Homemade, cheap, plasma CNC

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

18 Jul 2021 09:47 #215215

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Hey Phill,

I'll have to grab it off the CNC computer tomorrow.

I'm setup so I draw and convert with sheet cam on one computer, then usb transfer to cnc computer to cut.

I have sheet cam on the cnc computer but my tool list doesn't work and it is glitchy so I do this on the other computer first.

I am running the spaceship post processor from Rod.

On pierce and cut everything works fine.

I'll have to grab it off the CNC computer tomorrow.

I'm setup so I draw and convert with sheet cam on one computer, then usb transfer to cnc computer to cut.

I have sheet cam on the cnc computer but my tool list doesn't work and it is glitchy so I do this on the other computer first.

I am running the spaceship post processor from Rod.

On pierce and cut everything works fine.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

18 Jul 2021 10:13 #215218

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

No worries, I wouldn't be able to do much tonight anyhow.

I am not sure about Rod's PP, I havent used it at all. We did have a PP here but some folk complained about the the workflow for doing spotting so SheetCam made their own which is packaged with the software. I then removed ours so we had one less thing to support. I haven't used the SheetCam one but I think Rod has, I still use our old one.

I am not sure about Rod's PP, I havent used it at all. We did have a PP here but some folk complained about the the workflow for doing spotting so SheetCam made their own which is packaged with the software. I then removed ours so we had one less thing to support. I haven't used the SheetCam one but I think Rod has, I still use our old one.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Jul 2021 21:32 #215260

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

I wouldn't use my post processor any more. I was using Phills for along time. I have used the Sheetcam one and it works too!

More recently Sheetcams post processor can be set to use the "magic" comments which then allows Sheetcam to be the master of settings so there is no longer any inconsistencies between Sheetcam and Plasmac. I think this is a good thing. There should only be a single point of truth and Sheetcam assumes it is that source. But Plasmac assumes the same too!

Its always a good idea to view a new postprocessor in a text editor as there can be some settings you can change in it.

More recently Sheetcams post processor can be set to use the "magic" comments which then allows Sheetcam to be the master of settings so there is no longer any inconsistencies between Sheetcam and Plasmac. I think this is a good thing. There should only be a single point of truth and Sheetcam assumes it is that source. But Plasmac assumes the same too!

Its always a good idea to view a new postprocessor in a text editor as there can be some settings you can change in it.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

18 Jul 2021 23:21 #215263

by tommylight

Replied by tommylight on topic Homemade, cheap, plasma CNC

A guide of the whole process from opening a dxf in sheetcam to saving it for PlasmaC would be nice - nesting included, if it mentions at the very beginning how to install/use/open/import the material and post, i swear i would not complain!

The following user(s) said Thank You: CarterKraft

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

19 Jul 2021 00:51 #215277

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

Not everyone uses SheetCam...There should only be a single point of truth and Sheetcam assumes it is that source. But Plasmac assumes the same too!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

19 Jul 2021 07:38 #215290

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

Of course, thats understood. The Sheetcam paradigm is a lot older than Plasmac's so its good it can be used as it was intended. So thanks for adding the enabling feature...

There should only be a single point of truth and Sheetcam assumes it is that source. But Plasmac assumes the same too!

Not everyone uses SheetCam...

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

19 Jul 2021 12:17 #215317

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

19 Jul 2021 12:19 #215318

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

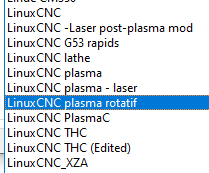

one below your cursor

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

02 Aug 2021 12:03 #216690

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Phil,

I tried this tonight finally, unfortunately my code knowledge is limited to basic arduino.

The cnc computer isn't on the net so i'll just type in below what i have tried. spoiler alert, it didn't work.

HAL file

# external output signals

# - - - LASER - - -

net laser <= hm2_7i96.0.ssr.00.out-01

INI file

BUTTON_2_NAME = LASER

BUTTON_2_CODE =laser

This doesn't work and I get the following error

"Unknown word starting with a (big red circle with white X in it)"

Any guidance on how to make it work would be greatly appreciated.

Cheers

I tried this tonight finally, unfortunately my code knowledge is limited to basic arduino.

The cnc computer isn't on the net so i'll just type in below what i have tried. spoiler alert, it didn't work.

HAL file

# external output signals

# - - - LASER - - -

net laser <= hm2_7i96.0.ssr.00.out-01

INI file

BUTTON_2_NAME = LASER

BUTTON_2_CODE =laser

This doesn't work and I get the following error

"Unknown word starting with a (big red circle with white X in it)"

Any guidance on how to make it work would be greatly appreciated.

Cheers

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

02 Aug 2021 13:01 - 02 Aug 2021 13:03 #216692

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

A few things probably to get you there...

1. In the ini file, the BUTTON_2 lines are not necessary, as there is a LASER button that does this all by default. The button is not shown by default unless you specify a laser offset in the .ini file. You need to add the offset line in the [QTPLASMAC] section of the .ini file:

Where "offset" is the distance from the centerline of the torch to the laser's cross hairs.

2. The output pin needs to be netted to qtplasmac.laser_on in the .hal file, like this:

Unsure how old your config is, but if you used pncconf recently, you may be able to go back in and specify a laser offset, as well as pick a pin for the laser output, which should do everything I mentioned above automagically.

3. A better explanation of what I just typed, as well as a detailed explanation of how to use the LASER button is covered here: linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

Let us know if you have any questions.

1. In the ini file, the BUTTON_2 lines are not necessary, as there is a LASER button that does this all by default. The button is not shown by default unless you specify a laser offset in the .ini file. You need to add the offset line in the [QTPLASMAC] section of the .ini file:

LASER_TOUCHOFF = Xoffset YoffsetWhere "offset" is the distance from the centerline of the torch to the laser's cross hairs.

2. The output pin needs to be netted to qtplasmac.laser_on in the .hal file, like this:

# - - - LASER - - -

net laser qtplasmac.laser_on <= hm2_7i96.0.ssr.00.out-01Unsure how old your config is, but if you used pncconf recently, you may be able to go back in and specify a laser offset, as well as pick a pin for the laser output, which should do everything I mentioned above automagically.

3. A better explanation of what I just typed, as well as a detailed explanation of how to use the LASER button is covered here: linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

Let us know if you have any questions.

Last edit: 02 Aug 2021 13:03 by snowgoer540.

Please Log in or Create an account to join the conversation.

Time to create page: 0.399 seconds