Bridgeport Torq-Cut TC4G Retrofit

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

26 Feb 2021 02:31 - 26 Feb 2021 02:38 #200169

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

Yes GE is greater or equal and LE is less or equal. EQ is equal.

M66 the high gear and low gear switch at the beginning of the two different parts and then else into what you basically have. This would probably need to look at parameter #5399 and look for a value GT 0. (since normally we are looking for -1 and triggering an abort) then go into else statements of you expect it to be false. You might have to break this into a bunch of small parts.

I am not good at any of this stuff and just recently started learning so double check the o code section of the documents section

linuxcnc.org/docs/2.8/html/gcode/o-code.html#ocode:conditional

So far I have figured out that it's easy to write out a sub to do something but it's a lot more difficult to figure out all the odd situations that may come up. In my case I am hoping I made my routine capable of removing my tool with a M6 T0

Fun stuff though.

M66 the high gear and low gear switch at the beginning of the two different parts and then else into what you basically have. This would probably need to look at parameter #5399 and look for a value GT 0. (since normally we are looking for -1 and triggering an abort) then go into else statements of you expect it to be false. You might have to break this into a bunch of small parts.

I am not good at any of this stuff and just recently started learning so double check the o code section of the documents section

linuxcnc.org/docs/2.8/html/gcode/o-code.html#ocode:conditional

So far I have figured out that it's easy to write out a sub to do something but it's a lot more difficult to figure out all the odd situations that may come up. In my case I am hoping I made my routine capable of removing my tool with a M6 T0

Fun stuff though.

Last edit: 26 Feb 2021 02:38 by Michael.

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

26 Feb 2021 03:04 - 26 Feb 2021 03:31 #200171

by chopper79

I did some testing on gear shift while rotating and I get some meshing noise. I also tried to shift it at a few different rpm points with the same results. The parameter sheet with the mill says that shift speed is 11. Maybe some meshing noise is normal and I should not worry about it.

Either way I will give it a couple attempts this weekend and see what the results are.

Thank you

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

For my mill I implemented the gear change with a hal component but I need to turn the spindle slowly when changing gears. I also have it trigger the gear change on an M3 or M4 instead of when S<rpm> is called. Mostly because the spindle is expected to rotate on an M3/4 and not on an S.

I did some testing on gear shift while rotating and I get some meshing noise. I also tried to shift it at a few different rpm points with the same results. The parameter sheet with the mill says that shift speed is 11. Maybe some meshing noise is normal and I should not worry about it.

Either way I will give it a couple attempts this weekend and see what the results are.

Thank you

Last edit: 26 Feb 2021 03:31 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

26 Feb 2021 03:28 #200172

by chopper79

That is what I am running into when thinking about the subroutines is what if this happens. Also other items such as you stated the M6T0 to remove the tool. I want to look at changing my sub so the ATC removes the tool if one is left in the spindle by accident. This would need to happen on the first tool change. Essentially Call any tool and the first move is to clear the spindle as sometimes I may forget to clear the spindle before shutting down. (It happens) Once this has happened then the sub functions as normal.

Looking to see if there is a retentive memory location that the last tool in the spindle was saved to a location so when the next time you fire the machine up it knows that Tnn is in the spindle. This will be something down the road to look at as well.

I have a lot of ideas on what I would like to have on the controller, just no clue as to how to implement them as of yet. Some of these are I/O screen for diagnostics, tool changer recovery, and other misc items that aid in troubleshooting.

I plan on keeping this machine for awhile so eventually I will just keep trying stuff out and learn what I can do implement some of the ideas I have. right now I just need to get the machine finished and functioning then I can add stuff later.

If it was easy then it would be no fun. So here is to fun!

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

So far I have figured out that it's easy to write out a sub to do something but it's a lot more difficult to figure out all the odd situations that may come up. In my case I am hoping I made my routine capable of removing my tool with a M6 T0

Fun stuff though.

That is what I am running into when thinking about the subroutines is what if this happens. Also other items such as you stated the M6T0 to remove the tool. I want to look at changing my sub so the ATC removes the tool if one is left in the spindle by accident. This would need to happen on the first tool change. Essentially Call any tool and the first move is to clear the spindle as sometimes I may forget to clear the spindle before shutting down. (It happens) Once this has happened then the sub functions as normal.

