My 7i76e Connection Sheet

- Gommiswald

- Offline

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 0

18 Apr 2017 20:04 #91598

by Gommiswald

Replied by Gommiswald on topic My 7i76e Connection Sheet

Sorry for the double post!!! I didn't know where to post my question.

623/5000

My solution is now that I connect the OMRON sensors to 5VDC.

Another question: Beckhoff AX2500 needs differential voltage signals (+ 10V / -10V) for the frequency and direction of rotation. (A servomotor as main spindle drive). Can one now simply connect Spindle + and Spindle - with the drive connections and the should then function? So spindle+ and spindle- means differential output?

And lastly: Why not switch a relay between the inductive proximity switches and the 7I76E connections? 24V switched by the FieldPower connection via a relay? There would be the whole thing with the resistance simply fall away?

623/5000

My solution is now that I connect the OMRON sensors to 5VDC.

Another question: Beckhoff AX2500 needs differential voltage signals (+ 10V / -10V) for the frequency and direction of rotation. (A servomotor as main spindle drive). Can one now simply connect Spindle + and Spindle - with the drive connections and the should then function? So spindle+ and spindle- means differential output?

And lastly: Why not switch a relay between the inductive proximity switches and the 7I76E connections? 24V switched by the FieldPower connection via a relay? There would be the whole thing with the resistance simply fall away?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

18 Apr 2017 21:41 #91607

by tommylight

More expencive, more work. Much safer and fully isolated from the machine.

Replied by tommylight on topic My 7i76e Connection Sheet

I do that for plasma cutters to limit imterferences, namely every limit switch and float switch has a relay power by 24V, the contacts just short the inputsbto the ground. Normaly closed limit switches, so whatever breaks betveen them, i get an error.And lastly: Why not switch a relay between the inductive proximity switches and the 7I76E connections? 24V switched by the FieldPower connection via a relay? There would be the whole thing with the resistance simply fall away?

More expencive, more work. Much safer and fully isolated from the machine.

Please Log in or Create an account to join the conversation.

- Gommiswald

- Offline

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 0

14 May 2017 20:55 #93199

by Gommiswald

Replied by Gommiswald on topic My 7i76e Connection Sheet

Hi

Now my little selfmade CNC Lathe works fine with the 7i76e Mesa Card. A great card with great functions. The problem with the feedback I solved from one side with the encoder output of the Beckhoff AX servo drive and the Index Signal I take from the Omron photosensor. I didn't need to change the voltage from 24 to 5V. I just connected the signal to an optocoupler relay and then to the encoder part of the 7i76e. First I had some problem, because I didn't get an index signal. This index signal is single ended and the signal A and B are differential. But at the moment, when I took away the connections of A- and B- and installed the jumpers 10-13 in the right order, the index signal runs great, so G76 threading works wonderful.

My experience is the one, that one has to try and change and try, until it works. But it is great, that there is a forum and I used it very often until the lathe worked as it has to work!

Best regards

Daniel

Now my little selfmade CNC Lathe works fine with the 7i76e Mesa Card. A great card with great functions. The problem with the feedback I solved from one side with the encoder output of the Beckhoff AX servo drive and the Index Signal I take from the Omron photosensor. I didn't need to change the voltage from 24 to 5V. I just connected the signal to an optocoupler relay and then to the encoder part of the 7i76e. First I had some problem, because I didn't get an index signal. This index signal is single ended and the signal A and B are differential. But at the moment, when I took away the connections of A- and B- and installed the jumpers 10-13 in the right order, the index signal runs great, so G76 threading works wonderful.

My experience is the one, that one has to try and change and try, until it works. But it is great, that there is a forum and I used it very often until the lathe worked as it has to work!

Best regards

Daniel

Please Log in or Create an account to join the conversation.

- Gommiswald

- Offline

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 0

19 Dec 2017 20:19 #103360

by Gommiswald

Replied by Gommiswald on topic My 7i76e Connection Sheet

Hi Norbert

Thanks a lot for your wiring diagram. A really great helpful piece of work. Just one question. I want to add an analog in on input 0 for feed override for my Schaublin 128CNC retrofit. Have you maybe a link for a HAL example to configure this analog- in "feed override".

Regards from Switzerland

Daniel

Thanks a lot for your wiring diagram. A really great helpful piece of work. Just one question. I want to add an analog in on input 0 for feed override for my Schaublin 128CNC retrofit. Have you maybe a link for a HAL example to configure this analog- in "feed override".

Regards from Switzerland

Daniel

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

19 Dec 2017 21:31 #103363

by rodw

Replied by rodw on topic My 7i76e Connection Sheet

Daniel, thats a really good idea and you would probably get more people to look at your question if you raised a seperate thread.

I think it would be pretty easy to do. The 7i76e has analog voltage pins that return the voltage read. Say you put a potentiometer on the field power (I will assume 24 volts), you would need to pick a voltage to represent zero override (say 12 volts). you could use mult2 (with the inverse of 12) to set a 0% to 200% range (0.0-2.0) If say you wanted to limit the control to only allow say 80% to 120% , you could use the scale component to achieve this.

