ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

28 Jul 2018 06:43 #115002

by tommylight

ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC was created by tommylight

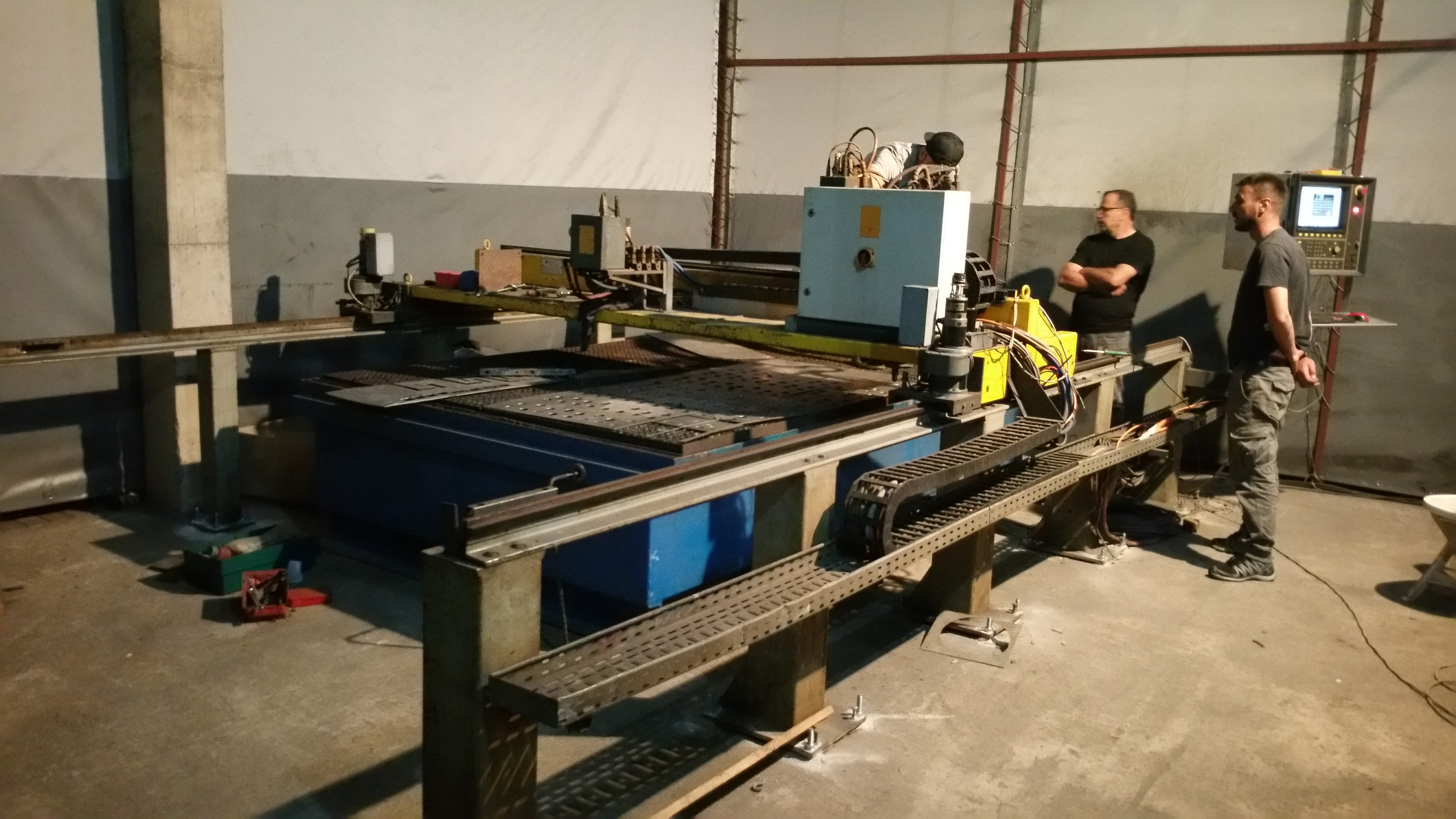

This is the ESAB Ultrarex UXD-P2500 retrofitted with Linuxcnc and Proma THC, using Mesa 6i25/7i77 as usual, added a stepper drive and motor to the Z axis wired to parallel port.

