Pressbrake CNC Control Setup Questions

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

16 Aug 2021 23:28 #217925

by andypugh

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

Can you check the pressure inputs (limit and actual) to the .comp with halmeter to check that they both move, and both have the same units?

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 114

- Thank you received: 31

17 Aug 2021 12:05 #217974

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

I checked both pressure inputs with halmeter and they both change.

Max pressure changes with spinbutton change and pressure corresponds with physical pressure gauge on machine.

Pressure is scaled from the analog signal to match PSI reading on gauge.Down motion does not stop in both lowering and bending status. (When pressure exceeds max pressure).

Max pressure changes with spinbutton change and pressure corresponds with physical pressure gauge on machine.

Pressure is scaled from the analog signal to match PSI reading on gauge.

# ---pressure transducer feedback signals/setup---

net pressure-fb-raw hm2_7i97.0.7i87.0.0.analogin0 scale.0.in

net pressure-fb scale.0.out pressgui.pressure-gauge press.pressure

net pressure-max pressgui.max_pressure-f press.max-pressure

setp scale.0.gain 600Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

17 Aug 2021 21:54 - 17 Aug 2021 21:56 #218023

by andypugh

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

It sort-of works for me, with the system going in to the "Overload" state of the pressure limit is exceeded.

You need something like:in the HAL.

But, also, the logic was a bit wrong. I think that this version is better, but once you have overloaded the system will only retract, it won't let you try again at the same position (unless you select the same bend again in the GUI, at least)

You need something like:

net limit pressgui.max_pressure-f press.max-pressure

net actual pressgui.pressure-gauge press.pressureBut, also, the logic was a bit wrong. I think that this version is better, but once you have overloaded the system will only retract, it won't let you try again at the same position (unless you select the same bend again in the GUI, at least)

Last edit: 17 Aug 2021 21:56 by andypugh.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 114

- Thank you received: 31

18 Aug 2021 14:44 #218075

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

18 Aug 2021 14:54 #218076

by andypugh

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

Great.

I am still aware that homing needs further thought.

I am still aware that homing needs further thought.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 114