Looking to see if there is a retentive memory location that the last tool in the spindle was saved to a location so when the next time you fire the machine up it knows that Tnn is in the spindle. This will be something down the road to look at as well.

I have a lot of ideas on what I would like to have on the controller, just no clue as to how to implement them as of yet. Some of these are I/O screen for diagnostics, tool changer recovery, and other misc items that aid in troubleshooting.

I plan on keeping this machine for awhile so eventually I will just keep trying stuff out and learn what I can do implement some of the ideas I have. right now I just need to get the machine finished and functioning then I can add stuff later.

If it was easy then it would be no fun. So here is to fun!

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

28 Feb 2021 21:05 #200463

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Working on the S word remap a bit and have run into a snag.

When I try to launch LCNC and error occurs

S/setspeed_epilog: Python argument types in

None.None(Interp,float)

did not match C++ signature: None(Interp {Ivalue},int, double))

Not sure what has went wrong at the moment. Using the standard python files that are built into LCNC and based on the documentation S remap is standard function.

Using REMAP= S prolog=setspeed_prolog ngc=gearchange epilog=setspeed_epilog

Is there something in the python files that needs changed for the S remap to work?

Attached is the stdglue python file and subroutine

When I try to launch LCNC and error occurs

S/setspeed_epilog: Python argument types in

None.None(Interp,float)

did not match C++ signature: None(Interp {Ivalue},int, double))

Not sure what has went wrong at the moment. Using the standard python files that are built into LCNC and based on the documentation S remap is standard function.

Using REMAP= S prolog=setspeed_prolog ngc=gearchange epilog=setspeed_epilog

Is there something in the python files that needs changed for the S remap to work?

Attached is the stdglue python file and subroutine

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

28 Feb 2021 22:21 - 28 Feb 2021 22:58 #200471

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Update...

I removed epilog from my ini file and LCNC launches with no errors. Testing the gear change and it works well (couple small changes I want to do). Only issue now is the S value is not passed through to the spindle.

Command M3s1000 (program or mdi)

Gear changes

No commanded rpm value passed through

I am thinking this is due to the epilog being removed, but with it there LCNC does not launch. So now that most of it works I need to see what is not happy when the epilog is placed back into the ini file. Maybe it is something in my subroutine just not sure at the moment.

Any suggestions let me know please

I removed epilog from my ini file and LCNC launches with no errors. Testing the gear change and it works well (couple small changes I want to do). Only issue now is the S value is not passed through to the spindle.

Command M3s1000 (program or mdi)

Gear changes

No commanded rpm value passed through

I am thinking this is due to the epilog being removed, but with it there LCNC does not launch. So now that most of it works I need to see what is not happy when the epilog is placed back into the ini file. Maybe it is something in my subroutine just not sure at the moment.

Any suggestions let me know please

Last edit: 28 Feb 2021 22:58 by chopper79.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

