My Newb Plasma Table Attempted Build

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 15:23 - 02 Jun 2020 15:30 #169811

by dvn4life1972

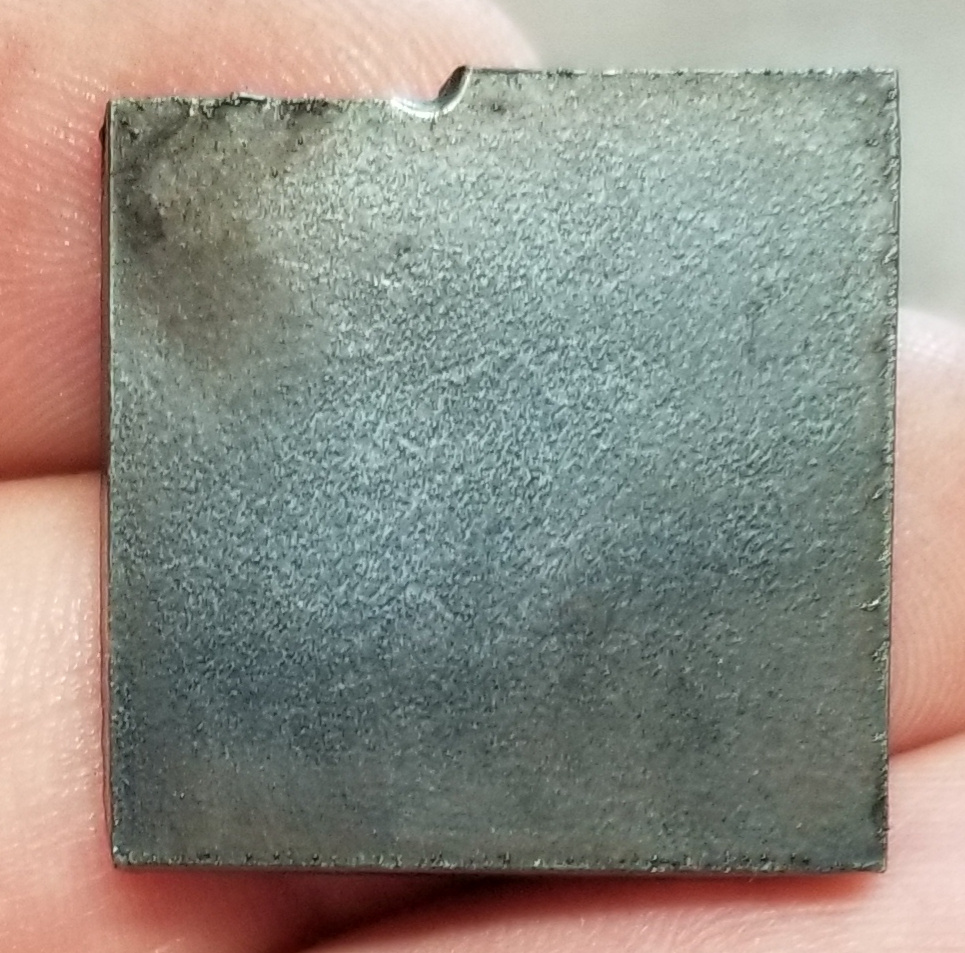

Phil, I made the adjustments on the float setup and that eliminated the choppy cuts at the corners. The step where the lead in/out is is still there. Attaching some photos. On the side where the step is, you can see that each side of that step on the X axis is square/perpendicular to the Y axis.

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Hard to tell from the pics but are any of the corners of the "square" actually square?

Is the notch on the X axis or the Y axis?

Can you post the code you cut with, it looks ok when I do it here but...

EDIT: To me it looks like your X and Y axes are not perpendicular.

Phil, I made the adjustments on the float setup and that eliminated the choppy cuts at the corners. The step where the lead in/out is is still there. Attaching some photos. On the side where the step is, you can see that each side of that step on the X axis is square/perpendicular to the Y axis.

Last edit: 02 Jun 2020 15:30 by dvn4life1972. Reason: Added gcode file

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 15:27 #169812

by dvn4life1972

Yes sir, attached. It's odd becaue this issue just seemingly popped up out of nowhere. Before I changed the pulleys and belts. Cut one part as many others, and it was fine, then the next part and all afterwards have had the same issue since.

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Can you post your current hal and ini files?

Yes sir, attached. It's odd becaue this issue just seemingly popped up out of nowhere. Before I changed the pulleys and belts. Cut one part as many others, and it was fine, then the next part and all afterwards have had the same issue since.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 16:08 #169817

by dvn4life1972

Yesterday when I had it all apart to change the pulleys and belts I cleaned all of those surfaces up. Still, I thought maybe there is something making it miss so I tried several different areas of the cutting space available and it repeats the identical issue no matter where the material is placed to be cut. That makes it seem to me that it isn't some debris in the track causing a skip.

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Was that slope programmed or the machine did that on it's own?

Are you by any chance getting the latency error when starting LinuxCNC ?

When the drives are powered and enabled, how easy it is to turn the motors shaft by hand ?

What drives and what microstepping ?

