Build: XZero Predator... With more teeth!

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

07 Jun 2019 00:02 #136135

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

How does linuxcnc handle a portrait monitor arrangement? I will eventually make myself a custom UI, but ill be using axis for now. If i arrange my lcd vertically, will it flip out?

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

07 Jun 2019 04:56 - 07 Jun 2019 05:03 #136167

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

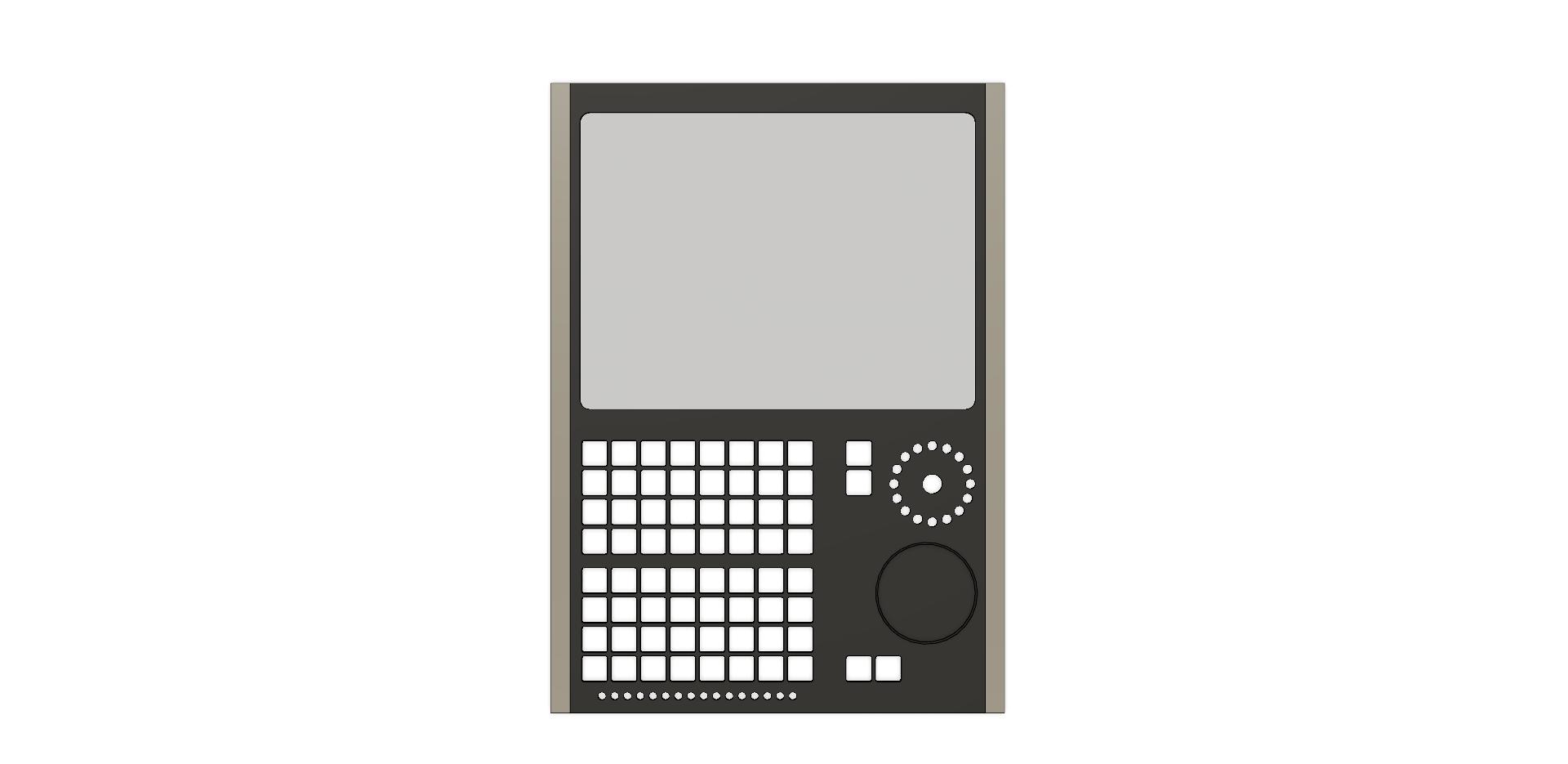

So, here's the idea for the panel layout.

