- Hardware & Machines

- CNC Machines

- Milling Machines

- Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

06 Sep 2020 17:31 - 27 Apr 2021 15:05 #181044

by new2linux

Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier was created by new2linux

I want to thank Todd Zuercher, tommylight, JR1050, PCW, OT-CNC, A-M-C support & the Moderator, piasdom for all the help and continued support. The procedures offered by A-M-C support were valid for testing that part of drives.

This has been an educating experience, for tuning of servos go to page 14.

Many, many, thanks to:

Todd Zuercher, tommylight, JR1050, PCW, OT-CNC, A-M-C support & the Moderator, piasdom for all the help & support.

I have a mill that was an original ProTrak Plus machine that has Advanced Motion Controls "brush type" 12A8 amplifiers that I need to upgrade to "Axcent" (the current model) amplifiers. The Axcent amp as additional DIP switch settings that tune the system.

What should my starting values be for the P, I, & D?

Attached are the data sheets:

Many thanks!

Edit: The 12a8 amp, had capacitor fail, at the same time a capacitor failed on the power supply. The current model "Axcent" amps were available when I made purchase.This is the original linuxcnc mill conversion post:https://forum.linuxcnc.org/forum/search?searchuser=new2linux&exactname=1&searchdate=all&childforums=1&start=0

This has been an educating experience, for tuning of servos go to page 14.

Many, many, thanks to:

Todd Zuercher, tommylight, JR1050, PCW, OT-CNC, A-M-C support & the Moderator, piasdom for all the help & support.

I have a mill that was an original ProTrak Plus machine that has Advanced Motion Controls "brush type" 12A8 amplifiers that I need to upgrade to "Axcent" (the current model) amplifiers. The Axcent amp as additional DIP switch settings that tune the system.

What should my starting values be for the P, I, & D?

Attached are the data sheets:

Many thanks!

Edit: The 12a8 amp, had capacitor fail, at the same time a capacitor failed on the power supply. The current model "Axcent" amps were available when I made purchase.This is the original linuxcnc mill conversion post:https://forum.linuxcnc.org/forum/search?searchuser=new2linux&exactname=1&searchdate=all&childforums=1&start=0

Last edit: 27 Apr 2021 15:05 by new2linux. Reason: back ground info; Edit 12/2020, 2nd Edit:servo tuning page 14

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21265

- Thank you received: 7261

16 Sep 2020 10:38 #182426

by tommylight

Replied by tommylight on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Sorry for the late reply.

Are the drives controlled by step/dir signals or analogue ?

Are the drives controlled by step/dir signals or analogue ?

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Elite Member

-

Less

More

- Posts: 284

- Thank you received: 31

21 Sep 2020 01:13 #183009

by JR1050

Replied by JR1050 on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Under the assumption that you have brushed dc motors, I would also guess your motors have tachs. This new drive will not support tach feedback, but you can still run it in velocity mode using the encoder.

Current mode is a pain and requires much higher gains then velocity mode, my experience with these type drives and current mode is set p until the motor oscillates then back off, set d until you get a crisp start and stop(no overshoot " critically dampened"). On velocity drives I usually set ff1 to 1.0 and add a tiny amount of p gain until the motor is stiff as possible with out overshoot. Somewhere there is a vey good thread about motor tuning and gains by Andy and I wanna say that current mode drives use ff0, but Im not swearing to it. Id start my p gain at 100 . and d at 1 in current mode.

Easier, set the drive for encoder feedback, get an encoder y board, run the encoder to both your new drives and the control, set ff1 to 1 and you will be 90% done. Alternatively, you can buy AMC 30a8 drives on eBay for $40 each and all you will need to do is set the velocity gain and ref gain on the drive and you will be back in business . The encoder velocity mode on AMC amps is very handy for dc motors with out tachs, like yellow cap Fanucs....

Current mode is a pain and requires much higher gains then velocity mode, my experience with these type drives and current mode is set p until the motor oscillates then back off, set d until you get a crisp start and stop(no overshoot " critically dampened"). On velocity drives I usually set ff1 to 1.0 and add a tiny amount of p gain until the motor is stiff as possible with out overshoot. Somewhere there is a vey good thread about motor tuning and gains by Andy and I wanna say that current mode drives use ff0, but Im not swearing to it. Id start my p gain at 100 . and d at 1 in current mode.

Easier, set the drive for encoder feedback, get an encoder y board, run the encoder to both your new drives and the control, set ff1 to 1 and you will be 90% done. Alternatively, you can buy AMC 30a8 drives on eBay for $40 each and all you will need to do is set the velocity gain and ref gain on the drive and you will be back in business . The encoder velocity mode on AMC amps is very handy for dc motors with out tachs, like yellow cap Fanucs....

