Build: XZero Predator... With more teeth!

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

08 Jul 2019 22:35 #138904

by Grotius

Replied by Grotius on topic Build: XZero Predator... With more teeth!

Respect for the one's that need no supplier's.

The best business model...

I think you could even print this from dust...

The best business model...

I think you could even print this from dust...

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

22 Jul 2019 16:05 #140196

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

I'm getting better at the printing of things.

PETG is the wrong choice i think for most of the parts i have in mind.Fractures very easily. not as bad as PLA, but bad.

I ordered some polypropylene and nylon, we'll see how that is.

I think I'll use polypropylene for some of the cover parts, which are likely to get hit by things, like wrenches, end mills, hot shards of aluminium, etc. Also anything that gets very wet as it resists almost every fluid. Not for everything though as its very expensive and flexy / soft (clear rubbermaid containers are polypropylene).

For the rest i may end up with nylon and ABS (stable when hot, strong, easily glued and painted). ABS is the cheapest by far - $16cdn/kg vs $44cdn/kg for nylon and $100cdn/kg for the polypropylene.

Fun fun

Also got ideas while printings. You could so easily 3d print sand casting patterns. I could print and cast and have machined for linear guides a "BF20" style mill frame in canada for much less than the whole machine costs and without all the crap you throw away anyway

Something i need to ponder later this year. after the 2 xzero machines are done.

PETG is the wrong choice i think for most of the parts i have in mind.Fractures very easily. not as bad as PLA, but bad.

I ordered some polypropylene and nylon, we'll see how that is.

I think I'll use polypropylene for some of the cover parts, which are likely to get hit by things, like wrenches, end mills, hot shards of aluminium, etc. Also anything that gets very wet as it resists almost every fluid. Not for everything though as its very expensive and flexy / soft (clear rubbermaid containers are polypropylene).

For the rest i may end up with nylon and ABS (stable when hot, strong, easily glued and painted). ABS is the cheapest by far - $16cdn/kg vs $44cdn/kg for nylon and $100cdn/kg for the polypropylene.

Fun fun

Also got ideas while printings. You could so easily 3d print sand casting patterns. I could print and cast and have machined for linear guides a "BF20" style mill frame in canada for much less than the whole machine costs and without all the crap you throw away anyway

Something i need to ponder later this year. after the 2 xzero machines are done.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

22 Jul 2019 18:24 #140210

by Grotius

Replied by Grotius on topic Build: XZero Predator... With more teeth!

You have too look at wrapping the button's, just like wrapping airplain's in rc-video's.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

22 Jul 2019 19:54 #140232

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Like hydrographics?

That sounds plausible actually, but how hard is that to line up straight on each button? Usually what i see is a bit, uh, free-form.

That sounds plausible actually, but how hard is that to line up straight on each button? Usually what i see is a bit, uh, free-form.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

22 Jul 2019 20:04 - 22 Jul 2019 20:10 #140235

by Grotius

Time 3.09

line up straight on each button?

See how he does the airplane window's... With a tape. very easy. In fact you don't need any application foil at all.

Replied by Grotius on topic Build: XZero Predator... With more teeth!

Time 3.09

line up straight on each button?

See how he does the airplane window's... With a tape. very easy. In fact you don't need any application foil at all.

Last edit: 22 Jul 2019 20:10 by Grotius.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

22 Jul 2019 20:10 #140236

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Oh, that's just vinyl sticker. That wont work well here. It's just a sticker that will peel off with grease and general touching.

You also cant "wrap" something small and sharp cornered like the buttons very well. there's a limit to the pliability of the vinyl.

You also cant "wrap" something small and sharp cornered like the buttons very well. there's a limit to the pliability of the vinyl.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

22 Jul 2019 20:13 #140238

by Grotius

Replied by Grotius on topic Build: XZero Predator... With more teeth!

Only aceton or thinner is a problem i think. Greece is not toxic.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

22 Jul 2019 20:16 #140239

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

this is what they stick on bicycles. not fully wrapped, but large vinyl stickers all over the fork and wheels..It's ruined usually after a few rides.and peels up with grease and oil.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

