Homemade, cheap, plasma CNC

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 13:25 #207450

by RNJFAB

Homemade, cheap, plasma CNC was created by RNJFAB

So long time reader, first time poster.

** Photos will be uploaded soon **

I'm in Australia so all measurements are in mm (25mm = 1 inch) and all $ are AUD (1AUD = 0.70USD)

I built my own CNC plasma, with lots of hiccups, and want to share my experience for others looking to go down this path.

My build started in Jan 2020, with the plan that this would be made for my students so they had access to a CNC, buying one was out of our reach.

With the help of a few mates (much smarted than me) I worked through getting the right advise on what to buy to reach the end goal, that being a CNC that had a working area of 1200x1200, capable of plasma and router setup, cheap, using the existing Plasma we had and routers.

So I started by finding hardware that would work for us, this was found in 1200mm ball screws and 1300mm linear rails (mistake). this coupled with NEMA 23 stepper motors(Good) and TH6600 stepper motors (Good), Mach 3 USB board (Mistake).

These were all put together with what I thought would be the best frame (using material I had scavenged over the years). This was 75x75x3mm Gal RHS.

Then the gantry from another piece of 75x75x3mm with some angle to hold the bearings.

I decided on a waterbed as a cheap and suitable solution, 50x50 angle with a 2mm base, fully welded.

** Photos will be uploaded soon **

I'm in Australia so all measurements are in mm (25mm = 1 inch) and all $ are AUD (1AUD = 0.70USD)

I built my own CNC plasma, with lots of hiccups, and want to share my experience for others looking to go down this path.

My build started in Jan 2020, with the plan that this would be made for my students so they had access to a CNC, buying one was out of our reach.

With the help of a few mates (much smarted than me) I worked through getting the right advise on what to buy to reach the end goal, that being a CNC that had a working area of 1200x1200, capable of plasma and router setup, cheap, using the existing Plasma we had and routers.

So I started by finding hardware that would work for us, this was found in 1200mm ball screws and 1300mm linear rails (mistake). this coupled with NEMA 23 stepper motors(Good) and TH6600 stepper motors (Good), Mach 3 USB board (Mistake).

These were all put together with what I thought would be the best frame (using material I had scavenged over the years). This was 75x75x3mm Gal RHS.

Then the gantry from another piece of 75x75x3mm with some angle to hold the bearings.

I decided on a waterbed as a cheap and suitable solution, 50x50 angle with a 2mm base, fully welded.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 13:27 #207451

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Attachments:

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

30 Apr 2021 13:40 - 30 Apr 2021 13:41 #207453

by AgentWD40

Replied by AgentWD40 on topic Homemade, cheap, plasma CNC

Nice! That Z is a beast!

Is it burning metal yet?

Is it burning metal yet?

Last edit: 30 Apr 2021 13:41 by AgentWD40.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 13:45 - 30 Apr 2021 13:47 #207454

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Last edit: 30 Apr 2021 13:47 by RNJFAB.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 13:48 - 30 Apr 2021 13:51 #207456

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Once up and running it worked great for what it was, a sub $2000 cnc plasma, that had a cutting area of 1200x1200, using the cheap Cut50 plasma capable of 6mm steel cutting.

This worked great, although there were quite a lot of adjustments and modifications that were made over the next 6 months to improve flaws with the initial design. New gantry to stop pitching, multiple z axis remakes, deeper waterbed, adjustable slat holders, water tank, pluming, control box, THC, etc.

Some of the little signs I was making.

This worked great, although there were quite a lot of adjustments and modifications that were made over the next 6 months to improve flaws with the initial design. New gantry to stop pitching, multiple z axis remakes, deeper waterbed, adjustable slat holders, water tank, pluming, control box, THC, etc.

Some of the little signs I was making.

Attachments:

Last edit: 30 Apr 2021 13:51 by RNJFAB.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 13:52 #207457

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Fast forward a few months and I realise that I have reached the limits of Mach 3 and its USB board, at this point I started looking for what other options were out there, I looked into a better board for Mach3 and in doing so looked for comparable systems with all the learned knowledge over the previous 12 months. It was around this time that Mach3 started to hiccup and I was loosing sheets of material as a step would be skipped or the alignment would go out causing an entire sheet of cutting to be wasted.