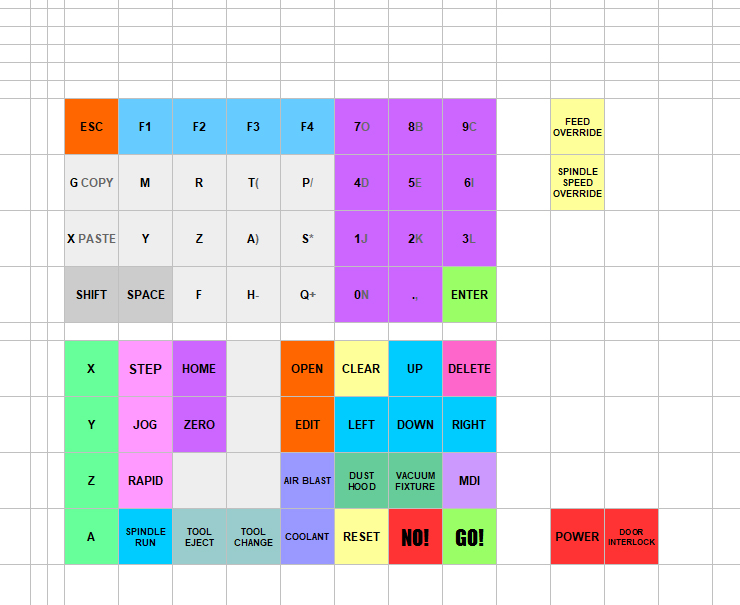

And the keys.

Seems 4 keypads plus a couple extra independent buttons works well enough. You get almost the full typing keyboard, number pad and function keys on the upper section. The lower section is for machine functions. I have 4 spare buttons right now, although I'm sure I've forgotten something.

The power button it the main on switch, it will be a mechanical momentary switch with an LED. Likewise the Door interlock button. Everything else is through the Arduino emulating a keyboard (at least, tentatively). The keys will be mapped to send out whatever signal is required - for example a shift + 7 would just send out the upper case letter O.

On the right we have an led ring with an encoder in the middle, this will be the feed and spindle speed override wheel. the buttons next to it will select between functions.

Below that will be the MPG wheel. It's modes are on the left of the lower keypad. XYZA, step, rapid, jog

Anyone see a button I need to add in for "regular usage"? for anything complicated you will just plug in a USB keyboard, so we don't need to overload the functions here. Just the ones required by the operator all the time.

At the bottom of the panel is 16 LEDs that will display spindle load.

One last feature is the side bars They are also RGB LEDs. They will display the status of the machine. Green when running, blue when idle, flashing red if there is an error. This is my version of a beacon.

The E Stop switch is not directly part of the panel. That's a button you smash, and this panel is printed plastic, so it will go nearby on the enclosure directly.

For anyone wondering how big this panel is.. That screen is a 10" IPAD display, without the touch overlay. So it's quite small by industrial control standards while having a larger display than most. Its 232mm wide, or about 9.1".

And the keys.

Seems 4 keypads plus a couple extra independent buttons works well enough. You get almost the full typing keyboard, number pad and function keys on the upper section. The lower section is for machine functions. I have 4 spare buttons right now, although I'm sure I've forgotten something.

The power button it the main on switch, it will be a mechanical momentary switch with an LED. Likewise the Door interlock button. Everything else is through the Arduino emulating a keyboard (at least, tentatively). The keys will be mapped to send out whatever signal is required - for example a shift + 7 would just send out the upper case letter O.

On the right we have an led ring with an encoder in the middle, this will be the feed and spindle speed override wheel. the buttons next to it will select between functions.

Below that will be the MPG wheel. It's modes are on the left of the lower keypad. XYZA, step, rapid, jog

Anyone see a button I need to add in for "regular usage"? for anything complicated you will just plug in a USB keyboard, so we don't need to overload the functions here. Just the ones required by the operator all the time.

At the bottom of the panel is 16 LEDs that will display spindle load.

