just another plasma build and then some :)

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

04 Mar 2020 12:10 #159188

by rodw

Replied by rodw on topic just another plasma build and then some :)

These are the

500 kg brutes of casters

I put in mine. Rated for 380 kg permanently.I also built some adjustable feet out of some M30 (30mm dia) threaded rod. I tried hard to mount the caseters offset to the legs so I could screw them in without removing the caster but it was never going to work. So I had to just weld nuts to the bottom of the legs and put the caster over them.

Even my half sized table is so heavy, its really hard to move anyway even without material and water on board. With the water table full, it would probably be 550kg excluding material. I should weigh it as I have a set of 4 vehicle weighing pads.

Even my half sized table is so heavy, its really hard to move anyway even without material and water on board. With the water table full, it would probably be 550kg excluding material. I should weigh it as I have a set of 4 vehicle weighing pads.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

04 Mar 2020 21:25 #159224

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

500 kg each is what mine are as well and i have 8 of them but mine don't lock like your and are leveling. there is a thumb screw that will raise or lower them independently. the table can be leveled this way. they are not on the wheels all the time and rest on rubber pads when you level the machine. mine is not to bad to move around but you can tell your moving some weigh when you push it around though. so far they work as i expected but things will get heavier as i go.

i am glad i used 8 of them it distributes the weight well across the frame.

i am glad i used 8 of them it distributes the weight well across the frame.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4698

- Thank you received: 1441

04 Mar 2020 22:05 #159227

by Todd Zuercher

Replied by Todd Zuercher on topic just another plasma build and then some :)

8 is great if your floor is perfectly flat. If not, what happens when you roll across a hi or low spot and all the weight sets on only 3 of them?

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

05 Mar 2020 01:27 #159233

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

that's why you get leveling feet in the first place. i don't plan on moving this around that much honestly. when in use all the feet are in contact with the floor so 8 of them are working together. if i move it i will cross my fingers i guess and hope my floor is flat

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

05 Mar 2020 21:02 #159281

by andypugh

I think that the rule for castors is that only three count. As you can only really guatantee that three at a time are touching the floor.

Replied by andypugh on topic just another plasma build

Yeah you probably should be right with eight castors.

I think that the rule for castors is that only three count. As you can only really guatantee that three at a time are touching the floor.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

05 Mar 2020 22:04 #159290

by thefabricator03

I was not aware of that rule. Makes sense though.

Might explain why the 250kg rated units failed on my webbing baskets.

Replied by thefabricator03 on topic just another plasma build

Yeah you probably should be right with eight castors.

I think that the rule for castors is that only three count. As you can only really guatantee that three at a time are touching the floor.

I was not aware of that rule. Makes sense though.

Might explain why the 250kg rated units failed on my webbing baskets.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

06 Mar 2020 08:48 #159302

by machinedude

Replied by machinedude on topic just another plasma build

i just dug around a little bit and what i found is a 33% safety factor should be figured into sizing. so in my case if i expect 4,500 lbs then i should add 33% to that weight which would put me at 5,985 lbs with my safety factor. since they are rated at 1,100 each six of them would cover my needs and still have some room to spare since that would give you 6,600 lbs of support since i have eight of them my safety factor is much higher than 33% and closer to 95% for my safety factor. so i would say i am good and have no need to worry.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 Mar 2020 04:26 #159370

by machinedude

Replied by machinedude on topic just another plasma build

had a chance to put some power to this build and i was thinking the Z axis was going to be pretty slow with a direct drive but i was wrong there. the Z axis is down right fast for a stepper system. i was trying to get it to stall but it just kept giving? the cross axis did about as good as i was thinking but the long axis ran into some screw whip pretty quickly. so i have to see if i can find a solution to improve that axis.

driving the nut would be a solution if i had room but i think that's going to be difficult with how the frame is built. i do have another idea to would work good with how my frame is built so i have to play around with it a little bit to see if i can make it happen.

driving the nut would be a solution if i had room but i think that's going to be difficult with how the frame is built. i do have another idea to would work good with how my frame is built so i have to play around with it a little bit to see if i can make it happen.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 Mar 2020 00:41 - 11 Mar 2020 00:41 #159727

