- Hardware & Machines

- CNC Machines

- Milling Machines

- Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier

- PCW

-

- Offline

- Moderator

-

- Posts: 17590

- Thank you received: 5145

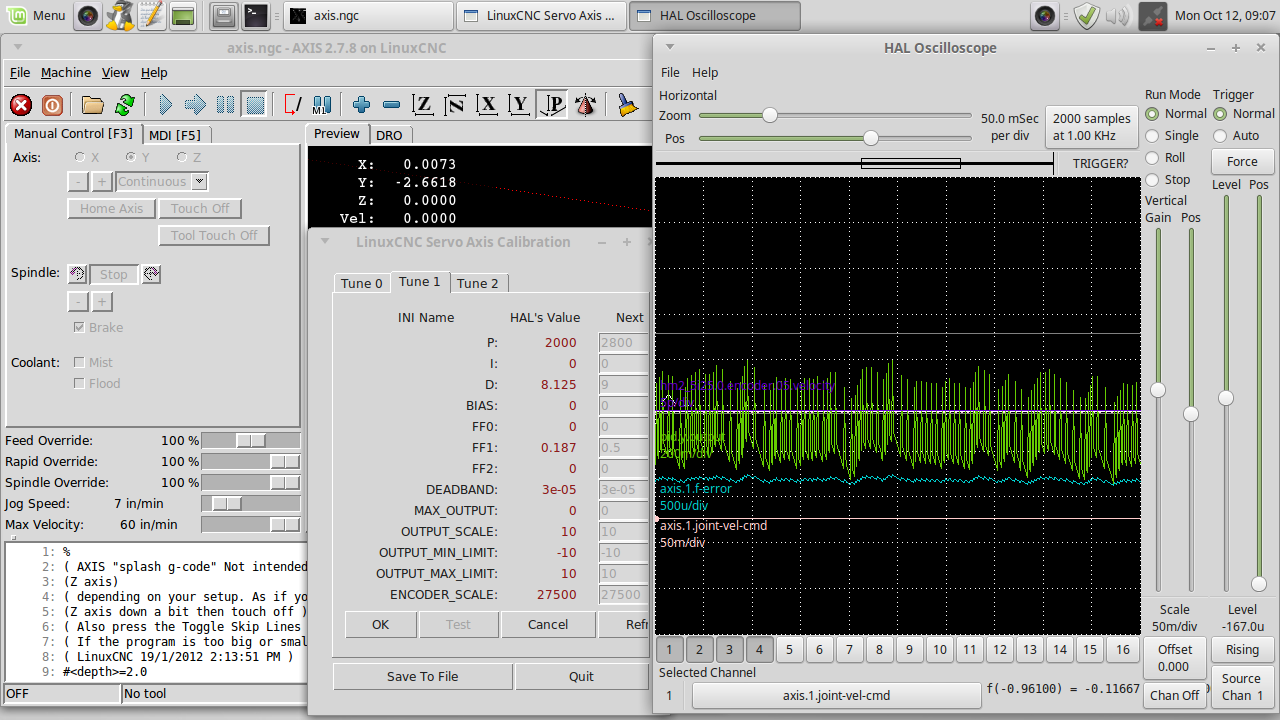

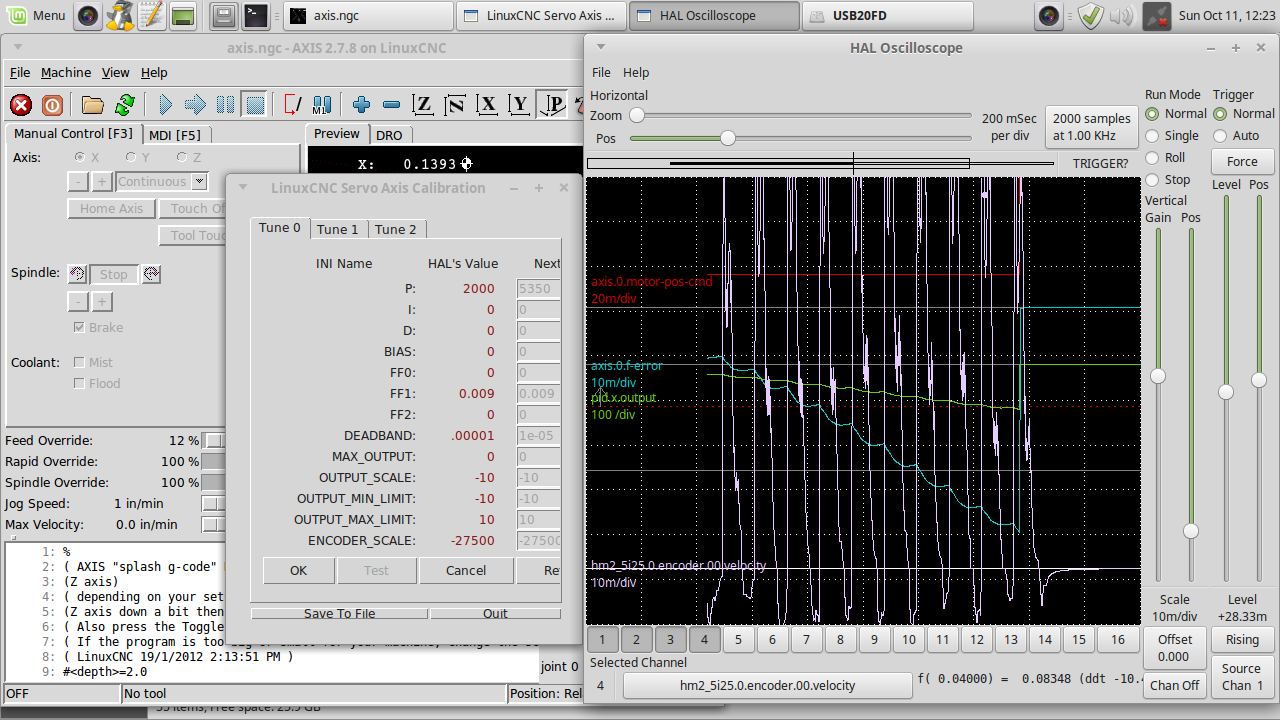

It should be tunable but is a bit fussier to tune than velocity mode drives. It also may need a

shorter than normal servo thread period as Todd mentioned.

For single PID loop torque mode rough rule-of-thumb tuning:

You want to set D as high as is stable (it will get crunchy/buzzy if too high) and then

back off maybe 30% then do the same with P. Then you add FF2 until the lag during

acceleration is compensated. finally add I until it becomes unstable and then back

off about 50%

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

- Posts: 711

- Thank you received: 9

I reached out to asked the tech at A-M-C and Yes, the AB15A100 drive can accept feedback from a single ended incremental encoder.

Yes the switches to set the drive for Encoder Velocity mode if you use an encoder. I am reviewing to see which pins on the signal connector are used for the A and B channels of the encoder. As per AMC tech this looks like a good fix..

The AB15A100 does not support back EMF as a form of feedback for velocity control.

