MonoKrom - QtPyVCP GUI for PlasmaC and Mill

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

28 Sep 2020 12:09 #184151

by tommylight

Replied by tommylight on topic MonoKrom - QtPyVCP GUI for PlasmaC

OH Hell NO !!!Can we get a cool little animated paper clip to bounce around the screen and periodically offer help and tips and tricks?!

The following user(s) said Thank You: oddwick, AgentWD40

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

28 Sep 2020 12:21 #184155

by rodw

CBEAR, the original NC control from Amada was a push button affair. The previous owners ( a lawn mower manufacturer about a mile from my shop) had a few Amadas all retofitted with the Icon100 Presstek Control. See icontrol.net.au/

Its a 6 axis servo controller. The local Prestek technician who did the retofit 2-3 years ago has been around a couple of time to get it going and is very helpful and knowledgeable. He has not even sent me a bill!

My machine only has X & Y axes and I asked him how hard it would be to control the other axes if I was silly enough to add a few more servos and he said it could be done pretty easilly.

You can create your own punches and dies in the software by filling out a few measurements. There are a few videos on their site to give you a feel for it and also I think you can download a demo of the software. When I popped in the Odroid, a copy of Windows 10 and a new touch screen, I was able to set that all up away from the press.

It has a cool looking graphical screen you can draw your parts but the tech said most people just build a list of bends. I think that would be pretty easy to achieve in Qtpyvcp. It does a lot of error checking and it won't run until all systems are green for go! There are also a few other settings for retract and dwell on each bend as well. You could just build a csv file to represent each bend. You can't drag and drop bends so yes, if you knew the maths and how to calibrate for bend depth, It would be pretty easy.and be rolled up into a custom component

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC

Rod, is this the stock controller on your brake, or is this something that you're working on making? I've wondered why there aren't many, if any, linux controlled press brakes. I see enough of them up for sale with bad controllers, and the controllers themselves cost a fortune. I figured that there would be some linux retrofits out there. It seems like one could be made fairly easily. I don't know how to code for it, but I could definitely help write the formulas that would be needed on the computed calculation side of things.

CBEAR, the original NC control from Amada was a push button affair. The previous owners ( a lawn mower manufacturer about a mile from my shop) had a few Amadas all retofitted with the Icon100 Presstek Control. See icontrol.net.au/

Its a 6 axis servo controller. The local Prestek technician who did the retofit 2-3 years ago has been around a couple of time to get it going and is very helpful and knowledgeable. He has not even sent me a bill!

My machine only has X & Y axes and I asked him how hard it would be to control the other axes if I was silly enough to add a few more servos and he said it could be done pretty easilly.

You can create your own punches and dies in the software by filling out a few measurements. There are a few videos on their site to give you a feel for it and also I think you can download a demo of the software. When I popped in the Odroid, a copy of Windows 10 and a new touch screen, I was able to set that all up away from the press.

It has a cool looking graphical screen you can draw your parts but the tech said most people just build a list of bends. I think that would be pretty easy to achieve in Qtpyvcp. It does a lot of error checking and it won't run until all systems are green for go! There are also a few other settings for retract and dwell on each bend as well. You could just build a csv file to represent each bend. You can't drag and drop bends so yes, if you knew the maths and how to calibrate for bend depth, It would be pretty easy.and be rolled up into a custom component

The following user(s) said Thank You: pinder

Please Log in or Create an account to join the conversation.

- KCJ

-

- Offline

- Moderator

-

Less

More

- Posts: 328

- Thank you received: 267

28 Sep 2020 12:28 #184159

by KCJ

Replied by KCJ on topic MonoKrom - QtPyVCP GUI for PlasmaC

Rod, we have an old but massive (65,000lb) 6mmx3500mm mild steel capacity folding machine. If I had the time I'd love to convert it to LinuxCNC, but I'm afraid we'll just have to scrap it. I've been slowly removing and saving all the good bits like motors and drives, so it won't be a total loss.

The following user(s) said Thank You: rodw, pinder

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

28 Sep 2020 12:58 #184164

by rodw

What no MonoKrom-Fold?

I was thinking that if all of the data was collected in a csv file for each bend, it could just spit out a bit of calculated gcode to drive the axes and actuate the ram when you pressed the pedal. Something like Axis remote might be able to send the gcode without actually writing out a file.

You might be able to create a Vismach model to run through a sim on another tab (which is included in the Icon).

Anyway, enough of this, we need a plasma cutter to make parts for the folder first!

