerful.

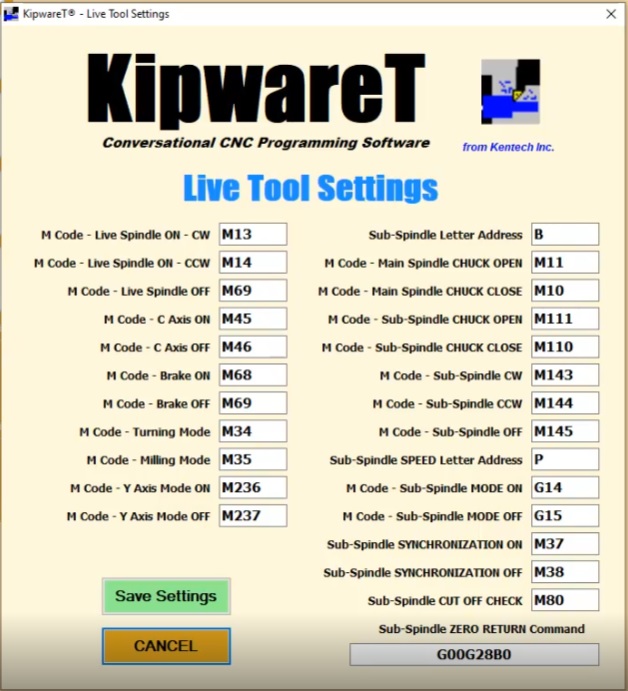

Discussing with Kentech if they could provide a G-Code file of my hex head shaft, they requested I fill in a G-Code Live tool setting sheet which is used by the SW to append the appropriate G_codes for your machine.

Except, I do not know what G_Codes to use!

Anyway, they did a sample G_code file for me. I also did one with e_Cam.The two files could not be more different! I tried to compare the G_Codes to LinxCNC's Gcode list, etc, and am lost.

I have attached the two G-code sample files ...

I would like top appeal to some LinuxCNC G_code boffins to please give me some guidance on this. I am not sure how my current C_axis implementation is going to work with this in coordinated C/X manner.

At a bit of a loss!

EDIT:

After digging more, I suspect I need to use G12.1 and G13.1 ( Polar Interpolation modes) and this does not exist on LinuxCNC I believe.

In which case I may be wasting my time with a C axis and live tooling on this lathe..

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4660

- Thank you received: 2078

I think, in order to use a 'regular' XYZ Gcode on a XZC machine you would need to create your own kinematic.So I am trying to understand what G/M codes would perform this motion in Linuxcnc, and am not having much luck.

I made a sim-config using a rough custom kinematic: forum.linuxcnc.org/38-general-linuxcnc-q...tics?start=10#212389

If you can get the required math done in a relatively affordable CAM then I would think that to be the better solution. The sample code you attached that uses XZC moves looks promising.

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

- Posts: 180

- Thank you received: 43

One only ends up discovering these things when you get to the stage where you start digging deep to understand...

The file I attached - the one with XZC moves - is also rather useless I fear.. It commands G18 mode, then has lots of arc moves with I/J which cannot work in XZ plane - J is only applicable in XY plane. Blindly changing all J to K does not work - results in 'Radius to end of arc differs from radius to start' errors galore as well.

Using G17 instead of G18 is inappropriate in a lathe...

I any case, I don't see how arcs could implement the likeness of a polar computation. the CAm would really need to break up the polar moves into (small) incremental C angle and X cordinated moves - No CAM I tried can do that.

All other CAM's I have evaluated - CAMWORKS, MASTERCAM, SPRUTECAM, EXCAM, etc, expect an industry style cnc machine - FANUC full monty, HAAS, Mori, Mazaak, Doosan, etc, and so expect full polar interpolation functions (D12.1/D13.1, etc) and don't do the math for a simpleton machine like mine..

Appears there is no useful solution here, not even a complex one. Have to take a breath and contemplate what next..

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

- Posts: 529

- Thank you received: 140

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 808

I've been following your progress with interest.Appears there is no useful solution here, not even a complex one. Have to take a breath and contemplate what next..

I, too, did not realize that polar interpolation was unavailable in LCNC. I've been delving in to LCNC on my mill (retrofit about finished) as a training exercise for when my XZC live-tool lathe control dies.

Before throwing in the towel, you might approach some commercial CAM post processor vendors/authors about it. It may be possible to have the post processor compute & output XZC moves without the use of G12.1. Or at least post the question on the various CAM user forums and see if anyone else has a similar situation.

I use F360 for my lathe (Fanuc 21TB by Emco), and the post processor does not output G12.1/G13.1 moves. It outputs straight X/Z/C moves, and there's just IK G18 moves (no J).

I think polar interpolation was created to make it easier to hand-program complicated moves on fairly simple part features. CAM doesn't (or shouldn't) need the machine to interpolate anything; just to go where it's told.

-Ralph

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- Developments on my Home built 5C CNC Lathe - new spindle and progress on the ATC