Useful Plasma Thread

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

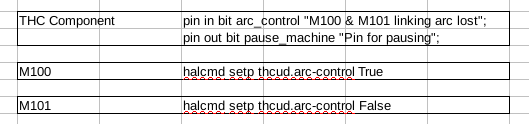

If you have a component written. It has the in and output signals we need.

It can interact directly with M codes, user interfaces, etc real time.

So better is to work around the to make M code list, this list is a user friendly list and also reduces the comp file code, a Macro does not have to be compiled, and simplyfies the structure in drastic way. Also users can make a quick modification to a existing Macro and don't have to worry about learning the whole process how to be a top c programmer.

This is how you can do a Macro :

#!/bin/bash

A=$(halcmd getp thcud.enable)

if [ "$A" = TRUE ]; then

halcmd setp thcud.arc-control True

halcmd setp grotius_gui.arc_lost_led True

else

echo " THC ENABLE is not active "

fi

exit 0It first looks if the THC is enabled.

It triggers if the arc okey signal is not lost during the cutting process. This real time interrupt model is only done by the component.

So the component handles only the real time interrupts. Logic parts can be programmed in the Macro's themself.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11629

- Thank you received: 3916

I am very comfortable programming in C and have had previously written Interrupt Service Routines (which is what the servo thread really is). By breaking it up into components, it should be more robust and easier to read as each components source should mostly fit in < 100 lines of code.

Some comments.

1. This will be designed so all torch height control is done internally within Linuxcnc and will not accommodate an external THC such as Proma ot the current THCUD/THC components. LinuxCNC is better than that!

2. It will require a method to read torch voltage (eg. Mesa THCAD at $69 becomes a very cheap THC).

3. Using internal code and PID based control should eliminate the need for a THC response speed setting.

4. Islander261 and I have experimented with using a standard M67/M68 command to allow multiple GUI settings to be set from within Gcode using just one analog pin (with an appropriate python screen handler) so you can change settings on screen and within Gcode. So I don't want to be too prescriptive about what Gcode does what, Just that every required Gcode function is supported.

5. Grivalajp has already shared some python code that uses modbus to talk to the Hypertherm RS485 port. Eventually, I would like to replace this with a hardware module so that there is no need to have a USB connection back to the PC. It would be much nicer if there was only on ethernet connection to the control box. This should be able to be supported using the smart serial port on a Mesa card and the right firmware (available for the 7i76e).

6. I have often wondered about writing a seperate touch off component that enables motion.spindle-at-speed when Arc is on, back at cut height after pierce delay so that there is no Gcode pierce routine required.. I've added it to the list.

Thanks for all the feedback. As I said most of this has been written so if I can stay motivated, it might not take long.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21171

- Thank you received: 7234

@Tommy,

Very good !

How did you write the Toma code? Making this code is almost impossible to do without being a expert. So that's why

i have repect for you. Even proma has used your code.

I did not write all of it, some other Linuxcnc user wrote most of it, it has parts of 2 configs put together and added what was needed to work properly with the UP/DOWN/ARCOK THC types. Also removed the need for a second parallel port as that made further complications for most users. Also some motherboards tend to change the PCI card addresses at random when set to automatically configure PCI bus so it would end up needing an address change quite often.

The code itself is made out of many components and logic and can be understood if followed carefully, but it is complicated and hard to process without some visual help. I did search today for a PDF that i had found at the time i did that config and that helped immensely to grasp what was going on, but i could not find it.

I have to e-mail Proma the new config after some cleaning and more user friendly explanations i made on Sunday.

Regards and thank you for all your work to improve Linuxcnc.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

Yesterday i had an issue about the limited M code list. We can go up to M999. We just have to change some things.

These codes are currently undefined in the current implementation of LinuxCNC

and may be used to define new M-codes:

M10

M11 M12 M13 M14 M15 M16 M17 M18 M19 M20

M21 M22 M23 M24 M25 M26 M27 M28 M29 M31 M32 M33 M34 M35 M36 M37 M38 M39 M40

M41 M42 M43 M44 M45 M46 M47 M54 M55 M56 M57 M58 M59 M74 M75 M76 M77 M78 M79 M80

M81 M82 M83 M84 M85 M86 M87 M88 M89 M90

M91 M92 M93 M94 M95 M96 M97 M98 M99

All codes between `M199` and `M999`.

