just another plasma build and then some :)

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2020 06:12 #161914

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

i think long hours is an under statement  labor of love it seems. i think the sense of accomplishment is what we get out of it.

labor of love it seems. i think the sense of accomplishment is what we get out of it.

that axis could go faster but until i do something on the ball screw for whip that's the happy spot for the screw the way it sits now. acceleration is good here. it will do .3 G but it will shake things accelerating that quick. .1 to .15 G seem good on the frame work. traverse is probably slightly over 300 IMP for now.

that axis could go faster but until i do something on the ball screw for whip that's the happy spot for the screw the way it sits now. acceleration is good here. it will do .3 G but it will shake things accelerating that quick. .1 to .15 G seem good on the frame work. traverse is probably slightly over 300 IMP for now.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

29 Mar 2020 06:47 #161916

by thefabricator03

Replied by thefabricator03 on topic just another plasma build and then some :)

How much longer do you think it will take to get it cutting?

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2020 10:20 #161939

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

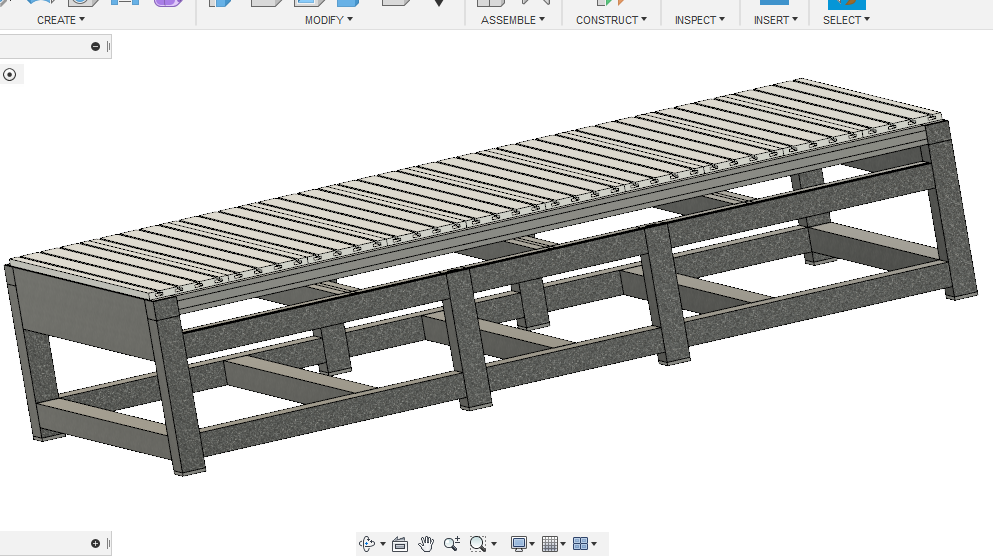

depends on what i plan on cutting, this is why i was working on drag chain. i could see cables getting pinched and getting messed up. i know PVC plastic sheet is going to be first. and then aluminium for a T slot table top. my frame is just a skeleton at this point. the whole thing will look something like this screen grab i modeled up so i can sort out my mold for E.G.

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2020 10:32 #161941

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

if i was locked up like the rest of the country and stuck here not able to work i would say i would be cutting pretty quick. but we make medical parts at my work so we are still working to maintain the supply chain. so i'm still moving at a snails pace as a result of not having a ton of time to work on my stuff at home.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

