Bridgeport Torq-Cut TC4G Retrofit

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

09 Jan 2021 03:26 - 09 Jan 2021 03:29 #194560

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

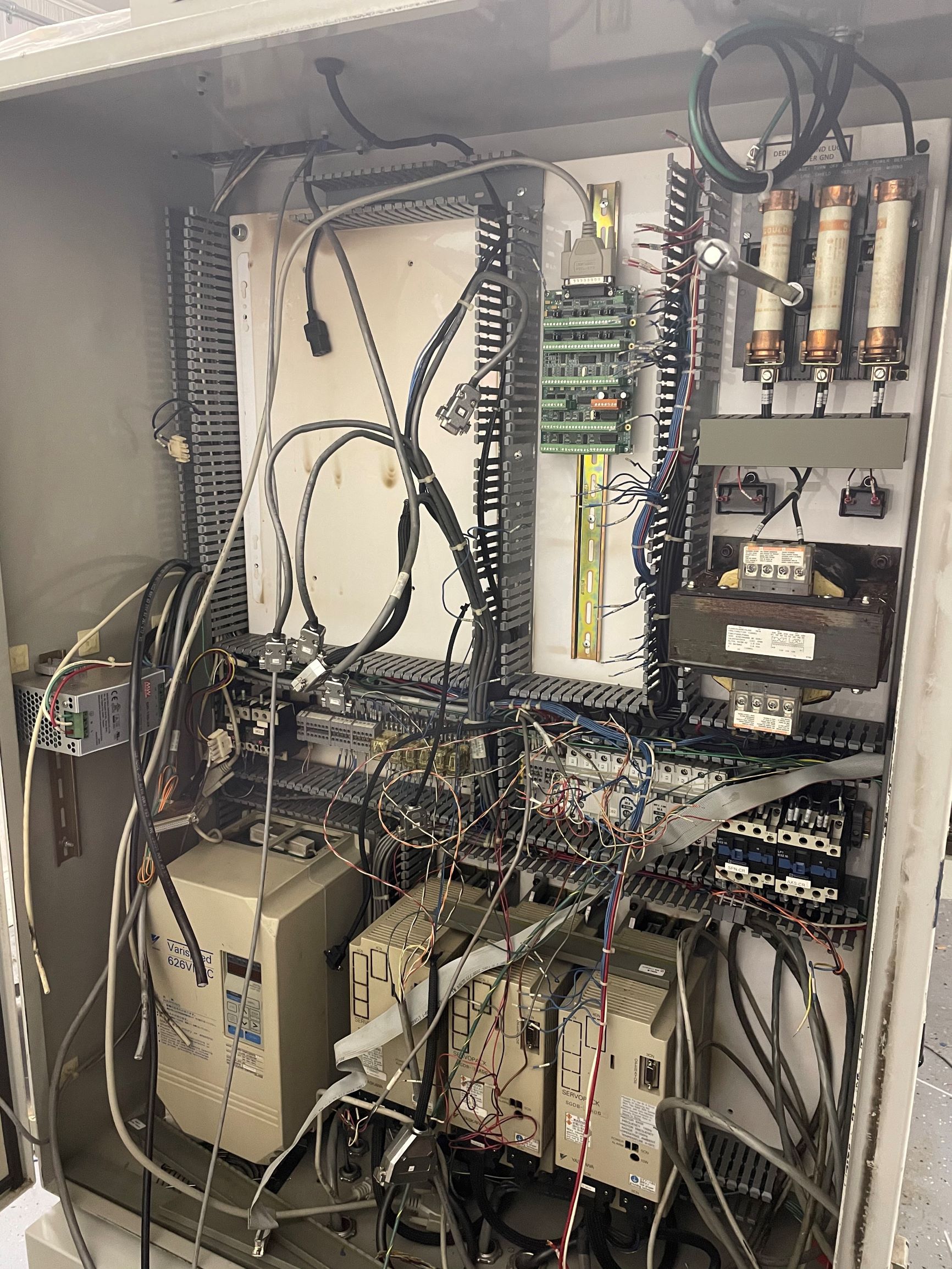

Well here is the next update...

1) Spindle motor pinion gear installed on motor

2) Spindle motor installed and wired

3) Head, tool changer, and valve wire replaced

4) New tool release buttons and plate

5) Old boards out of cabinet

6) New lube line for table

7) All components wired and ready to be landed to the 7i77

Hoping to have ~30% of the wiring landed by the end of the weekend. Getting closer to bringing it back to life.

1) Spindle motor pinion gear installed on motor

2) Spindle motor installed and wired

3) Head, tool changer, and valve wire replaced

4) New tool release buttons and plate

5) Old boards out of cabinet

6) New lube line for table

7) All components wired and ready to be landed to the 7i77

Hoping to have ~30% of the wiring landed by the end of the weekend. Getting closer to bringing it back to life.

