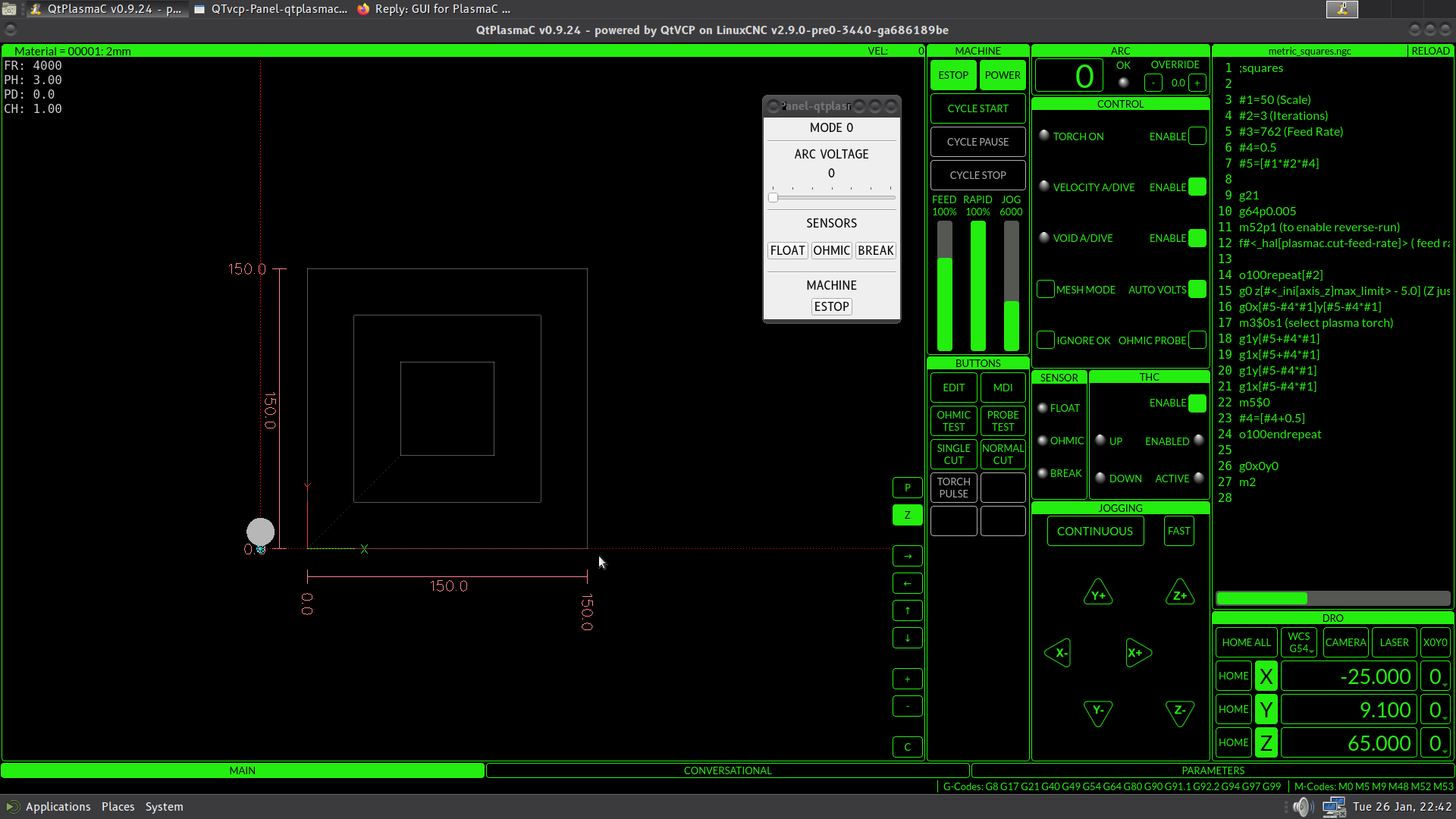

GUI for PlasmaC - QtPlasmac

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21231

- Thank you received: 7249

For the time being i do use only one size on all 4 machines.It would be soooo much easier if there was only one GUI size...

