Random stuff, reduction, servo motors, ideas and thoughts

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

03 May 2020 01:13 #166455

by machinedude

Replied by machinedude on topic Random stuff, reduction, servo motors, ideas and thoughts

i think if you get to fine with a 1 micron when it comes time to tune between the linear scale loop and the rotary encoder on the other loop it can make it more difficult to get the to signals to fall where they should be, the DMM servo encoders have counts around 65,000 PPR so finding a linear scale that is close factors into it. the amount of error in the system quality of components used all factor into it.

basically your control is making comp on the fly so it all has it part in the system.

basically your control is making comp on the fly so it all has it part in the system.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11635

- Thank you received: 3916

03 May 2020 04:33 #166467

by rodw

Replied by rodw on topic Random stuff, reduction, servo motors, ideas and thoughts

I've never played with servos but I think it will happen one day. I don't think there is any need to match the PPR between the two feedback loops.If there is a variation, it is just that the outer loop will tell the inner loop to change position so they won't be fighting each other. LCNC will always remain the master.

You've complicated you build by adding a router. The last week or so, I've been chatting to the Aussie distributor of LAM Technologies that Tommy rates so highly. I'm also working with an engineer who is working on a stepper motor design model which is pretty sophisticated. I think we've all agreed that for plasma, a properly engineered and configured stepper motor system will never loose steps because there is no cutting forces involved. So steppers are still good candidates for plasma tables.

The LAM drivers are interesting becasue they accept AC input so they can be used with a (toroid) transformer without adding any rectification circuit to get it to DC.

You've complicated you build by adding a router. The last week or so, I've been chatting to the Aussie distributor of LAM Technologies that Tommy rates so highly. I'm also working with an engineer who is working on a stepper motor design model which is pretty sophisticated. I think we've all agreed that for plasma, a properly engineered and configured stepper motor system will never loose steps because there is no cutting forces involved. So steppers are still good candidates for plasma tables.

The LAM drivers are interesting becasue they accept AC input so they can be used with a (toroid) transformer without adding any rectification circuit to get it to DC.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

03 May 2020 05:11 #166469

by machinedude

Replied by machinedude on topic Random stuff, reduction, servo motors, ideas and thoughts

i complicate everything i touch  but if the build gets better having a gantry mill will be useful. bigger project like this one won't be so drawn out next time around. things are so much easier when you have the machine big enough for the task.should have named my build thread the machine that will eventually built my plasma table

but if the build gets better having a gantry mill will be useful. bigger project like this one won't be so drawn out next time around. things are so much easier when you have the machine big enough for the task.should have named my build thread the machine that will eventually built my plasma table

the more voltage you can get into a stepper the better they do. before my little lathe controller went i had a small power supply on the motors and they worked but it ran slow. when i put the 70 V power supply on the same motors it was like they were supper charged . 70 V is the max but what a change it made.

the more voltage you can get into a stepper the better they do. before my little lathe controller went i had a small power supply on the motors and they worked but it ran slow. when i put the 70 V power supply on the same motors it was like they were supper charged . 70 V is the max but what a change it made.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11635

- Thank you received: 3916

03 May 2020 06:02 #166471

by rodw

Replied by rodw on topic Random stuff, reduction, servo motors, ideas and thoughts

Yeh, I learnt that lesson too. I'm using 48 volts now and 50 volts is the max my drivers will take but the LAM drivers can handle up to 135 volts. I was looking at 90 volts because there are torque curves for the motors. But it would probably be a AUD $2k+ upgrade for the spaceship. Once I know what the upgrade plan is, I might get a toroid made to the exact spec required. Other than maybe an increase in rapids, I would not get that much benefit other than more torque for faster acelleration. Oh and maybe 50% improvement in rapids (but 21 m/min is not bad now).

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21171

- Thank you received: 7235

03 May 2020 09:42 #166489

by tommylight

Replied by tommylight on topic Random stuff, reduction, servo motors, ideas and thoughts

Ooopps forgot to mention that Lam does AC powered stepper drives also !

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11635

- Thank you received: 3916

03 May 2020 09:48 #166491

by rodw

Tommy, thanks for that. Your forgetfulness cost me a lot of headaches! It is quite a big advantage in a country where it is easy to get a heavy toroid transformer made to order by people who don't build a rectifier for it! Plus it means eliminating some components which means a better MTBF. Stefan said the shipping on a prebuild toroid with a rectifier cost him AUD $200 which is 70% of the cost of the LAM driver....

Replied by rodw on topic Random stuff, reduction, servo motors, ideas and thoughts

Ooopps forgot to mention that Lam does AC powered stepper drives also !

Tommy, thanks for that. Your forgetfulness cost me a lot of headaches! It is quite a big advantage in a country where it is easy to get a heavy toroid transformer made to order by people who don't build a rectifier for it! Plus it means eliminating some components which means a better MTBF. Stefan said the shipping on a prebuild toroid with a rectifier cost him AUD $200 which is 70% of the cost of the LAM driver....

