Brother TC-225 / TC-229 adventure!

- Williamabbe

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

27 Feb 2021 18:23 #200325

by Williamabbe

Replied by Williamabbe on topic Brother TC-225 / TC-229 adventure!

Hello! I have Brother tc-227 that I’ve been converting. Running dyn4 servos and drives on xyz and also installing a Delta C2000 drive for the original spindle motor. Also running a SZGH 5 axis controller on it. Does anyone have the pin outs on the CN2 20 pin connector that goes from the spindle motor to the main original Sanyo drive? With replacing the old drive I need the encoder pin outs to hook up to the Delta drive with the encoder card. Thanks!

Have a pic of it attached.

Have a pic of it attached.

Please Log in or Create an account to join the conversation.

- timfaber

-

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 3

27 Feb 2021 20:38 #200340

by timfaber

Replied by timfaber on topic Brother TC-225 / TC-229 adventure!

Sorry can't help you out with the pin outs

How are you liking that SZGH controller? Good documentation, post processors, simultaneously control?

How are you liking that SZGH controller? Good documentation, post processors, simultaneously control?

Please Log in or Create an account to join the conversation.

- timfaber

-

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 3

28 Feb 2021 10:39 #200387

by timfaber

Replied by timfaber on topic Brother TC-225 / TC-229 adventure!

the atc brake pack controller on my tc225 has model number SBR-32 ZP and its by oriental motor

Please Log in or Create an account to join the conversation.

- timfaber

-

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 3

24 Apr 2021 12:10 #206947

by timfaber

Replied by timfaber on topic Brother TC-225 / TC-229 adventure!

Any change you have your hal and ini files laying around for me?

Please Log in or Create an account to join the conversation.

- gcofieldd

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

30 Apr 2021 21:40 #207493

by gcofieldd

Replied by gcofieldd on topic Brother TC-225 / TC-229 adventure!

Hi Williamabbe,

Take a look at this thread on CNCZone. The individual did a conversion on a TC-225 and used a Delta C2000 with the stock brother spindle motor and it sounds like he had a hell of a time getting it to work.

www.cnczone.com/forums/vertical-mill-lat...-tc225-retrofit.html

Take a look at this thread on CNCZone. The individual did a conversion on a TC-225 and used a Delta C2000 with the stock brother spindle motor and it sounds like he had a hell of a time getting it to work.

www.cnczone.com/forums/vertical-mill-lat...-tc225-retrofit.html

Please Log in or Create an account to join the conversation.

- gcofieldd

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

24 Aug 2021 19:33 #218638

by gcofieldd

Replied by gcofieldd on topic Brother TC-225 / TC-229 adventure!

@ihavenofish

I was thinking about upgrading the servos on my TC-225 to 750W on X and Y and 1kW on Z. When you were working on both your machines (TC-225 and TC-229) did you notice if the ball screws were the same size? Also, what did you end up doing with the original spindle motor and drive off your TC-229?

I was thinking about upgrading the servos on my TC-225 to 750W on X and Y and 1kW on Z. When you were working on both your machines (TC-225 and TC-229) did you notice if the ball screws were the same size? Also, what did you end up doing with the original spindle motor and drive off your TC-229?

Please Log in or Create an account to join the conversation.

- Superdave

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

11 Sep 2021 18:03 #220240

by Superdave

Replied by Superdave on topic Brother TC-225 / TC-229 adventure!