03 Mar 2021 22:21 - 03 Mar 2021 22:35 #200948

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

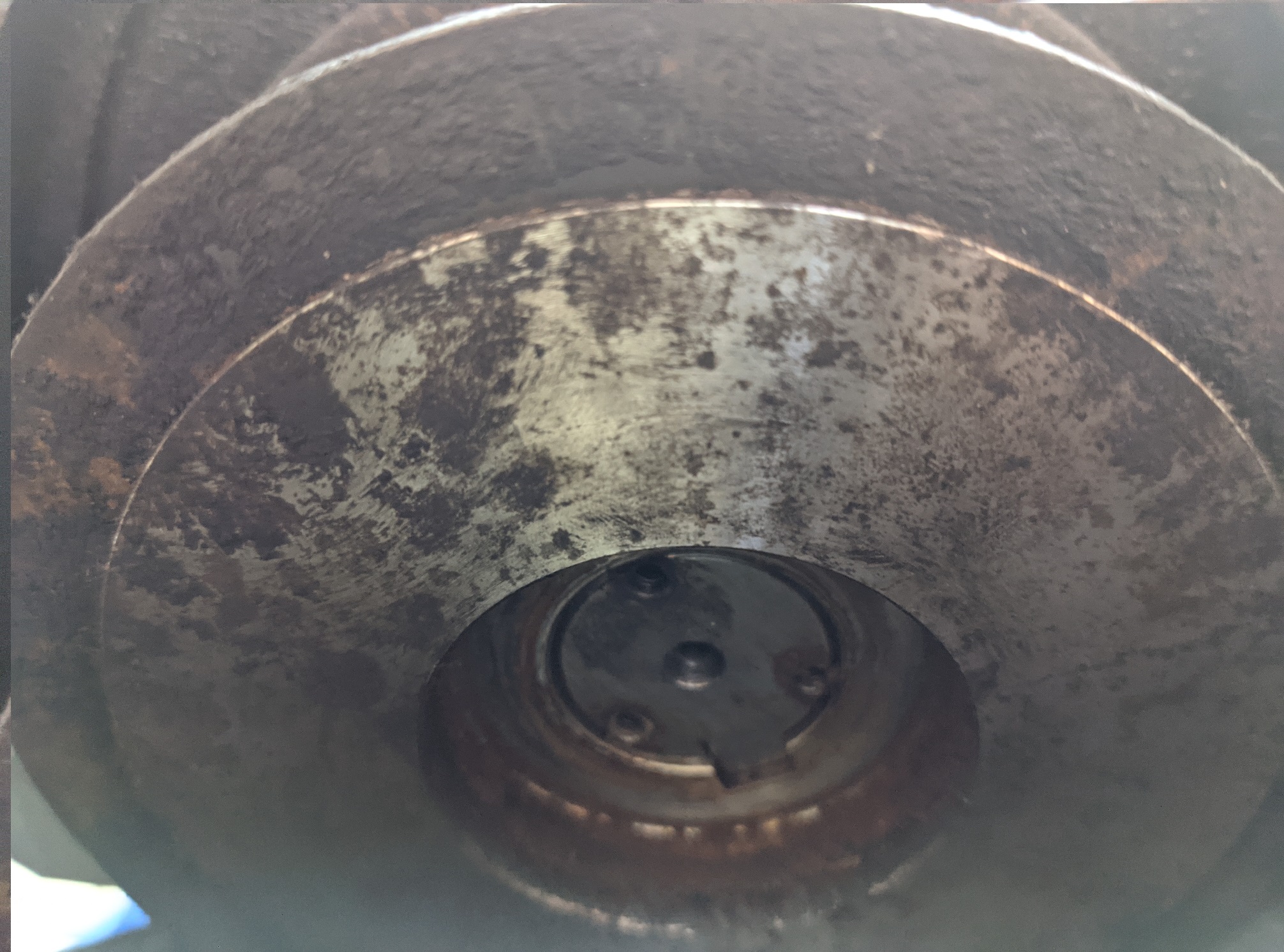

When you rebuilt your spindle motor, how was your pulley configured on the shaft and how did you get it off the shaft. I have attached pictures of mine. It had 3 small screws holding an end camp to the shaft. There is a collar between the pulley and motor casing that seems to keep the pulley in place. Before I start pulling on this or applying heat I wanted to make sure there is nothing I am missing. This appears to be a press fit and the axial offset is handled by the collar and end plate.

Last edit: 03 Mar 2021 22:35 by Michael.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