At this point I discovered LinuxCNC and some of its capabilities, scared because I'm not super programming inclined (like most of you smart people here) and worried that it would be too big of a transition, I delayed this for about 6 months. Finally after meeting a fellow forum user (and Linux master - RodW) I was ready to take the plunge into LinuxCNC.

I went with a MESA 7i96 board with THCAD10. This was chosen for price and my level of machine inputs and outputs (10 inputs, 3 outputs). The inital changeover was full of headaches, physical connections were straight forward based on the information from manuals and this forum, however the Linux setup proved too much for me. At this point I somehow managed to wipe my laptop trying to dual boot with windows and Linux (I'm blaming lack of sleep leading up to this). At this point I was done, exhausted, brain fried, 12 months worth of drawings, cut files, tool settings, etc, gone, lost.......

At this point I discovered LinuxCNC and some of its capabilities, scared because I'm not super programming inclined (like most of you smart people here) and worried that it would be too big of a transition, I delayed this for about 6 months. Finally after meeting a fellow forum user (and Linux master - RodW) I was ready to take the plunge into LinuxCNC.

I went with a MESA 7i96 board with THCAD10. This was chosen for price and my level of machine inputs and outputs (10 inputs, 3 outputs). The inital changeover was full of headaches, physical connections were straight forward based on the information from manuals and this forum, however the Linux setup proved too much for me. At this point I somehow managed to wipe my laptop trying to dual boot with windows and Linux (I'm blaming lack of sleep leading up to this). At this point I was done, exhausted, brain fried, 12 months worth of drawings, cut files, tool settings, etc, gone, lost.......

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

30 Apr 2021 15:26 #207460

by robertspark

Replied by robertspark on topic Homemade, cheap, plasma CNC

sometimes you can use disc recovery software (I have been successful in the past sometimes with formatted drives and sometimes failed drives too)

I have never paid for the software as there are some free software solutions about.

welcome to linuxcnc

I have never paid for the software as there are some free software solutions about.

welcome to linuxcnc

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 20:34 - 30 Apr 2021 22:24 #207484