X axis has 2 servo motors, Y axis has 1 servo motor and Z axis uses a stepper motor attached with a coupler to the existing DC motor to avoid making fittings and holders and gears etc.

Took about 4 full days to finish, but lasted a bit longer due to waiting for the Proma Elektronika THC.

It uses the attached Linuxcnc config.

Fully automated and much more easier to use. Draw in Inkscape, export directly to gcode and open in Linuxcnc, press start, that is it, nothing more so no remaps, not subroutines, no touch off, nothing, everything is implemented in Linuxcnc HAL.

Usually takes about 2 days for anyone to be able to fully use the machine, from drawing to final products.

Pictures attached, it is quite big and it has more rails to be extended even further.

Control panel left as is with a new monitor and computer, Mesa boards, stepper drive and Proma THC mounted inside.

Here is a youtube video of it in action, was dark so not very good.

X axis has 2 servo motors, Y axis has 1 servo motor and Z axis uses a stepper motor attached with a coupler to the existing DC motor to avoid making fittings and holders and gears etc.

Took about 4 full days to finish, but lasted a bit longer due to waiting for the Proma Elektronika THC.

It uses the attached Linuxcnc config.

Fully automated and much more easier to use. Draw in Inkscape, export directly to gcode and open in Linuxcnc, press start, that is it, nothing more so no remaps, not subroutines, no touch off, nothing, everything is implemented in Linuxcnc HAL.

Usually takes about 2 days for anyone to be able to fully use the machine, from drawing to final products.

Pictures attached, it is quite big and it has more rails to be extended even further.

Control panel left as is with a new monitor and computer, Mesa boards, stepper drive and Proma THC mounted inside.

Here is a youtube video of it in action, was dark so not very good.

The following user(s) said Thank You: chimeno, snugglylovemuffin, FooBar

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

24 Aug 2018 16:51 #116554

by tommylight

Replied by tommylight on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

Had an issue with it, one side of the gantry would miss the position and halt throwing following errors. After some investigation turned out the slotted disk on the encoder had developed a bit of rust !

New encoder and moved on. Works 12 hours a day every day without a hitch.

New encoder and moved on. Works 12 hours a day every day without a hitch.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

24 Aug 2018 17:25 #116555

by BigJohnT

Replied by BigJohnT on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

Nice!

JT

JT

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- snugglylovemuffin

-

- Offline

- Elite Member

-

Less

More

- Posts: 209

- Thank you received: 11

15 Dec 2018 22:18 #122457

by snugglylovemuffin

Replied by snugglylovemuffin on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

That's amazing! Retrofitting old machines looks like good business

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Uzikas

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

03 Feb 2020 16:12 #156452

by Uzikas

Replied by Uzikas on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

hi, Tommy, I have the same situation...can you help me litlle bit? I need supprot from you. How can I reach you?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

03 Feb 2020 18:40 #156459

by tommylight

What do you need help with?

Replied by tommylight on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

For the next few days, only here on the forum.hi, Tommy, I have the same situation...can you help me litlle bit? I need supprot from you. How can I reach you?

What do you need help with?

Please Log in or Create an account to join the conversation.

- Uzikas

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

03 Feb 2020 19:03 #156462

by Uzikas

Replied by Uzikas on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

I have an old the same Ultrarex uxd-p. If I'll leave the old servo motors and servo drivers. Just fit's 6i25 or 5i25 card and 7i77. It's possible? Did you leave everything just change motors and motor's drivers and cards?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

03 Feb 2020 21:58 #156478

by tommylight

Replied by tommylight on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

Translation is not ok.

I used the old servo motors and drives, limit switches, E-stop loop, most of the wiring

added

a 6i25 and 7i77, new PC with monitor, power supplies, added a stepper motor and drive to one of the Z axis ( has 2 Z axis ), a Proma THC150.

