1982 Matsuura MC-500v Retrofit

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

11 Feb 2017 18:07 - 12 Feb 2017 16:47 #87830

by chopper79

Replied by chopper79 on topic 1982 Matsuura MC-500v Retrofit

Just seen this.... I was starting to lean towards ground after looking at it some more. I will give it a shot and see if I can at least get the fwd led to illuminate.

Thank you PCW

***Update on spindle drive***

If you have the Yaskawa VS-626 MTII on your machine (Matsuura MC-500v2) then you will need the following:

Pins on connector 1CN

Pin 9 = Analog speed control +/- 10v

Pin 10 = Analog speed control gnd

Pin 13 = Estop

Pin 15 = Signal ground

Pin 16 = Spindle forward

Pin 17 = Spindle reverse

Pin 22 = Spindle orientation command

Pin 15 (signal ground) need to be closed to the pin needed. Such as 7i77 24v+ output goes to a relay and the relay closes the connection from pin 15 to pin needed on VFD. The VFD pins take a ground input not + voltage

Pins 9 and 10 will go to the spindle output designated on the 7i77. The 7i77 will drive these directly.

Also do not over look the outputs on the VFD.

At speed output (Just nice to have so LCNC knows that spindle is at requested speed)

Orientation complete output (need for ATC)

There are other outputs that could be handy also if used.

See previous posts for all manuals and schematics of factory wiring and components.

Thank you PCW

***Update on spindle drive***

If you have the Yaskawa VS-626 MTII on your machine (Matsuura MC-500v2) then you will need the following:

Pins on connector 1CN

Pin 9 = Analog speed control +/- 10v

Pin 10 = Analog speed control gnd

Pin 13 = Estop

Pin 15 = Signal ground

Pin 16 = Spindle forward

Pin 17 = Spindle reverse

Pin 22 = Spindle orientation command

Pin 15 (signal ground) need to be closed to the pin needed. Such as 7i77 24v+ output goes to a relay and the relay closes the connection from pin 15 to pin needed on VFD. The VFD pins take a ground input not + voltage

Pins 9 and 10 will go to the spindle output designated on the 7i77. The 7i77 will drive these directly.

Also do not over look the outputs on the VFD.

At speed output (Just nice to have so LCNC knows that spindle is at requested speed)

Orientation complete output (need for ATC)

There are other outputs that could be handy also if used.

See previous posts for all manuals and schematics of factory wiring and components.

Last edit: 12 Feb 2017 16:47 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

11 Feb 2017 23:23 #87845

by chopper79

Replied by chopper79 on topic 1982 Matsuura MC-500v Retrofit

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7247

12 Feb 2017 02:33 #87853

by tommylight

Replied by tommylight on topic 1982 Matsuura MC-500v Retrofit

Just so you know, i'watching you !

Dude, where's my beer?

Nice progress, for sure.

I finished mine a few days ago, in the mean time i did another retrofit on a plasma cutter, also finished today.

Regards,

Tom

Dude, where's my beer?

Nice progress, for sure.

I finished mine a few days ago, in the mean time i did another retrofit on a plasma cutter, also finished today.

Regards,

Tom

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

12 Feb 2017 04:48 - 12 Feb 2017 16:30 #87858

by chopper79

Replied by chopper79 on topic 1982 Matsuura MC-500v Retrofit

Thank you

Sounds like me right now.... Trying to finish this thing up and multiple projects right now. I hope the classic ladder will be smooth sailing. Never worked with CL before so this will get interesting I am sure.

Sounds like me right now.... Trying to finish this thing up and multiple projects right now. I hope the classic ladder will be smooth sailing. Never worked with CL before so this will get interesting I am sure.

Last edit: 12 Feb 2017 16:30 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

12 Feb 2017 16:27 - 12 Feb 2017 16:28 #87873

by chopper79

Replied by chopper79 on topic 1982 Matsuura MC-500v Retrofit

While working on finishing the I/O. I have been thinking about the classic ladder for my ATC.

Sequence:

M6 T# called out

Z axis goes to change position (switches are located to detect if it is at position)

Spindle orientates

tool magazine moves in

Tool releases

Tool magazine moves down

Tool magazine rotates CW or CCW to the called tool

(Need to check if there is a air blast to clear the taper and chips before mag moves up)

Magazine moves up

Tool clamps

Magazine moves away

Machine goes back to work......