Edit: So differential encoders have additional set of Complimentary or “mirror image” signals to reduce "electrical noise". Encoders with "index" often have an additional channel, referred to as index channel. This channel outputs one pulse per revolution, and is typically an extremely narrow pulse equal to about one-quarter of the width of an A or B channel pulse, but it can be wider. The encoder index can be used for homing (absolute position reference) and for commutation alignment.

I am not shore at this time.

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

- Posts: 711

- Thank you received: 9

I have a better appreciation how encoders are input can be used for more than a single way (or work around) of input, depending on what you have to start with.

many thanks!

Edit: Many thanks to each of you, who took the time to inform me for my poor understanding of how encoders work, this "back EMF" is a "work around" for the earlier equipment, is the way I think of it.

Edit: I have reread the all the posts and believe this is the preferred setup.

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

- Posts: 711

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

- Posts: 615

- Thank you received: 75

Something needs to feed back to the amc is what we are trying to tell you.

The prototracks I have used (90's vintage) had an encoder added to the table. Small toothed wheel that would make an indent in the cast iron table, essentially creating a rack and pinion on a small scale that would count position. That encoder (Trak senor), if it works, you could use to read into linuxcnc (hook up to the 7i77 provided it's 5v ttl encoder?) and connect the motor encoder to the the amc.