So we can go up to M999. That is nice !! But i think we can go up to M10000 if we want, lets try it.

It is easer to understand M3 is related to M300 and so on.

For today my investegation ended here at line 148 : github.com/LinuxCNC/linuxcnc/blob/master...4ngc/interp_array.cc

At this moment i want a good time with my wife.

For tommorrow i have a new github linuxcnc version to try the exended Macro M999 and also try M10000.

You can see if it is working if it has a star.

github.com/michelwijnja/External_offsets...tive_feed_macro_plus

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

Expanding the M codes was succesfull in one file after compiling. I expanded the M-code array.

But it still is complaning after compiling and testing in terminal about : Uber 200 is not allowed.

So there is another file that is related to this maximum number.

github file

But now i have to find the other related files. The terminal give's to less information to solve this quickly. Is there a log file

that can trigger every single program step?

So i must look file by file tomorrow.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11629

- Thank you received: 3916

Then you could use M303 to pair with M3 in a logical manner. I don't think its a good idea to hack into the Linuxcnc core model.

I've added one more box to my diagram "touchoff exclusion". Say you don't want to touchoff until you are > 50mm form the last one, this will set a pin to be true if a touchoff is required (eg >50mm from last touchoff).

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

A Touchoff on/off button is very nice. I assume this will be added as Macro in g-code wich triggers the hal pin ?

I am curious how you program the 50mm variable distance in linuxcnc. I know sheetcam has a postprocessor who does this.

If you can do this in linuxcnc, this would be great !!

Problem with user defined macro's is the low range at this moment. It has enough macro's, but i like them to use in logic way that you can see that some macro's are related to each other. But i can better not waste precious time for this little thing.

Yes, it's very cheap for the product.Mesa THCAD at $69 becomes a very cheap THC).

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11629

- Thank you received: 3916

You could attach this signal to a motion.digital-in-nn pin where you could retrieve the state in gcode with a M66 if touching off in gcode. The maths is based on Pythagoras theorem. You should not need to do anything in gcode to tell it when you are touching off as the system already knows.

I've also written a simpler version that tracks the y position and enables a pin when it is greater than a set distance (half the table length). Why? well the pin can trigger an air ram to open a shutter to zone the table. This need to be fleshed out to a multizone system, but 2 zones is already supported.

component downdraft "LinuxCNC HAL component that triggers plasma zone";

description

"""

Component to trigger zones on a down draft system

""";

author "Rod Webster";

pin in float position "Motion signal for Axis position";

pin out bit trigger "True if downdraft segment should be triggered";

param rw float cutover "Absolute axis coordinate above which triggers zone change";

function _;

license "GPL";

;;

#include <rtapi_math.h>

FUNCTION(_) {

if(position > cutover)

trigger = 1;

else

trigger = 0;

}

Added this to the list

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21171

- Thank you received: 7234

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

I was thinking about the probe function wich you can set over xy distance.

The pythagoras formula is one option, like Rod has written.

Here i have a signal sample how you can trigger very simple over x and y distance.

The result will be no circular distance calculation but a rectangular distance calculation. In this way it is also possible to only measure at y axis or only at x axis distances. Most of time inox plates are bended over the short side.

.

Component for manipulate probe times over x and y distance.

Pin in bit probe-enable. "Connect to Gui button or G-code Macro signal";

Pin in bit probe-trigger "Triggers Arc-on signal at start";

Pin in float position-x. "Connect to x axis position";

Pin in float position-y "Connect to y axis position";

Param rw float Save-x-pos. "Saves the x axis position at probe-trigger signal";

Param rw float Save-y-pos. "Saves the y axis position at probe-trigger signal";

Param rw float Probe-distance "Probe distance value over x and y axis, can be separated"

Pin out bit. Probe-execute "probe-distance reached, enable probe Macro";Anonther function is the auto restart function. To make and adapt this function would be also great !!

If you look at the plasma start procedure :

1. Probe on or off.

2. M3 and wait for arc-on signal to move, if time out trigger auto restart component.

3. If arc-on, then do your thing.

So now it looks like we are building the THC features in building blocks, user's can add building blocks to their needs.

It would also be easyer for others to upload new features to this forum, that features can be loaded and tested in minutes.

I have tested that problably a component.so file is enough to load directly without first the need to compiling the component.comp file.

But i think i have to test this over different disto's.

Please Log in or Create an account to join the conversation.