One last feature is the side bars They are also RGB LEDs. They will display the status of the machine. Green when running, blue when idle, flashing red if there is an error. This is my version of a beacon.

The E Stop switch is not directly part of the panel. That's a button you smash, and this panel is printed plastic, so it will go nearby on the enclosure directly.

For anyone wondering how big this panel is.. That screen is a 10" IPAD display, without the touch overlay. So it's quite small by industrial control standards while having a larger display than most. Its 232mm wide, or about 9.1".

Attachments:

Last edit: 07 Jun 2019 05:03 by ihavenofish.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

07 Jun 2019 16:20 #136212

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Some key layout changes.

Got rid of the MPG speed buttons. Instead when you press JOG the upper right dial will regulate the speed. The dial will also control spindle speed if you manually turn the spindle on. I think the spindle control would be automated MDI commands. When you turn it on, its M3 S12000 as a default. Then when you rotate he dial, it increments S in by 1000rpm. My spindle is 6000rpm to 24000rpm.

Renamed the reset button to enable. Makes more sense with that name. This is the "power on" (F2) at the top left in linuxcnc. It will flash orange when you start the machine and then go solid orange when you press it and linuxcnc turns on.

Clear is for clearing out errors, though I'm not yet sure how I'd map that to a key.

I made SHIFT LOAD = RELOAD G-code file. Seems logical. I'm not sure what other G-code navigation I "need". I do tend to program on the machine, a lot actually. I'm thinking I have a little Microsoft Bluetooth mini keyboard that I should just tuck into a pocket on the side of the machine. I don't want a mouse though.

I have 6 open keys for everything I've forgotten

Got rid of the MPG speed buttons. Instead when you press JOG the upper right dial will regulate the speed. The dial will also control spindle speed if you manually turn the spindle on. I think the spindle control would be automated MDI commands. When you turn it on, its M3 S12000 as a default. Then when you rotate he dial, it increments S in by 1000rpm. My spindle is 6000rpm to 24000rpm.

Renamed the reset button to enable. Makes more sense with that name. This is the "power on" (F2) at the top left in linuxcnc. It will flash orange when you start the machine and then go solid orange when you press it and linuxcnc turns on.

Clear is for clearing out errors, though I'm not yet sure how I'd map that to a key.

I made SHIFT LOAD = RELOAD G-code file. Seems logical. I'm not sure what other G-code navigation I "need". I do tend to program on the machine, a lot actually. I'm thinking I have a little Microsoft Bluetooth mini keyboard that I should just tuck into a pocket on the side of the machine. I don't want a mouse though.

I have 6 open keys for everything I've forgotten

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

07 Jun 2019 16:41 #136220

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Looks Like someone's done the HID thing already.

I don't read russian though. I *think* I see code for a driver on that forum page.. Need to examine it. I know nothing about writing drivers... YET

I don't read russian though. I *think* I see code for a driver on that forum page.. Need to examine it. I know nothing about writing drivers... YET

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

08 Jun 2019 22:15 - 08 Jun 2019 22:17 #136311

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

One sanyo P5 400w ac servo on the way. This will be my tester to see if it is going to work.

I have both mesa 7i76 and 7i77 so I can give analogue control a try again. See if it behaves better than the old sanyo drives did. Most likely though we will use step and direct, use the drives auto tuning, and hook linear scales directly to the drives as well. let the drives do the hard part, let Linux just feed it a path. the drives have all sort of other output back to the control for alarms, errors, torque sensing, etc.

I yanked the Brother control panel which we wont use anymore and stole all its buttons!

We have the E stop, 2 green, 2 red buttons, a switch ill use for he compressor, and a key switch ill use for door interlock instead of the upper pane button.

For reasons I don't remember I threw away the tc229 panel, which was dumb, because it was an array of microswitch keys I could have used.

I have both mesa 7i76 and 7i77 so I can give analogue control a try again. See if it behaves better than the old sanyo drives did. Most likely though we will use step and direct, use the drives auto tuning, and hook linear scales directly to the drives as well. let the drives do the hard part, let Linux just feed it a path. the drives have all sort of other output back to the control for alarms, errors, torque sensing, etc.

I yanked the Brother control panel which we wont use anymore and stole all its buttons!