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

- Posts: 711

- Thank you received: 9

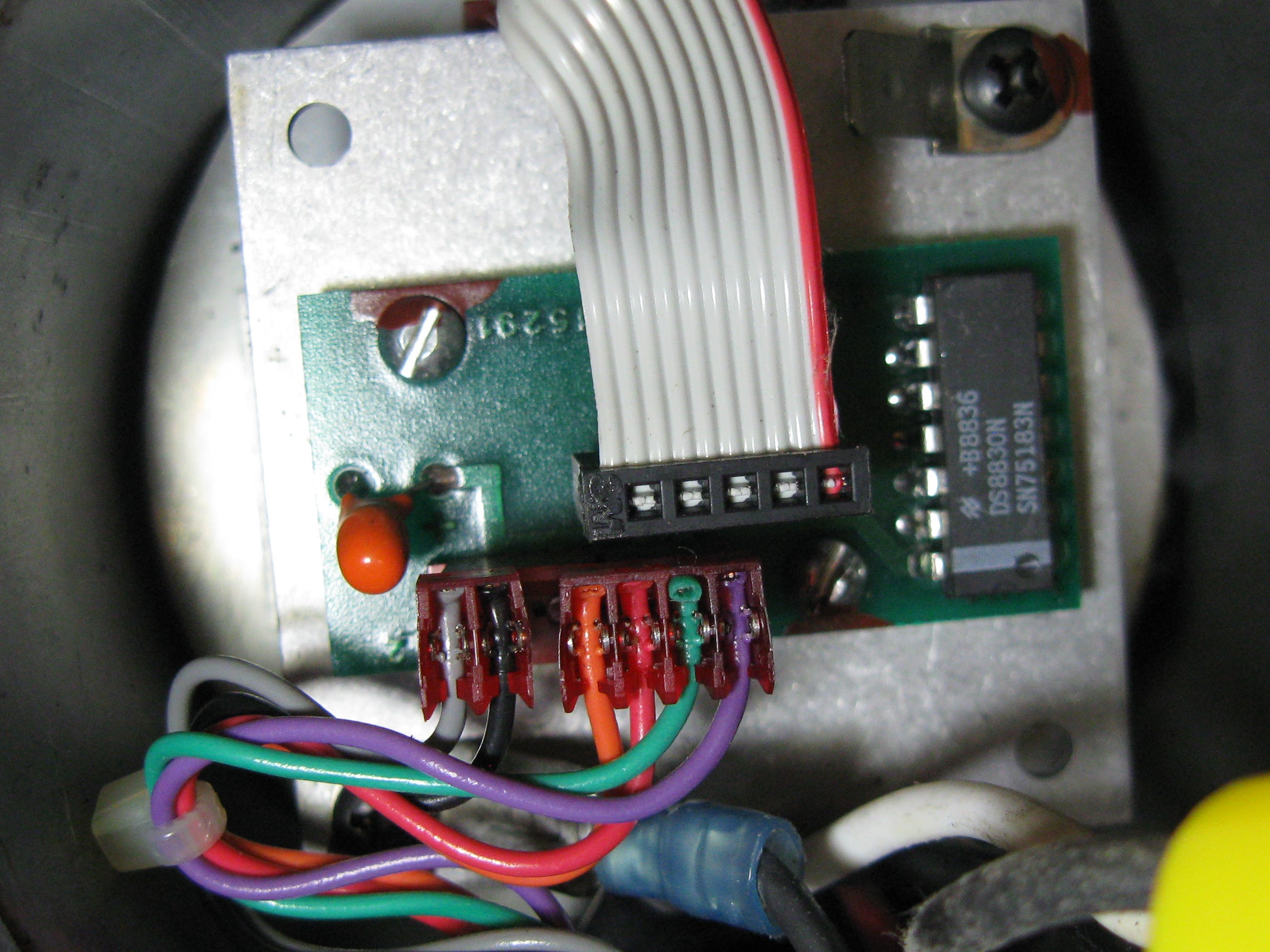

I believe something is "goofed up" and I need to get the part ordered, if the part is the encoder can I replace with something that makes sense.