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11635

- Thank you received: 3916

03 May 2020 09:49 - 03 May 2020 09:49 #166492

by rodw

Replied by rodw on topic Random stuff, reduction, servo motors, ideas and thoughts

Oops my forgetfulnses forgot to add the smiley face. I'm not really cranky with you!

Last edit: 03 May 2020 09:49 by rodw.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 May 2020 14:59 #168796

by machinedude

Replied by machinedude on topic Random stuff, reduction, servo motors, ideas and thoughts

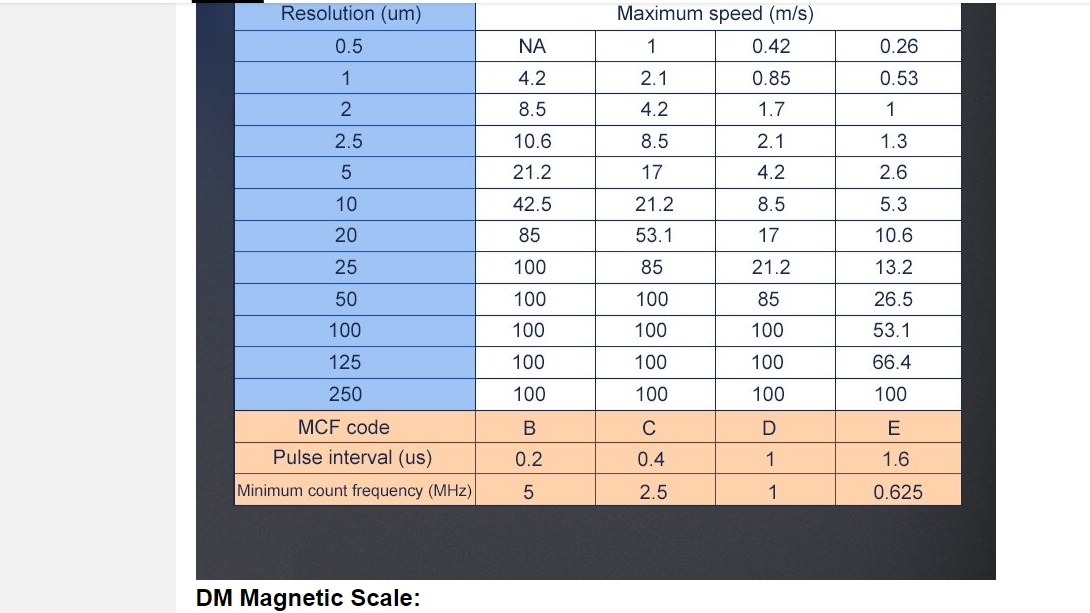

just to add some information about linear scales of the magnetic type. i just picked up 3 of these and in the process of ordering i leaned than there is a big difference between how fast the reader heads can follow the signals when you get into the 1um range of scales and readers. it turns out that even though they can work well at 1 um they can't read the signals all that fast so this limits the rapid rates of the machine. at the 5 um ranges they can do well over 2000 imp which is crazy fast for any home build. every manufacture is different so this is something that has to be looked at closely before you pick a brand of linear scale. for me i had to think about total cost since the budget keeps getting tighter and tighter  but Ditron scales are reasonable in price so that's the direction i went. seems they have a decent product and i have came across a few good reviews so i will soon fin out if that is right or not

but Ditron scales are reasonable in price so that's the direction i went. seems they have a decent product and i have came across a few good reviews so i will soon fin out if that is right or not  i also ended up going with the 5 um scales since the 1 um scales would be to slow and defeat the whole idea of closing the loop and having accurate positioning.

i also ended up going with the 5 um scales since the 1 um scales would be to slow and defeat the whole idea of closing the loop and having accurate positioning.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

24 May 2020 16:26 #168801

by Henk

Replied by Henk on topic Random stuff, reduction, servo motors, ideas and thoughts

I was planning to buy Dutton magnetic sales as well. What kind of speed would you say is achievable with the 1um scales?

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 May 2020 18:14 - 26 May 2020 04:11 #168812

by machinedude

Replied by machinedude on topic Random stuff, reduction, servo motors, ideas and thoughts

the Ditron site has them listed at 4m/s but i don't think that is correct and i think it is more like 4m/m on a 1 um reader and scale. because the person i spoke with told me the 5 um will do 150m/m which i think is more in line with what i seen as far a reader head speeds from other manufactures. this was on their store on aliexpress so maybe the actual website might confirm the correct speed for sure. most of the website information is not in English and only a few aspects are readable for me at least.

this was added after i bought my set of scales but clears some concerns up. so a 1um scale would appear to do up to 2000 IPM and a 5 um scale would appear to do up to 10,000 IPM which seems pretty fast to me? so i would take this with a gain of salt and do some research

this was added after i bought my set of scales but clears some concerns up. so a 1um scale would appear to do up to 2000 IPM and a 5 um scale would appear to do up to 10,000 IPM which seems pretty fast to me? so i would take this with a gain of salt and do some research

Last edit: 26 May 2020 04:11 by machinedude. Reason: more information

Please Log in or Create an account to join the conversation.

Time to create page: 0.166 seconds