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

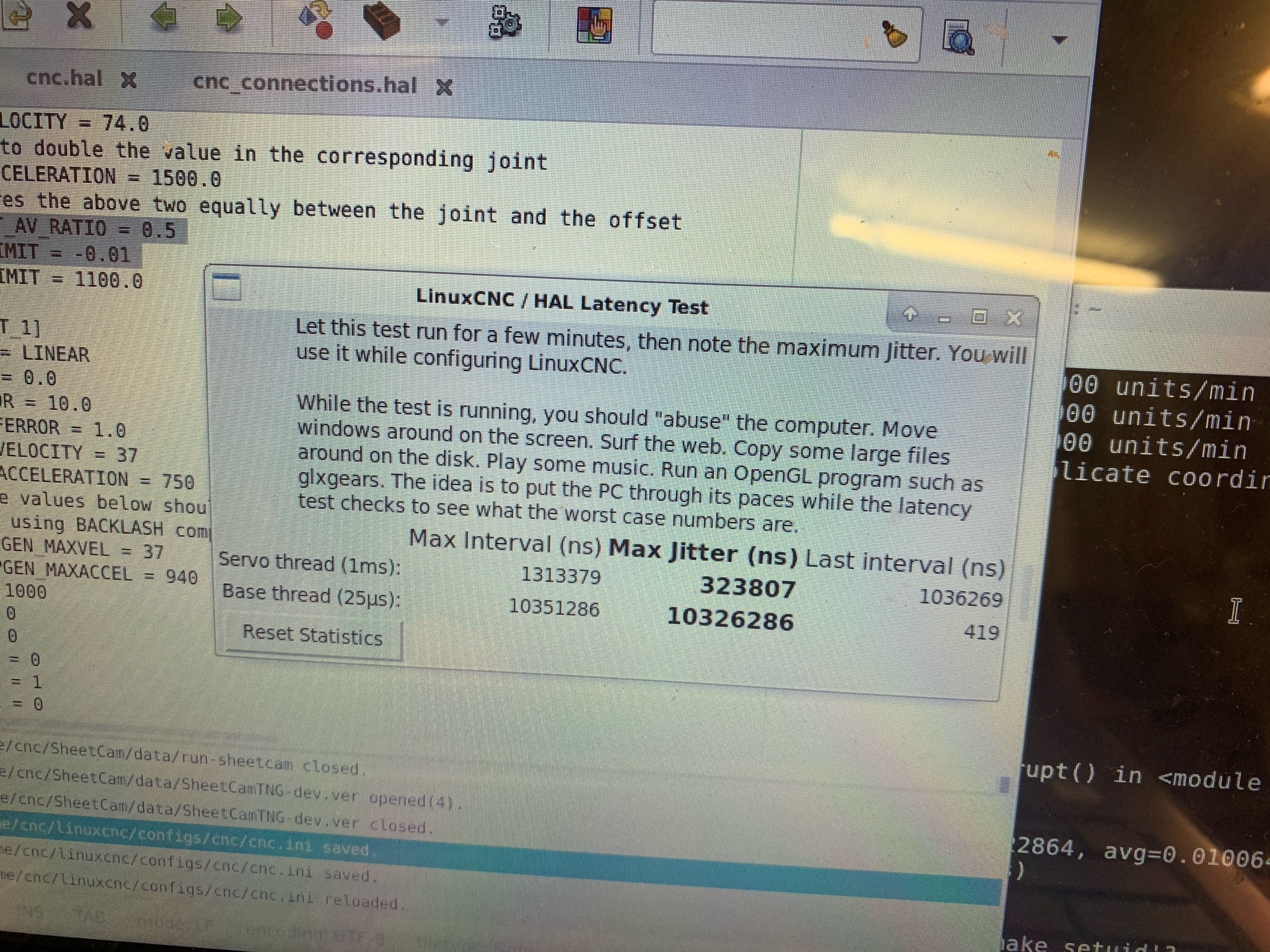

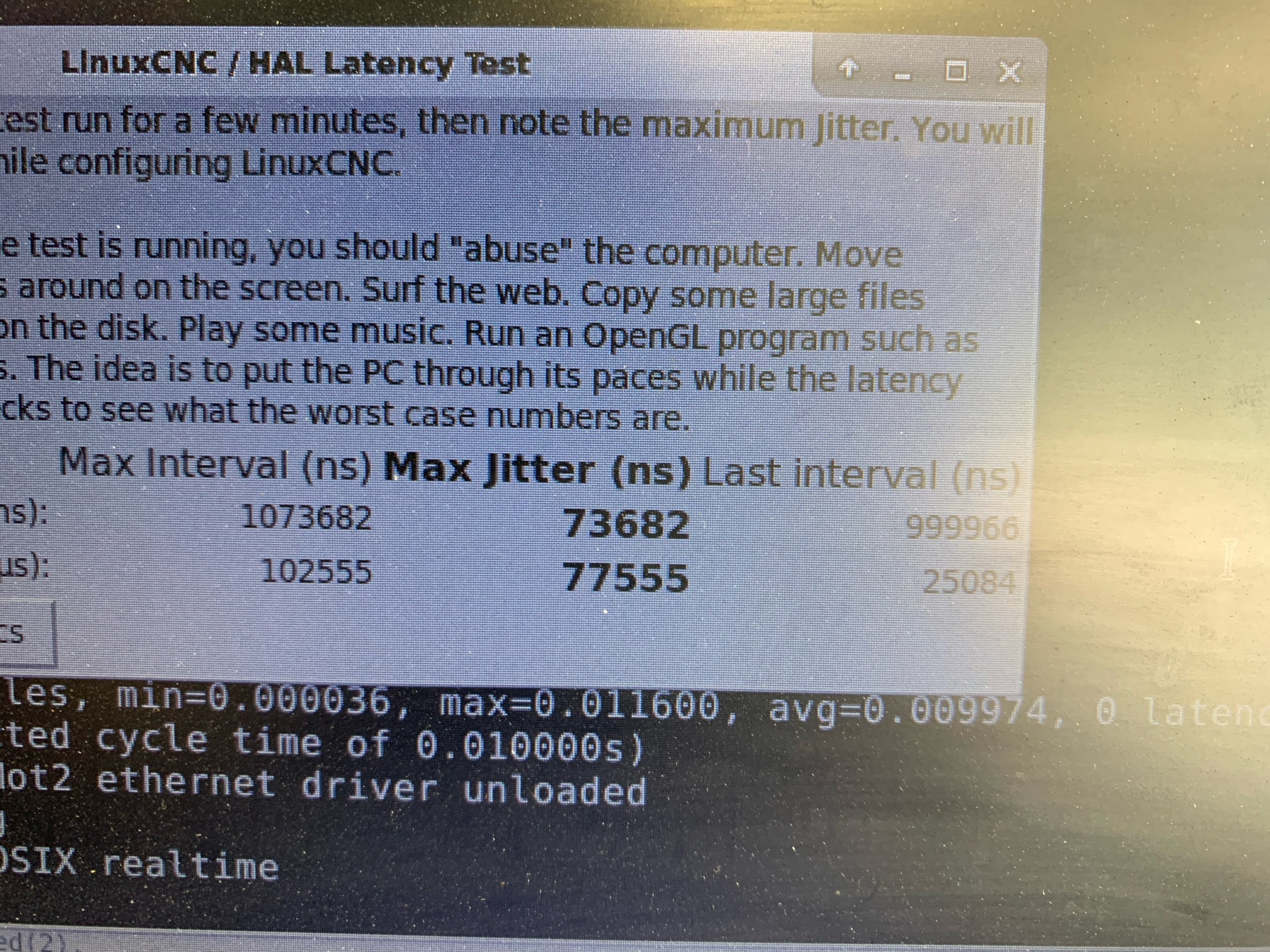

So with a new laptop capable of Linux, I started to load everything, first problem was the latency tests, these were coming back at around 10 000 000. Yes 10 million, way too high for LinuxCNC to run. The IT guys did everything to get the laptop to work (I chose a laptop as I wanted the touch screen) but we were unable to get latency under 5 million until we changed a bunch of bios settings and turned off some of the systems in the back end of the laptop. This got us down to under 1 million which was ok for us to get a connection.

With the help of RodW who came out and helped work through a series of my mistakes, we were able to get a machine that moved, it didn't work but it did move. Victory I thought was close. WRONG.

With the help of RodW who came out and helped work through a series of my mistakes, we were able to get a machine that moved, it didn't work but it did move. Victory I thought was close. WRONG.

Last edit: 30 Apr 2021 22:24 by RNJFAB.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

30 Apr 2021 20:35 #207485

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Rod left me with a list of things to get sorted, these were around the limit/home proximity sensors. So I worked away on these and continue to improve the Hal and ini files as I read and learned (lots from Rod and a little from google). I had good movement, accurate travel distance, good speed. I finally was ready to go from linuxCNC to PlasmaC, I realised that I needed another wire to feed the probe sensor(5V) so cut a wire that was running to the proximity sensor(24V) and shorted the board, pooooooffffffff, the MESA 7i96 let out the magic smoke. dead. gone.

As you can imagen, at this point I though about just giving up and throwing it all away, how do I explain to the wife that the board I waited 6 weeks for, I just fried, and now I have to buy another one. Lucky she understands that I make mistakes, but I learn and I love making things.

................ more to come

As you can imagen, at this point I though about just giving up and throwing it all away, how do I explain to the wife that the board I waited 6 weeks for, I just fried, and now I have to buy another one. Lucky she understands that I make mistakes, but I learn and I love making things.

................ more to come

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

30 Apr 2021 22:32 #207497

by robertspark

Replied by robertspark on topic Homemade, cheap, plasma CNC

did you have a real-time kernel installed?

getting jitter like that implies not using the RT kernel

getting jitter like that implies not using the RT kernel

Please Log in or Create an account to join the conversation.

Time to create page: 0.742 seconds