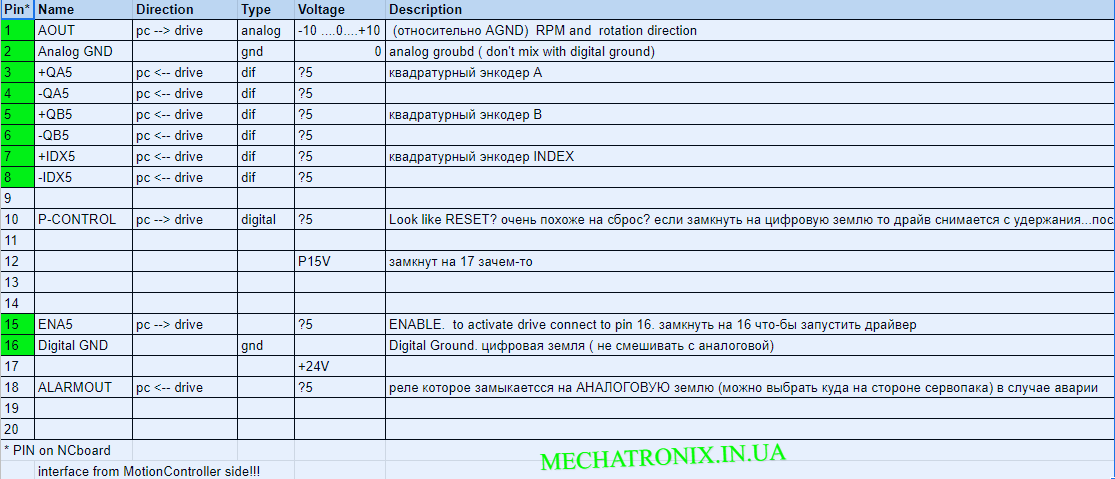

Hello I have a tc 215 I'm trying to retrofit and I was wandering if you have the pin out for the ra12m drives. They still work as do my servos. Can't seem to find info anywhere thanks dave

Please Log in or Create an account to join the conversation.

- IceBear

-

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

07 Oct 2021 18:08 #222476

by IceBear

Replied by IceBear on topic Brother TC-225 / TC-229 adventure!

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 988

- Thank you received: 281

19 Oct 2021 21:40 #223594

by ihavenofish

the 2 machines have the same force. 229 has 10 pitch screws and the 225 is 5 pitch. basically the 229 is faster with the same linear force and acceleration ability. 750w are overkill on the 225 in a lot of ways, but that's really all you can buy new for a fair price. 86mm motors cost way more for some reason and used sanyos cost more than new deltas. youll need to make adapters and get new couplings.

i sold both of my machines now. i will eventually buy another, but i think i will try to deliberately find a tc228, which is very similar to the 229, but still has an analogue spindle. replacing the serial spindle drive is just so much money. The guy that bought mine replaced the motor if i recall as it was easier than anything else. my friend is using an AB 3000 drive for his, but its derated to 1kw or so and even then the drive cost like $500-$1000 used.

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

hi, missed these posts.@ihavenofish

I was thinking about upgrading the servos on my TC-225 to 750W on X and Y and 1kW on Z. When you were working on both your machines (TC-225 and TC-229) did you notice if the ball screws were the same size? Also, what did you end up doing with the original spindle motor and drive off your TC-229?

the 2 machines have the same force. 229 has 10 pitch screws and the 225 is 5 pitch. basically the 229 is faster with the same linear force and acceleration ability. 750w are overkill on the 225 in a lot of ways, but that's really all you can buy new for a fair price. 86mm motors cost way more for some reason and used sanyos cost more than new deltas. youll need to make adapters and get new couplings.

i sold both of my machines now. i will eventually buy another, but i think i will try to deliberately find a tc228, which is very similar to the 229, but still has an analogue spindle. replacing the serial spindle drive is just so much money. The guy that bought mine replaced the motor if i recall as it was easier than anything else. my friend is using an AB 3000 drive for his, but its derated to 1kw or so and even then the drive cost like $500-$1000 used.

Please Log in or Create an account to join the conversation.

- szary11

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

24 Dec 2021 08:02 #229865

by szary11

Replied by szary11 on topic Brother TC-225 / TC-229 adventure!

Gents,

I need some help. For tool change I have to change max limit of Z axis from 0 to 140, perform the toolchange and then switch it back to original one.

I have used ini.z.max_limit and that seems to be set ok, I see the borders of working space reflected on axis visual window and the pin value change on Show HAL Configuration menu.

But still, motion seems to be unaware of limits change, whenever I try to move Z into positive values, it throws me an error "joint position exceeding positive limit".

Although I have not switched kinematics I hoped that maybe forcing synchronization via issues M66 E0 L0 would help, but no luck, still no change.

Any idea on what else might missing?

I need some help. For tool change I have to change max limit of Z axis from 0 to 140, perform the toolchange and then switch it back to original one.

I have used ini.z.max_limit and that seems to be set ok, I see the borders of working space reflected on axis visual window and the pin value change on Show HAL Configuration menu.

But still, motion seems to be unaware of limits change, whenever I try to move Z into positive values, it throws me an error "joint position exceeding positive limit".

Although I have not switched kinematics I hoped that maybe forcing synchronization via issues M66 E0 L0 would help, but no luck, still no change.

Any idea on what else might missing?

Please Log in or Create an account to join the conversation.

Time to create page: 0.488 seconds