03 Mar 2021 22:38 #200949

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

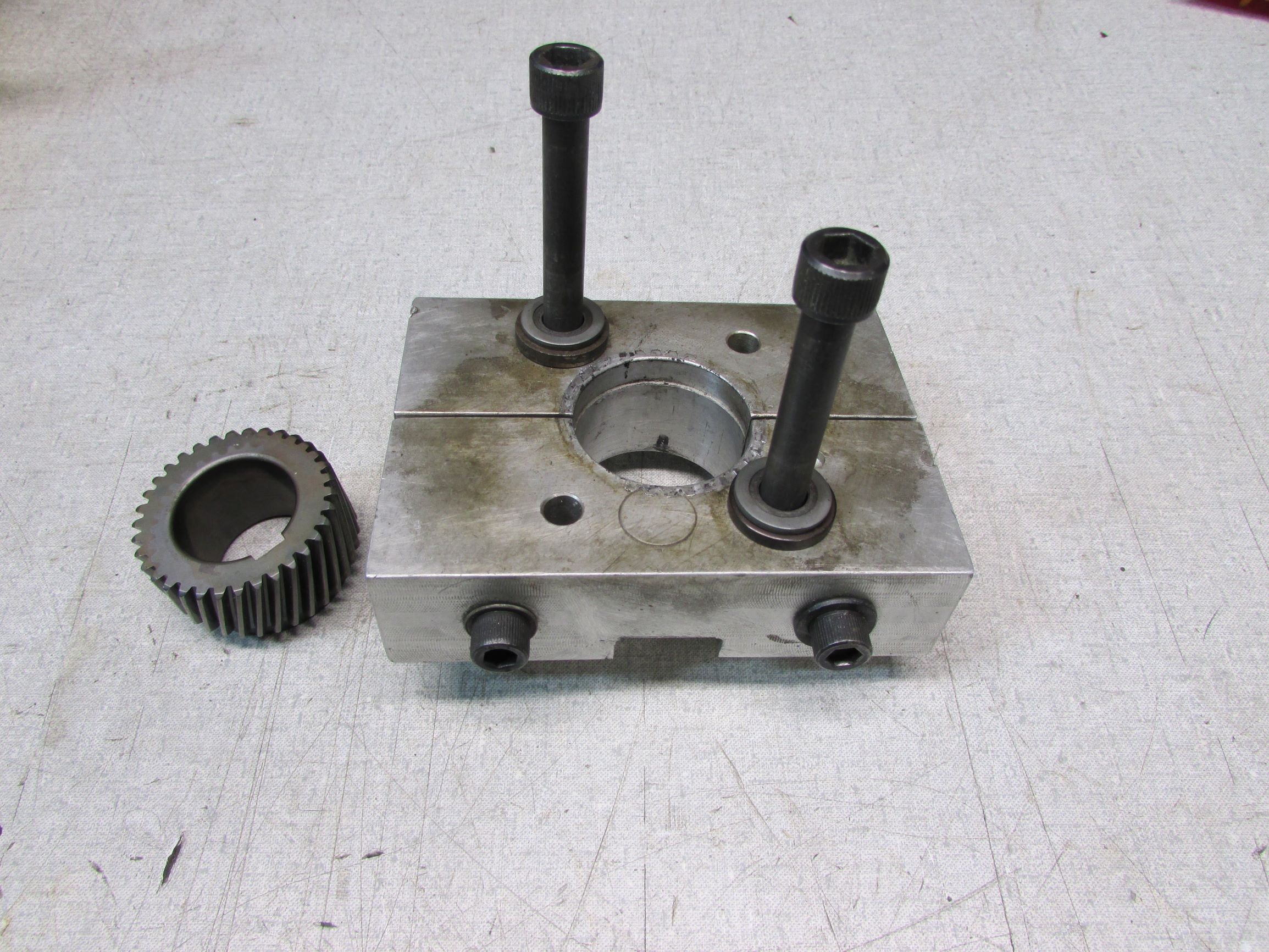

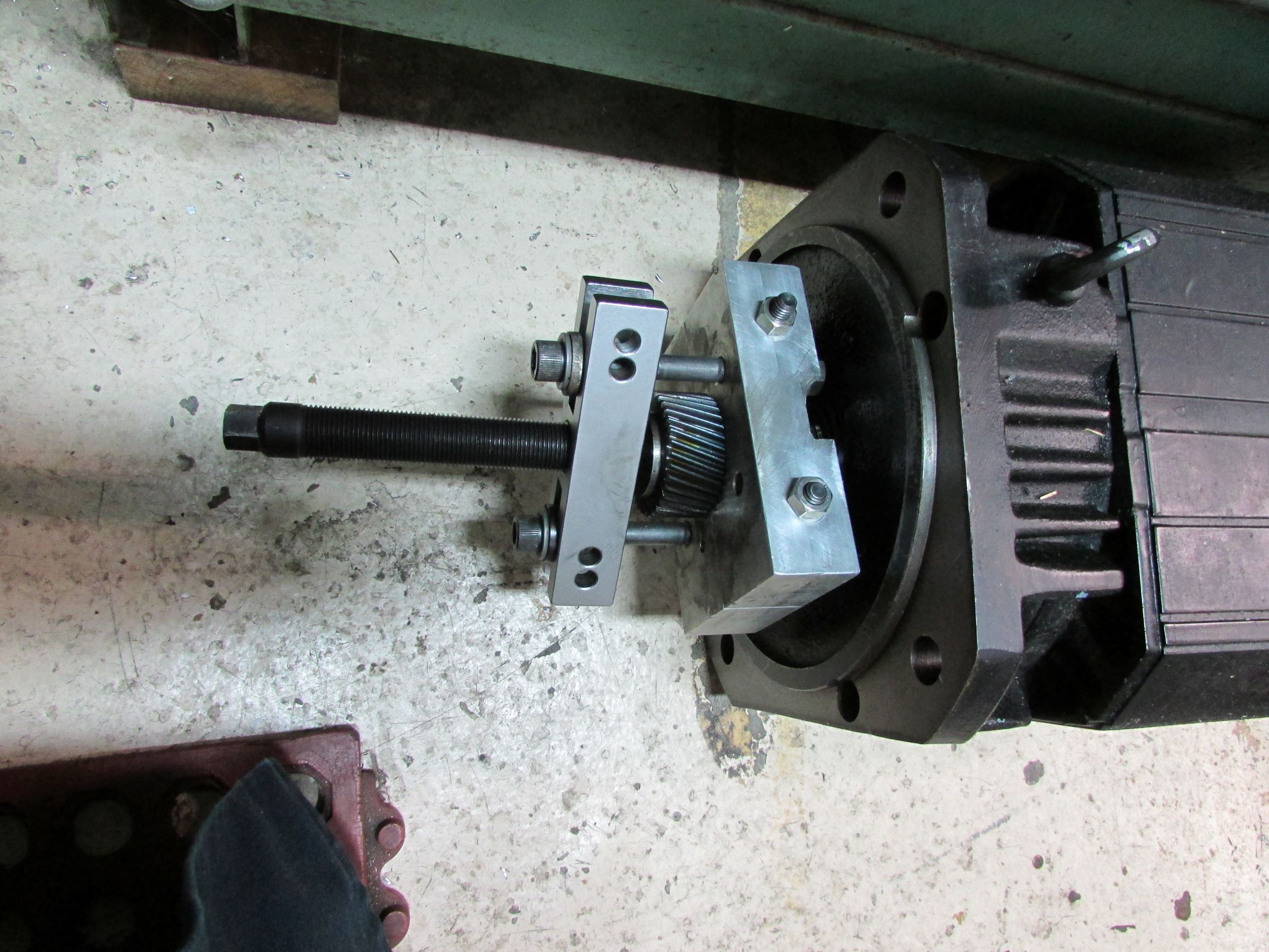

Yeah that was a fun one...

1) Remove the (3) screws and end cap

2) I had to make a puller setup for it

3) The gear is shrink fit not press fit

4) Used an induction heater to heat it then remove

5) Used an induction heater to heat for installation

Blow torch would work as well I would think, but would allow the heat to soak into the motor by the time it was to temperature. I purchased one of those hand held induction heaters from ebay and it works awesome! I had to get the gear up to ~ 500°F to remove and install which took about 45 sec with the induction heater.

The collar on there is just a spacer so the offset distance is correct for proper gear meshing.

1) Remove the (3) screws and end cap

2) I had to make a puller setup for it

3) The gear is shrink fit not press fit

4) Used an induction heater to heat it then remove

5) Used an induction heater to heat for installation

Blow torch would work as well I would think, but would allow the heat to soak into the motor by the time it was to temperature. I purchased one of those hand held induction heaters from ebay and it works awesome! I had to get the gear up to ~ 500°F to remove and install which took about 45 sec with the induction heater.