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC

Rod, we have an old but massive (65,000lb) 6mmx3500mm mild steel capacity folding machine. If I had the time I'd love to convert it to LinuxCNC, but I'm afraid we'll just have to scrap it. I've been slowly removing and saving all the good bits like motors and drives, so it won't be a total loss.

What no MonoKrom-Fold?

I was thinking that if all of the data was collected in a csv file for each bend, it could just spit out a bit of calculated gcode to drive the axes and actuate the ram when you pressed the pedal. Something like Axis remote might be able to send the gcode without actually writing out a file.

You might be able to create a Vismach model to run through a sim on another tab (which is included in the Icon).

Anyway, enough of this, we need a plasma cutter to make parts for the folder first!

The following user(s) said Thank You: KCJ, pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

28 Sep 2020 13:03 #184165

by pinder

The very first thing would be to add linear encoders.

Those wired to mesa and to linuxcnc.

Then we need some control valves for hydraulic pumps.

Using some kind of PID, we have to sync axis displacement and DRO.

when we get the z (or Y vertical axis, tool) moving.

Which is most important I think.

we can use some steppers amd linear guides for back suppprt.

When we are able to control all axis precisly then a GUI with all formulas for bend angles can be used.

I hope I'm somewhat right. or just ignore me.

I cant stay quiet.

Replied by pinder on topic MonoKrom - QtPyVCP GUI for PlasmaC

Idea for Linuxcnc Press brake.Rod, we have an old but massive (65,000lb) 6mmx3500mm mild steel capacity folding machine. If I had the time I'd love to convert it to LinuxCNC, but I'm afraid we'll just have to scrap it. I've been slowly removing and saving all the good bits like motors and drives, so it won't be a total loss.

The very first thing would be to add linear encoders.

Those wired to mesa and to linuxcnc.

Then we need some control valves for hydraulic pumps.

Using some kind of PID, we have to sync axis displacement and DRO.

when we get the z (or Y vertical axis, tool) moving.

Which is most important I think.

we can use some steppers amd linear guides for back suppprt.

When we are able to control all axis precisly then a GUI with all formulas for bend angles can be used.

I hope I'm somewhat right. or just ignore me.

I cant stay quiet.

The following user(s) said Thank You: rodw, Franklin

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

28 Sep 2020 13:17 #184168

by rodw

You just want to paint the world yellow!

I kinda think CBEAR is right. once you got into it, it would be pretty simple.

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC

Idea for Linuxcnc Press brake.

The very first thing would be to add linear encoders.

Those wired to mesa and to linuxcnc.

Then we need some control valves for hydraulic pumps.

Using some kind of PID, we have to sync axis displacement and DRO.

when we get the z (or Y vertical axis, tool) moving.

Which is most important I think.

we can use some steppers amd linear guides for back suppprt.

When we are able to control all axis precisly then a GUI with all formulas for bend angles can be used.

I hope I'm somewhat right. or just ignore me.

I cant stay quiet.

You just want to paint the world yellow!

I kinda think CBEAR is right. once you got into it, it would be pretty simple.

The following user(s) said Thank You: pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