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

23 Sep 2020 16:37 - 23 Sep 2020 17:21 #183497

by new2linux

Replied by new2linux on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

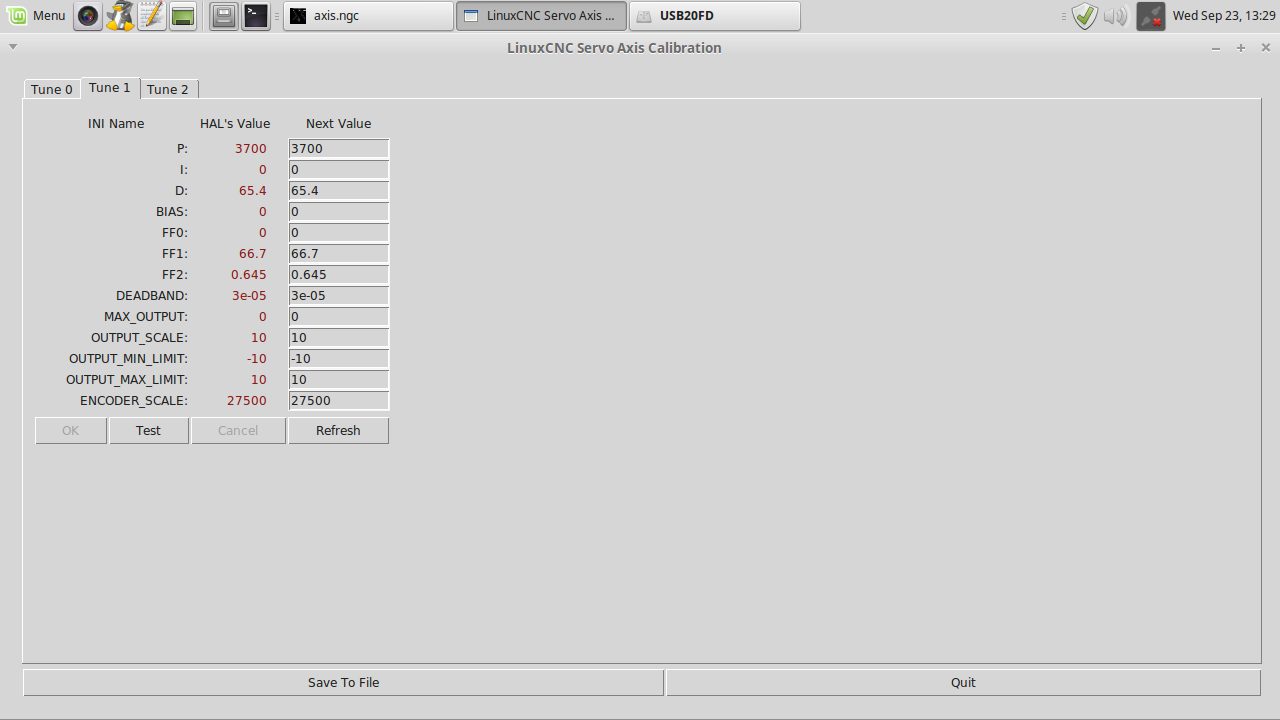

Many thanks to tommylight and JR1050 for your help. I have been working with AMC engineer and the recommendation is "current mode" drive set up. The motors are DC "brushed type" with encoders, other that that I know very little about them. Today I have the ability to use the "Linuxcnc logo" cutter path to provide motion to motors, they are noisy, especially at low speed. Lots of rigidity, hard to move off stop position with motors energized. It appears to me the original P,I & D settings are being used unless the drives know how to work around this.

Attachments:

Last edit: 23 Sep 2020 17:21 by new2linux. Reason: add screenshot

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21265

- Thank you received: 7261

23 Sep 2020 16:54 #183498

by tommylight

Replied by tommylight on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Seems like something is not tuned properly as servo motors should be quiet while moving and stationary.

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

24 Sep 2020 16:41 - 24 Sep 2020 20:34 #183609

by new2linux

Replied by new2linux on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

I warmly welcome suggestions, and kindly thank those who may have some thoughts to share, or suggest some reading for myself that may help. After some emails to AMC support I am at the point where I need to set motor w/o belt/load to not move when adjusting POT #4. I have a jumper to connect pins 4 & 5 to 2 (ground). I am at a loss to understand how to apply power to motor so I can adjust POT4.

This is from support.

To set pot 4 on the AB15A100, you need to ground pins 4 and 5, and then adjust pot 4 until the motor is not moving.

many thanks!

