Pressbrake CNC Control Setup Questions

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

Variable, servo controlandypugh wrote:Is R just up/down, or variable?

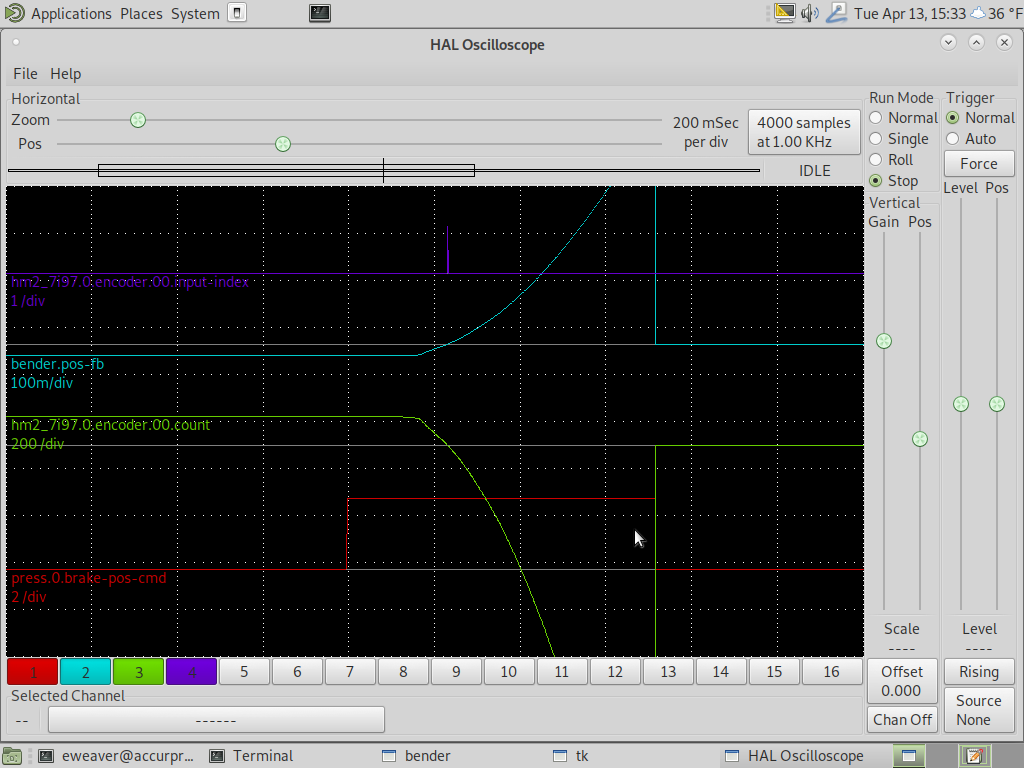

Missed that detail, My encoder is the LS 629 Selectable every 50 mm by magnet, Standard setting: 1 reference mark at midpoint.Which encoder do you have? One with distance coding or single index in mid-travel?

Is it an index pulse, or high for half the scale and low for the other half?

It looks like the magnet is located close to the top of the ram stroke. Earlier I had checked it with halscope and it seemed to be an index pulse.

I'll see if I can come up with some ideas. What you have looks like a good start. Keep it a fairly basic gui.It's up to you. How about drawing a mockup of what you think that the UI should look like?

Maybe have the start/stop, main control buttons at the top. Group the ram settings together, somewhat separate from the backstop settings. Thought I might try to have it touchscreen if possible. I have a 3M Microtouch monitor on it now, but I'm not sure if I'll be able to get it to work.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Yes i am, and i have seen that pic before (i think).

So i still insist it never happened!

I don't think so. But is this better for proof photos.app.goo.gl/gws6Cd18iB1zs8zf8

First bending test 5mm plate

Please Log in or Create an account to join the conversation.

- aluplastvz

- Offline

- Senior Member

-

- Posts: 52

- Thank you received: 9

OK, and now load / save / saveas / quit work.

(re-uploaded the zip file)

I will stop now, awaiting feedback from someone who has at least used a press brake.

What would be useful? "dublicate bend" button?