- Thank you received: 31

06 Dec 2021 23:07 #228476

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

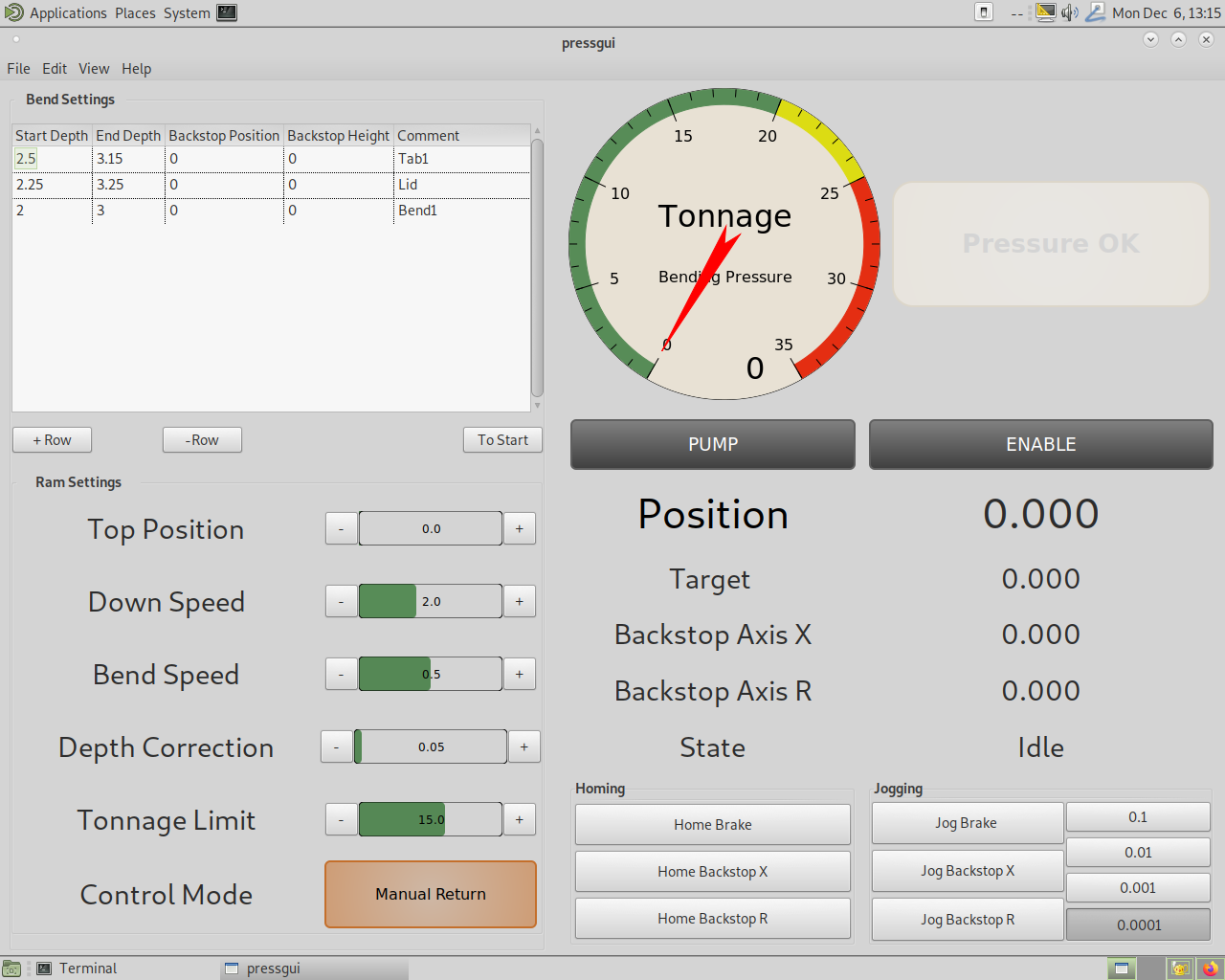

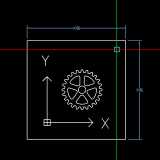

Here is an update on my CNC Pressbrake control.

The ram control is working good, I'm using it regularly for bending.

I'll attach my latest files. My pressbrake is set up for imperial units.

The backstop can be jogged, but the homing for the backstop still needs work.

This is a stand-alone setup made possible with the efforts of Andy Pugh's press.comp.

Thanks All!

Screenshot:

The ram control is working good, I'm using it regularly for bending.

I'll attach my latest files. My pressbrake is set up for imperial units.

The backstop can be jogged, but the homing for the backstop still needs work.

This is a stand-alone setup made possible with the efforts of Andy Pugh's press.comp.

Thanks All!

Screenshot:

Attachments:

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

04 Jan 2022 23:20 #230805

by andypugh

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

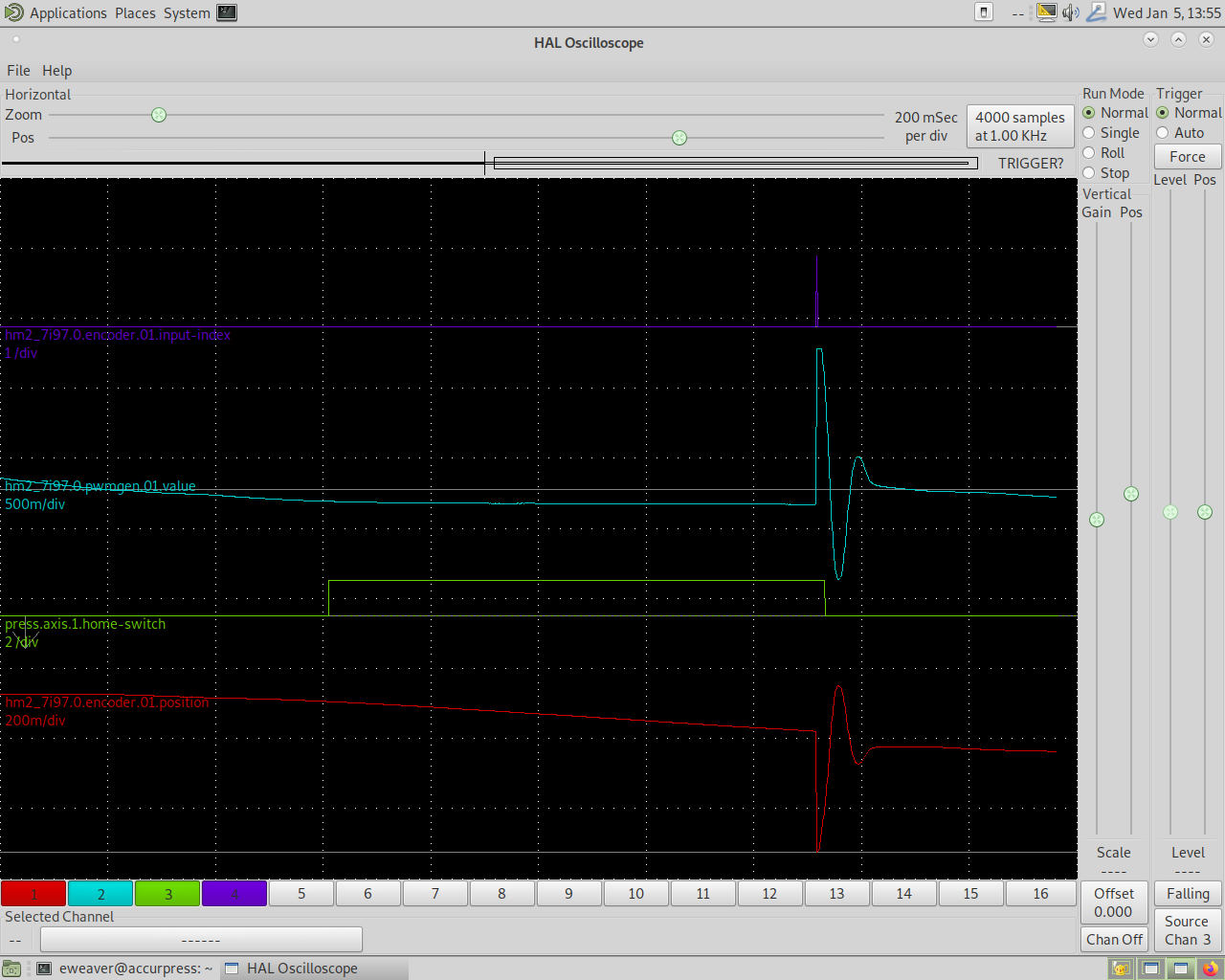

Is the backstop homing the same whether it starts on the home switch or off the home switch?

Is there any chance that you can get a Halscope recording of the backstop motion? (I realise that this might be tricky)

Is there any chance that you can get a Halscope recording of the backstop motion? (I realise that this might be tricky)

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 114

- Thank you received: 31

05 Jan 2022 00:50 #230816

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

It's been awhile since I tried homing the backstop.

I'll see if I have time tomorrow to get some halscope readings and some more info on the backstop's motion while homing.

I'll see if I have time tomorrow to get some halscope readings and some more info on the backstop's motion while homing.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 114

- Thank you received: 31

05 Jan 2022 20:18 #230894

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

The backstop homes, but as it hits the index point it jerks rapidly before it goes to its home search velocity.

I start the control with the backstop close to the point where the home switch drops from high to low so that the encoder count starts close to 0. That way when homing applies the offset, it is minimal. The farther from the homing point, the longer the fast travel is.

I'll try and get a halscope screenshot starting off of the homeswitch.

Halscope screenshot, Starting on home switch:

I start the control with the backstop close to the point where the home switch drops from high to low so that the encoder count starts close to 0. That way when homing applies the offset, it is minimal. The farther from the homing point, the longer the fast travel is.

I'll try and get a halscope screenshot starting off of the homeswitch.