There are limit switches for

Mag in + out

Tool 1

Z axis tool change position

Mag up and down

Need to figure out how to use classic ladder to make this. I have never used CL before so this will be an interesting experience.

Sequence:

M6 T# called out

Z axis goes to change position (switches are located to detect if it is at position)

Spindle orientates

tool magazine moves in

Tool releases

Tool magazine moves down

Tool magazine rotates CW or CCW to the called tool

(Need to check if there is a air blast to clear the taper and chips before mag moves up)

Magazine moves up

Tool clamps

Magazine moves away

Machine goes back to work......

There are limit switches for

Mag in + out

Tool 1

Z axis tool change position

Mag up and down

Need to figure out how to use classic ladder to make this. I have never used CL before so this will be an interesting experience.

Last edit: 12 Feb 2017 16:28 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

13 Feb 2017 13:19 - 13 Feb 2017 13:23 #87906

by chopper79

Replied by chopper79 on topic 1982 Matsuura MC-500v Retrofit

Almost finished with the wiring for all of the I/O. Down to my last 4 outputs on the 7i77 and if all goes well I will have exactly enough to complete the wiring. Inputs are not even close to being used up. (May need to by an additional output board)

Ran across two contacts that go up the tool change assembly. There are already two that go there so I am trying to figure out what those additional two would be used for?

The tool change assembly works (mag in , mag out, rotate cw, rotate ccw)so not sure why they second contacts. My guess is since one goes to magazine forward/reverse and the other goes to magazine cw/ccw is that they are brakes of some sort.

I will have to given them a trigger while rotating the tool changer and see if a brake is applied to dead stop the rotation. This would make sense to me as if I rotate the tool change now it seems to not always line up correctly. Seems to have a little free spin as the motor coast to stop.

I will update more about this later today or tomorrow.

Ran across two contacts that go up the tool change assembly. There are already two that go there so I am trying to figure out what those additional two would be used for?

The tool change assembly works (mag in , mag out, rotate cw, rotate ccw)so not sure why they second contacts. My guess is since one goes to magazine forward/reverse and the other goes to magazine cw/ccw is that they are brakes of some sort.

I will have to given them a trigger while rotating the tool changer and see if a brake is applied to dead stop the rotation. This would make sense to me as if I rotate the tool change now it seems to not always line up correctly. Seems to have a little free spin as the motor coast to stop.

I will update more about this later today or tomorrow.

Last edit: 13 Feb 2017 13:23 by chopper79.

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

13 Feb 2017 13:28 #87907

by skunkworks

Replied by skunkworks on topic 1982 Matsuura MC-500v Retrofit

Yes - probably the brakes. I had to do some funky stuff to get that to work in ladder. IIRC - I run the motor until it hits the limit - then apply the brake relay while the motor is still on for a short amount of time (power needs to be applied to the motor for the brake to work). Then both the motor and brake is turned off. (They motors get pretty hot if you leave the brake and motor on)

Both motors act the same (rotation and in-out)

sam

Both motors act the same (rotation and in-out)

sam

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- sinusvag

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 1

13 Feb 2017 17:46 #87922

by sinusvag

Replied by sinusvag on topic 1982 Matsuura MC-500v Retrofit

Nice write-up! Will be interesting to follow the classicladder part!