Last edit: 09 Jan 2021 03:29 by chopper79.

The following user(s) said Thank You: arvidb, tommylight

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

14 Jan 2021 00:09 - 14 Jan 2021 00:16 #195273

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Quick question...

Thinking about changing over to a 7i92 from the 6i25 I purchased, (Cleaner install is all),

The question I have is the 7i92 and 7i92m are identical excluding the m version has the male db25 connector and the standard 7i92 has a female connector correct?

**** I answered my own question. The standard has a female connector. ****

Thinking about changing over to a 7i92 from the 6i25 I purchased, (Cleaner install is all),

The question I have is the 7i92 and 7i92m are identical excluding the m version has the male db25 connector and the standard 7i92 has a female connector correct?

**** I answered my own question. The standard has a female connector. ****

Last edit: 14 Jan 2021 00:16 by chopper79.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

14 Jan 2021 00:27 #195276

by tommylight

Replied by tommylight on topic Bridgeport Torq-Cut TC4G Retrofit

I always use the 7i92M as it can be plugged directly to a 7i77.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

14 Jan 2021 00:46 #195277

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

As do I. Just this time I may have to go the other way. Running out of room where I had things planned out. We shall see though

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

18 Jan 2021 21:13 #195832

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Still working on the wiring and decided to change course a bit. Decided to go ahead and use the machine over ethernet. This will give me an opportunity to try the Rpi4 down the road after everything is functioning. Also needed more outputs (Short by 3 on the 7i77). Had to place an order for the following:

* 7i92m and a 7i84.

* Misc items from a couple other places. (Switches, wires, power supplies, etc. since I decided to add a couple features)

Once these come in I will be able to finish up the last bit of the wiring and begin testing.

Next update will be this weekend I am hoping.

* 7i92m and a 7i84.

* Misc items from a couple other places. (Switches, wires, power supplies, etc. since I decided to add a couple features)

Once these come in I will be able to finish up the last bit of the wiring and begin testing.

Next update will be this weekend I am hoping.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

18 Jan 2021 21:46 #195838

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

Same combo I went with for my TC-22. Built and installed the computer at the console and ran the cat5 back to the cabinet. Been considering putting the 7i84 in the console also to avoid running so many console button wires back to the cabinet.