We have the E stop, 2 green, 2 red buttons, a switch ill use for he compressor, and a key switch ill use for door interlock instead of the upper pane button.

For reasons I don't remember I threw away the tc229 panel, which was dumb, because it was an array of microswitch keys I could have used.

Attachments:

Last edit: 08 Jun 2019 22:17 by ihavenofish.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

08 Jun 2019 23:52 #136318

by tommylight

Replied by tommylight on topic Build: XZero Predator... With more teeth!

Luckily I can buy those colored buttons here, plenty of, as long as the color is red and normally closed ones !!!

Oh well, I have to make do with whatever is on hand, but those e-stop thingies are always NO and NC in one setup.

Oh well, I have to make do with whatever is on hand, but those e-stop thingies are always NO and NC in one setup.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

09 Jun 2019 02:26 #136337

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

SHINY!

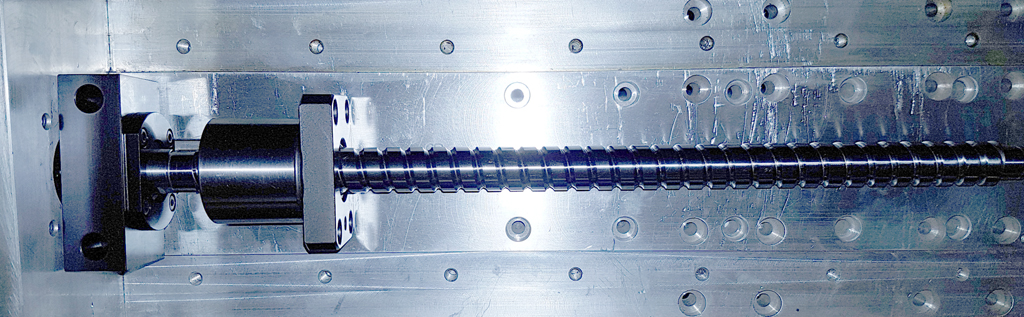

Found a new THK bnk2010 c5 ground screw in my box o parts. I tweaked my new Z axis design to accept it. In addition to being more precise, its rated to run over 3000rpm. So my Z will go 1181 ipm now.

Zoom!

I will part off the excess length, tap the end for M6, and screw on a washer with a thick O ring as a bumper. This was a major issue on the old Z. The Z would fall and slam into a stop screw metal to metal. BAD!

Found a new THK bnk2010 c5 ground screw in my box o parts. I tweaked my new Z axis design to accept it. In addition to being more precise, its rated to run over 3000rpm. So my Z will go 1181 ipm now.

Zoom!

I will part off the excess length, tap the end for M6, and screw on a washer with a thick O ring as a bumper. This was a major issue on the old Z. The Z would fall and slam into a stop screw metal to metal. BAD!

