GUI for PlasmaC - QtPlasmac

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

08 Feb 2021 11:54 #197990

by rodw

Replied by rodw on topic GUI for PlasmaC - QtPlasmac

No it needs to be pressed to enable the circuit on power up even if the estop is not triggered.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

08 Feb 2021 12:08 #197994

by robertspark

Replied by robertspark on topic GUI for PlasmaC - QtPlasmac

latching circuit / latching enable?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

08 Feb 2021 12:24 #197997

by rodw

Yeh, there are a few ways to wire it in that did my head in

I've got a contactor coming so will know more when I get it and experiment more.

The way I have it now more or less replicates how my press brake works, A momentary switch turns the hydraulic pump on and it trips out if you hit estop so if power is lost in a blackout, the motor is not enabled when power is restored without human intervention.

There is no GUI power button on that machine even though it is a touch screen device so I think the power on button in most linuxcnc GUIs is not required.

Replied by rodw on topic GUI for PlasmaC - QtPlasmac

latching circuit / latching enable?

Yeh, there are a few ways to wire it in that did my head in

I've got a contactor coming so will know more when I get it and experiment more.

The way I have it now more or less replicates how my press brake works, A momentary switch turns the hydraulic pump on and it trips out if you hit estop so if power is lost in a blackout, the motor is not enabled when power is restored without human intervention.

There is no GUI power button on that machine even though it is a touch screen device so I think the power on button in most linuxcnc GUIs is not required.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

08 Feb 2021 13:10 #198000

by robertspark

Replied by robertspark on topic GUI for PlasmaC - QtPlasmac

Something like a 1 shot timer is sometimes used for these sorts of things (or at least to be used when I still was a spark.

The one shot timer allowed everything to get powered up, and then for it to kick in the momentary pulse to allow for the latching circuit to be powered.

The estop (or another device [fire detector, current overload etc]) broke the latching circuit power supply and the oneshot would not fire again until power was reset.

Sorry, I know how to physically do / mark such a device with physical components and I can do it in software with a microcontroller, but not in linuxcnc / python (yet).

The one shot timer allowed everything to get powered up, and then for it to kick in the momentary pulse to allow for the latching circuit to be powered.

The estop (or another device [fire detector, current overload etc]) broke the latching circuit power supply and the oneshot would not fire again until power was reset.

Sorry, I know how to physically do / mark such a device with physical components and I can do it in software with a microcontroller, but not in linuxcnc / python (yet).

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

08 Feb 2021 18:00 #198033

by rodw

Replied by rodw on topic GUI for PlasmaC - QtPlasmac

Thanks Robert.

We'd probably use the oneshot component to do it from HAL

So we'd just need to find a pin to fire it.

(ASIDE: If you go to the bottom of the main documents page and click on the button "Expand Man Pages" all the components and their documentation will be revealed. I spent hours reading those docs! Just make sure you read the docs for the version you are using.)

I'd already decided the green button needs to be replaced by a relay so the green button (if used) could be remote from the contactor. The safety relay docs refers to ESC (external start conditions) which is what you describe.

This is still all a learning curve. I had some rather interesting discussions about the estop chain with some very qualified people. The long and the short of that was if you are using a number of estops around a large machine, unless you want to route mains power everywhere (which is in itself a safety issue), you need to use a safety relay to comply with ISO 13850,. This red one here cost me AUD $250

Anyway, thanks for the idea. Having never used a CNC machine before I built one, I don't have any reference point.

Sorry, I know how to physically do / mark such a device with physical components and I can do it in software with a microcontroller, but not in linuxcnc / python (yet).

We'd probably use the oneshot component to do it from HAL

So we'd just need to find a pin to fire it.

(ASIDE: If you go to the bottom of the main documents page and click on the button "Expand Man Pages" all the components and their documentation will be revealed. I spent hours reading those docs! Just make sure you read the docs for the version you are using.)

I'd already decided the green button needs to be replaced by a relay so the green button (if used) could be remote from the contactor. The safety relay docs refers to ESC (external start conditions) which is what you describe.

This is still all a learning curve. I had some rather interesting discussions about the estop chain with some very qualified people. The long and the short of that was if you are using a number of estops around a large machine, unless you want to route mains power everywhere (which is in itself a safety issue), you need to use a safety relay to comply with ISO 13850,. This red one here cost me AUD $250

Anyway, thanks for the idea. Having never used a CNC machine before I built one, I don't have any reference point.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

08 Feb 2021 18:53 #198044

by robertspark

Replied by robertspark on topic GUI for PlasmaC - QtPlasmac

I just use a series of estop (mushroom) buttons that are wired in series and all are normally closed.

if I press any estop, then stuff stops in a controlled manor. (the servo and vfd loose their OKtoRUN signals and stop, the steppers loose their enable signals)

nothing looses it's power supply (not good practice)

no it's not iso13850 compliant.... but that is only for some specific (daft??) reasons, and nothing to do with the relay. (shrouded mushroom buttons, keyed mushroom buttons (ok not daft), mushroom buttons without text (daft))

www.google.com/url?sa=t&source=web&rct=j...72F7d4DzpoB4HsUnRdzv

but then I am in my own garage where no one else has access to, and it's not used for commercial purposes.

the worst practice I've seen is full modbus control of a vfd without an stop interlock.....

if I press any estop, then stuff stops in a controlled manor. (the servo and vfd loose their OKtoRUN signals and stop, the steppers loose their enable signals)

nothing looses it's power supply (not good practice)

no it's not iso13850 compliant.... but that is only for some specific (daft??) reasons, and nothing to do with the relay. (shrouded mushroom buttons, keyed mushroom buttons (ok not daft), mushroom buttons without text (daft))

www.google.com/url?sa=t&source=web&rct=j...72F7d4DzpoB4HsUnRdzv

but then I am in my own garage where no one else has access to, and it's not used for commercial purposes.

the worst practice I've seen is full modbus control of a vfd without an stop interlock.....