The collar on there is just a spacer so the offset distance is correct for proper gear meshing.

Attachments:

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

03 Mar 2021 22:40 - 03 Mar 2021 22:46 #200950

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Shoot... After I posted your pictures showed up. Do you have a transmission? Is that the spindle motor or the transmission output shaft?

I would use a standard pulley puller and an impact gun for that setup. Should need a little heat and some penetrating fluid maybe.

I am beginning to wish I did not have the transmission... I need to make it shift gears and I am no good at code..haha

I would use a standard pulley puller and an impact gun for that setup. Should need a little heat and some penetrating fluid maybe.

I am beginning to wish I did not have the transmission... I need to make it shift gears and I am no good at code..haha

Last edit: 03 Mar 2021 22:46 by chopper79.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

04 Mar 2021 00:07 #200965

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

Yeah I realized you have the transmission also. But technically the motor shaft and whatever its attached to should be similar. I will give it some heat and see if we can get it to move. Also may make something like your puller. I don't have a puller that gets around the flanges on these pulleys. I could just put the torch next to the pulley and spin the spindle at 10 rpm until it falls off!?!

If you remove your transmission the spindle motor should need an adapter plate (maybe able to reuse the one on the transmission) to mount to the head and a drive pulley and be good to go, 8000rpm 32 ft lbs torque. Unless you are tapping or doing all your work in steel with large cutters I don't see the need for the transmission. My spindle is shot so I am exploring a rebuild or new spindle made overseas with a higher rpm limit. All my work is small cutters in aluminum so I can afford to loose some power.

I looked at your S remap stuff but am no good at code. I would love to see what you did for the tool change remap though. I am waiting on a sensor and will be trying to implement mine shortly.

If you remove your transmission the spindle motor should need an adapter plate (maybe able to reuse the one on the transmission) to mount to the head and a drive pulley and be good to go, 8000rpm 32 ft lbs torque. Unless you are tapping or doing all your work in steel with large cutters I don't see the need for the transmission. My spindle is shot so I am exploring a rebuild or new spindle made overseas with a higher rpm limit. All my work is small cutters in aluminum so I can afford to loose some power.

I looked at your S remap stuff but am no good at code. I would love to see what you did for the tool change remap though. I am waiting on a sensor and will be trying to implement mine shortly.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

04 Mar 2021 00:47 - 09 Mar 2021 01:58 #200972

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

I looked to remove the transmission, but the motor will not fit in the location (mounting flange is to wide). so I put the transmission back on...

I am going another direction then remapping S. It works minus not passing the speed command back out. I am in the process of implementing a comp file to do the transmission gear change right now.

1) I can get it to change to low gear, but not back to high gear when the speed is > xx.

2) The solenoid valves do not shut off after gear change to low

Need to do some more on the comp file to which is a major learning curve for me. Right now I need to get the comp file to provide a set rpm out during gear change. Currently it will keep the spindle rpm at the commanded value while changing the gear to low (s200 and it changes and grinds ). Need to do the following:

). Need to do the following:

1) command speed (M3s200)

2) rpm drops to 11 rpm

3) gear changes

4) check for sensor status

5) ramp back up to commanded speed * the gear ratio

I may be in over my head right now but what the heck giving it a go anyway...

I am going another direction then remapping S. It works minus not passing the speed command back out. I am in the process of implementing a comp file to do the transmission gear change right now.

1) I can get it to change to low gear, but not back to high gear when the speed is > xx.

2) The solenoid valves do not shut off after gear change to low

Need to do some more on the comp file to which is a major learning curve for me. Right now I need to get the comp file to provide a set rpm out during gear change. Currently it will keep the spindle rpm at the commanded value while changing the gear to low (s200 and it changes and grinds

1) command speed (M3s200)

2) rpm drops to 11 rpm

3) gear changes

4) check for sensor status

5) ramp back up to commanded speed * the gear ratio

I may be in over my head right now but what the heck giving it a go anyway...

Last edit: 09 Mar 2021 01:58 by chopper79.

Please Log in or Create an account to join the conversation.

Time to create page: 0.328 seconds