"duplicate bending "

In practice, this was useful

Thanks Andy for this job

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

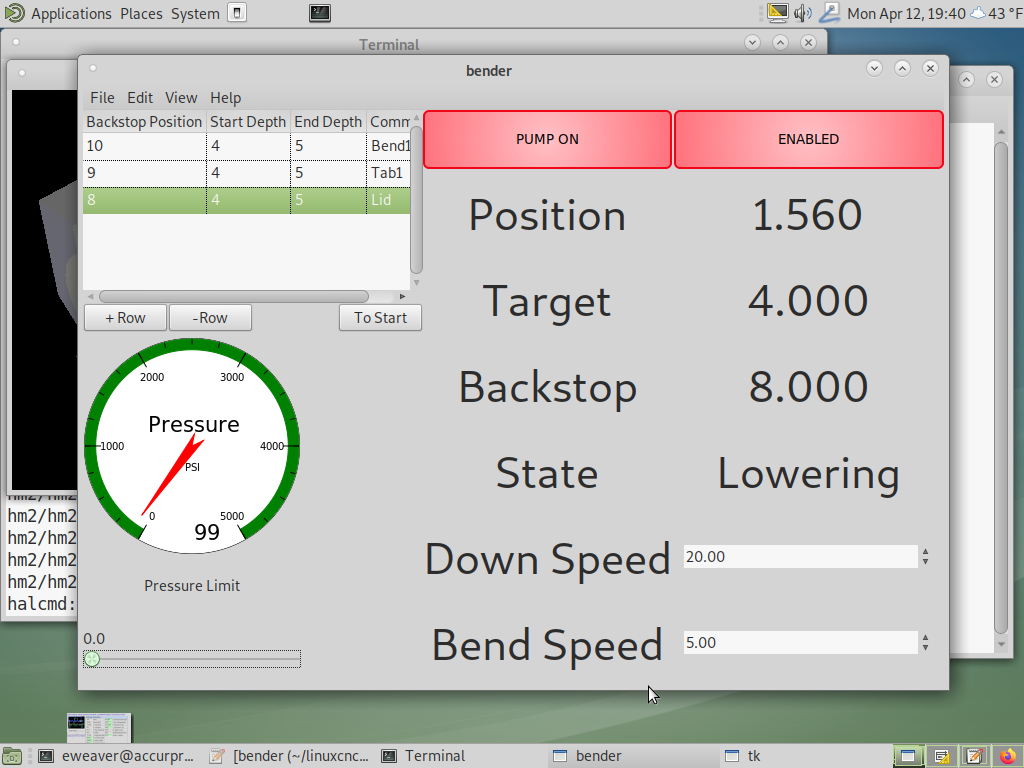

I have added a couple of buttons, one to turn on the pump and one to enable motion.

Note that the buttons both have a HAL pin to change their displayed colour.

What I would expect is:

setp bender.pump-enable 1

setp bender.enable-enable 0

bender.pump-button -> pump on

pump pressure-good -> bender.pump-light bender.enable-enable

bender.enable-button -> bender.enable-light, press.0.interlock simple-tp.0.enable, simple-tp.1.enable, pid.0.enable, pid.1.enable.........

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

Now for setting up the back gauge and doing some experimenting to see what all else it needs yet.

One thing I thought of is:

It has a pressure transducer that gives the bending pressure.

I would like to be able to set an adjustable MAX pressure, so that the bending pressure can be limited by what tonnage rating tooling is in the press brake at the time. Should this be done in HAL or be part of the press.comp?

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Adding another state "overpressure" that only allows motion up.

Also, I think that perhaps the gauge belongs on the right too, though I can't decide top, bottom or under the on/off buttons.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

The encoder's index is about 40mm (1.57 in. on our side of the pond) down from the top of the ram travel.

The encoder's count and position pins both line up 0 with the index. (attached index halscope)

Should I put a HAL offset between

net brake-fb <= hm2_7i97.0.encoder.00.position

net brake-fb => press.0.brake-pos-fb bender.pos-fb pressgui.posAlso the encoder reading shows about .024 in. negative from commanded position and when at rest.

Does that indicate that I am off on the PID tuning?

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Do I somehow need to home the ram at startup?

I think so.

It would be an extra state in the press.comp state machine.

I think that in this case you can use the mesa card index-enable to get very accurate homing.

It's a bit late here to add it tonight. I will try to remember tomorrow.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

If anyone else has any input or suggestions on what options we might need yet, let us know. It's been years since I worked with a CNC pressbrake.

Thanks,

Earl W.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Though there is still the issue of pedal-controlled up/stop/down in realtime, that really doesn't want to be handled in the GUI.

Please Log in or Create an account to join the conversation.