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

08 Feb 2021 19:08 #198047

by rodw

Replied by rodw on topic GUI for PlasmaC - QtPlasmac

Yeh, its not a case of what you can do but what you have to do. I lost the argument. I think the risk assessment might set a lower bar for plasma machines than other machines.

The following user(s) said Thank You: robertspark

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

08 Feb 2021 19:16 #198052

by robertspark

Replied by robertspark on topic GUI for PlasmaC - QtPlasmac

it's difficult to rewrite the risk assessment with less fingers or no eyesight later....

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

12 Feb 2021 20:18 #198567

by robertspark

Replied by robertspark on topic GUI for PlasmaC - QtPlasmac

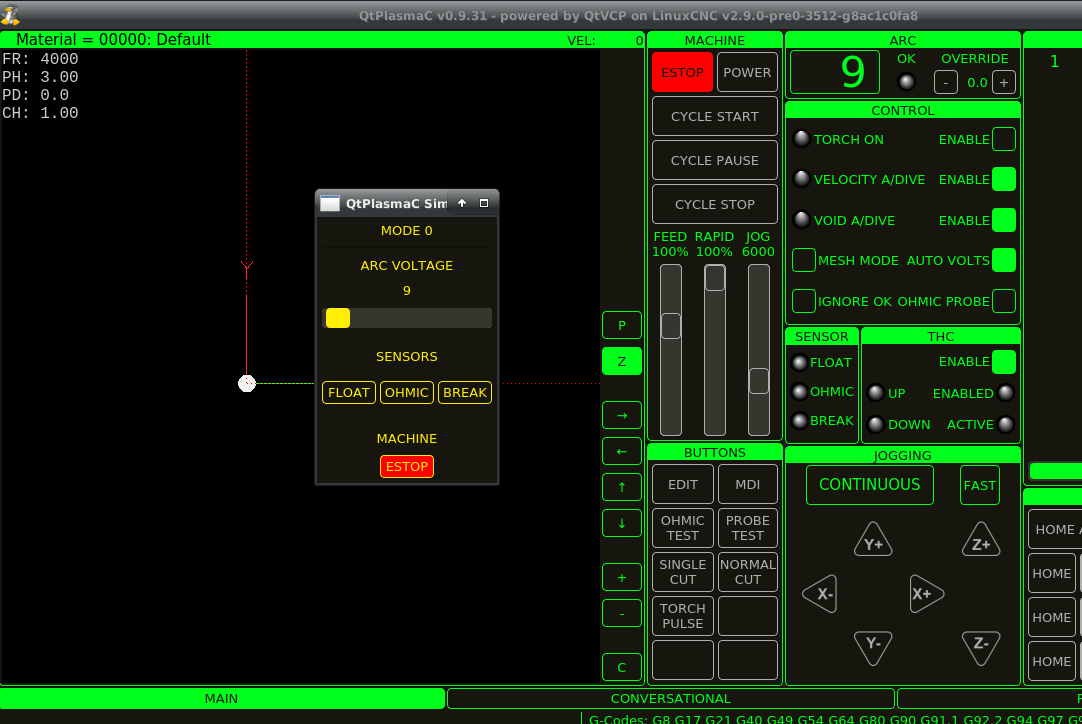

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

13 Feb 2021 03:37 #198641

by phillc54

Replied by phillc54 on topic GUI for PlasmaC - QtPlasmac

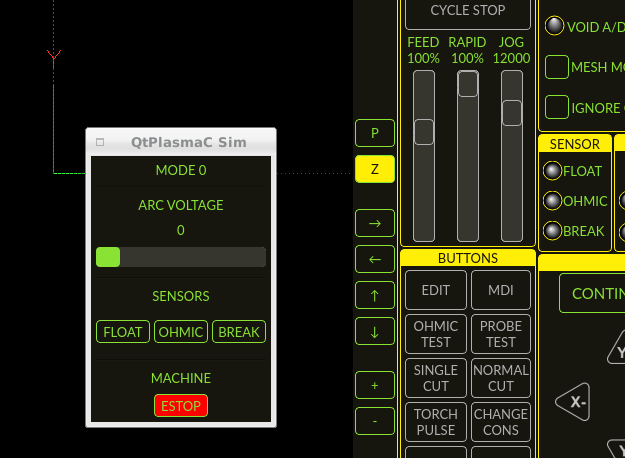

There you go, it now uses Foreground, Background, Alt Background and Estop from the Parameters tab.Question, is it possible that this could follow the same colour scheme as the background

(every armchair user is a critic....

Attachments:

The following user(s) said Thank You: rodw, robertspark, snowgoer540

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.237 seconds