just another plasma build and then some :)

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

01 Dec 2019 21:20 #151701

by machinedude

Replied by machinedude on topic just another plasma build

one other thing i happen to come across was a bolted frame vs welded in vibration dampening. i seen something about bolted frames having better qualities in that respect? i have no idea if it's true or not but i will see sooner or later.

ideally i would like to see if i can end up with a few different head heads to attach to this table for different processes. so this build will end up routing and possibly light gantry milling and then onto plasma just because the first two are low investment compared to a plasma unit.

i think once i get the table top frame work solid the gantry would do well since it's pretty solid despite being aluminum. my gantry is probably close to 200 lbs and i have the motors to handle that sort of work as well.

if light milling works well i am no longer limited to pierce thickness and can do much thicker work. i would like to do a zoned vacuum table in aluminum and have a removable water table for the plasma end when i get to it.

this is not a light weight build at all i should be well over 2,000 lbs minus the water table part of it when i get done.

if nothing else this whole thing should be entertaining at least

ideally i would like to see if i can end up with a few different head heads to attach to this table for different processes. so this build will end up routing and possibly light gantry milling and then onto plasma just because the first two are low investment compared to a plasma unit.

i think once i get the table top frame work solid the gantry would do well since it's pretty solid despite being aluminum. my gantry is probably close to 200 lbs and i have the motors to handle that sort of work as well.

if light milling works well i am no longer limited to pierce thickness and can do much thicker work. i would like to do a zoned vacuum table in aluminum and have a removable water table for the plasma end when i get to it.

this is not a light weight build at all i should be well over 2,000 lbs minus the water table part of it when i get done.

if nothing else this whole thing should be entertaining at least

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3913

04 Dec 2019 07:58 #151955

by rodw

Did someone mention China! I'm there right now but I think a flat pack plasma might be a bit beyond my carry on luggage limit!

I'm in Shanghai for an automotive trade show. Spent the last 2 days walking and still have not got around all of the 6000 exhibitors.

Replied by rodw on topic just another plasma build

Sure would make it easy to get a flat pack made and sent to you from China. Assembly Required!!

Did someone mention China! I'm there right now but I think a flat pack plasma might be a bit beyond my carry on luggage limit!

I'm in Shanghai for an automotive trade show. Spent the last 2 days walking and still have not got around all of the 6000 exhibitors.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

04 Dec 2019 08:18 #151957

by machinedude

Replied by machinedude on topic just another plasma build

that's OK. like i said i have multiple plans for different uses so i would never find a pre made kit to equal the train wreck of ideas floating about in my head  so your off the hook on smuggling anything out of the country

so your off the hook on smuggling anything out of the country  besides i doubt they have WiFi in the camps so the community here would miss you

besides i doubt they have WiFi in the camps so the community here would miss you

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3913

04 Dec 2019 08:30 #151958

by rodw

Plus they fingerprinted and photographed every foreigner as we entered the country. Pretty amazing place.

Replied by rodw on topic just another plasma build

that's OK. like i said i have multiple plans for different uses so i would never find a pre made kit to equal the train wreck of ideas floating about in my head

so your off the hook on smuggling anything out of the country

besides i doubt they have WiFi in the camps so the community here would miss you

Plus they fingerprinted and photographed every foreigner as we entered the country. Pretty amazing place.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

04 Dec 2019 08:35 #151959

by machinedude

Replied by machinedude on topic just another plasma build

i'll take your word for it and just admire from afar  internet has all kinds of pictures that will do just fine for me

