Bridgeport Torq-Cut TC4G Retrofit

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

23 Apr 2020 00:18 - 23 Apr 2020 00:20 #165167

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Took more covers off and found more stuff to clean. Also seems like there is a Y axis thrust bearing going out.

A thought on the trust bearings... There are no oil lines going to them and I am sure that the previous owner did not PM this thing. I think I am going to run oil lines to the thrust bearings and meter the volume to an acceptable mount specified by the bearing OEM. This should help extend the life of them.

A thought on the trust bearings... There are no oil lines going to them and I am sure that the previous owner did not PM this thing. I think I am going to run oil lines to the thrust bearings and meter the volume to an acceptable mount specified by the bearing OEM. This should help extend the life of them.

Attachments:

Last edit: 23 Apr 2020 00:20 by chopper79.

The following user(s) said Thank You: arvidb, tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7246

23 Apr 2020 10:29 #165205

by tommylight

Replied by tommylight on topic Bridgeport Torq-Cut TC4G Retrofit

That still looks pretty clean compared to a Hurco i retrofitted a while ago, it was full even under the covers!

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

29 Apr 2020 23:58 #166173

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Yeah it is not terrible, but still dirtier than I care for. I will have to say that this is going to take longer than I wanted due to me taking the mill down to the casting. This includes rails, ball screws, oil lines, everything comes off. Only way I can get all the junk off of the mill and get a solid paint job on it.

I will update more when I get things torn down and begin the journey going back together.

One other thing..... I have a TC2G up for grabs now if anyone is interested before I start taking it apart and selling off parts. (No need or room for both machines.)

I will update more when I get things torn down and begin the journey going back together.

One other thing..... I have a TC2G up for grabs now if anyone is interested before I start taking it apart and selling off parts. (No need or room for both machines.)

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7246

30 Apr 2020 07:16 #166194

by tommylight

Replied by tommylight on topic Bridgeport Torq-Cut TC4G Retrofit

I am to damn far from everything !One other thing..... I have a TC2G up for grabs now if anyone is interested before I start taking it apart and selling off parts. (No need or room for both machines.)

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

01 May 2020 13:40 #166312

by Todd Zuercher

Where is it located and what do you want for it?

Replied by Todd Zuercher on topic Bridgeport Torq-Cut TC4G Retrofit

Yeah it is not terrible, but still dirtier than I care for. I will have to say that this is going to take longer than I wanted due to me taking the mill down to the casting. This includes rails, ball screws, oil lines, everything comes off. Only way I can get all the junk off of the mill and get a solid paint job on it.

I will update more when I get things torn down and begin the journey going back together.

One other thing..... I have a TC2G up for grabs now if anyone is interested before I start taking it apart and selling off parts. (No need or room for both machines.)

Where is it located and what do you want for it?

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

13 May 2020 02:13 #167597

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

East Tennessee and 4k would be nice.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

13 May 2020 02:16 - 13 May 2020 02:24 #167598

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

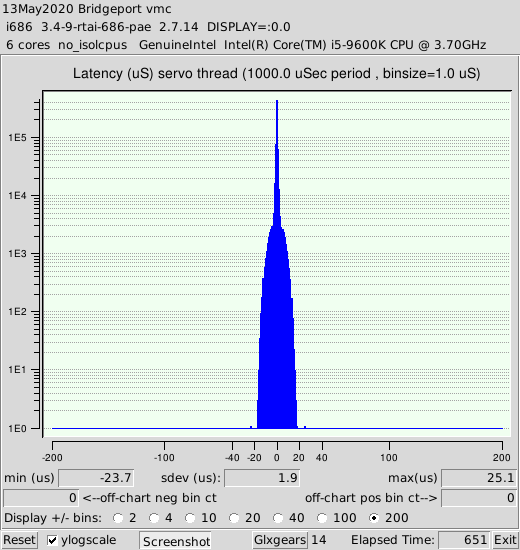

Attachments:

Last edit: 13 May 2020 02:24 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