Cheers from Sweden

Cheers from Sweden

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

14 Feb 2017 03:41 #87939

by chopper79

Replied by chopper79 on topic 1982 Matsuura MC-500v Retrofit

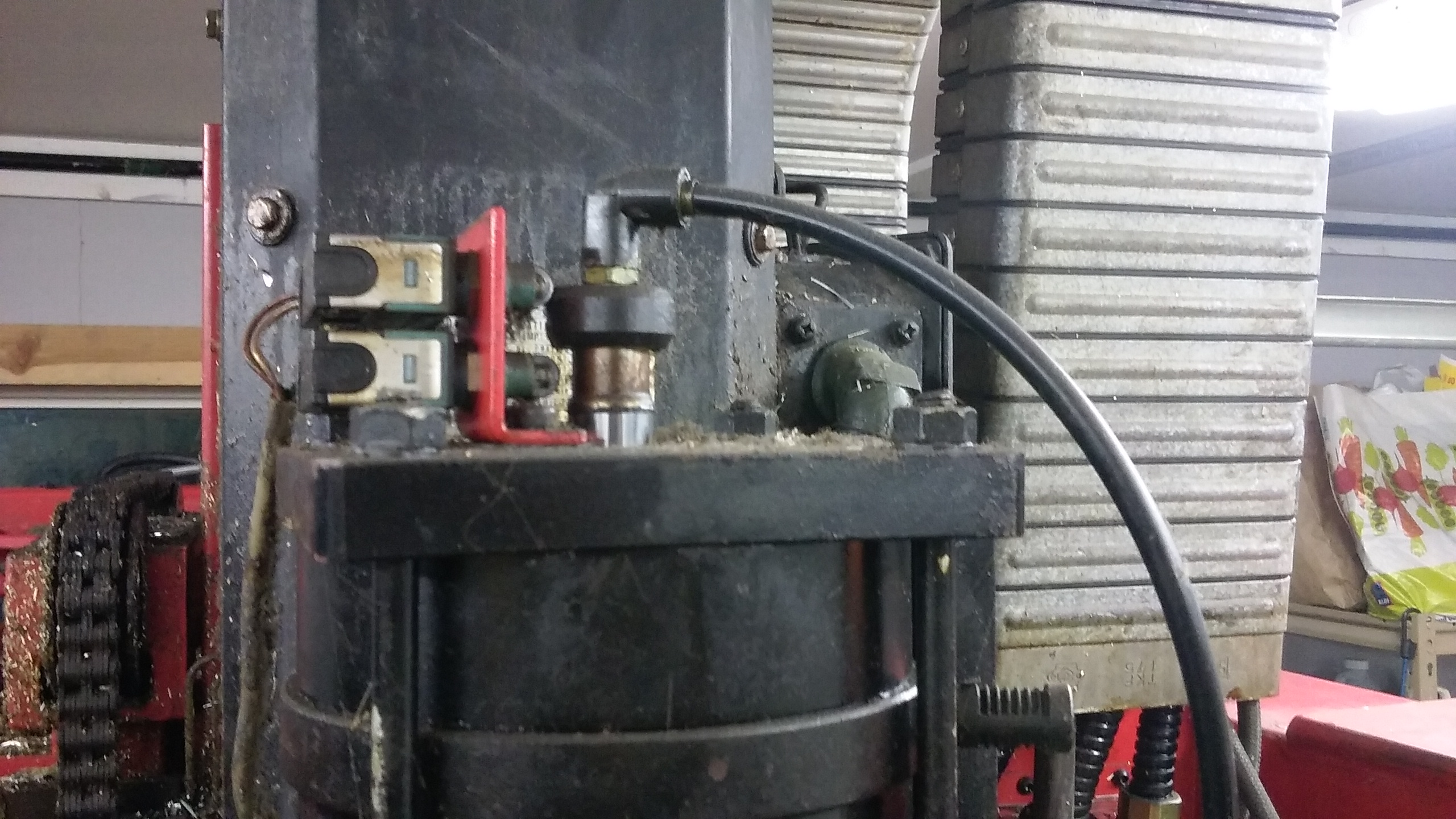

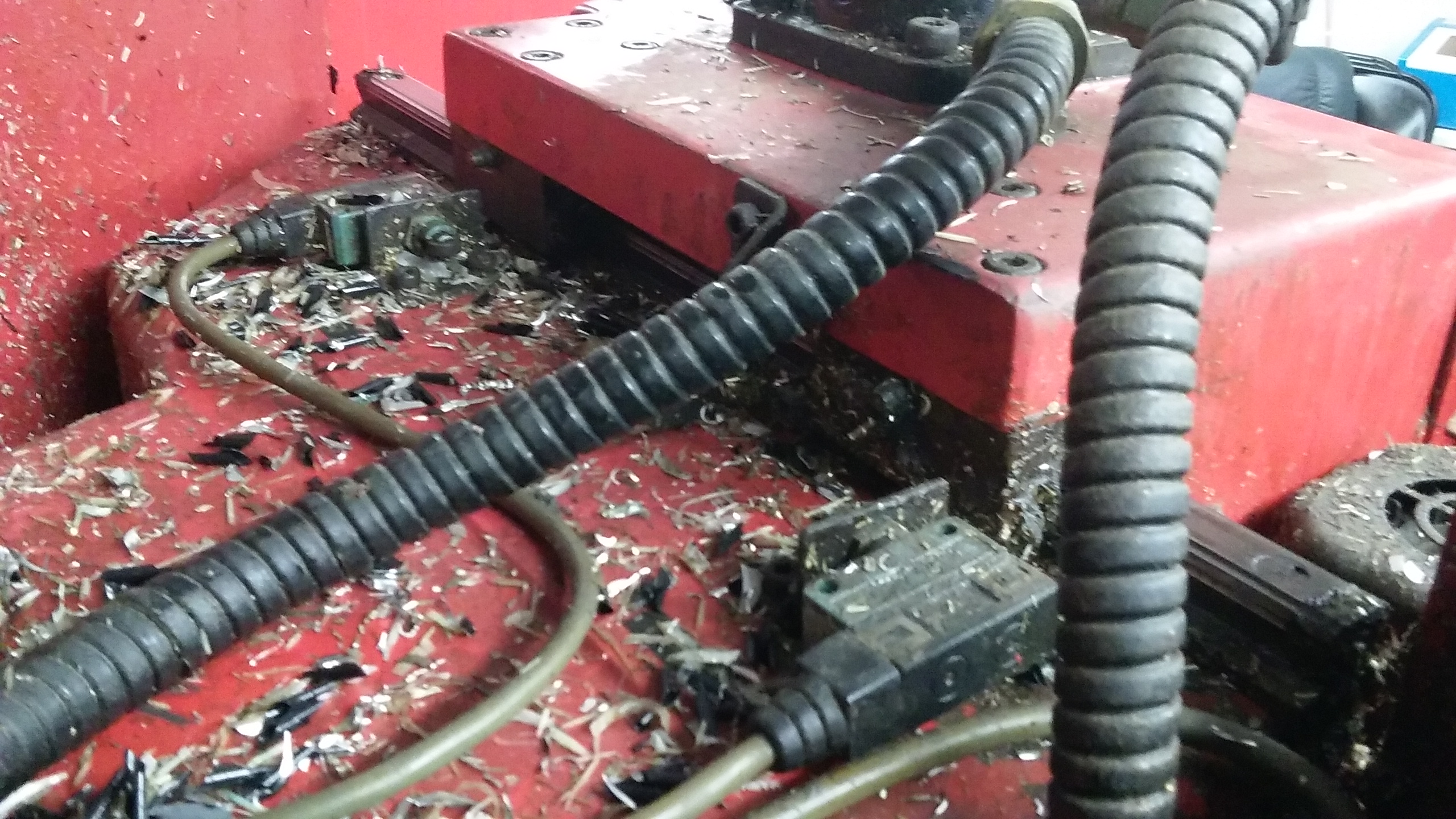

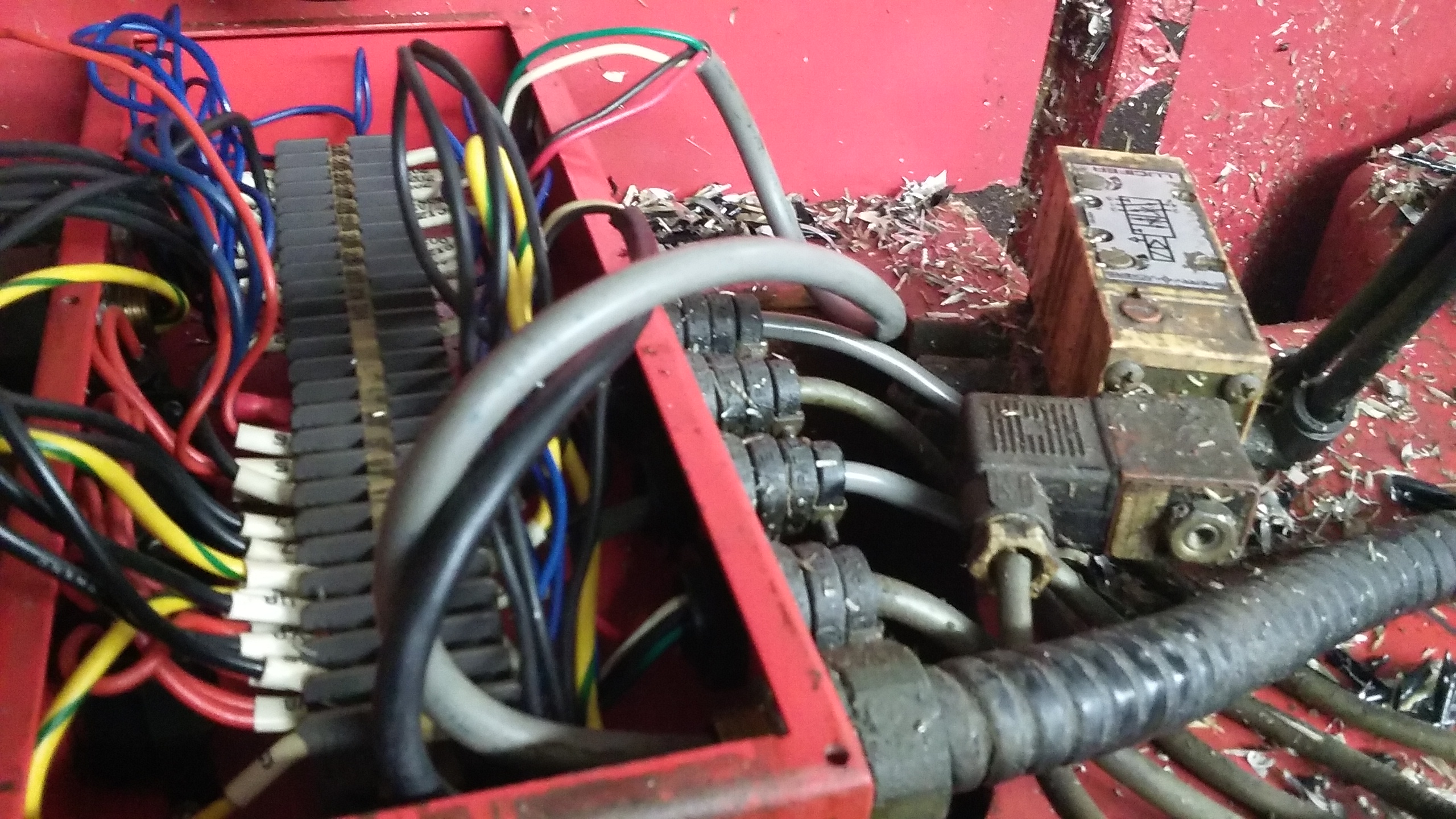

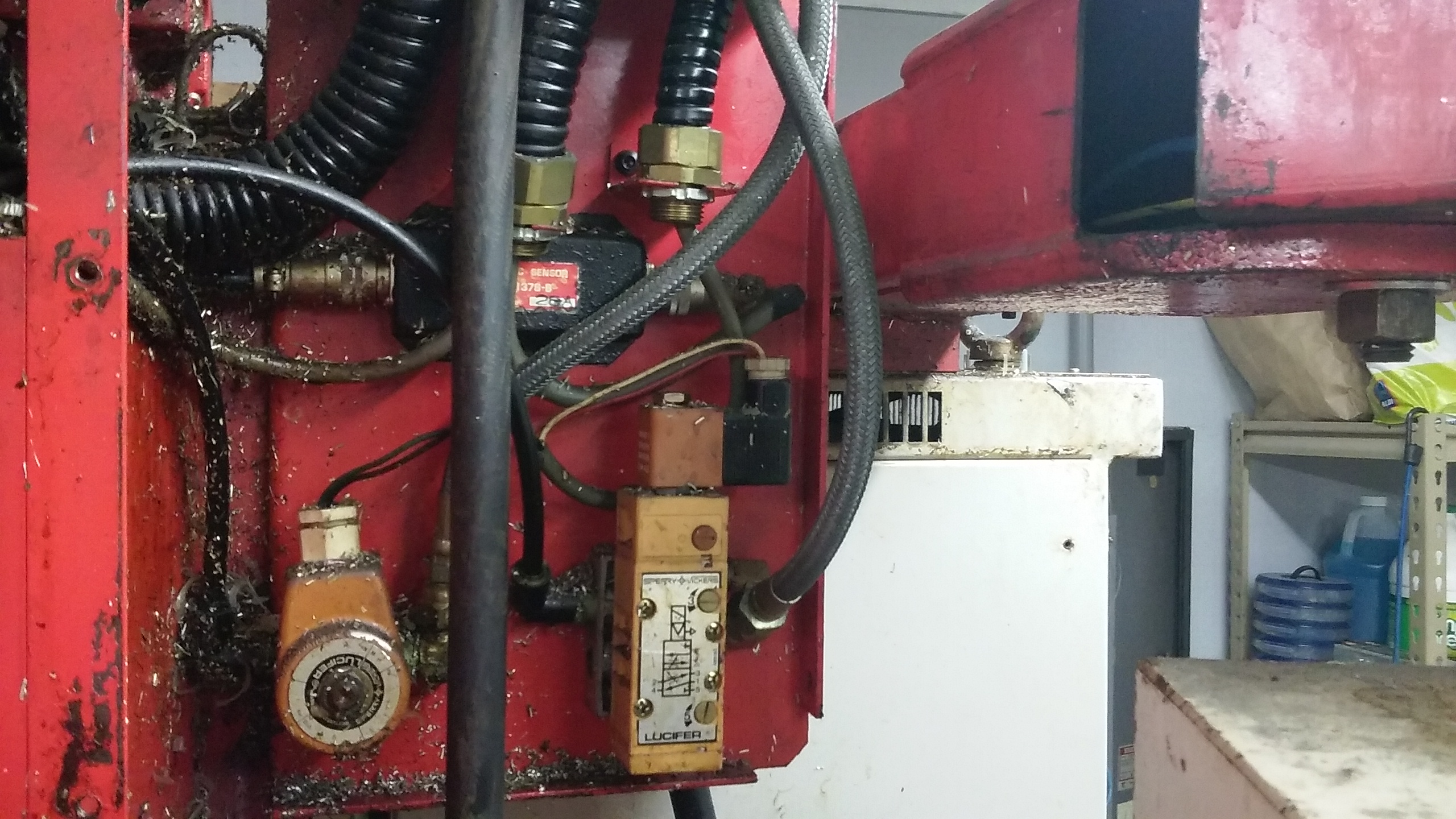

This is where the limits and connections are located for the ATC. (Pardon the mess. Previous owner must not liked to clean)

Draw bar limits

Tool magazine up and down limits