This is "Y axis"

This is "x axis"

From earlier post, by Todd Zuercher:

You had to know this when you connected them to the Mesa card. How many wires did you hook up there? Was there an A, /A, B, and /B plus index and power wires or just A and B with index and power wires? (Index is optional.) If it were the 2nd you would have had to move the encoder jumpers on the 7i77.

If the encoders are differential. Hopefully Peter (or someone else) might chime in on the best way to connect the encoder signal to the single ended inputs on the drive, because I'm not sure.

If I could reach out to Peter, If you can share your thoughts about the "single ended inputs on the drive" or if I can get a better understanding I will ask the question to the A-M-C technician. The A-M-C technician is helpful but need I need to know the question well enough to get complete response.

I am ever so thankful to those who enable this forum to work so well, and warmly welcome assistance to point me in the correct direction or if suggestive reading or If I have not set up the hal scope correctly or other thoughts you may have.

many thanks

Edit: I swapped the motor and encoder from the "x" axis to the "y" axis and the "x" axis motor would not work with the setting that the "y" axis had moved under power. It is my belief that the encoder on the "x" axis has the issue. I was unable to tune the motor.

Attachments:

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

- Posts: 711

- Thank you received: 9

I put question to the tech at AMC, the response: single ended encoder input only!

Need to confirm the correct encoder.

Many thanks!

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

- Posts: 615

- Thank you received: 75

Edit: I swapped the motor and encoder from the "x" axis to the "y" axis and the "x" axis motor would not work with the setting that the "y" axis had moved under power. It is my belief that the encoder on the "x" axis has the issue. I was unable to tune the motor.

Before buying a new encoder, I would load each encoder channel into halscope and compare it to the one that works to see if it indeed is faulty. Assuming they are still wired to the 7i77.

If your machine has handwheels you can move the table without powering up the motors and look for a clean square wave coming from the encoder.

If you are asking how to connect the encoder to your new drives, you should be able to just connect A and B and Ground if they get power from an external 5v (7i77). Someone correct me if I'm giving the wrong info please.

On my AMCs I use the old tach feedback but will be doing a BL setup soon for a 4th axis and will read in one encoder. So I'll be going through the same thing. Is it acceptable to say split a A, /A, B, /B, with a Y harness and tie one end to 7i77 using all channels and connect only A, B and Ground on the drive?

I'll dig up my post from a while back tuning the amc. I recall having an issue with one pot setting (a recommended full cw or ccw? setting from the manufacturer) that just made it impossible for me to tune.there is a part "goofed up" because tuning was impossible and if you hold the hand wheel for the "x axis" while the motor is energized it has vibration you can feel in your hand and never becomes firm against rotation.

Check your reference pot gain. Try mid range. That should stiffen it up.

forum.linuxcnc.org/27-driver-boards/3860...rive-tuning?start=20

Please Log in or Create an account to join the conversation.

- new2linux

- Offline

- Platinum Member

-

- Posts: 711

- Thank you received: 9

When I tested by swapping (x axis encoder and power cable at the back of cabinet) with (y axis encoder and power cable at the back of cabinet) in addition to trying to tune this (use "test" & "cancel" after each change) axis as well. I have saved a file for setup axis x and a 2nd file for y axis. The hand wheel needs to be much stiffer. I will try looking for "a clean square wave coming from the encoder" & try the y axis as well. I will read your link, and evaluate POT 1 adjustment.

The encoders I see available have a coupling to motor shaft, I can see how covenant a factory original is. Ideally I would like a after market brand. I still wonder about encoder count, I realize it is referenced in other areas of the program and not locked in stone.

Many thanks

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

- Posts: 615

- Thank you received: 75

2000 count should be fine. What are you doing with the original Track Encoder, the table mounted unit? What count was that?

Please Log in or Create an account to join the conversation.

- Hardware & Machines

- CNC Machines

- Milling Machines

- Replacing Advanced Motion Controls "brush type 12A8 with "Axcent" amplifier