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11672

- Thank you received: 3934

It has everything to do with torch height, autovolts is based on the torch height (Phill, correct me if i am wrong here), it is sampled at whatever the cut height is set to and used as a reference,

Its actually sampled at the end of the THC delay provided the current velocity is near the desired cut velocity, otherwise it waits until it is. Then the THC is enabled. If you do not have a THC delay set, then the sampled voltage will be too high as the piercing voltage peak has not subsided so you will get erroneous results.

So auto volts compensates for worn consumables becasue as the electrode is consumed, the arc gets longer at a constant height above the material and therefore higher voltage ocurrs.

If you are using auto volts, you don't know what the voltage set point is so an override makes more sense. The standard number is accepted as being 10 volts per mm of height so a 1 volt override is 0.1mm. (Be aware I measured 7.53 volts on my Everlast so thats just approximate.)

I actually used a speed override yesterday for I think the first time. I was cutting 1.6mm and there is no cut chart for it so I told Sheetcam to use the 2mm settings and applied a speed override. Much easier than adding a new cut chart entry.

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Away

- Elite Member

-

- Posts: 197

- Thank you received: 63

Can we have a delay value by default if delay is missing o r too short when use autovolts? I mean these delay is required for the proper voltage sampling, that way the non expert can achieve better results.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11672

- Thank you received: 3934

linuxcnc.org/docs/devel/html/plasma/plas...imer.html#_thc_delay

It is very machine dependent. I've not done any tests but I believe its tied to machine acceleration which I did not understand until recently. I think we need to run some tests in halscope. Based on one knowledgeable member's feedback, it might be better to eliminate the delay altogether and enable the THC when it reaches cut velocity or a short delay thereafter.

This kinda makes sense becasue the arc cannot be at the desired voltage for a given material until it actually reaches the cut velocity! Before then, it has to be too high due to the slower than desired velocity

EDIT: I think its possible we have blindly followed convention set by external THC's, not by what is right with a motion controller controlling the whole THC process.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

- Posts: 915

- Thank you received: 216

tiny suggestion(s) maybe consider increasing the size of the tabs at the bottom of the page + material selection and gcode preview (open)

I agree with tommylight regarding the LED sizes + voltage {and the voltage offset / override +/- buttons) {given thats the important info you need from across the room / quick glance and quick adjustment)

Just wondering if there is a way to make the elements a proportional percentage to allow for automatic scaling (??)

I'm "playing" with a copy of the screenset as I really like the clean / flat look of it for a lathe.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

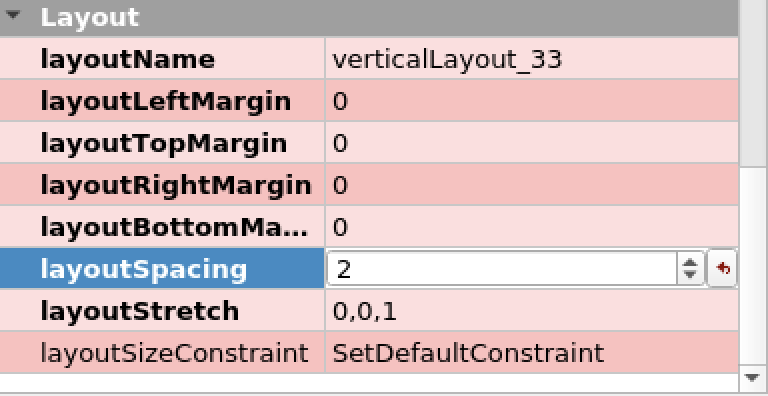

To a degree, you can set the layout stretch for the different elements in the layout. You also need to specify min and max sizes if you want to restrict anything.Just wondering if there is a way to make the elements a proportional percentage to allow for automatic scaling (??)

In the following you could make the layout stretch say 3,5,1

I had intended to begin this after I get the functionality and docs finished but If someone else wants to take it up then great.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

BumpIf anyone out there is good at creating small images and are looking for something to do it would be nice if we could get some decent images for the conversational side of things rather than the ugly ones I managed to cobble together.

The images we need are located here and are the images beginning with conv_

The smaller images display at around 54x54 and the large ones at 196x196 and I believe the supported formats are: BMP GIF JPG JPEG PNG PBM PGM PPM XBM XPM X11

Thanks, Phill.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

- Posts: 915

- Thank you received: 216

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.