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

09 Jun 2019 22:44 #136415

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

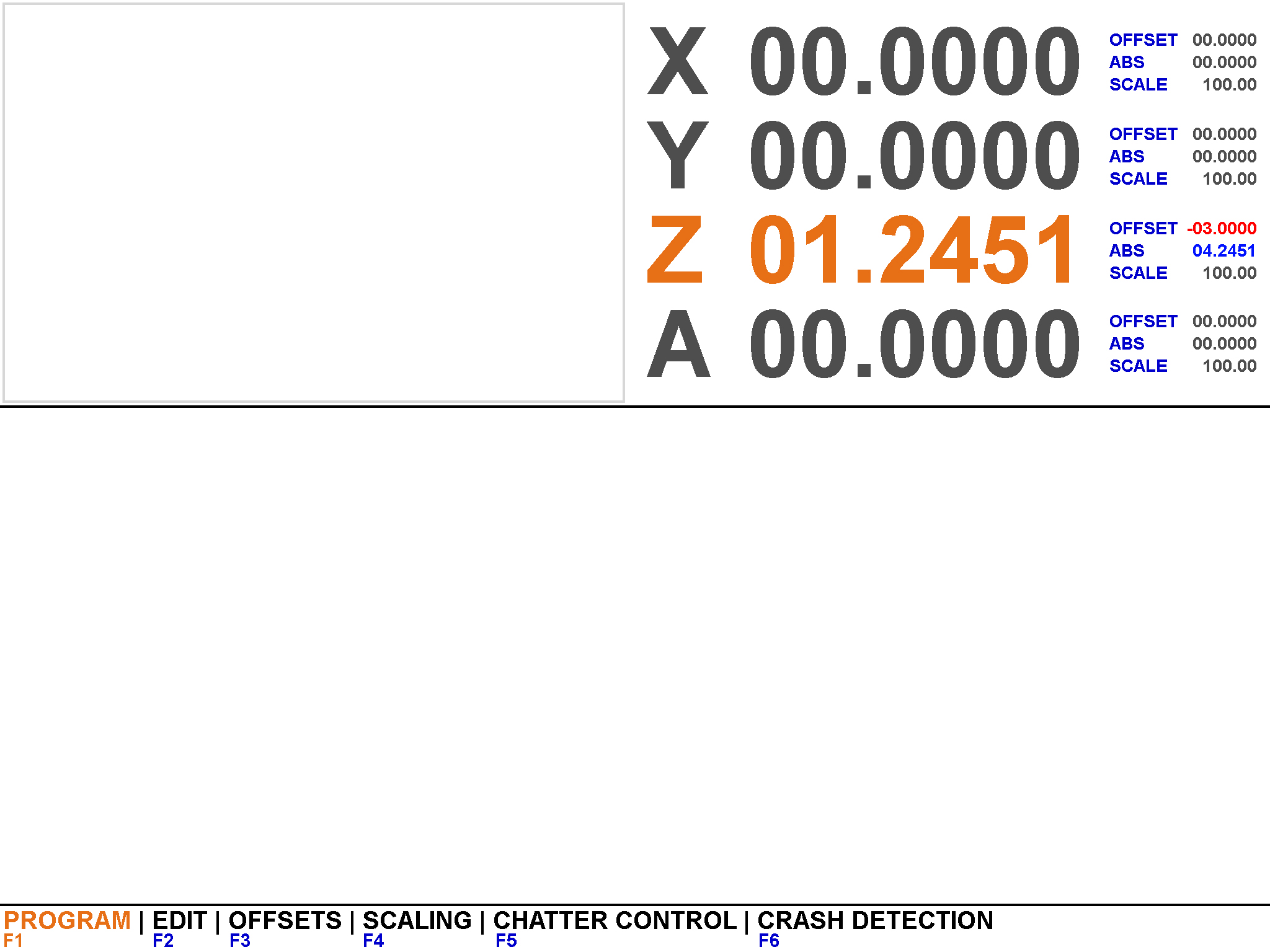

More panel layout alterations.

I've basically written instructions on using the machine, and this is telling me what buttons are needed to actually follow said instructions.

I've coupled it with a UI now that has "pages" where the F keys are context sensitive.

Got me wondering now, can linuxcnc do this type of probing?

In which it creates a map of the surface, correcting the Z offset dynamically. It seems like it would be pretty simple in my head (like everything complicated ) I supposed it doesn't even need to be dynamic, and could just perform some math on the file and resave it as a compensated version. Hmmm. That actually does sound fairly easy.

) I supposed it doesn't even need to be dynamic, and could just perform some math on the file and resave it as a compensated version. Hmmm. That actually does sound fairly easy.

I've basically written instructions on using the machine, and this is telling me what buttons are needed to actually follow said instructions.

I've coupled it with a UI now that has "pages" where the F keys are context sensitive.

Got me wondering now, can linuxcnc do this type of probing?

In which it creates a map of the surface, correcting the Z offset dynamically. It seems like it would be pretty simple in my head (like everything complicated

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

09 Jun 2019 23:12 #136419

by tommylight

Replied by tommylight on topic Build: XZero Predator... With more teeth!

Shiny and nice !

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

10 Jun 2019 01:13 #136432

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Mmm Shiny. haha.