30 Sep 2020 04:24 - 30 Sep 2020 04:25 #184348

by pinder

Replied by pinder on topic MonoKrom - QtPyVCP GUI for PlasmaC

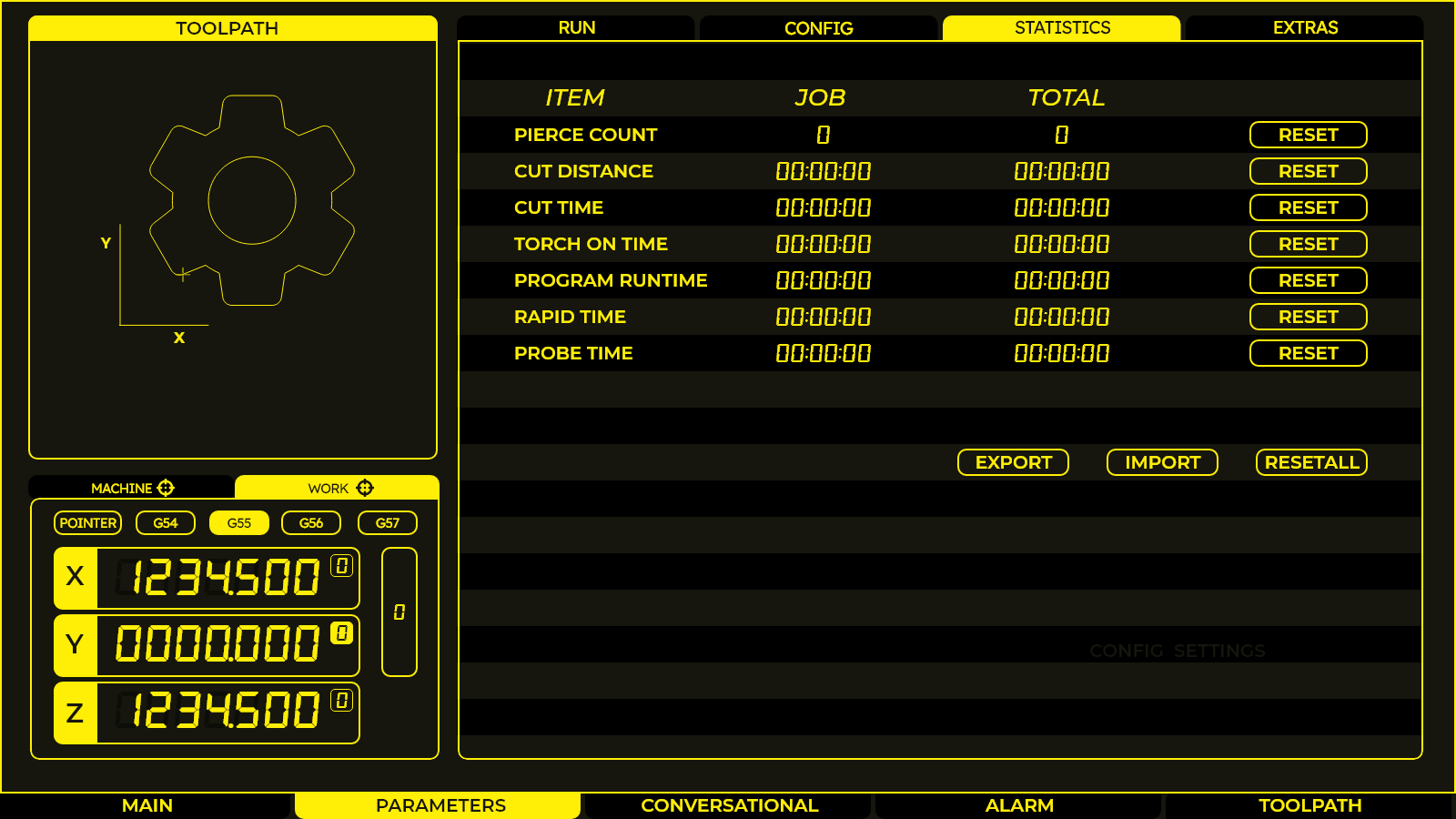

Statistics panel done;

I'll get some hands-on with qt designer.

I think option of exporting stat data to csv or other suitable format would be excellent for some people, even importing it will help in some cases.

if it is stored in csv, then i thin it will be pretty simple.

svg is in the zip

I'll get some hands-on with qt designer.

I think option of exporting stat data to csv or other suitable format would be excellent for some people, even importing it will help in some cases.

if it is stored in csv, then i thin it will be pretty simple.

svg is in the zip

Attachments:

Last edit: 30 Sep 2020 04:25 by pinder.

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

30 Sep 2020 06:18 - 30 Sep 2020 06:21 #184355

by pinder

Replied by pinder on topic MonoKrom - QtPyVCP GUI for PlasmaC

Attachments:

Last edit: 30 Sep 2020 06:21 by pinder.

Please Log in or Create an account to join the conversation.