29 Aug 2019 16:56 #143577

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

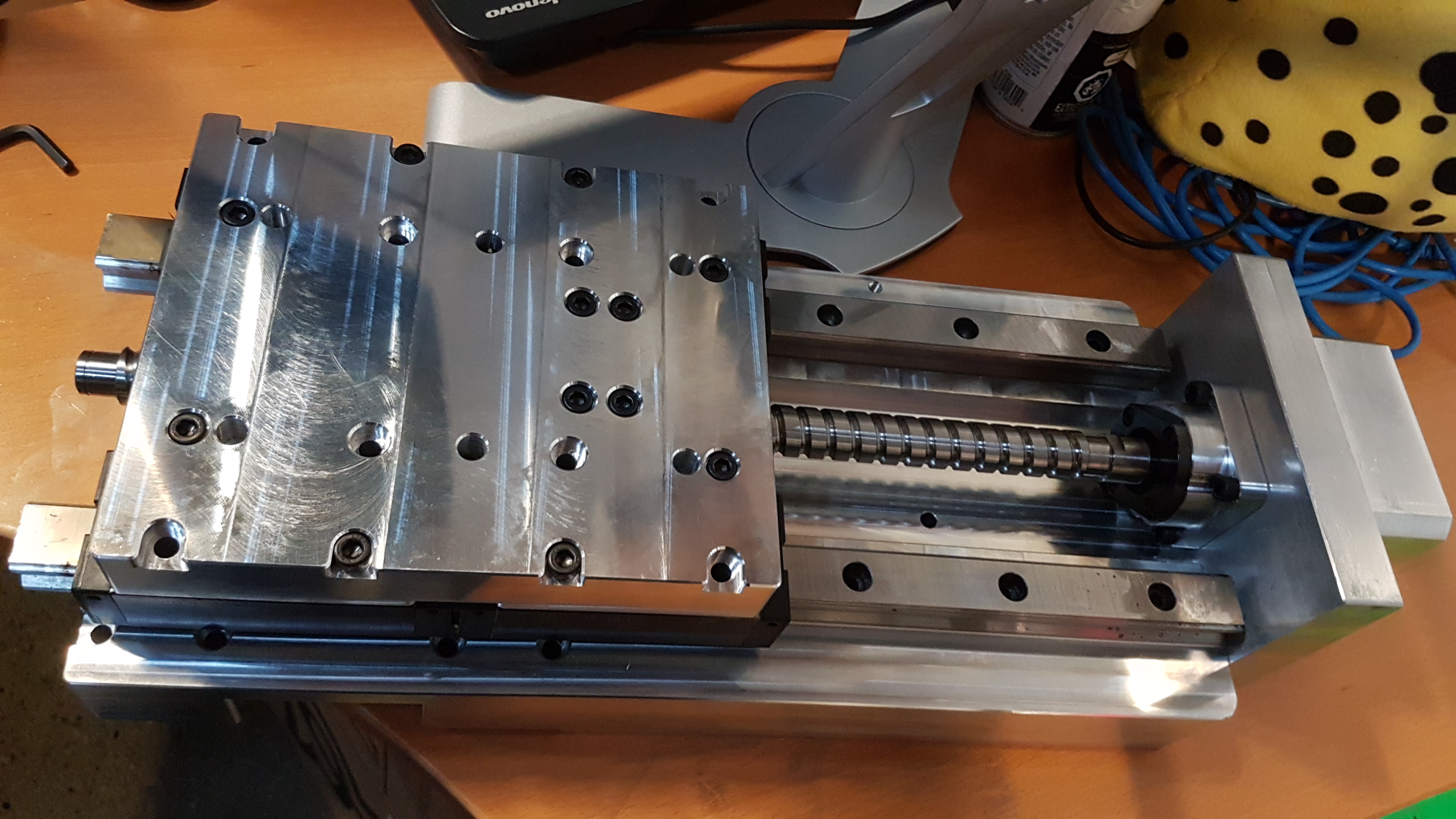

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

02 Oct 2019 20:49 #146898

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

alright, time to get back to the control stuff.

I have an ATC question.

If i use a servo to drive the carousel, do I just use one of the spare step and direction axes and make my subroutine control it? Is there an example of this? (the set up part, so it can be commanded - let's call it W - but not show as an axis in the UI) I'm using a mesa 7i76

There will be a "stowed" position, and then 10 tool positions on the carousel, all with absolute positions that would be commanded as an "hidden" axis.

I have an ATC question.

If i use a servo to drive the carousel, do I just use one of the spare step and direction axes and make my subroutine control it? Is there an example of this? (the set up part, so it can be commanded - let's call it W - but not show as an axis in the UI) I'm using a mesa 7i76

There will be a "stowed" position, and then 10 tool positions on the carousel, all with absolute positions that would be commanded as an "hidden" axis.

Please Log in or Create an account to join the conversation.

Time to create page: 0.216 seconds