16 Aug 2020 16:33 #178412

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

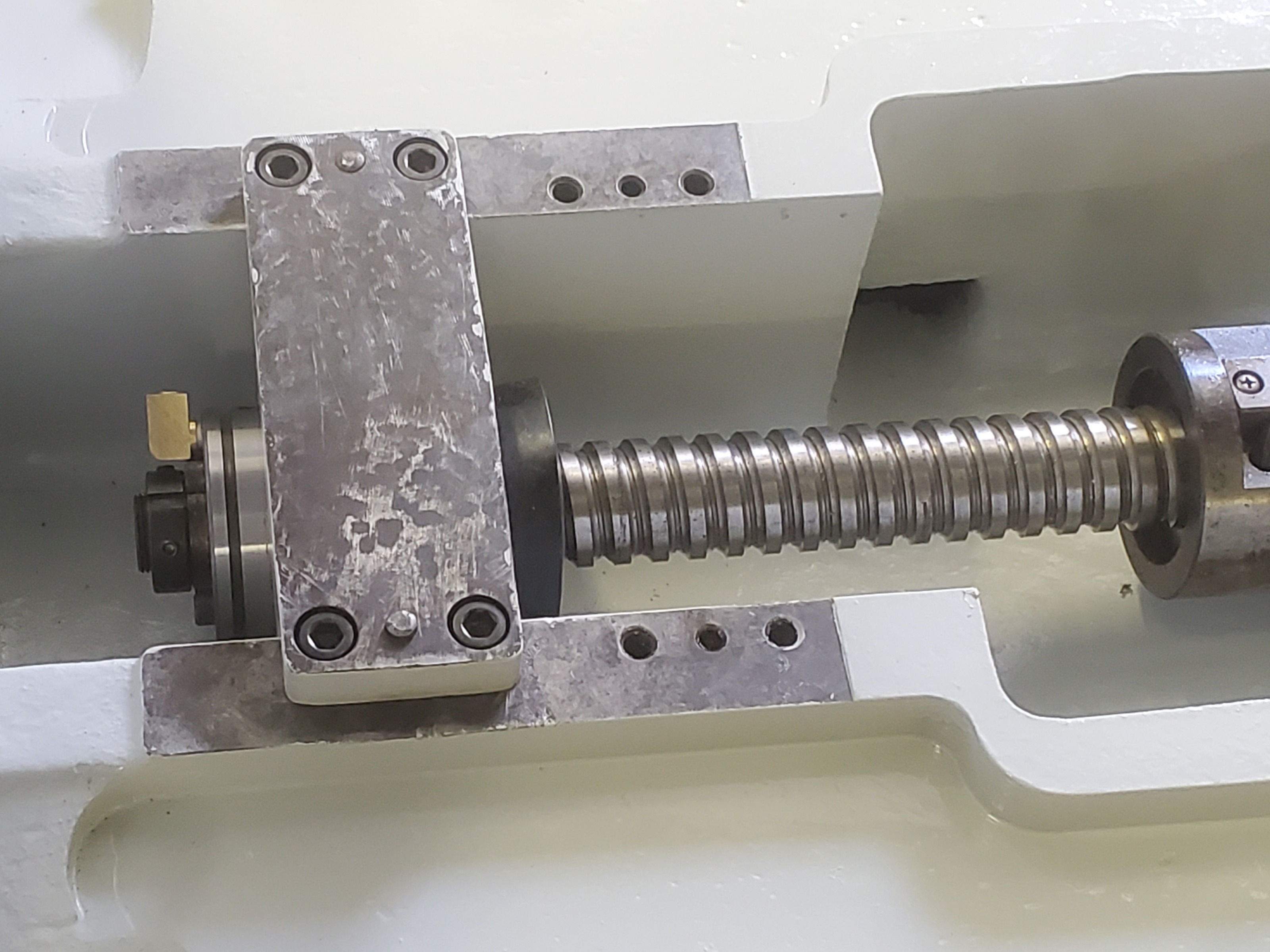

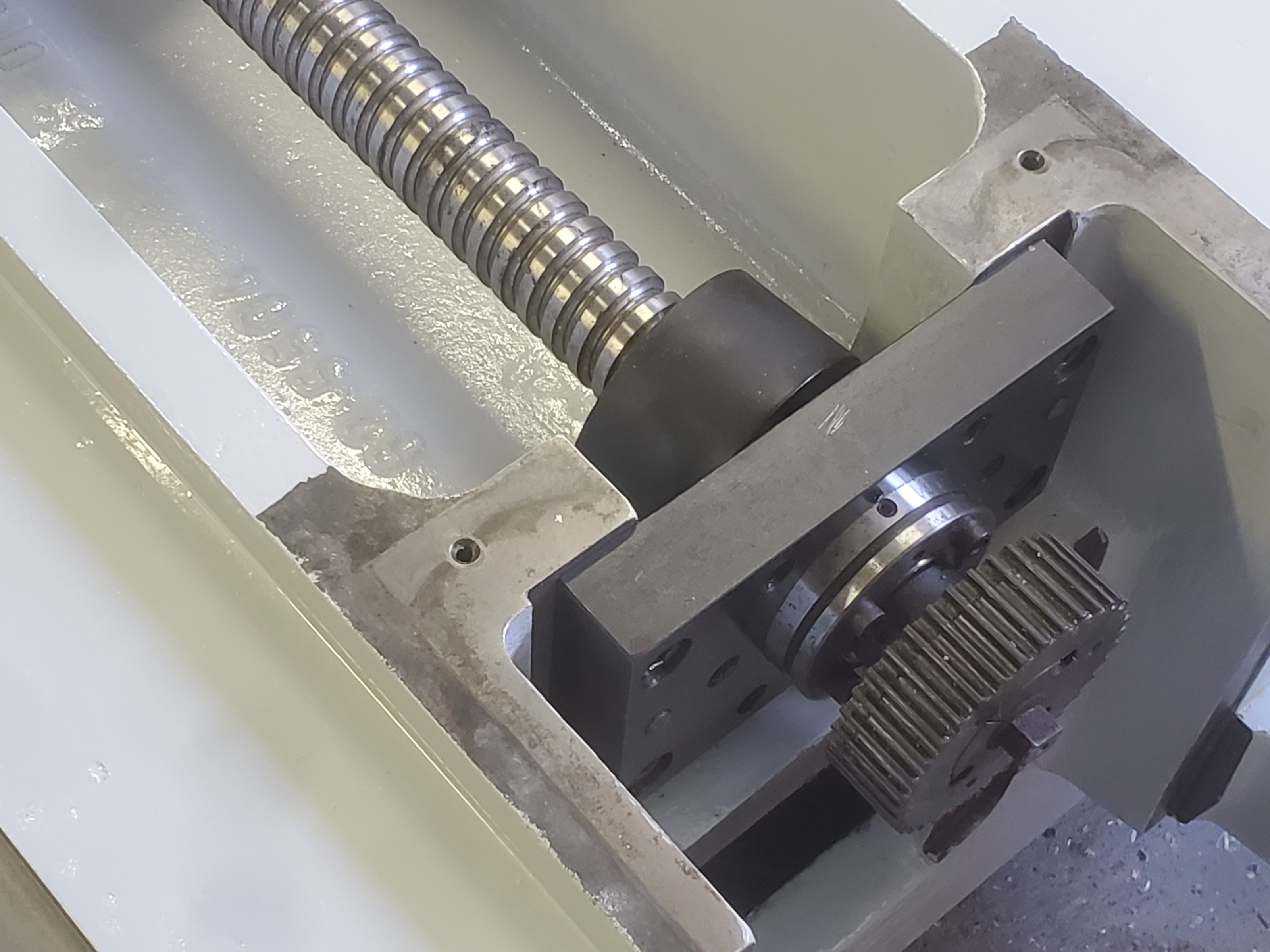

Well it has been awhile since I posted any updates due to work, farm, and family. Here is the current state of the mill.

1) Torn down and all rails and ball screws came off. Removed paint and prepped surfaces This thing was bare casting minus the electrical enclosure.

2) Painted (SW Sher-Kem paint)

3) Starting to go back together (Z axis rails and ball screw back in along with spindle cartridge and head).

4) Adding lubrication to all the thrust bearings as there was none from the factory and that just did not seem right to me. Need to do the front thrust bearing still.

As I find time to do more I will update.

1) Torn down and all rails and ball screws came off. Removed paint and prepped surfaces This thing was bare casting minus the electrical enclosure.

2) Painted (SW Sher-Kem paint)

3) Starting to go back together (Z axis rails and ball screw back in along with spindle cartridge and head).

4) Adding lubrication to all the thrust bearings as there was none from the factory and that just did not seem right to me. Need to do the front thrust bearing still.

As I find time to do more I will update.

The following user(s) said Thank You: arvidb, tommylight, johnmc1

Please Log in or Create an account to join the conversation.

- Catch22

-

- Offline

- Elite Member

-

Less

More

- Posts: 222

- Thank you received: 17

10 Sep 2020 16:10 #181651

by Catch22

Replied by Catch22 on topic Bridgeport Torq-Cut TC4G Retrofit

Thats looking awesome.....

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

19 Dec 2020 22:53 #192485