internet has all kinds of pictures that will do just fine for me

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

06 Feb 2020 23:53 #156667

by machinedude

Replied by machinedude on topic just another plasma build

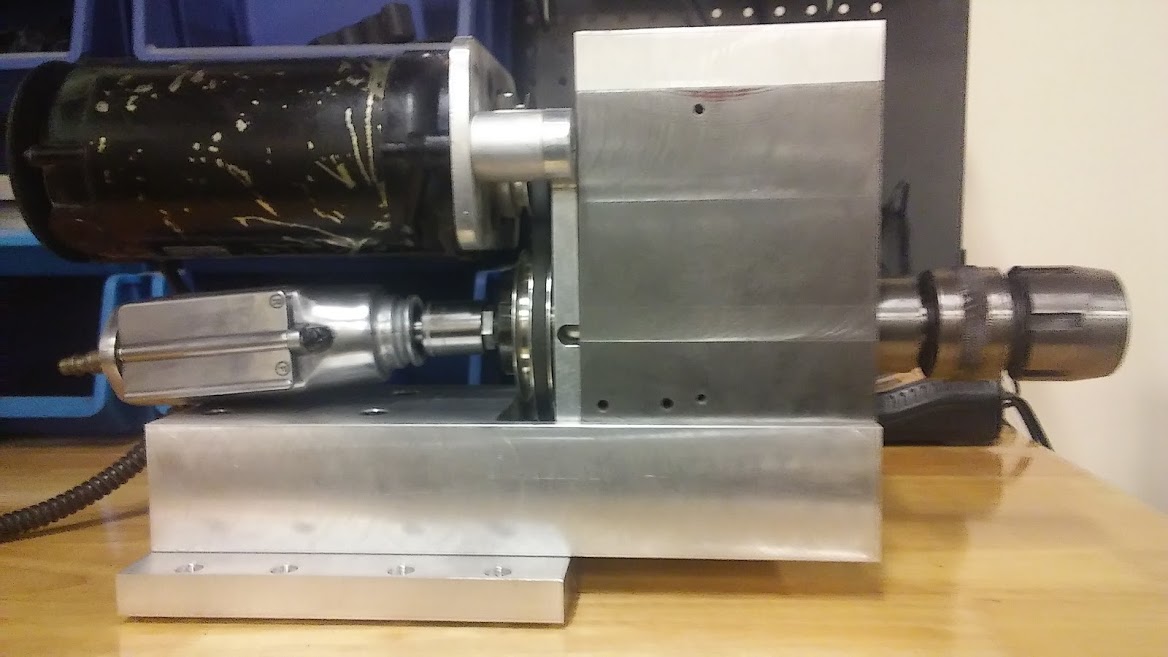

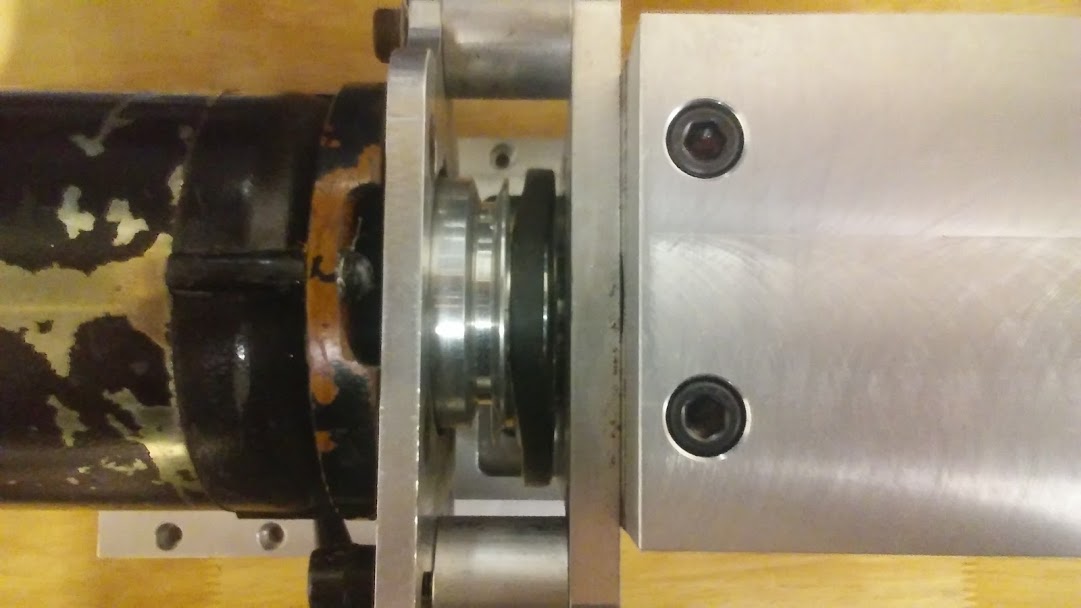

so you see people putting air drills on Plasma so i figured i would make gantry mill head to mount for large work from a mini mill spindle i had sitting around doing nothing  first stab at it was not that great since the spindle center line was to far off the Z axis so i got creative and spun the entire thing 180 degrees and cut that distance in half so it now sits about 4" off the bearing blocks for the Z axis.

first stab at it was not that great since the spindle center line was to far off the Z axis so i got creative and spun the entire thing 180 degrees and cut that distance in half so it now sits about 4" off the bearing blocks for the Z axis.

not sure how well it will work but figured i would see if i could get it to work for something useful i had this on a T slot fame machine and got it to cut around 28 IPM with about 1/16 step over in aluminum but was not happy with the light T slot frame.i think this spindle will do better on a decent frame with some weight to it.

it was free so might as well play around with it and see if i can make use of it.

i had this on a T slot fame machine and got it to cut around 28 IPM with about 1/16 step over in aluminum but was not happy with the light T slot frame.i think this spindle will do better on a decent frame with some weight to it.

it was free so might as well play around with it and see if i can make use of it.

not sure how well it will work but figured i would see if i could get it to work for something useful

Attachments:

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

06 Feb 2020 23:58 #156668

by thefabricator03

Replied by thefabricator03 on topic just another plasma build

Thats pretty cool.

