Emcoturn 120 lathe retrofit

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

11 Aug 2016 02:34 #78593

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Aug 2016 16:39 #78715

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

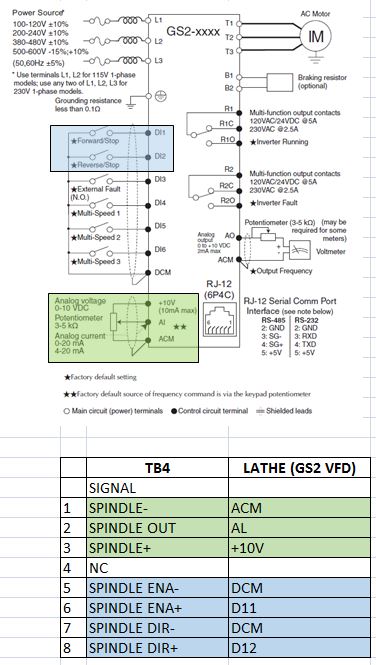

I connected the VFD and programmed it per the previous posts. The fwd/rev is working perfectly, but enable is not working. It may be the Linuxcnc tool, Im not sure. I tried to enable it by shorting the DCM/D2 and that does change the VFD to run state. I left them crossed and used the spindle tool to try to turn the spindle and it errored the VFD. I think the problem is the spindle tool starts at 0 rpm. You set the direction then have to hit the (+) button to increase speed from 0, this causes the VFD to overload. I assume this is what blew out the Chinese VFD. SO obviously I dont want to do this anymore. Is there another tool I can add that will set the speed then direction then so go? I thinks thats what I need to do. If there is a gcode/mcode series I could enter in the midi line that would be OK too.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

13 Aug 2016 17:20 #78716

by tommylight

Replied by tommylight on topic Emcoturn 120 lathe retrofit

I think you need to set the "ramp up" to at least 5 to 10 seconds, since it has a lot of weight to move. I had it set at 7 for a drill with gear reduction, otherwise it would overload always at start.

Tom

Tom

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Aug 2016 17:21 - 13 Aug 2016 17:24 #78717

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

update.

by typing s1000, m3 I get nothing

I jumped DCM/D12 (VFD start/stop)

then s1000 m3 I get 1000rpm fwd, m5 stop, m4 1000 reverse.

so everything is working except enable signal from 7i76e. I assume it is a programming issue for the HAL pin. Any suggestions?

by typing s1000, m3 I get nothing

I jumped DCM/D12 (VFD start/stop)

then s1000 m3 I get 1000rpm fwd, m5 stop, m4 1000 reverse.

so everything is working except enable signal from 7i76e. I assume it is a programming issue for the HAL pin. Any suggestions?

Last edit: 13 Aug 2016 17:24 by LutzTD.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17627

