Bridgeport Torq-Cut TC4G Retrofit

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

15 Mar 2021 09:18 #202320

by andypugh

The index pulse is often too short to see in Halmeter. I wouldn't read too much into not seeing it.

If you "sets" the index-enable true, however, you should see that reset (once) at the same point in the spindle rotation every time.

Replied by andypugh on topic Bridgeport Torq-Cut TC4G Retrofit

Can you see the index in halmeter going true/false every rotation?

The index pulse is often too short to see in Halmeter. I wouldn't read too much into not seeing it.

If you "sets" the index-enable true, however, you should see that reset (once) at the same point in the spindle rotation every time.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

17 Mar 2021 05:14 #202560

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

I have se questions about your paint choice.

1 Have you used this before?

2 How does it hold up to coolant?

3 Did you use the recommended hardner?

4 Did you go down to bare metal?

5 If not what prep did you do?

6 Cost of the paint and amount used

Thank you

1 Have you used this before?

2 How does it hold up to coolant?

3 Did you use the recommended hardner?

4 Did you go down to bare metal?

5 If not what prep did you do?

6 Cost of the paint and amount used

Thank you

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

17 Mar 2021 21:05 - 17 Mar 2021 21:07 #202641

by chopper79

I was trying to sets spindle-index-enable before net spindle-index-enable <=> hm2_[HOSTMOT2](BOARD).0.encoder.05.index-enable

net spindle-index-enable <=> spindle.0.index-enable

When you mentioned that the signal needs created first is what prompted me to rearrange the position of the sets. Which I then remembered that I have ran into issues in the past when creating my HAL files due to arrangement orders. Once rearranged, it worked fine.

That's what happens when you only get to do this every couple years. I need to do it more often...

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

That should work.

One possible issue is that we have had trouble with the docs build inserting dashes "–" in the docs rather than hyphens "-", so perhaps if you copy-pasted that would cause the problem.

Otherwise, I am puzzled.

I was trying to sets spindle-index-enable before net spindle-index-enable <=> hm2_[HOSTMOT2](BOARD).0.encoder.05.index-enable

net spindle-index-enable <=> spindle.0.index-enable

When you mentioned that the signal needs created first is what prompted me to rearrange the position of the sets. Which I then remembered that I have ran into issues in the past when creating my HAL files due to arrangement orders. Once rearranged, it worked fine.

That's what happens when you only get to do this every couple years. I need to do it more often...

Last edit: 17 Mar 2021 21:07 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

17 Mar 2021 21:15 - 17 Mar 2021 21:16 #202644

by chopper79

Well... I got excited and started to go to town on the config and forgot to save a master copy of the working one. Now I am in the process of redoing it as I made a bunch of changes and nothing works right now. I forgot to follow my own rule and that is to save a copy when a milestone is reached so I could always revert back.

I will get it redone this week and post it. Well post the working unfinished config anyway.

Sorry about that!

My toolchange.ngc file is attached though

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Mind sharing your hal and ini up to this point? Curious what your tool change looks like.

Clean machine you have there. I am disassembling my enclousre and cleaning/prepping for paint while I wait for my spindle to get back. Mine is pretty beat though.

Well... I got excited and started to go to town on the config and forgot to save a master copy of the working one. Now I am in the process of redoing it as I made a bunch of changes and nothing works right now. I forgot to follow my own rule and that is to save a copy when a milestone is reached so I could always revert back.

I will get it redone this week and post it. Well post the working unfinished config anyway.

Sorry about that!

My toolchange.ngc file is attached though

Last edit: 17 Mar 2021 21:16 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

17 Mar 2021 21:24 - 17 Mar 2021 22:02 #202646

by chopper79

1) Never used this type of paint before. But based on research and recommendation I chose to try it.

2) Not sure, but seems like it will be fine.

3) No hardener (Air dry and is rock hard after a couple days, but could add a hardener)

4) Bare metal where I could which was most of it (This paint is a direct to metal product. does fine on old paint also as long as it is clean and not loose)

5) Cleaned with simple green, then acetone, then sanded, then acetone, then paint. (Not been able to chip it with finger nails and no chips when I dropped a hammer on it. Grease and oil wipe right of with no issue.)

6) $80/gal and I purchased (2) gallon. Wasted 1/2 of first gallon as I did not use if fast enough and the lid was cracked. If everything was prepped then 2-3 gals would do the whole machine easy.

I applied with a brush and a fine roller. I will probably spray the enclosure, but then again may just roll it as the paint levels great.

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

I have se questions about your paint choice.

1 Have you used this before?

2 How does it hold up to coolant?

3 Did you use the recommended hardner?

4 Did you go down to bare metal?

5 If not what prep did you do?

6 Cost of the paint and amount used

Thank you

1) Never used this type of paint before. But based on research and recommendation I chose to try it.