Can wait to see it in action!

Can wait to see it in action!

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 Feb 2020 00:05 #156669

by machinedude

Replied by machinedude on topic just another plasma build

this spindle has the speed range for mild steel cutting and i think it might work in a mild steel for some stuff as well. you see a lot of people try to tackle steel with a high speed spindle for wood all the time and they never do well this might be a solution since it will have a high and low range to get some proper speeds for steel and heavy enough bearings as well.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

08 Feb 2020 21:33 #156783

by machinedude

Replied by machinedude on topic just another plasma build

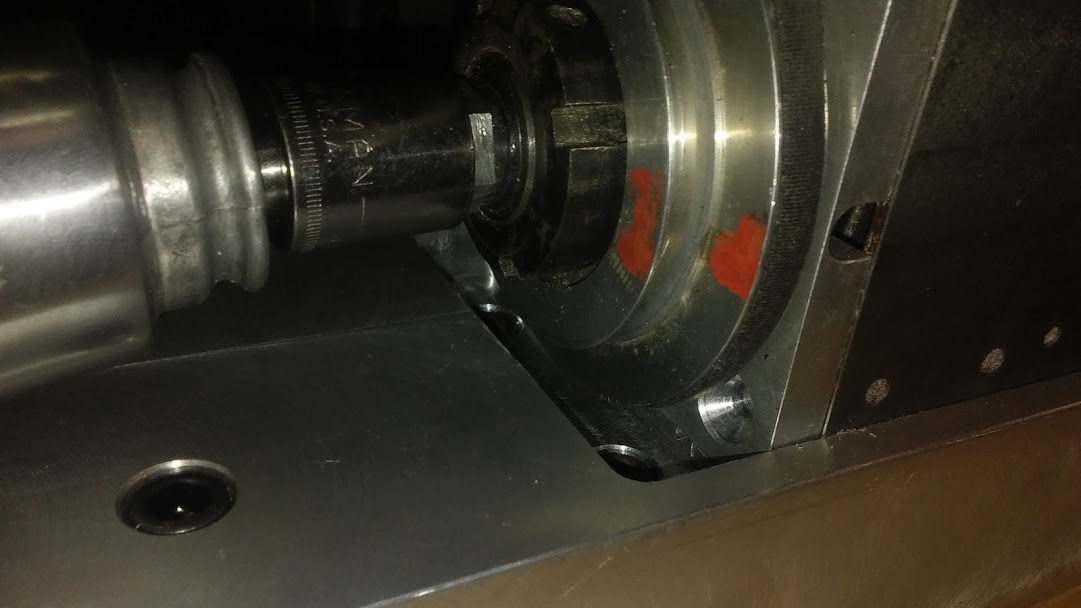

re worked a few things to see if i could give this thing the best chance of working well and after spending another day messing with it it's a little closer to being something useful but i think the weak link is the T slot extrusion beam across the table. i had the Z axis completely off the machine and had it in a vise on the bridgeport and that end is solid. i get some deflection once everything is on the cross beam. i have one other thing i could try to make the cross beam more solid and i am sure it would help some. only down side is adding more weight to the gantry in the process.

weight is not an issue with the mini mill head i had it going up and down the axis with a cordless drill with the clutch on the lowest setting and it work fine here with no issues there.

weight is not an issue with the mini mill head i had it going up and down the axis with a cordless drill with the clutch on the lowest setting and it work fine here with no issues there.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Feb 2020 07:06 #156837

by machinedude

Replied by machinedude on topic just another plasma build

the other thing i was thinking about was the fill the hollow voids in the T slot cross beam with epoxy granite. if this would be enough to fix the deflection it would have an added bonus of vibration dampening on top of that which would be a big plus for this kind of application. i know the T slot is going to resonate a lot as is. i doubt the little bit of cast iron on the spindle housing will dampen much.

i have played around with epoxy granite and it is pretty amazing how much it deadens resonance. the compression strength is about the same as concrete but the material only shrinks about a .001 (imperial) and .03 mm for you metric folks cool stuff

cool stuff

i have played around with epoxy granite and it is pretty amazing how much it deadens resonance. the compression strength is about the same as concrete but the material only shrinks about a .001 (imperial) and .03 mm for you metric folks

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 4.841 seconds