- Thank you received: 5157

13 Aug 2016 17:38 #78718

by PCW

Replied by PCW on topic Emcoturn 120 lathe retrofit

If the analog output works, enable is asserted

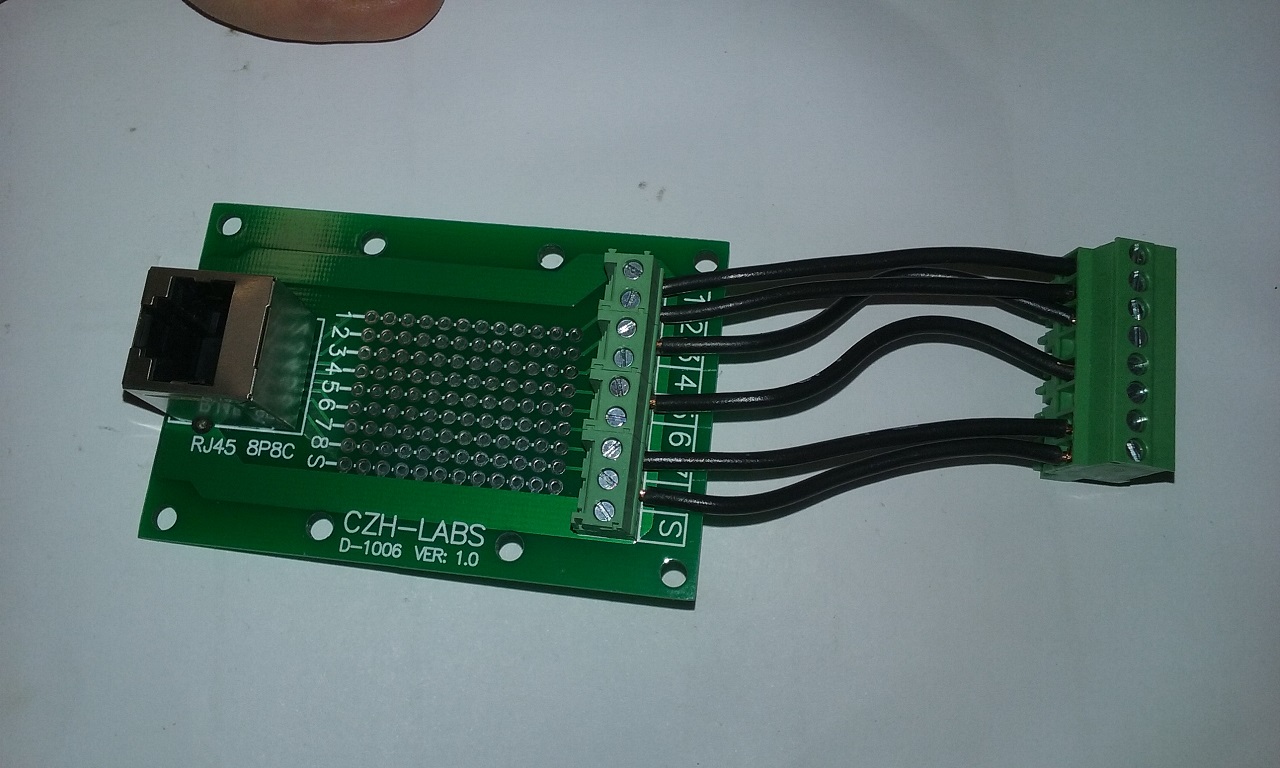

Another forum poster had a problem with the 8 pin plug on a a 7I76E

you might check continuity through the plug.

We have not seen any problems we these before but we may have a bad lot

Another forum poster had a problem with the 8 pin plug on a a 7I76E

you might check continuity through the plug.

We have not seen any problems we these before but we may have a bad lot

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Aug 2016 17:47 - 13 Aug 2016 17:54 #78720

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

let me check again

Last edit: 13 Aug 2016 17:54 by LutzTD.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Aug 2016 18:02 #78721

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Aug 2016 18:39 #78724

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

update. I had set the VFD to high torque start, that was the issue. I then set it for scurve start 5sec, scurve stop 5sec and its all working great. It will start from 0 using the GUI tool and everything. So this is done I think.

Now I would like to have the encoder output displayed. I set this up using an AB with index encoder wired to the 7i76e encoder input pins but I dont know how to read it to see if it is operating properly. Any ideas?

Now I would like to have the encoder output displayed. I set this up using an AB with index encoder wired to the 7i76e encoder input pins but I dont know how to read it to see if it is operating properly. Any ideas?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17627

- Thank you received: 5157

13 Aug 2016 18:50 - 13 Aug 2016 18:50 #78725

by PCW

Replied by PCW on topic Emcoturn 120 lathe retrofit

You can use halmeter to check the encoder operation and scaling

Spindle encoders should be scaled so that 1 spindle turn reads as a feedback position change of 1.00

That is, hm2_7i76e.0.encoder.00.position should advance by 1.00 for each spindle turn

Index can be checked with halcmd (setting the index enable signal) and halmeter

(watching the index enable signal to see the it gets cleared on index detection)

Spindle encoders should be scaled so that 1 spindle turn reads as a feedback position change of 1.00

That is, hm2_7i76e.0.encoder.00.position should advance by 1.00 for each spindle turn

Index can be checked with halcmd (setting the index enable signal) and halmeter

(watching the index enable signal to see the it gets cleared on index detection)

Last edit: 13 Aug 2016 18:50 by PCW.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

13 Aug 2016 19:29 - 13 Aug 2016 19:29 #78727

by LutzTD

can I turn the encoder by hand or does the spindle need to be running (for enable signal)? If Im looking for the position change to be 1 on each turn sounds like it will be really fast if the spindle is running

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

You can use halmeter to check the encoder operation and scaling

Spindle encoders should be scaled so that 1 spindle turn reads as a feedback position change of 1.00

That is, hm2_7i76e.0.encoder.00.position should advance by 1.00 for each spindle turn

Index can be checked with halcmd (setting the index enable signal) and halmeter

(watching the index enable signal to see the it gets cleared on index detection)

can I turn the encoder by hand or does the spindle need to be running (for enable signal)? If Im looking for the position change to be 1 on each turn sounds like it will be really fast if the spindle is running

Last edit: 13 Aug 2016 19:29 by LutzTD.

Please Log in or Create an account to join the conversation.

Time to create page: 0.335 seconds