If that slope was not programmed, one axis is binding, so if you can, remove the belts and move the axis by hand slowly while feeling for any bumps or binding.

Yesterday when I had it all apart to change the pulleys and belts I cleaned all of those surfaces up. Still, I thought maybe there is something making it miss so I tried several different areas of the cutting space available and it repeats the identical issue no matter where the material is placed to be cut. That makes it seem to me that it isn't some debris in the track causing a skip.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 16:57 #169821

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21198

- Thank you received: 7241

02 Jun 2020 17:00 #169822

by tommylight

Replied by tommylight on topic My Newb Plasma Table Attempted Build

Check the DRO while cutting, is the axis causing that divot on the same position at the beginning and at the end of that cut ?

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

02 Jun 2020 17:27 #169832

by Mike_Eitel

Replied by Mike_Eitel on topic My Newb Plasma Table Attempted Build

I have no glue of plasma but i would guess that your driver catches some extra pulses as emf when you start. I would have a look into grounding.

What hapens when you fix a pen and run the same code without an arc

Just my 5c

Mike

What hapens when you fix a pen and run the same code without an arc

Just my 5c

Mike

The following user(s) said Thank You: tommylight, dvn4life1972

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 18:07 #169846

by dvn4life1972

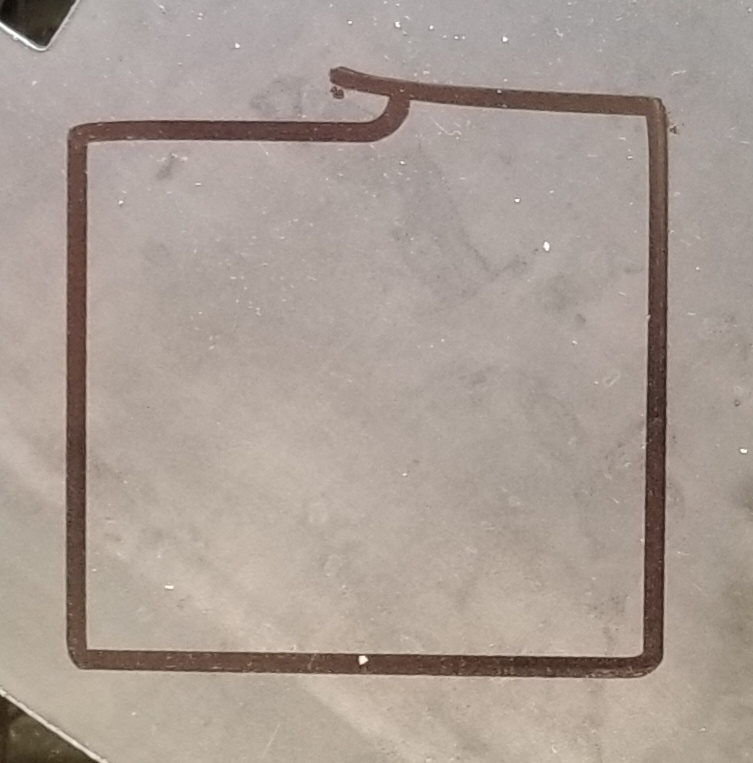

Just did this and the DRO shows at the beginning (after lead in on X axis) -.205 on the Y, then turns onto the Y axis cut down to 3.205, then back on X for 3.205, then up the Y for 3.205, then the Y axis position shows -.205 when coming back to where the divot/step is. So basically the DRO is not reflecting what the machine is actually doing there.

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Check the DRO while cutting, is the axis causing that divot on the same position at the beginning and at the end of that cut ?

Just did this and the DRO shows at the beginning (after lead in on X axis) -.205 on the Y, then turns onto the Y axis cut down to 3.205, then back on X for 3.205, then up the Y for 3.205, then the Y axis position shows -.205 when coming back to where the divot/step is. So basically the DRO is not reflecting what the machine is actually doing there.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 18:09 #169847

by dvn4life1972

Just tried this and it does the same thing with the plasma powered down completely. The proportions are a bit off because of the probing, but it's doing the same thing without any opportunity for interference from the plasma for sure.

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

I have no glue of plasma but i would guess that your driver catches some extra pulses as emf when you start. I would have a look into grounding.

What hapens when you fix a pen and run the same code without an arc

Just my 5c

Mike

Just tried this and it does the same thing with the plasma powered down completely. The proportions are a bit off because of the probing, but it's doing the same thing without any opportunity for interference from the plasma for sure.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11653

- Thank you received: 3924

02 Jun 2020 18:12 #169849

by rodw

Replied by rodw on topic My Newb Plasma Table Attempted Build

i would write my own square in gcode. Its likely a bug in the shape gcodegenerated

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Jun 2020 18:14 #169850

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Before I did that run with the plasma off and used a marker, I was going back over any changes to anything that were made around the time this started happening. I changed consumables to finecut, and although I don't remember for sure I believe before that 1st bad run I had updated linuxcnc/plasmac. Maybe I should go back to v2.8 (I'm on master now) and see what happens. I don't think it would be whatever was available from updating, but maybe my shoddy internet connection resulted in some errors in the download...? I think at this point it's worth a try.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.267 seconds