I think it would be pretty easy to do. The 7i76e has analog voltage pins that return the voltage read. Say you put a potentiometer on the field power (I will assume 24 volts), you would need to pick a voltage to represent zero override (say 12 volts). you could use mult2 (with the inverse of 12) to set a 0% to 200% range (0.0-2.0) If say you wanted to limit the control to only allow say 80% to 120% , you could use the scale component to achieve this.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

24 Dec 2017 00:53 #103502

by andypugh

Replied by andypugh on topic My 7i76e Connection Sheet

Check the manual, some analogue inputs on some boards (7i64 for example) are 3.3V max.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

24 Dec 2017 00:59 #103503

by rodw

The 7i76e analog inputs discussed on this thread are 8 bit, 36.3 volts full scale with an accuracy of +-5%

Replied by rodw on topic My 7i76e Connection Sheet

Check the manual, some analogue inputs on some boards (7i64 for example) are 3.3V max.

The 7i76e analog inputs discussed on this thread are 8 bit, 36.3 volts full scale with an accuracy of +-5%

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- +Jan+

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 16

30 Dec 2017 14:29 - 30 Dec 2017 14:30 #103851

by +Jan+

Replied by +Jan+ on topic My 7i76e Connection Sheet

Hello,

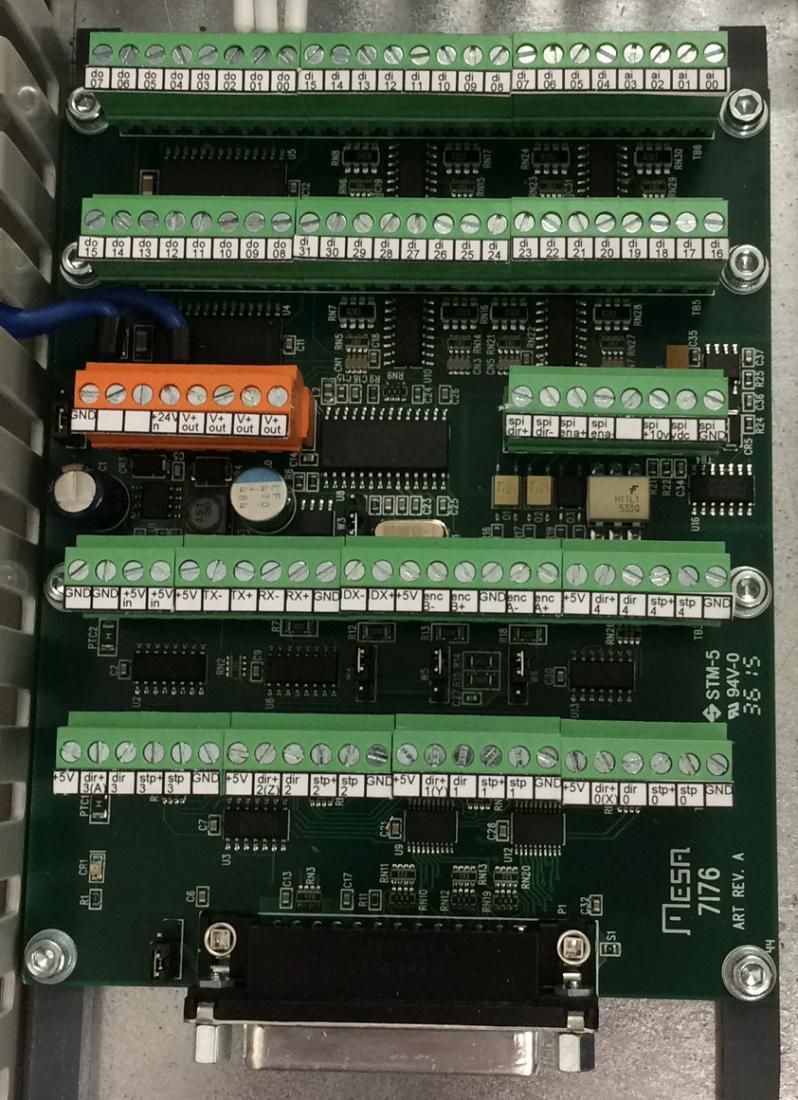

I think this might fit here, some days ago I made labels for the clamping brackets of the 7i76:

I attach the pdf and dxf file. I`ve printed them sticked them on doublesided tape.

Best wishes

Jan

I think this might fit here, some days ago I made labels for the clamping brackets of the 7i76:

I attach the pdf and dxf file. I`ve printed them sticked them on doublesided tape.

Best wishes

Jan

Last edit: 30 Dec 2017 14:30 by +Jan+.

The following user(s) said Thank You: phillc54, tecno, snoozer77, silopolis, The_wolf_of_walmart, palmac, Flyer007 and 2 other people also said thanks.

Please Log in or Create an account to join the conversation.

- tecno

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

30 Dec 2017 14:36 #103852

by tecno

Replied by tecno on topic My 7i76e Connection Sheet

Nice job Jan

Please Log in or Create an account to join the conversation.

- Moronicsmurf

-

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 2

30 Dec 2017 15:24 #103854

by Moronicsmurf

Replied by Moronicsmurf on topic My 7i76e Connection Sheet

Very nice, this will help a bundle. =)

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.165 seconds