Tool magazine in and out limits

Connection points for the tool magazine CW and CCW. The limits are under the magazine

Junction box for all tool magazine limits, power, and goofy light. Also note the pneumatic valve for magazine down

Pneumatic valves for draw bar and taper clean out

That's all the updates I have for tonight. Hope to dive into the last (4) I/O connections tomorrow night and then start on the classic ladder.

Draw bar limits

Tool magazine up and down limits

Tool magazine in and out limits

Connection points for the tool magazine CW and CCW. The limits are under the magazine

Junction box for all tool magazine limits, power, and goofy light. Also note the pneumatic valve for magazine down

Pneumatic valves for draw bar and taper clean out

That's all the updates I have for tonight. Hope to dive into the last (4) I/O connections tomorrow night and then start on the classic ladder.

The following user(s) said Thank You: johnmc1

Please Log in or Create an account to join the conversation.

- johnmc1

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 21

14 Feb 2017 10:41 #87948

by johnmc1

Replied by johnmc1 on topic 1982 Matsuura MC-500v Retrofit

Good Day chopper79,

Thanks for sharing your experience and description of your Matsuura mill refit.

This knowledge will be invaluable when I refit my matsuura vertical mill.

Cheers john

Thanks for sharing your experience and description of your Matsuura mill refit.

This knowledge will be invaluable when I refit my matsuura vertical mill.

Cheers john

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

Time to create page: 0.263 seconds