2) Not sure, but seems like it will be fine.

3) No hardener (Air dry and is rock hard after a couple days, but could add a hardener)

4) Bare metal where I could which was most of it (This paint is a direct to metal product. does fine on old paint also as long as it is clean and not loose)

5) Cleaned with simple green, then acetone, then sanded, then acetone, then paint. (Not been able to chip it with finger nails and no chips when I dropped a hammer on it. Grease and oil wipe right of with no issue.)

6) $80/gal and I purchased (2) gallon. Wasted 1/2 of first gallon as I did not use if fast enough and the lid was cracked. If everything was prepped then 2-3 gals would do the whole machine easy.

I applied with a brush and a fine roller. I will probably spray the enclosure, but then again may just roll it as the paint levels great.

Last edit: 17 Mar 2021 22:02 by chopper79.

The following user(s) said Thank You: arvidb, Michael

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

17 Mar 2021 21:33 #202650

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Finding the HAL file hard to keep up with. Going to look at doing a component to handle all this stuff. I might call it vmc.comp and it will handle the orientation and transmission/gearbox items. Might even try my hand at adding tool change in it as well. Passing in and out of multiple components is making me crazy. We will see what kind of weird stuff I come up with, if anything...

This will test my lack of C knowledge to the max.

This will test my lack of C knowledge to the max.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

17 Mar 2021 22:47 #202668

by andypugh

Right. If a signal does not exist when you get to a "net" command then it is created. But a signal isn't created by a "sets". (though it theory it could be).

You _could_ use

Replied by andypugh on topic Bridgeport Torq-Cut TC4G Retrofit

I was trying to sets spindle-index-enable before net spindle-index-enable <=> hm2_[HOSTMOT2](BOARD).0.encoder.05.index-enable

Right. If a signal does not exist when you get to a "net" command then it is created. But a signal isn't created by a "sets". (though it theory it could be).

You _could_ use

newsig spindle-index-enable

sets spindle-index-enable 1

....

net spindle-index-enable...

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

19 Mar 2021 16:47 - 19 Mar 2021 16:57 #202857

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Attached is my current HAL and INI per request.

These are by no means finished so ignore the commented out items or if anything is laid out funny. The config works well excluding orientation which is where everything went bad on me (orientation items are incomplete).

I was going to use the VFD orientation but found that when I switched gears on the transmission the orientation never would line back up at the appropriate angle (No way to know where the gears lined up so no way to use the VFD orientation).

This prompted me to start on the orientation side of things. Using the orient component worked for me but the PID for the orient does not know what to do in low gear vs high gear. The angle always was correct though, but in high gear the spindle would vibrate badly and in low gear it is perfect.

Thought about making it only allow orientation in low gear, but then that causes time and part wear issues. Having to switch to low gear every time I tool changed or oriented the spindle means cycling the valves a lot more. Still working on this part as of now... May be able to do something so that if the spindle is in high gear then divide PID value by transmission ratio. Might have to try it using a scale of some sort.

These are by no means finished so ignore the commented out items or if anything is laid out funny. The config works well excluding orientation which is where everything went bad on me (orientation items are incomplete).

I was going to use the VFD orientation but found that when I switched gears on the transmission the orientation never would line back up at the appropriate angle (No way to know where the gears lined up so no way to use the VFD orientation).

This prompted me to start on the orientation side of things. Using the orient component worked for me but the PID for the orient does not know what to do in low gear vs high gear. The angle always was correct though, but in high gear the spindle would vibrate badly and in low gear it is perfect.

Thought about making it only allow orientation in low gear, but then that causes time and part wear issues. Having to switch to low gear every time I tool changed or oriented the spindle means cycling the valves a lot more. Still working on this part as of now... May be able to do something so that if the spindle is in high gear then divide PID value by transmission ratio. Might have to try it using a scale of some sort.

Last edit: 19 Mar 2021 16:57 by chopper79.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

19 Mar 2021 18:04 #202869

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

Thank you for sharing the files!

You have to get rid of that transmission. Unless you plan on doing a lot of tapping or steel work. My spindle is out for repair and I had them check to see what max rpm could be for the stock bearings. I was happy to find out it's a bit over 11k rpm. So I am having them bed the bearings at 10k, check for heat issues and plan to run the motor with a 56t pulley to get 10k out of it. I do almost exclusively aluminum so speed is my friend.