- KCJ

-

- Offline

- Moderator

-

Less

More

- Posts: 328

- Thank you received: 267

30 Sep 2020 11:15 - 30 Sep 2020 11:15 #184371

by KCJ

Replied by KCJ on topic MonoKrom - QtPyVCP GUI for PlasmaC

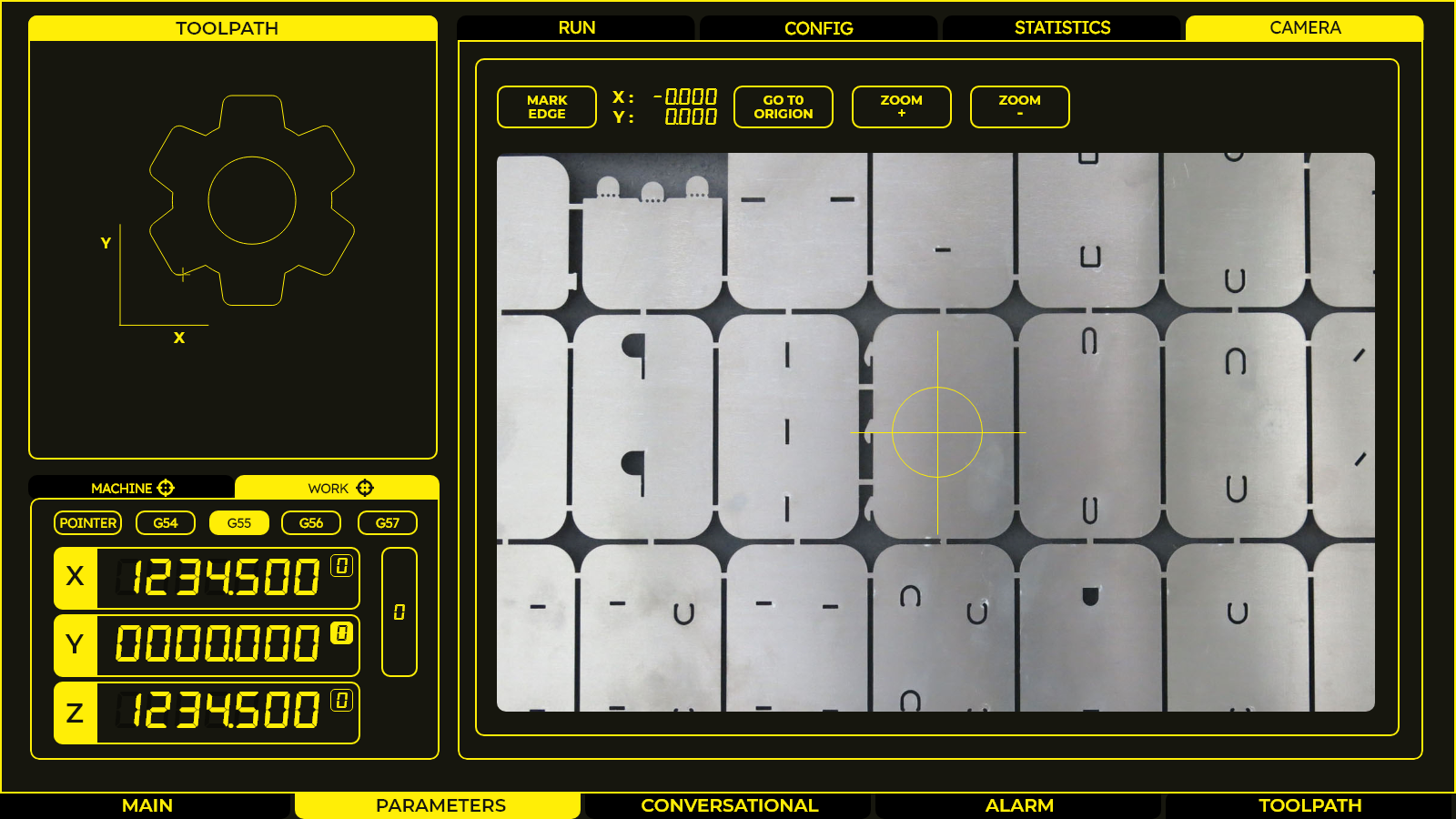

Looks good!

A camera panel is a requirement I think. And is easy to add from a programing point of view, so there is no reason not to.

I made great ptoy on reading and writing the run setting last night. I'll post when I get home from work this evening.

Pinder, can you wip up a simple design for a splash screen witth loading progress indicator? I'm no good at design...

Cheers,

Kurt

A camera panel is a requirement I think. And is easy to add from a programing point of view, so there is no reason not to.

I made great ptoy on reading and writing the run setting last night. I'll post when I get home from work this evening.

Pinder, can you wip up a simple design for a splash screen witth loading progress indicator? I'm no good at design...

Cheers,

Kurt

Last edit: 30 Sep 2020 11:15 by KCJ.

The following user(s) said Thank You: pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

30 Sep 2020 11:30 #184372

by pinder

Replied by pinder on topic MonoKrom - QtPyVCP GUI for PlasmaC

SureLooks good!

A camera panel is a requirement I think. And is easy to add from a programing point of view, so there is no reason not to.

I made great ptoy on reading and writing the run setting last night. I'll post when I get home from work this evening.

Pinder, can you wip up a simple design for a splash screen witth loading progress indicator? I'm no good at design...

Cheers,

Kurt

The following user(s) said Thank You: KCJ

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.341 seconds