02 Apr 2020 21:26 #162496

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

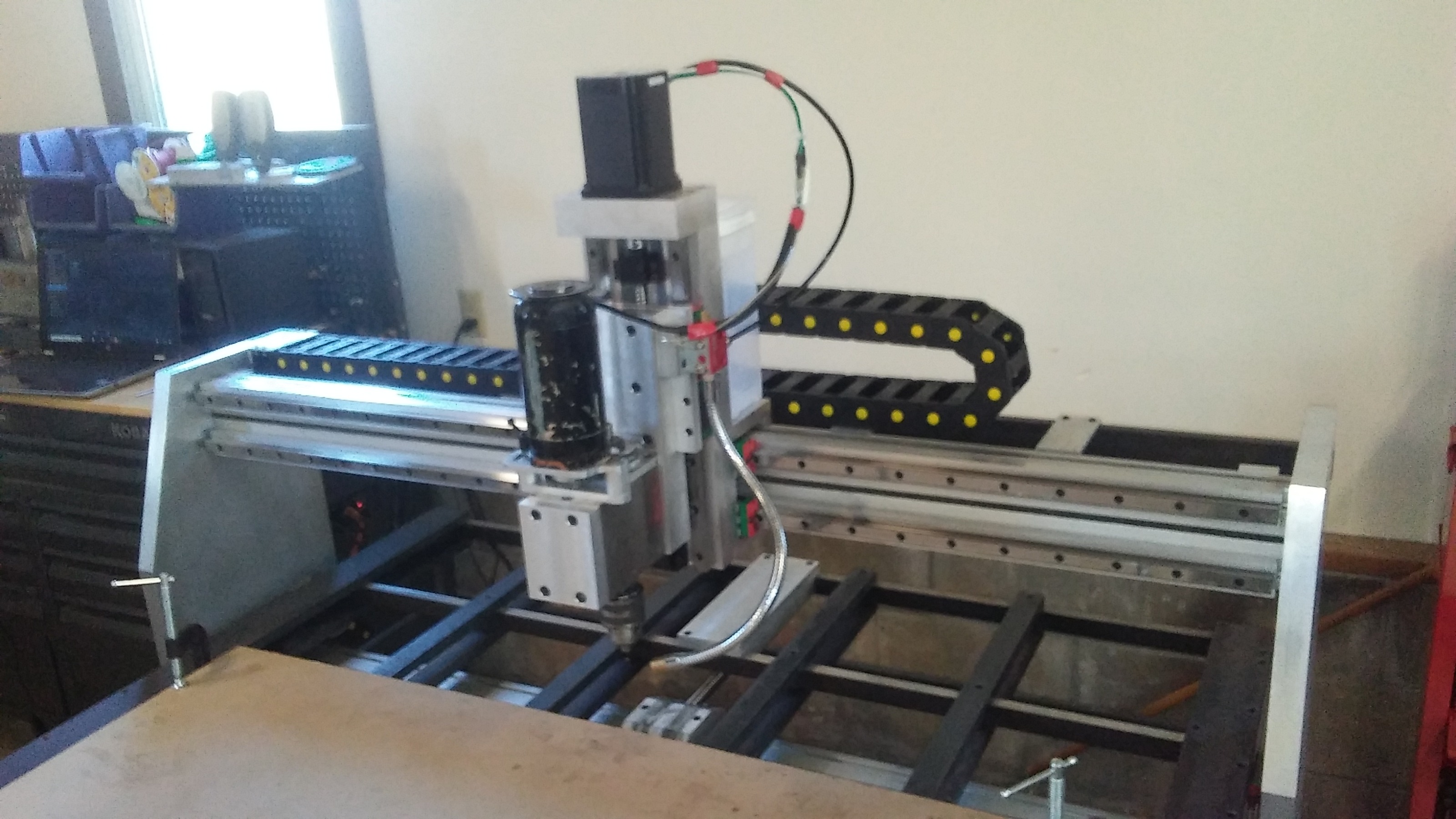

i did manage to get the drag chain mounted along the side and got power to the spindle and rigged up something temporary for now. i have to mess with the pulley on the spindle to get the belt alignment right. i just tossed it together quickly for fitting and mounting before. i think by the weekend i should be at least cutting some plastic. i will probably mount the mist coolant up before that though just to get it out of the way.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

03 Apr 2020 21:07 #162608

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

got the spindle pulley lined up with the belt and got my mister mounted but still have to come up with a way to hold the coolant tank in place. but the ledge on the back of the Z axis looked like a good spot for the tank to find it's home and hitch a ride  i have an air line routed through the drag chain and plan on making a manifold to transition from the plastic air line to a ball valve so i can turn the air on and off nothing fancy just manual controls

i have an air line routed through the drag chain and plan on making a manifold to transition from the plastic air line to a ball valve so i can turn the air on and off nothing fancy just manual controls

it's pretty sad when the highlight of your trip to the dollar store results in you finding a storage container with a lid that is just the right size for your CNC builds

it's pretty sad when the highlight of your trip to the dollar store results in you finding a storage container with a lid that is just the right size for your CNC builds

Attachments:

The following user(s) said Thank You: phillc54, tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

04 Apr 2020 10:21 #162663

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

i have seen a few people who always ask what to use in a mist coolant system? well over the years every shop i have worked at has always used this stuff. Kool mist 77 is what i will use. 1 gallon of coolant costs around $40 but it gets mixed with water and only takes 4 oz. per gallon. so you get 32 gallons of mist coolant for $40

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

04 Apr 2020 12:11 #162667

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

today is my lucky day  i found a 1/4 NPT tap so i can make my manifold for the air supply and control

i found a 1/4 NPT tap so i can make my manifold for the air supply and control  thought i seen one in my grandfathers old stash of stuff. he has been gone for some time now but is hoarding ways still pay off from time to time

thought i seen one in my grandfathers old stash of stuff. he has been gone for some time now but is hoarding ways still pay off from time to time  thanks Pap

thanks Pap

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

05 Apr 2020 01:16 #162737

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

my new timing pulley's came as well and the manual air control works nice. the machine cuts MDF and plastic but i need some more calibration it seems. sizes are off a little. i thought it might have been lost steps but i think it's in the calibration. square and parallel seem good with repeatability being good. so that's where my luck ran out  tomorrows another day

tomorrows another day

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

05 Apr 2020 02:18 #162739

by thefabricator03

Replied by thefabricator03 on topic just another plasma build and then some :)

Not to be a asshole and shit on what you have done. But with my experience with my plasma machine is that it gets very dirty very quickly depending on the cutting you are doing.

My air scribe assembly looked nice and shiny when I first installed it. Now is covered in a thick layer of plasma dust from the water splashing up and the dust it has collected in the air when wet.

I would look into some kind of shield to stop the water splashing on the milling components.

My air scribe assembly looked nice and shiny when I first installed it. Now is covered in a thick layer of plasma dust from the water splashing up and the dust it has collected in the air when wet.

I would look into some kind of shield to stop the water splashing on the milling components.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.244 seconds