Do you have the documentation for it, especially the schematics ?

I used the old servo motors and drives, limit switches, E-stop loop, most of the wiring

added

a 6i25 and 7i77, new PC with monitor, power supplies, added a stepper motor and drive to one of the Z axis ( has 2 Z axis ), a Proma THC150.

Do you have the documentation for it, especially the schematics ?

Please Log in or Create an account to join the conversation.

- Uzikas

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

04 Feb 2020 20:38 #156538

by Uzikas

Replied by Uzikas on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

Yes I have. Could you share schemes or pictures with connections? Did you connect THC to card 7i77? or it`s separate ? what kind of power supplies did You install?stepper motor? driver? THC only one on plasma cutting? sorry for questions, but it`s very important for me

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

04 Feb 2020 21:04 #156541

by tommylight

Replied by tommylight on topic ESAB Ultrarex UXD-P 2500 retrofit with Linuxcnc and Proma THC

If you have the schematics, you will need an electronics expert, there are to many wires to be wired properly and any mistake will end up in tears.

No amount of pictures will help you if you are not sure what each wire there does.

Start by studying the schematics with someone who knows electronics, check the schematics and the physical wires, find where each of them is located and how it is connected, especially the following:

Find the E-stop loop and figure out how it connected to the computer, you will have to wire this to the 7i77 input later.

Find the Enable wire that goes from the computer to the drives ( drives are in small boxes near the motors, not in any of the machine enclosures ), you will need to connect this to a 7i77 output later.

Find the analogue inputs for each servo drive, there are 3 drives so you will need to find all 3 of the cables to connect them to the 7i77 analogue outputs.

Find the encoder wires from all 3 servo motors, this is easier as they are separate for each motor, to be connected to 7i77 encoder inputs.

Find the limit switch cables, there are 3 of them used for homing and limits, to be wired to 7i77 inputs.

There is another extreme limit switch under the gantry on the left side when looking from the computer's side, do not touch this one and do not wire it to anything !!!!! This one cuts all the interlocks and power to drives in case of run away !

Keep in mind that making the interlocks work will need wiring on the big box located on the gantry, as they are controlled by several voltages, e-stop and enable. If i remember correctly there is only a single wire involved but i can not recall how and where, it was very hard to find it.

All the wires have labels, there are also numbering of each and every connector in the schematics, except there was an error on this documentation that had me chasing two connectors for over 3 hours, they are labelled wrong.

No amount of pictures will help you if you are not sure what each wire there does.

Start by studying the schematics with someone who knows electronics, check the schematics and the physical wires, find where each of them is located and how it is connected, especially the following:

Find the E-stop loop and figure out how it connected to the computer, you will have to wire this to the 7i77 input later.

Find the Enable wire that goes from the computer to the drives ( drives are in small boxes near the motors, not in any of the machine enclosures ), you will need to connect this to a 7i77 output later.

Find the analogue inputs for each servo drive, there are 3 drives so you will need to find all 3 of the cables to connect them to the 7i77 analogue outputs.

Find the encoder wires from all 3 servo motors, this is easier as they are separate for each motor, to be connected to 7i77 encoder inputs.

Find the limit switch cables, there are 3 of them used for homing and limits, to be wired to 7i77 inputs.

There is another extreme limit switch under the gantry on the left side when looking from the computer's side, do not touch this one and do not wire it to anything !!!!! This one cuts all the interlocks and power to drives in case of run away !

Keep in mind that making the interlocks work will need wiring on the big box located on the gantry, as they are controlled by several voltages, e-stop and enable. If i remember correctly there is only a single wire involved but i can not recall how and where, it was very hard to find it.

All the wires have labels, there are also numbering of each and every connector in the schematics, except there was an error on this documentation that had me chasing two connectors for over 3 hours, they are labelled wrong.

Please Log in or Create an account to join the conversation.

Time to create page: 0.180 seconds