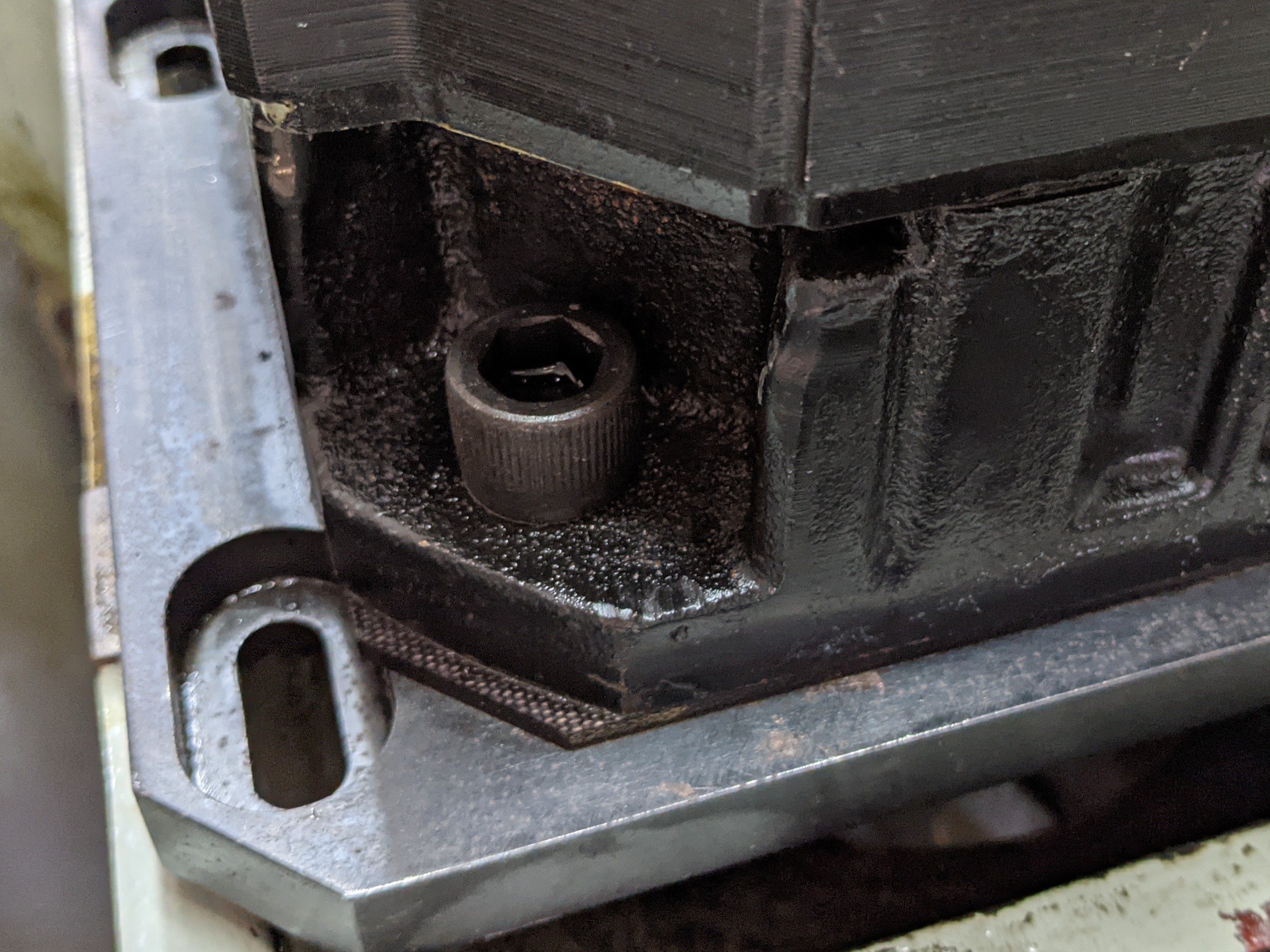

I attached a picture of the spindle motor adapter plate that the 8k spindles use in place of the transmission if you have any interest or need to ditch it some day. It's a simple part to make. Only critical tolerance would be parallelism.

You have to get rid of that transmission. Unless you plan on doing a lot of tapping or steel work. My spindle is out for repair and I had them check to see what max rpm could be for the stock bearings. I was happy to find out it's a bit over 11k rpm. So I am having them bed the bearings at 10k, check for heat issues and plan to run the motor with a 56t pulley to get 10k out of it. I do almost exclusively aluminum so speed is my friend.

I attached a picture of the spindle motor adapter plate that the 8k spindles use in place of the transmission if you have any interest or need to ditch it some day. It's a simple part to make. Only critical tolerance would be parallelism.

Attachments:

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

19 Mar 2021 18:13 #202871

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

I may remove the transmission one day, but I plan on doing steel and cast iron along with aluminum. Right now I will keep pushing forward with the transmission.

Please Log in or Create an account to join the conversation.

Time to create page: 0.258 seconds