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Still working on getting the machine back together. Painting is coming along nicely, but slow due to work and misc. Should be able to begin wiring in 3-4 weeks as all major items will be done by then.

1) Rebuilt the transmission (Awaiting install)

2) All heavy components including machine bed have been installed.

3) Painted multiple parts

4) Began running new air lines and any needed oil lines.

5) Awaiting new spindle motor bearings, so rebuild of motor can begin. (Currently disassembled, just awaiting bearings)

I sometimes think that I should have just cleaned it up and put it to work. I would have regretted not doing it as I have found many items needing repaired/replaced. I guess it would have eventually happened anyway.

Next post will include picture updates as I am slacking on them right now. Just want to update the thread if anyone was wonder if the project was still alive.

1) Rebuilt the transmission (Awaiting install)

2) All heavy components including machine bed have been installed.

3) Painted multiple parts

4) Began running new air lines and any needed oil lines.

5) Awaiting new spindle motor bearings, so rebuild of motor can begin. (Currently disassembled, just awaiting bearings)

I sometimes think that I should have just cleaned it up and put it to work. I would have regretted not doing it as I have found many items needing repaired/replaced. I guess it would have eventually happened anyway.

Next post will include picture updates as I am slacking on them right now. Just want to update the thread if anyone was wonder if the project was still alive.

Please Log in or Create an account to join the conversation.

Time to create page: 0.518 seconds