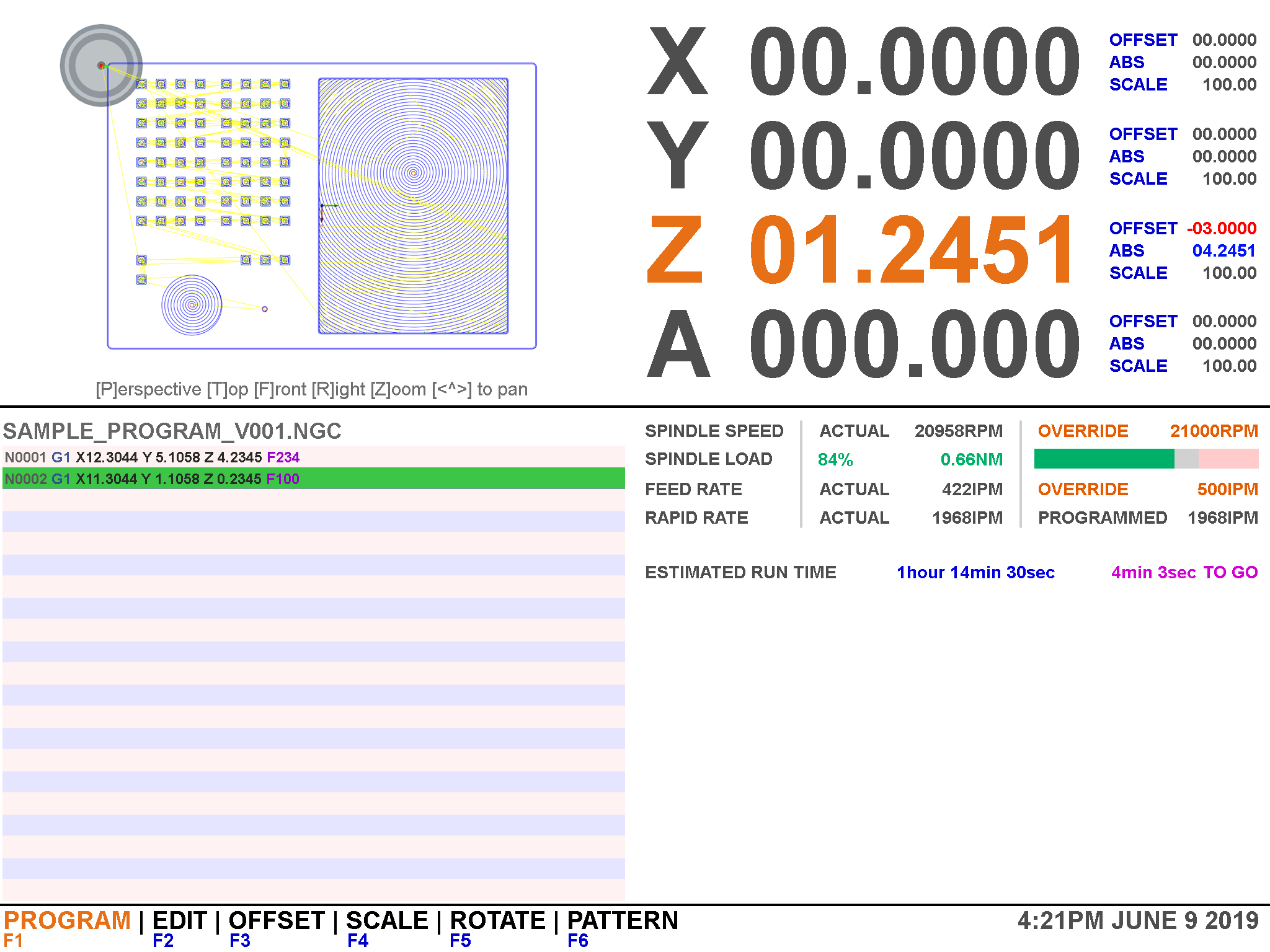

So, I did a little more GUI fleshing out. This is the just the program run screen... What you would see when you load programs and run them. You don't end up needing a whole lot on screen when you don't have to click stuff with a mouse.

On most screens, only the lower part will change and the 3D view and DRO will stay.

So, I did a little more GUI fleshing out. This is the just the program run screen... What you would see when you load programs and run them. You don't end up needing a whole lot on screen when you don't have to click stuff with a mouse.

On most screens, only the lower part will change and the 3D view and DRO will stay.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.436 seconds