Halscope screenshot, Starting on home switch:

Attachments:

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 114

- Thank you received: 31

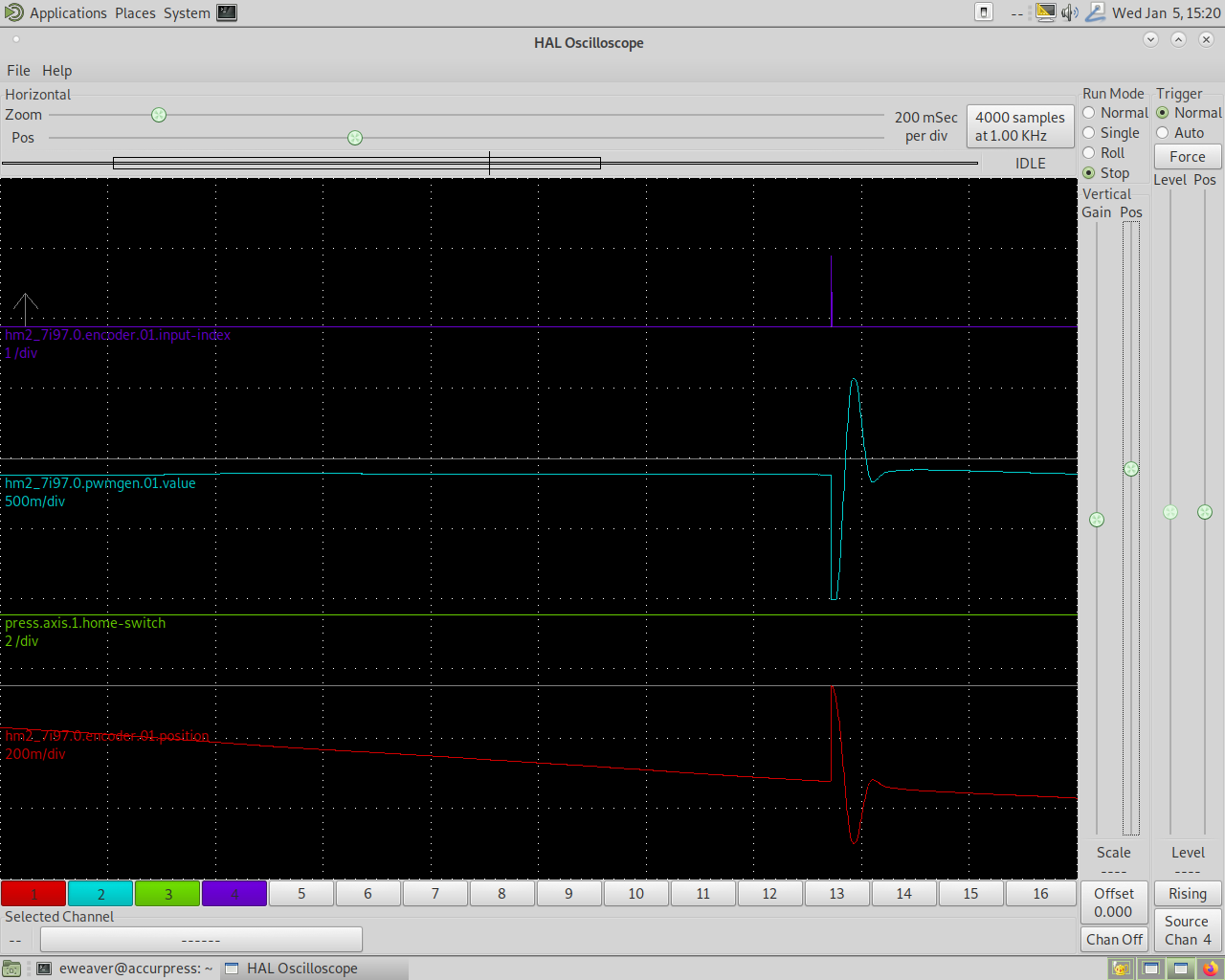

05 Jan 2022 21:26 #230902

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.263 seconds