Edit: After more conversation with AMC about "Current mode" vs. "Velocity Mode" and the DIP switch settings there may not be any advantage to the AB15A100 drive, the tuning need to be done at the controller. I need to start again and try the "velocity mode" method.

This is from support.

To set pot 4 on the AB15A100, you need to ground pins 4 and 5, and then adjust pot 4 until the motor is not moving.

many thanks!

Edit: After more conversation with AMC about "Current mode" vs. "Velocity Mode" and the DIP switch settings there may not be any advantage to the AB15A100 drive, the tuning need to be done at the controller. I need to start again and try the "velocity mode" method.

Last edit: 24 Sep 2020 20:34 by new2linux. Reason: More info; velocity mode prefered, as per JR1050!

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Elite Member

-

Less

More

- Posts: 284

- Thank you received: 31

24 Sep 2020 21:39 #183628

by JR1050

Replied by JR1050 on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Pin 4&5 are your drive signal, you are referencing them to ground , so you are in no way commanding the motor to move. Pot 4 is for offset, it can increase or decrease gain. You power the amp up and adjust the pot so the shaft is locked and has zero movement. Make sure you set the current limit gain scaling correct for you motor, there are dip switches that scale from 100 to 50% full current and a pot that can adjust the current gain lower still. AMC is correct in telling you the tuning is done at the controller, the current loop can be scaled, but it is a MAJOR pia, you will need a scope. You should also have a reference gain pot, which can decrease the gain of the input signal.

To use velocity mode, you will need some sort of feedback. Older Amc drives would run in velocity mode using back emf, Im not sure you have this option.

Truthfully, you would be better off looking for an amp that uses tach feedback, lots of 30a8's on ebay. Again you could but (they are like $15 each )a couple encoder y boards and use encoder velocity.

To use velocity mode, you will need some sort of feedback. Older Amc drives would run in velocity mode using back emf, Im not sure you have this option.

Truthfully, you would be better off looking for an amp that uses tach feedback, lots of 30a8's on ebay. Again you could but (they are like $15 each )a couple encoder y boards and use encoder velocity.

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

24 Sep 2020 22:02 - 24 Sep 2020 22:21 #183633

by new2linux

Replied by new2linux on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

JR1050, Many thanks for you thoughts, please point me in the correct direction!! This is the motor tag, I have search many times and could not find any information like the " current limit gain scaling that is correct for the motor" or any technical data. I believe they are re branded product.

The motors have encoders built on them, going back to power supply box, so high power and encoder control cable, is this what is required for Encoder Velocity Mode? The 12a8 were set up in current mode I think. If I need to do more reading please point me in the correct direction, I offer my many thanks for all who make this forum possible. The original equipment was a Prototrak Plus, currently same motors and power supply.

Edit:I am using a Mesa 7i77 & 5i25 cards with Prototrak Plus motors and power supply. Brush Type

The file size to large will try again later.

The motors have encoders built on them, going back to power supply box, so high power and encoder control cable, is this what is required for Encoder Velocity Mode? The 12a8 were set up in current mode I think. If I need to do more reading please point me in the correct direction, I offer my many thanks for all who make this forum possible. The original equipment was a Prototrak Plus, currently same motors and power supply.

Edit:I am using a Mesa 7i77 & 5i25 cards with Prototrak Plus motors and power supply. Brush Type

The file size to large will try again later.

Last edit: 24 Sep 2020 22:21 by new2linux. Reason: try 2nd screenshot

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Elite Member

-

Less

More

- Posts: 284

- Thank you received: 31

24 Sep 2020 23:34 - 24 Sep 2020 23:38 #183647

by JR1050

Replied by JR1050 on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Look at the original dip switch settings on the drive and compare them to the settings in the manual. Do these motors have tachs? The motors would not list a scale of any kind. Email magnatek and ask for product data for that part number. If they have tachs , they were in tach velocity mode, they could be set up for either back emf or current mode. They look like the outside of the motor is chrome plated, if so , they are probably Electrocraft.

Last edit: 24 Sep 2020 23:38 by JR1050.

The following user(s) said Thank You: new2linux

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

Less

More

- Posts: 711

- Thank you received: 9

25 Sep 2020 12:06 #183710

by new2linux

Replied by new2linux on topic Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

JR1050, thanks for your help! The tag on the motors are to "look" chrome, 1 of them unless you hold just right the writing is not visible, just shinny. The motors are painted black, I will spend what ever to track down the Magnetek data, specifically "motor current ratings". Thanks

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Time to create page: 0.219 seconds