by machinedude

Replied by machinedude on topic just another plasma build

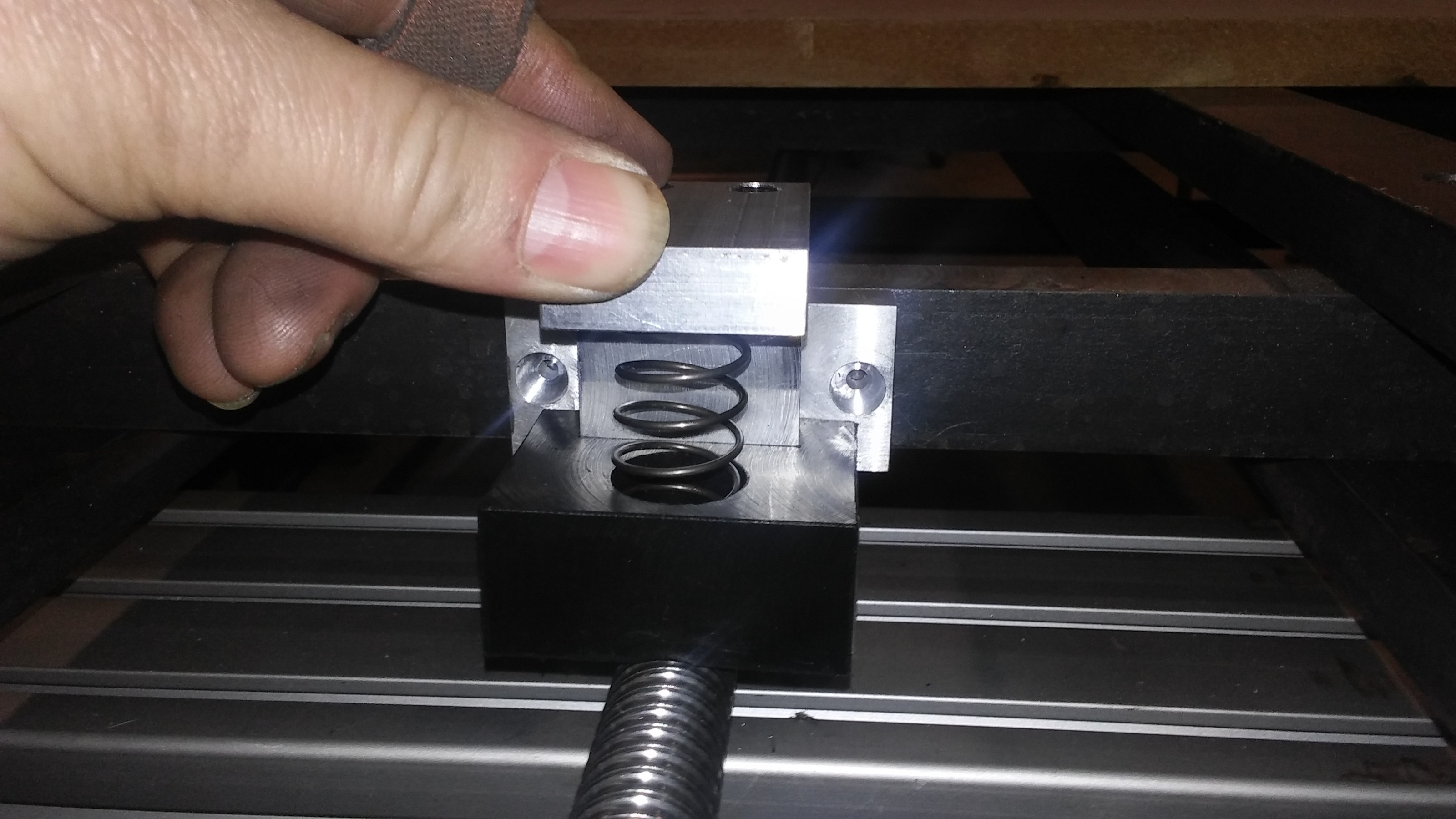

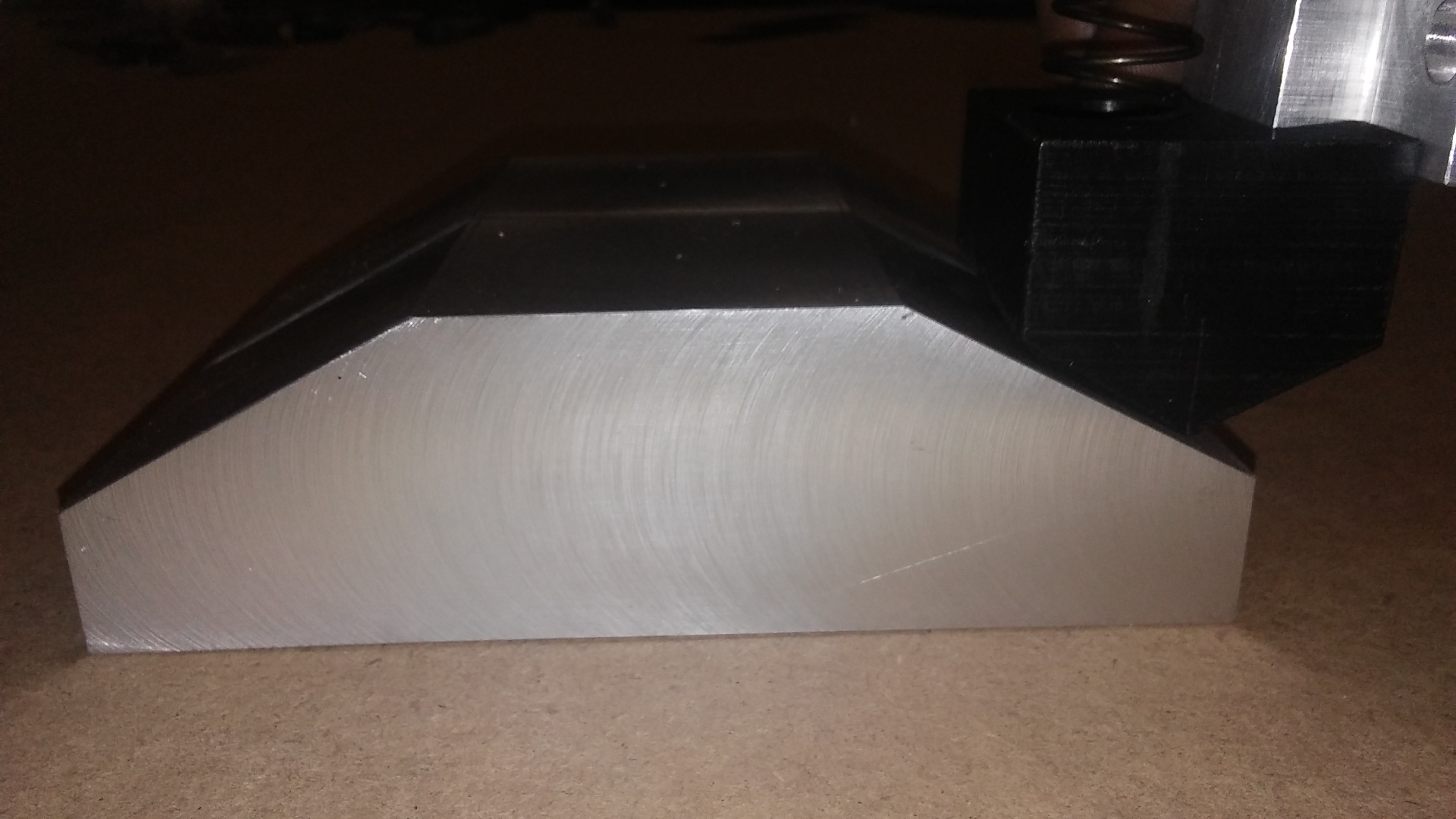

had some time to mess around with a way to control ball screw whip and this is the direction i am going with a solution. the plan is to come up with a way to support the screw and also allow the gantry drive beam to pass under it. the system i came up with should let me add as many as 6 guides but i know for sure i will need at least 2 of them if they work well?

what i have is a spring loaded guide that is located on a dove tail joint that locks the screw guide in on the side to side and the spring provides some tension on the top of the screw to act as a dampener for the screw. when the drive beam approaches it has a entry and exit ramp to push the guide up the dove tail to get it out of the way and the spring pushes it back down the exit ramp as it passes under the drive beam. the guide works well on the dove tail end so i think i am good there but i still have some work on the mounting part and clearance for the ball nut and ball nut housing still. I might loose a little travel on the long axis but if it works i don't mind the trade off for the gains.

what i have is a spring loaded guide that is located on a dove tail joint that locks the screw guide in on the side to side and the spring provides some tension on the top of the screw to act as a dampener for the screw. when the drive beam approaches it has a entry and exit ramp to push the guide up the dove tail to get it out of the way and the spring pushes it back down the exit ramp as it passes under the drive beam. the guide works well on the dove tail end so i think i am good there but i still have some work on the mounting part and clearance for the ball nut and ball nut housing still. I might loose a little travel on the long axis but if it works i don't mind the trade off for the gains.

Attachments:

Last edit: 11 Mar 2020 00:41 by machinedude.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

11 Mar 2020 02:25 #159739

by rodw

Replied by rodw on topic just another plasma build and then some :)

Why don't you look at a rotating nut design? Its very easy if you make a hub containing a bearing that goes around the nut. That way the alignment can't change. There are a few examples on cnc zone. Here is one with a drawing

www.cnczone.com/forums/diy-cnc-router-ta...ines/132889-cnc.html

www.cnczone.com/forums/diy-cnc-router-ta...ines/132889-cnc.html

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.199 seconds