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

18 Jan 2021 23:22 - 18 Jan 2021 23:33 #195845

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

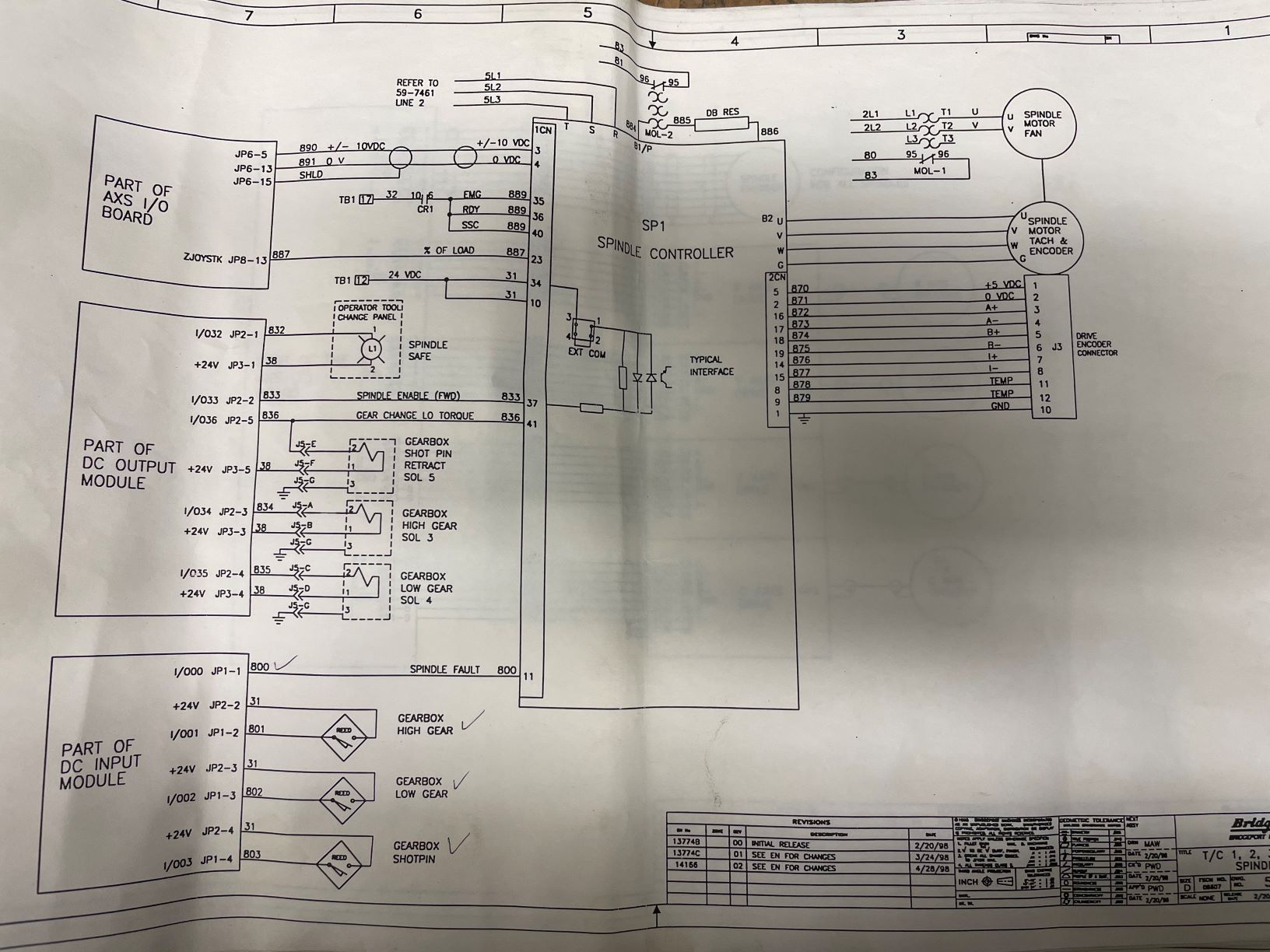

I am excited to work on the tool change code.

Need to first figure out how they are orienting the spindle as the machine did not utilize the orientation input on the vfd. I am thinking they utilized the torque limit mode (Pin 41) and fwd input (pin37). There is no sensor for it also, so it seem the vfd is put into incremental or absolute and then moved X amount of degrees from the index mark on the encoder. The orientation complete is also not utilized on the vfd so this makes me think that the controller had a programmed angle then when that was achieve, then the spindle locked and when no rotation was seen the tool change proceeded.

Just guessing here...

Need to first figure out how they are orienting the spindle as the machine did not utilize the orientation input on the vfd. I am thinking they utilized the torque limit mode (Pin 41) and fwd input (pin37). There is no sensor for it also, so it seem the vfd is put into incremental or absolute and then moved X amount of degrees from the index mark on the encoder. The orientation complete is also not utilized on the vfd so this makes me think that the controller had a programmed angle then when that was achieve, then the spindle locked and when no rotation was seen the tool change proceeded.

Just guessing here...

Attachments:

Last edit: 18 Jan 2021 23:33 by chopper79.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

19 Jan 2021 00:07 #195846

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

I have only gotten as far as to hook up the tool changer components to relays after deconstructing the boards they used to perform the changes. Have it all working individually but have not tackled the sequence yet.

Found a bad spindle bearing. Would love to know what the max speed I could get out of a spindle rebuild is. My 8k is cool but would be much happier in 12-16k range. Could end up going to a all in one motorized spindle if the price is similar.

Spindle wirong diagram looks similar. I don't believe I had an orient from the drive. Will need to be oriented off index.

Found a bad spindle bearing. Would love to know what the max speed I could get out of a spindle rebuild is. My 8k is cool but would be much happier in 12-16k range. Could end up going to a all in one motorized spindle if the price is similar.

Spindle wirong diagram looks similar. I don't believe I had an orient from the drive. Will need to be oriented off index.

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

19 Jan 2021 00:14 - 19 Jan 2021 00:19 #195847

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Yeah that is what I was figuring as well when it comes to orientation. Could always run a couple more wires and get orientation and orientation completed signals. Then reprogram the vfd a little bit so it looks for the input and then send the output.

I hope mine is 8k, so far it appears to be 6k, Will know more when I get the machine fired up again and look in the drive constants. Motor is capable of 8k based on data plate and manual but the bearings in the spindle motor are only rated for about 8k or a little less based on NTN website.

We shall see here someday soon....

I hope mine is 8k, so far it appears to be 6k, Will know more when I get the machine fired up again and look in the drive constants. Motor is capable of 8k based on data plate and manual but the bearings in the spindle motor are only rated for about 8k or a little less based on NTN website.

We shall see here someday soon....

Last edit: 19 Jan 2021 00:19 by chopper79.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

19 Jan 2021 00:35 #195848

by Michael

Replied by Michael on topic Bridgeport Torq-Cut TC4G Retrofit

Did you already have the bearing numbers or find them somewhere? I am very interested in what mine are but haven't dug into it or found information readily available.

Please Log in or Create an account to join the conversation.

Time to create page: 0.251 seconds